White nitrocellulose finish and preparation method thereof

A white and topcoat technology, applied in the field of nitro white topcoat and its preparation, can solve the problems of poor dispersion, low hardness of nitrowhite topcoat, high production cost, etc., achieve good fineness, reduce production equipment and production processes , the effect of reducing production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

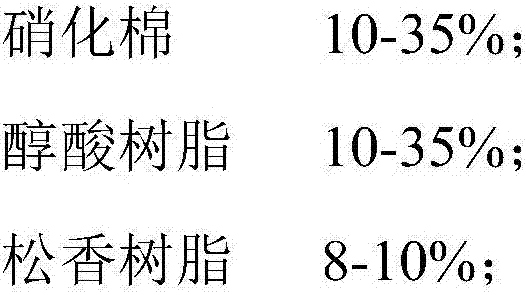

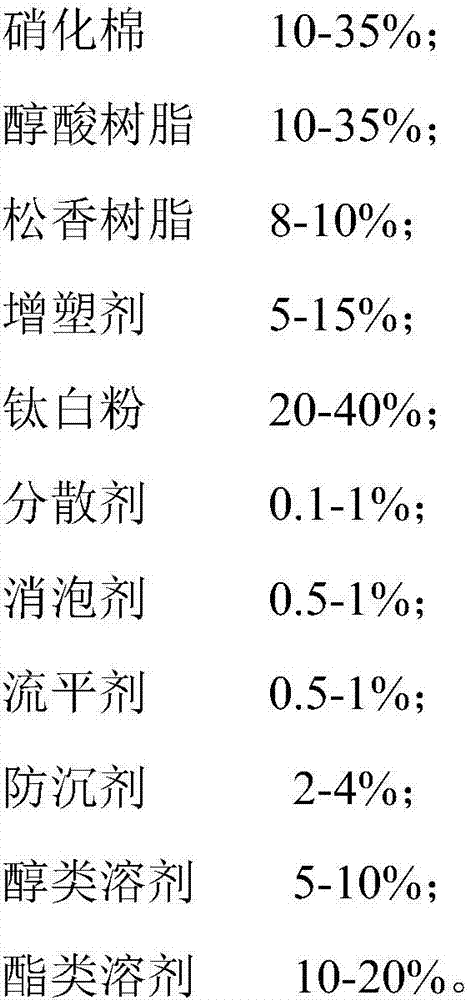

[0028] On the other hand, the embodiment of the present invention also provides a preparation method of nitro white finish paint. This preparation method comprises the steps:

[0029] S01: Weigh the raw materials of each component according to the components contained in the above-mentioned nitro white finish paint and their contents;

[0030] S02: performing the first mixing treatment on the rosin resin, plasticizer, dispersant, defoamer, anti-settling agent and 60-80% alcohol solvent to obtain the first mixed material;

[0031] S03: adding nitrocellulose, titanium dioxide and the remaining alcohol solvent to the above-mentioned first mixed material to perform a second mixed material to obtain a second mixed material;

[0032] S04: adding alkyd resin, leveling agent and 80-90% ester solvent to the second mixed material to perform a third mixed material to obtain a third mixed material;

[0033] S05: Use the remaining ester solvent to adjust the viscosity of the third mixed ...

Embodiment 1

[0041] A kind of nitro white finish paint, its formula sees embodiment 1 in table 1. The preparation method of this nitro white finish paint comprises the steps:

[0042] S11: According to the ingredients contained in the nitro white finish paint of Example 1 in Table 1 and their contents, the raw materials of each ingredient were weighed.

[0043] S12: dissolving the rosin resin into a rosin resin solution with xylene, and performing the first mixing treatment with plasticizer, dispersant, defoamer, anti-settling agent and 80% isopropanol to obtain the first mixed material ; Wherein, the conditions of the first mixing treatment are: the rotating speed is 200rpm-250rpm, and the time is 5min-10min.

[0044] S13: Add nitrocellulose, titanium dioxide and the remaining 20% isopropanol to the above-mentioned first mixed material to perform the second mixed material to obtain the second mixed material, and its fineness is ≤10 μm; wherein, the second mixed material The treatment ...

Embodiment 2

[0048] A kind of nitro white finish paint, its formula sees embodiment 2 in table 1. The preparation method of this nitro white finish paint comprises the steps:

[0049] S21: According to the ingredients contained in the nitro white finish paint of Example 2 in Table 1 and their contents, the raw materials of each ingredient were weighed.

[0050] S22: dissolving the rosin resin into a rosin resin solution with xylene, and performing the first mixing treatment with plasticizer, dispersant, defoamer, anti-settling agent and 75% isopropanol to obtain the first mixed material ; Wherein, the conditions of the first mixing treatment are: the rotating speed is 200rpm-250rpm, and the time is 5min-10min.

[0051] S23: Add nitrocellulose, titanium dioxide and the remaining 25% isopropanol to the above-mentioned first mixed material to perform the second mixed material to obtain the second mixed material, and its fineness is ≤10 μm; wherein, the second mixed material The treatment co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com