Method for preparing Bi2S3/TiO2 nanorod composite-film photo-anodes

A technology of nanorods and composite films, which is applied in the field of preparation of Bi2S3/TiO2 nanorod composite film photoanodes, which can solve the problems that visible light and photogenerated carriers are easy to recombine, and nanofilm materials cannot be effectively used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

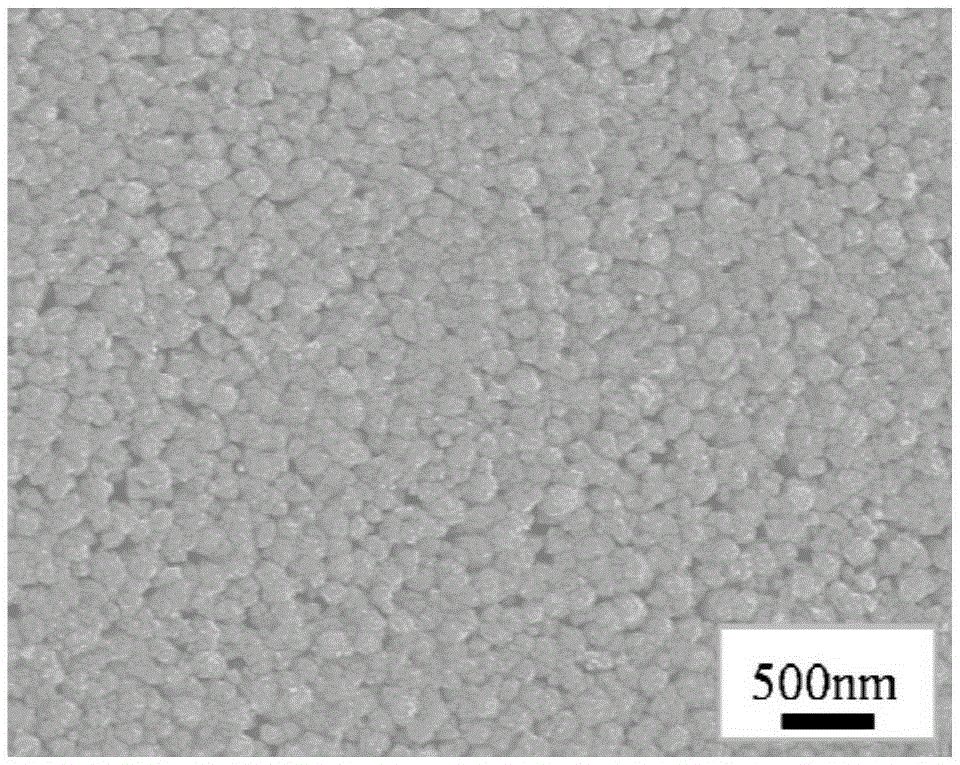

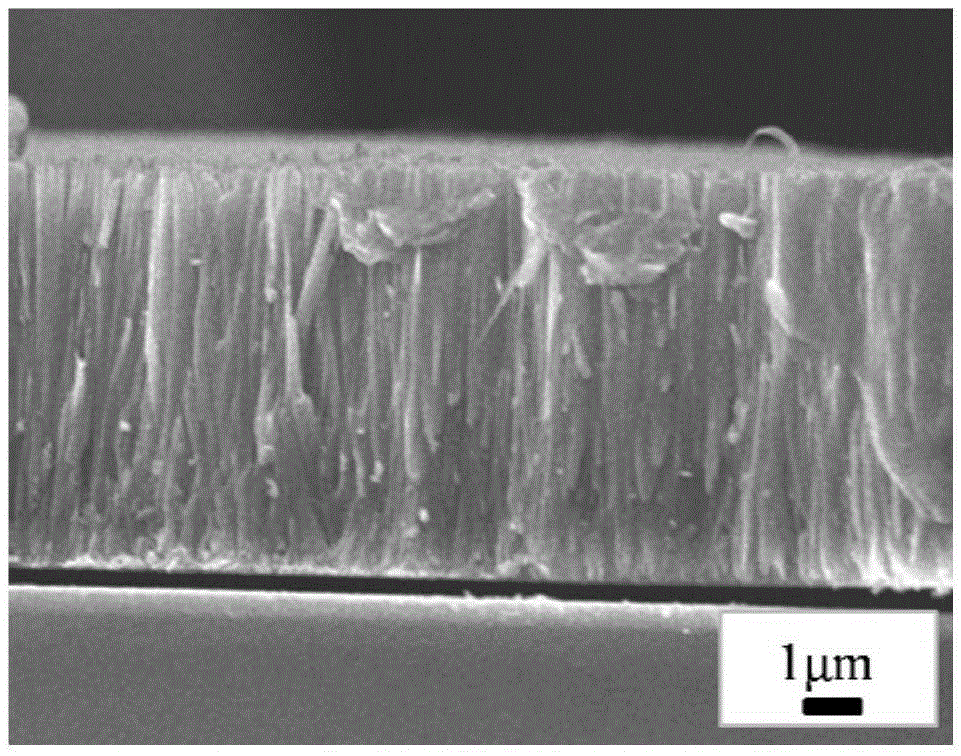

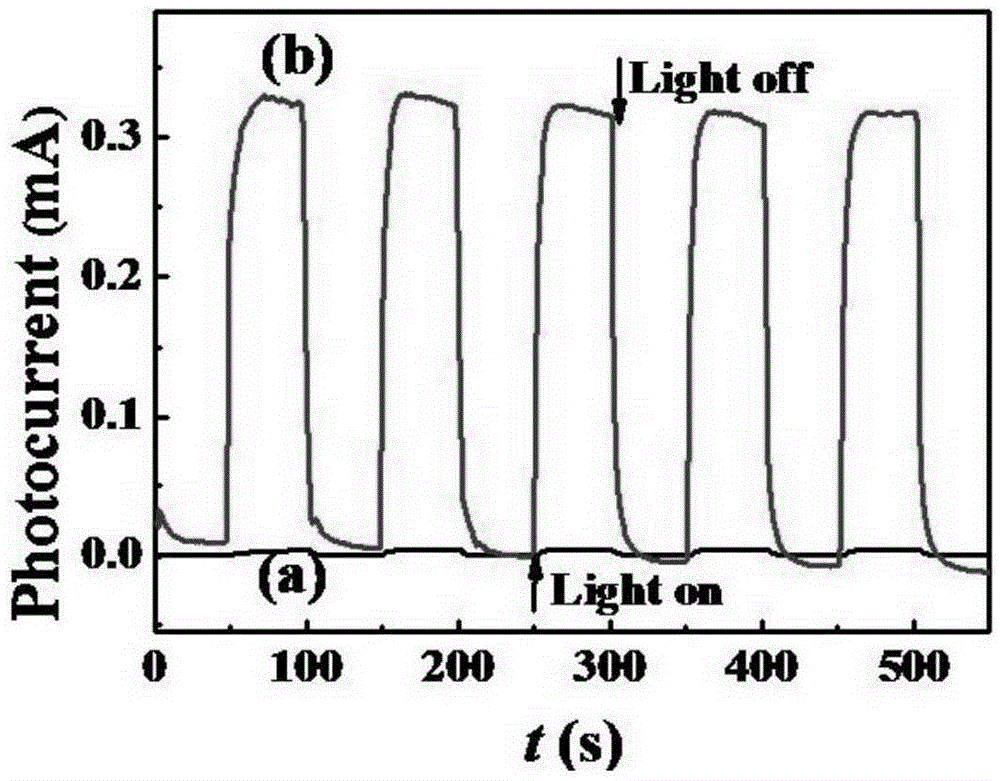

[0031] According to the above-mentioned technical scheme (concrete steps), prepare Bi 2 S 3 / TiO 2 Nanorod composite film, and test the cathodic protection effect of composite film as photoanode on 403 stainless steel.

[0032] Take a 2.2mm thick FTO conductive glass sample with a length of 15mm and a width of 10mm. Sequentially ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min.

[0033] TiO 2 Preparation of the seed layer: according to the above technical scheme, pipette 1mL of TiCl 4 Solution, carefully drop in 50g of ice water mixed solution to prepare TiCl 4 Aqueous solution, place the FTO substrate flat in the solution with the conductive surface upward, and heat-treat it in an oven at 70°C for 30 minutes. After the reaction is complete, take out the sample, wash it with deionized water, and put the sample into the muffle furnace after drying. Calcined at 550°C for 60min, then cooled to room temperature naturally.

[0034] TiO on FTO s...

Embodiment 2

[0042] According to the above-mentioned technical scheme (concrete steps), prepare Bi 2 S 3 / TiO 2 Nanorod composite film, and test the cathodic protection effect of composite film as photoanode on 403 stainless steel.

[0043] Take a 2.2mm thick FTO conductive glass sample with a length of 15mm and a width of 10mm. Sequentially ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min.

[0044] TiO 2 Preparation of the seed layer: according to the above technical scheme, pipette 1mL of TiCl 4 Solution, carefully drop in 50g of ice water mixed solution to prepare TiCl 4 Aqueous solution, place the FTO substrate flat in the substrate solution with the conductive surface upward, and heat-treat in an oven at 70°C for 30 minutes. After the reaction is complete, take out the sample, wash it with deionized water, and put the sample into the muffle furnace after drying. Calcined at 550 °C for 60 min, then cooled to room temperature naturally.

[0045] TiO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com