Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

395 results about "Corrosion potential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion potential is the electrode potential that the material surface acquires automatically in its environment. Corrosion potential can be measured by finding the potential difference between an appropriate reference electrode and the material's surface, usually a metal surface, when immersed in a given electrolyte.

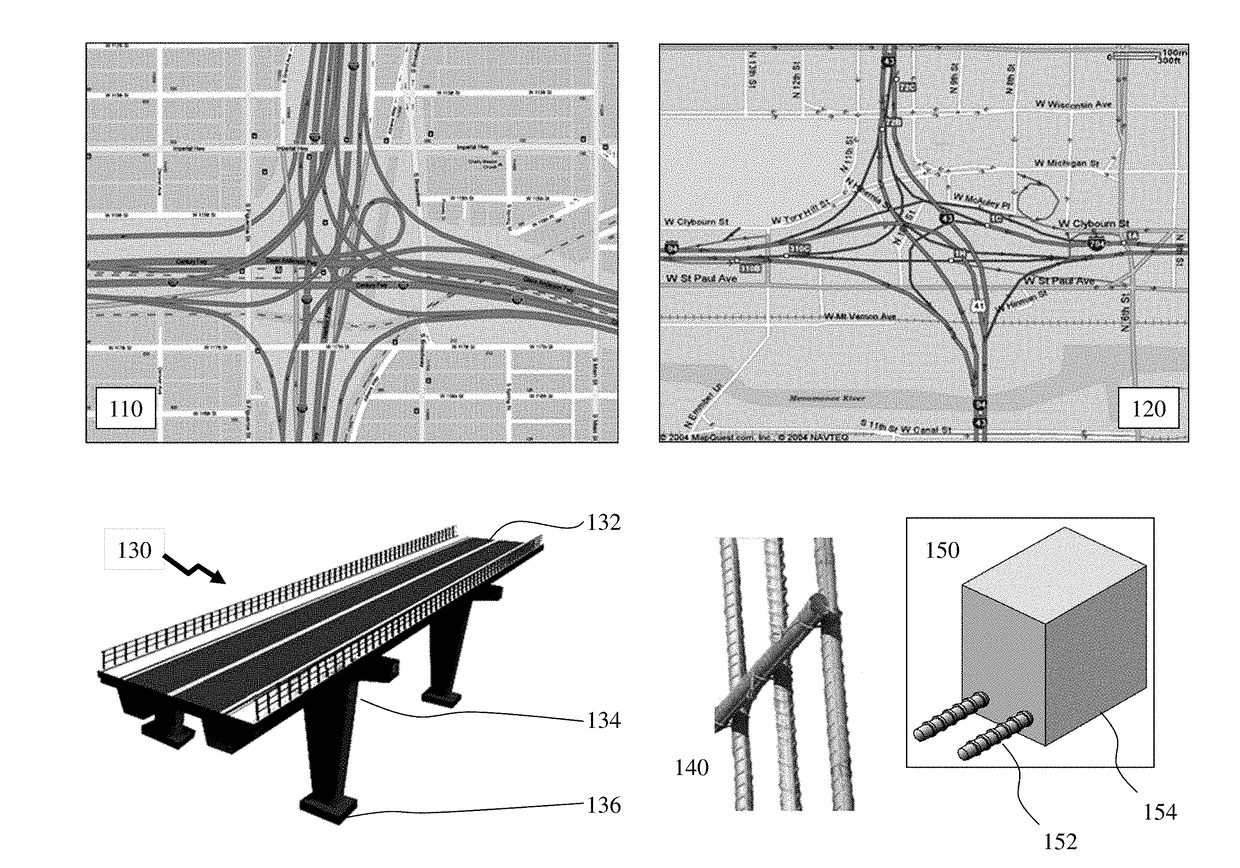

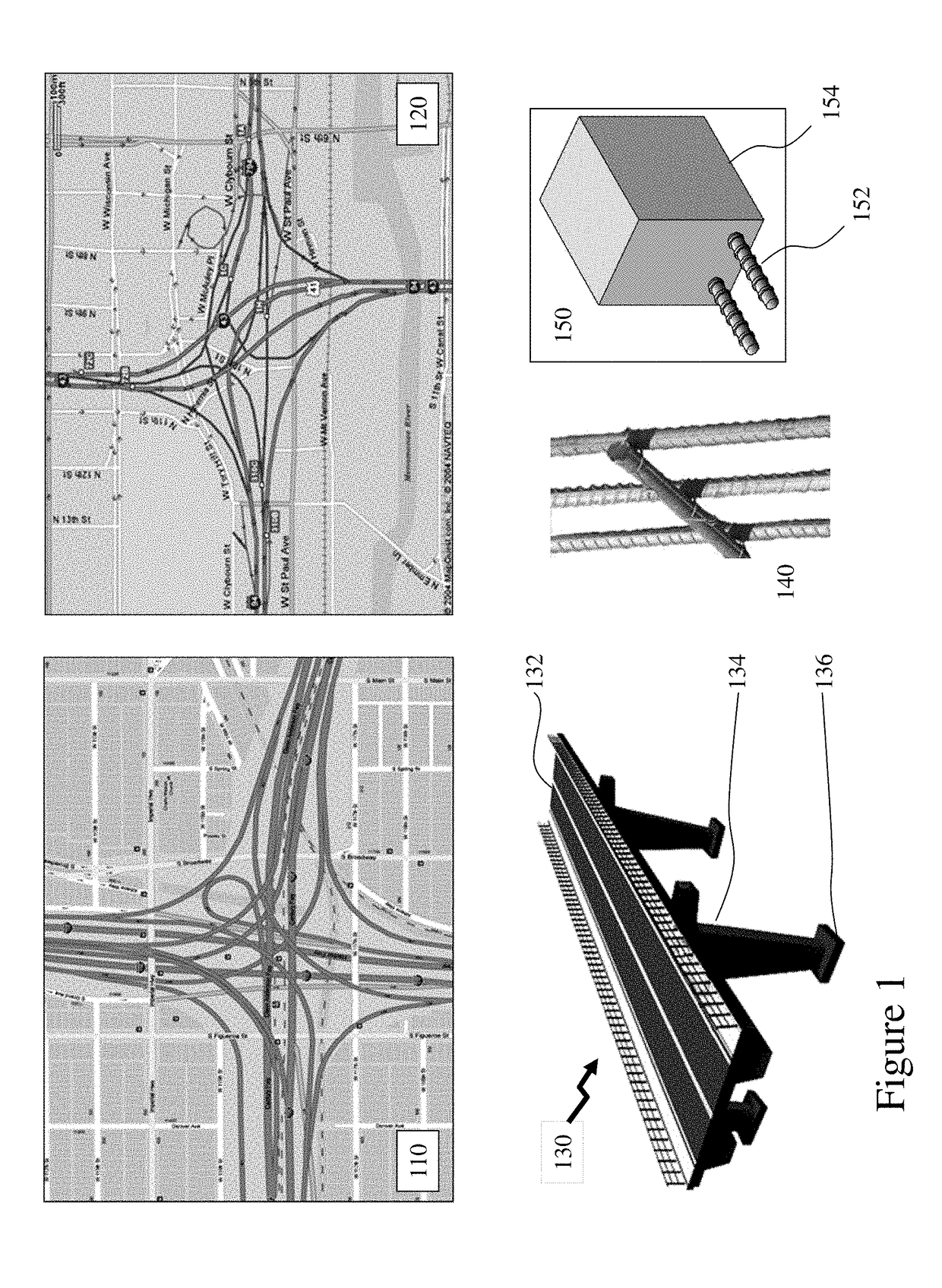

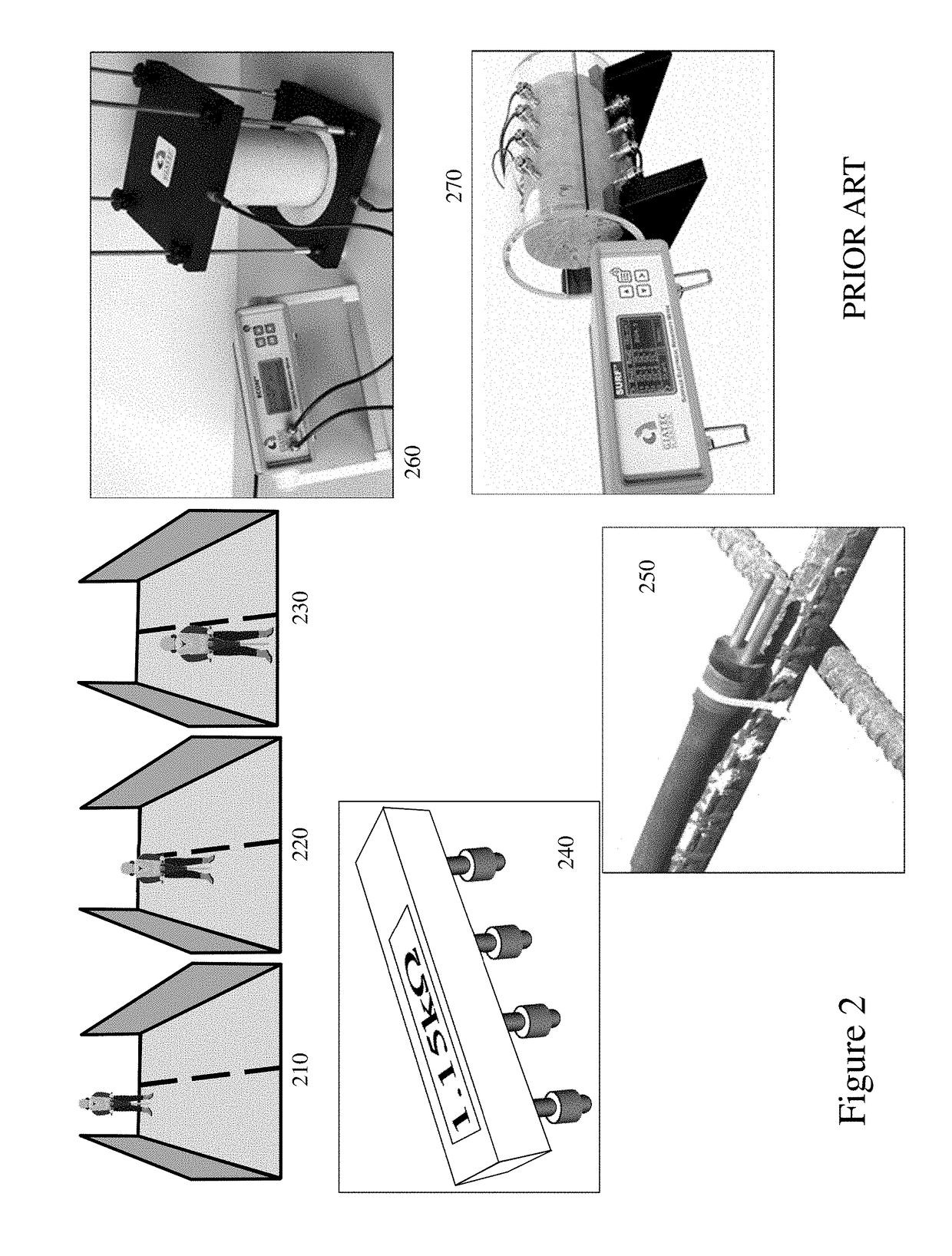

Method and systems relating to construction material assessment

ActiveUS20180238820A1Address limitationsForce measurement by measuring frquency variationsWeather/light/corrosion resistanceField testsWater content

Hundreds of thousands of concrete bridges, buildings etc. and hundreds of billions of tons of concrete require characterization throughout the process from manufacture to pouring and curing and on throughout service life. The characterization may relate to initial concrete properties, projected concrete properties, framework removal, corrosion, failure etc. Accordingly, a variety of measurements such as water content, electrical resistivity, and half-cell corrosion potential for example would be beneficially implemented as easy to use field test equipment or embedded sensors allowing lifetime monitoring to be performed rather than discrete assessments when issues become evident.

Owner:GIATEC SCI

Weldable aluminum product and welded structure comprising such a product

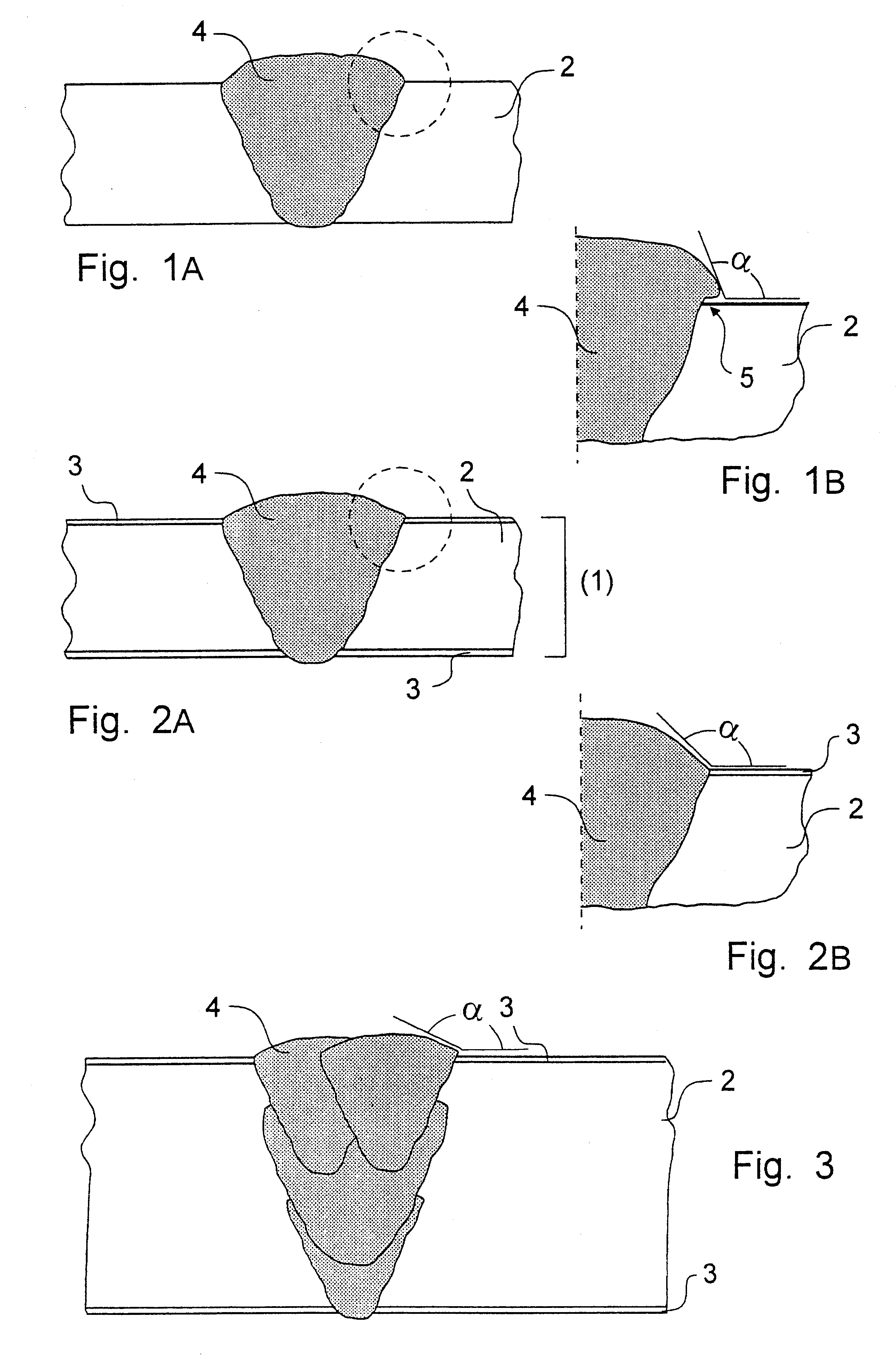

InactiveUS6337147B1Smooth transitionReduce the amount requiredElectric discharge heatingArc welding apparatusUltimate tensile strengthAluminium alloy

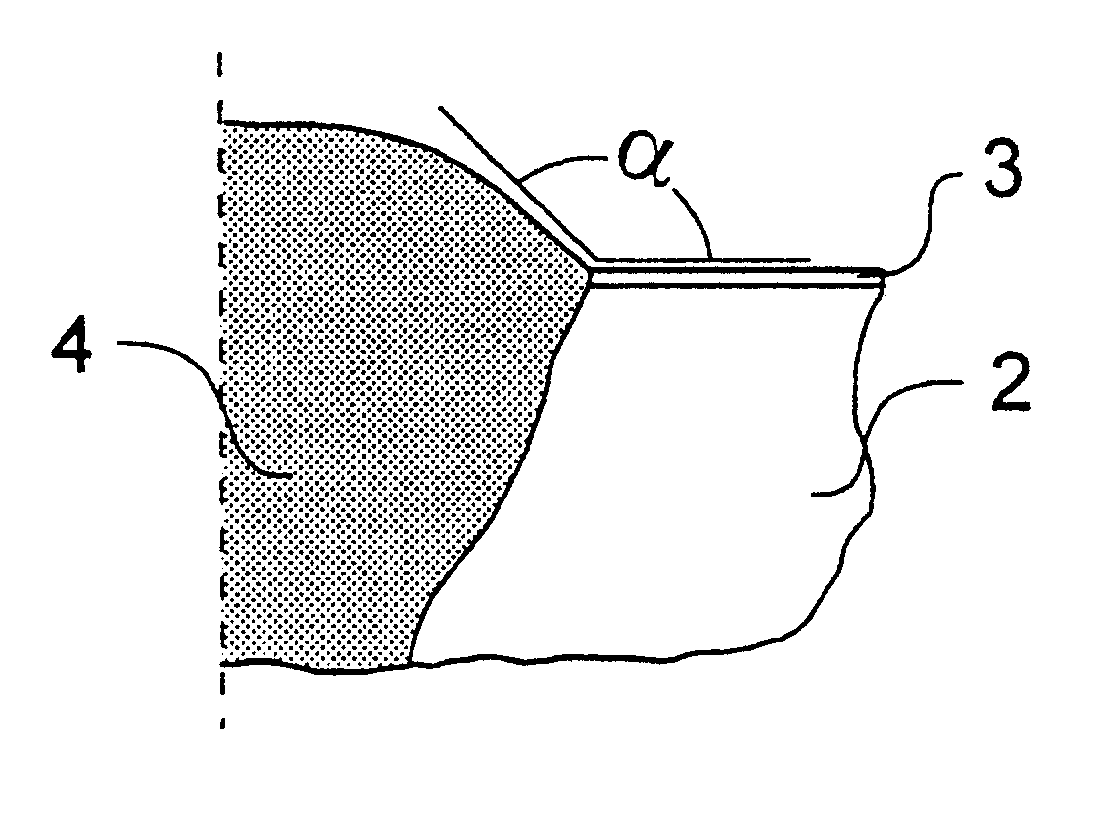

Improved shape and strength of the weld in a welded structure are obtained by use of a weldable aluminum product comprising a structural component which is a sheet, a plate or an extruded body and is made of an aluminum alloy containing not more than 1.5 wt % Zn. This component has, adhered on at least one side, a cladding layer made of an AA7xxx-series alloy having a corrosion potential lower than that of the alloy of the structural component. The alloy of the structural component is preferably an AA5xxx-series alloy containing Mg in the range 2 to 6 wt %.

Owner:CORUS ALUMINUM WALZPRODUKTE GMBH (DE)

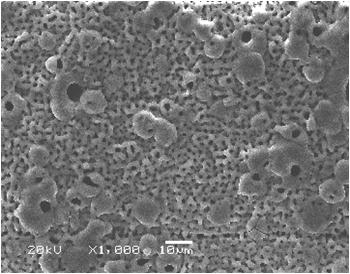

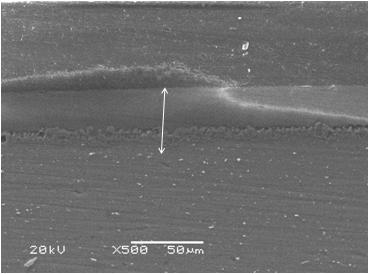

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

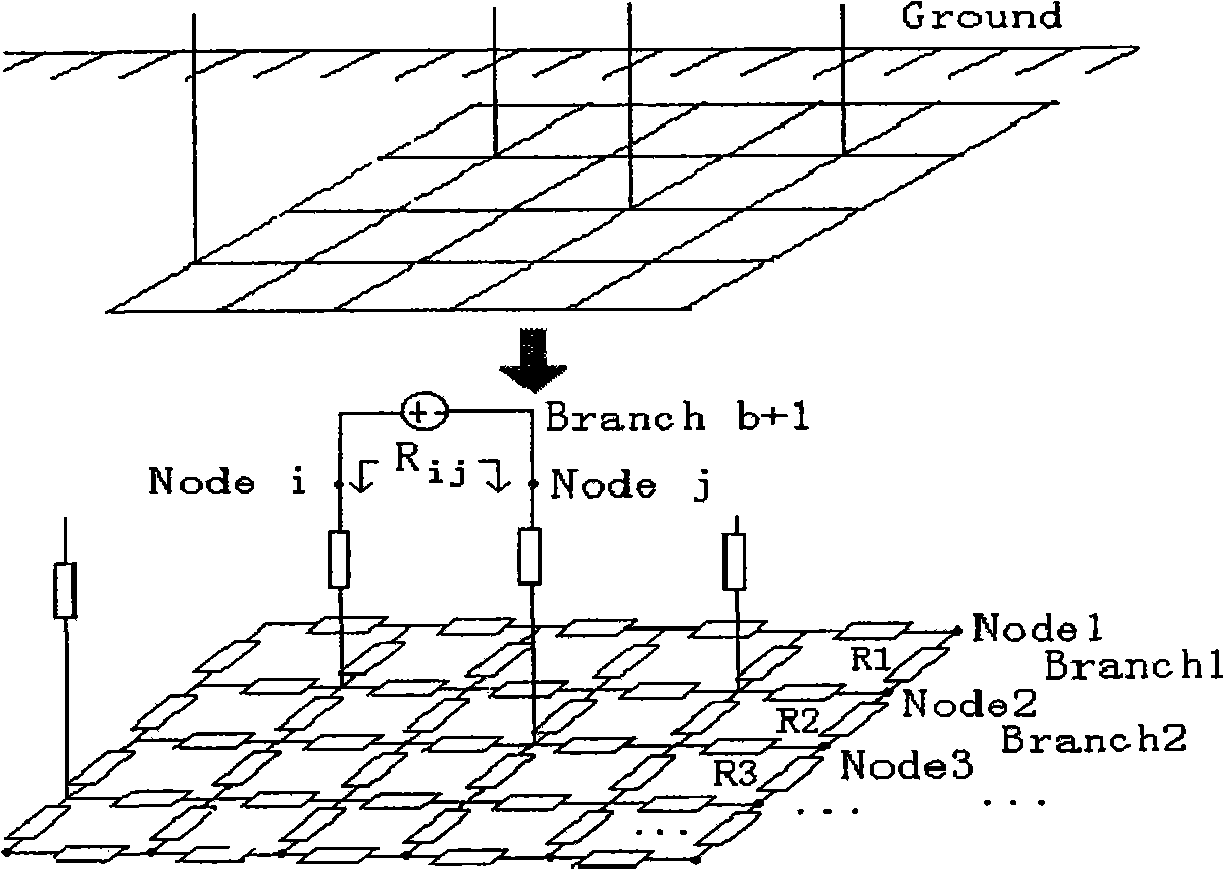

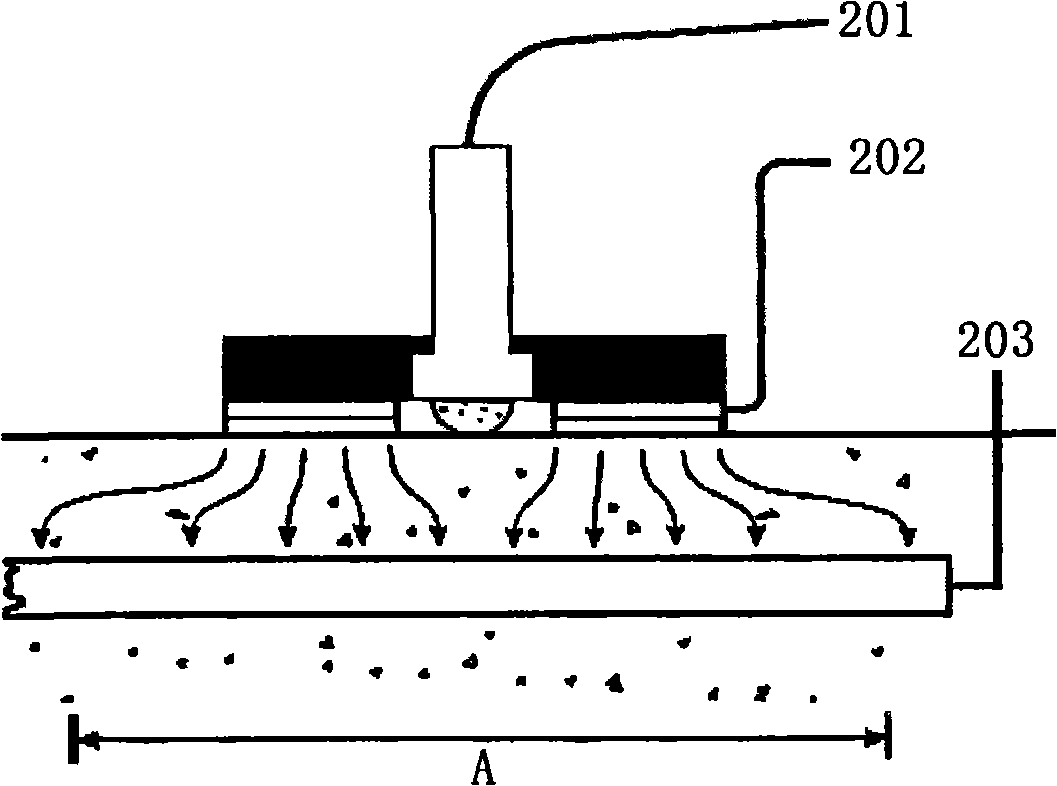

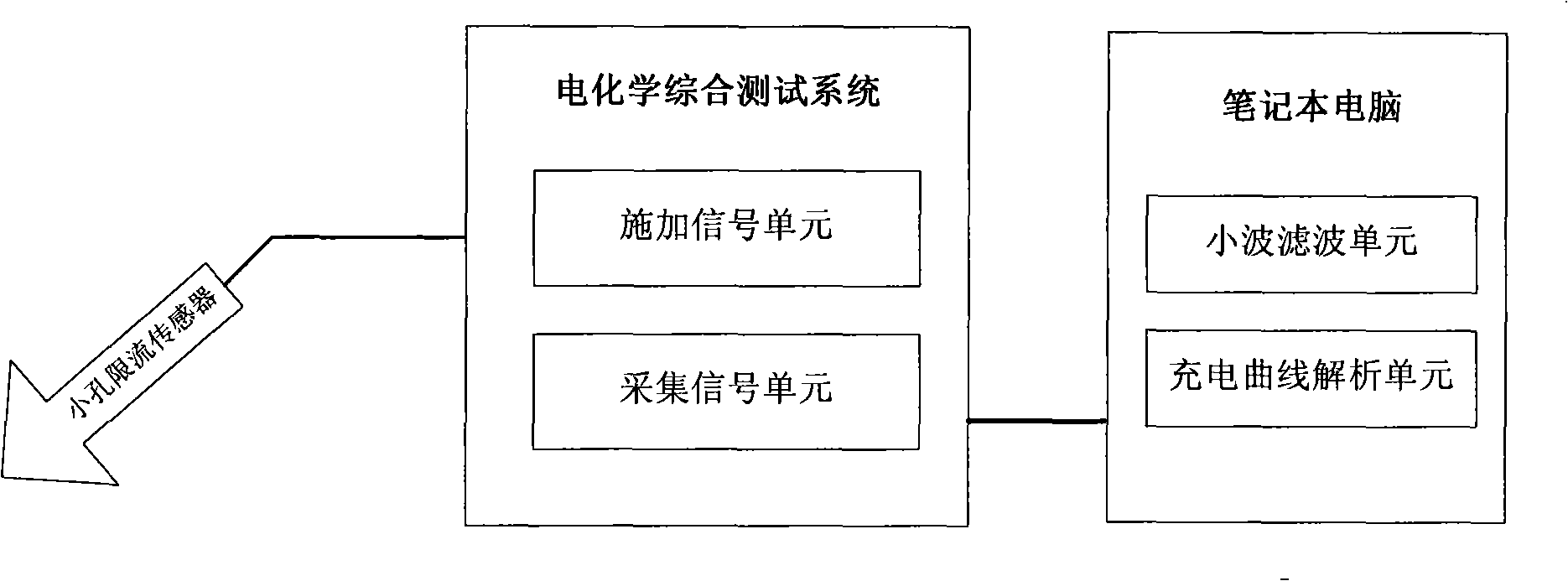

Ground net corrosion detection method and system

ActiveCN101315403AEasy to measureQuick testWeather/light/corrosion resistanceFault locationStep responseMetal

The invention provides a corrosion detection method for a grounding net, as well as a system. The method comprises the steps as follows: the corrosion potential of detected grounding net metal is measured, constant current step signals are applied to the detected grounding net metal, and the constant current step response signals are collected; the wavelet filter treatment is performed to the collected grounding net soil corrosion electrochemical detection data; and the corrosion electrochemical parameter analysis processing is performed to the grounding net soil corrosion electrochemical detection data after the wavelet filter treatment, thereby generating the grounding net soil corrosion detection result. The grounding net corrosion status is detected accurately and conveniently by the electrochemical detection method.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

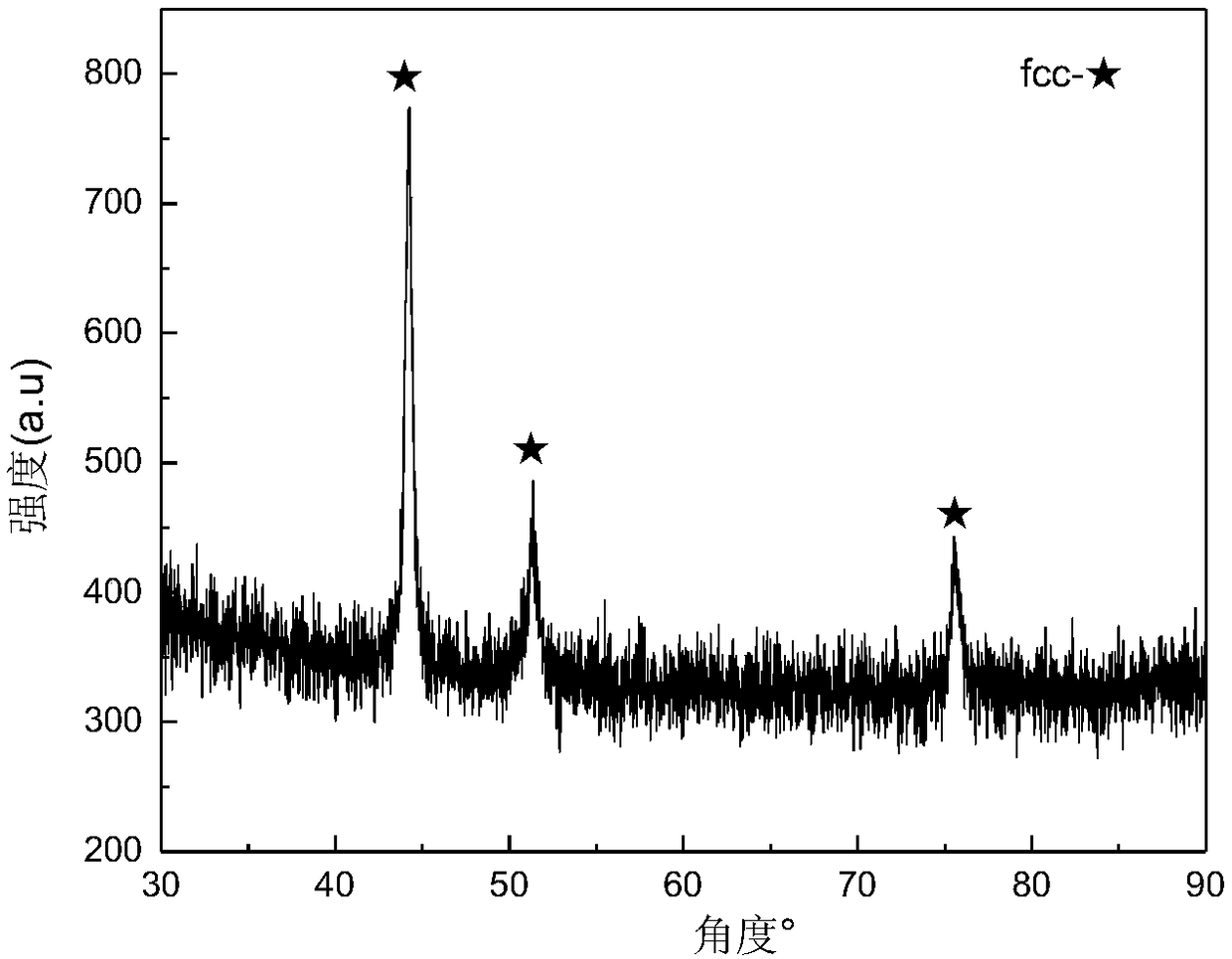

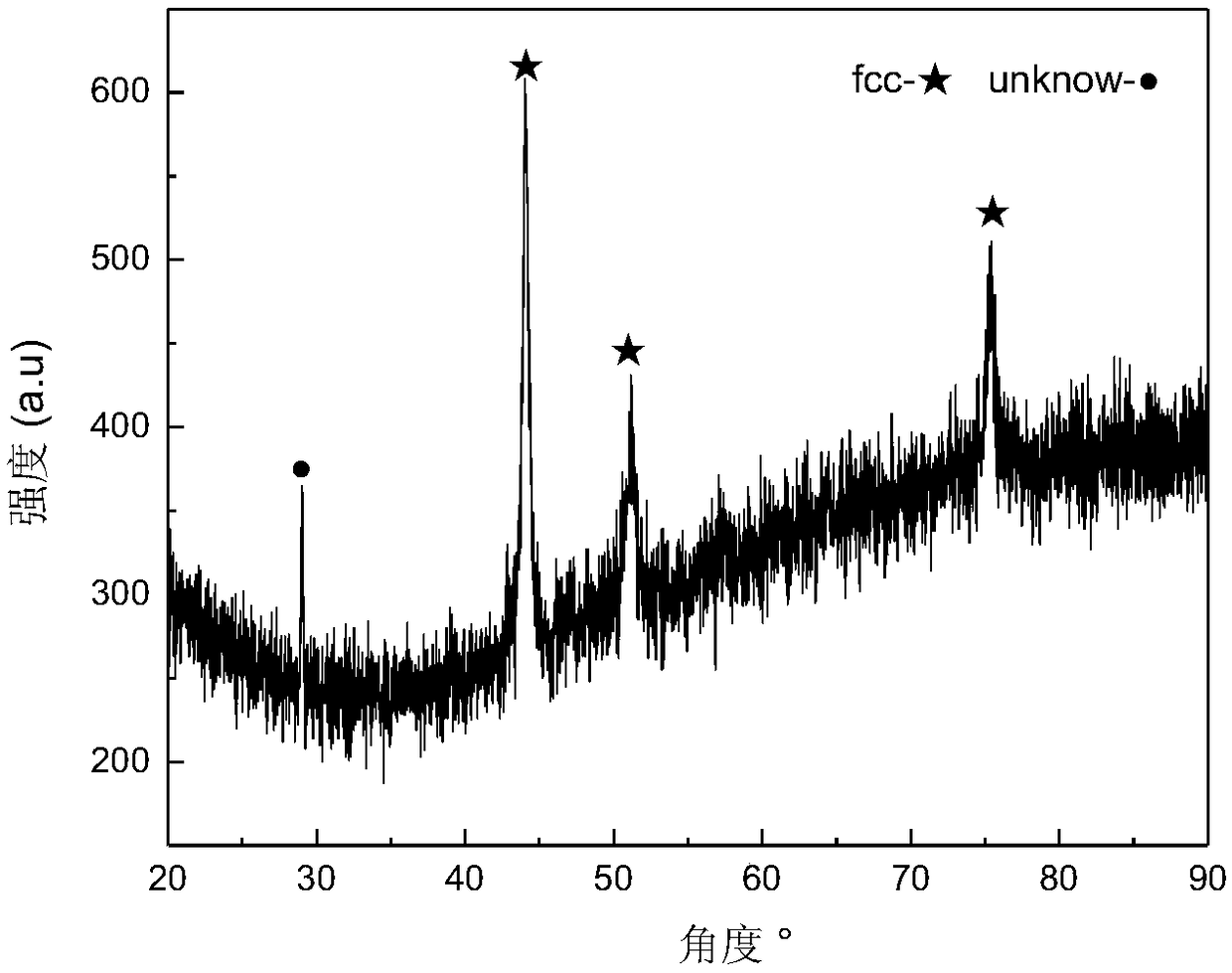

High-strength, corrosion-resistant and medium-entropy alloy and preparation method thereof

The invention discloses a high-strength, corrosion-resistant and medium-entropy alloy and a preparation method thereof. The component of the medium-entropy alloy is (CoCrNi)(100-x)Mnx, the atomic ratio of Co to Cr to Ni is (0.5-1):(0.5-1):(0.5-1), the value range of x is 1at%-10at%, , the alloy is formed through mixing, smelting, homogenizing treatment, rolling and heat treatment machining, the grain size of the alloy ranges from 30 mu m to 200 mu m, the manganese-rich phase is separated out of the grain boundary, the tensile strength of the alloy is higher than 1,200 MPa, the ductility is higher than 10%, the corrosion potential ranges from negative 0.43 V to negative 0.26 V, and the medium-entropy alloy is applicable to marine engineering equipment. The preparation process route of the alloy includes vacuum smelting, suction casting, homogenizing annealing, cold rolling and heat treatment. Co, Cr and Ni with the purity being 99% or higher are selected and weighed according to the proportion and are smelted repeatedly in a vacuum smelting furnace, suction casting forming is performed after the component is uniform, multi-pass cold rolling is adopted after annealing treatment, a plate which is 1-2 mm thick is obtained, the tensile strength of the plate is higher than 1,200 MPa, the ductility is higher than 10%, and the corrosion potential ranges from negative 0.43 V to negative0.26 V.

Owner:SOUTHEAST UNIV

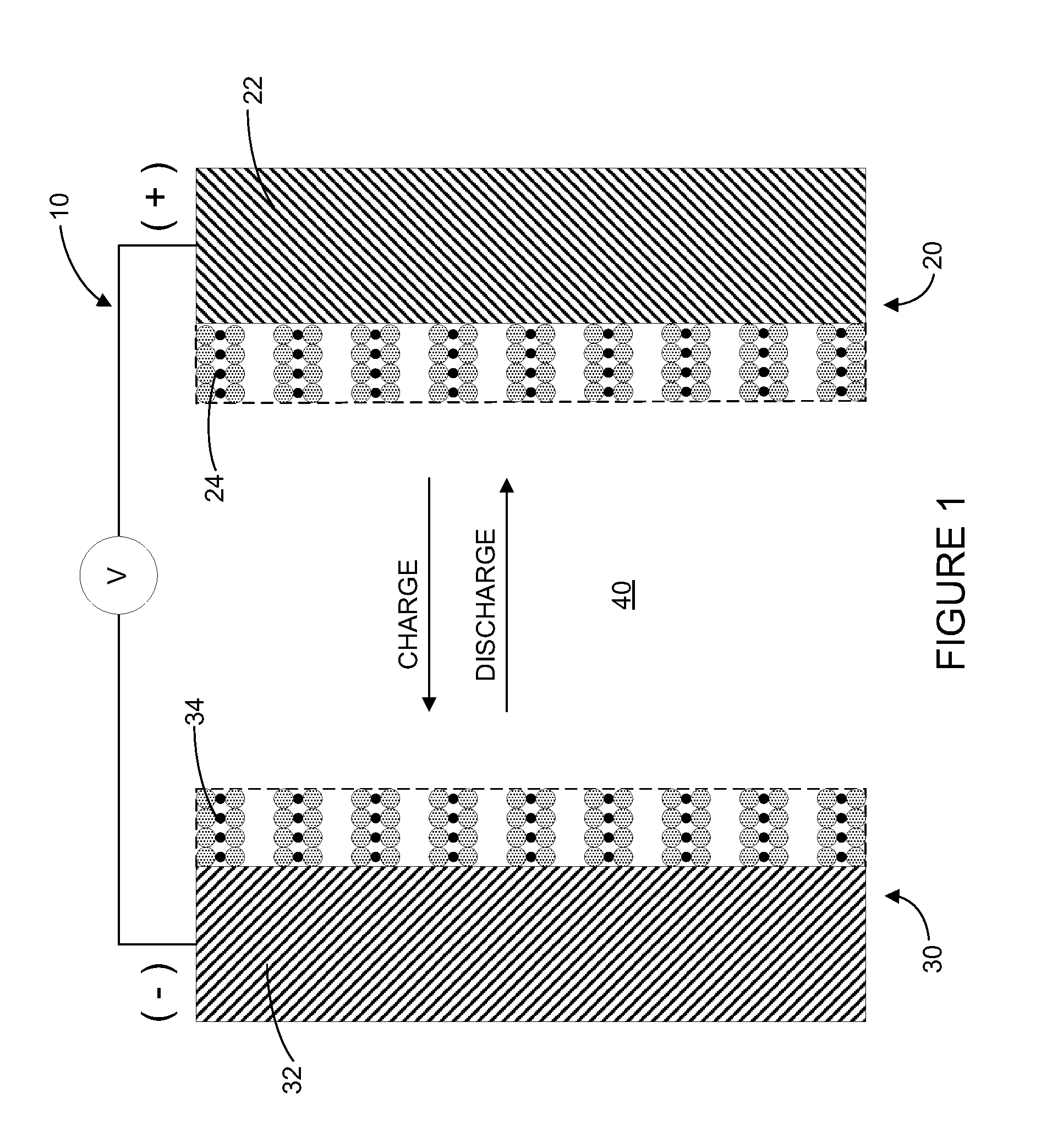

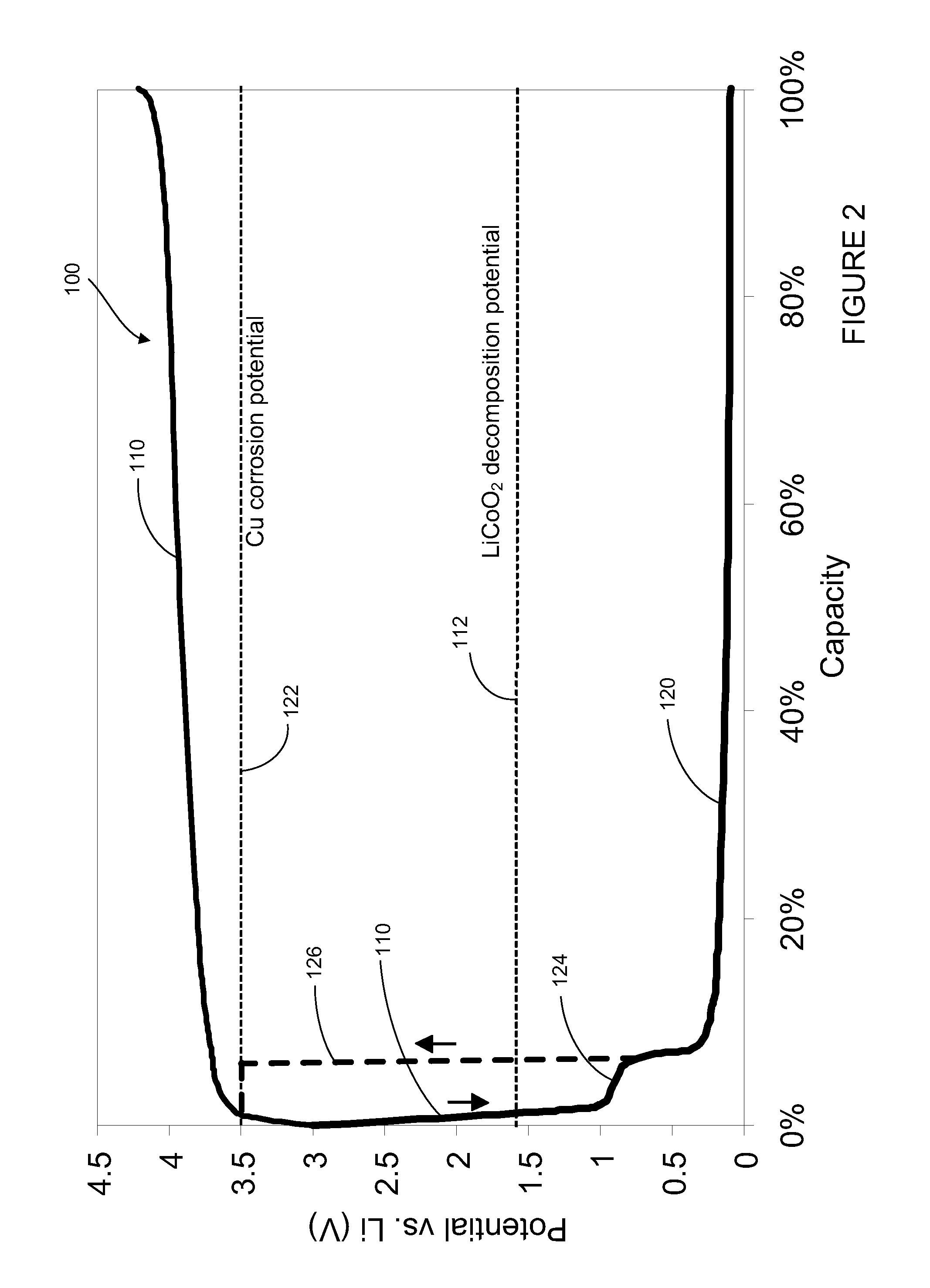

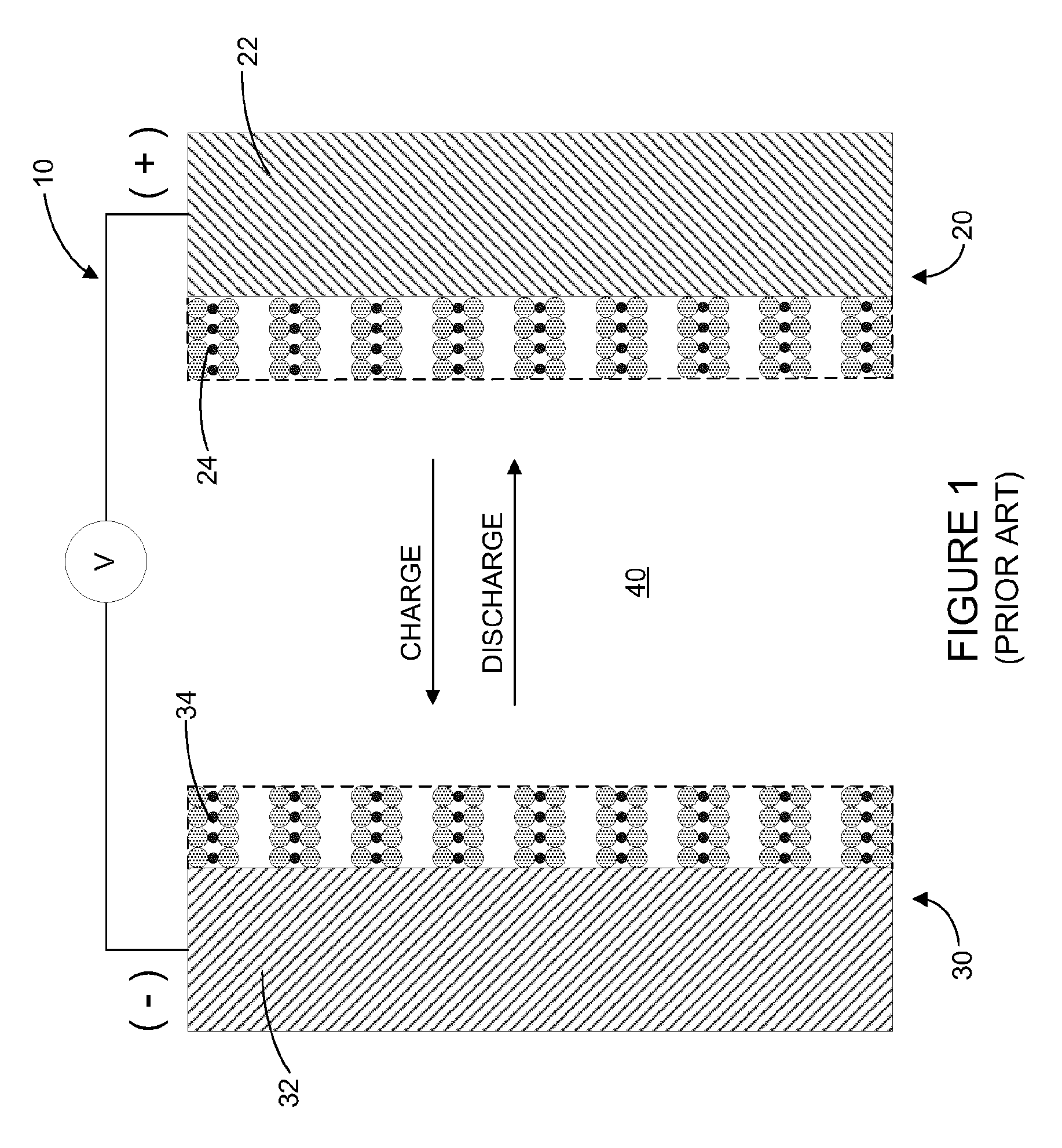

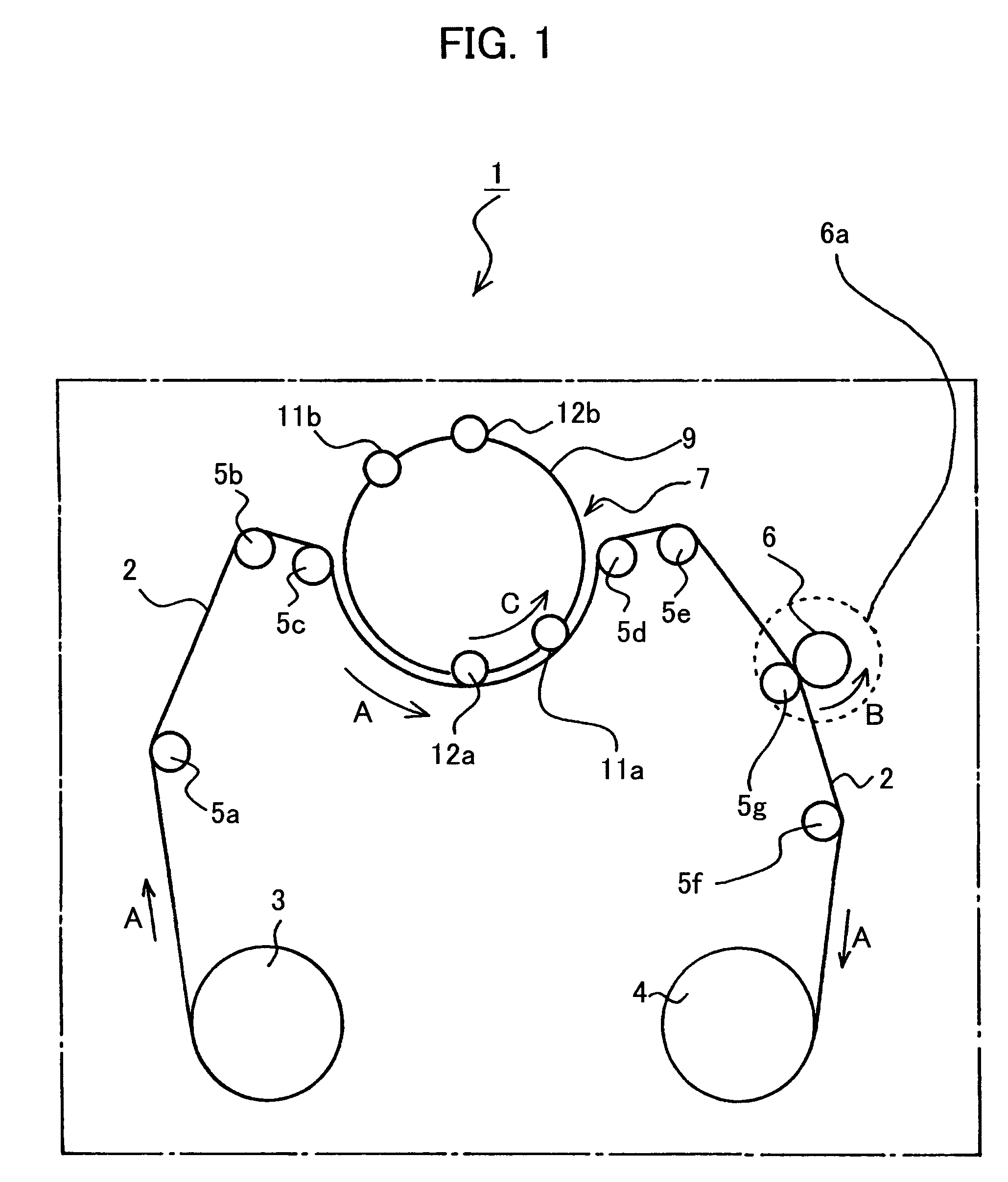

Lithium-ion battery

ActiveUS7794869B2Active material electrodesNon-aqueous electrolyte accumulator electrodesElectrical connectionEngineering

A battery includes a positive electrode having a current collector and a first active material and a negative electrode having a current collector and a second active material. The battery also includes an auxiliary electrode having a current collector and a third active material. The auxiliary electrode is configured for selective electrical connection to one of the positive electrode and the negative electrode. The first active material, second active material, and third active material are configured to allow doping and undoping of lithium ions. The third active material exhibits charging and discharging capacity below a corrosion potential of the current collector of the negative electrode and above a decomposition potential of the first active material.

Owner:MEDTRONIC INC

Coatings and Coating Systems for Metal Substrates

InactiveUS20090155598A1Improve corrosion resistanceSynthetic resin layered productsAnti-corrosive paintsMetallic substrateMetal substrate

Disclosed are methods of treating a metal to improve the metal's corrosion resistance. In one such method, the method is carried out by applying, to the surface of the metal, a coating which includes magnesium powder and a UV-curable or other radiation-curable binder. In another such method, the method is carried out by applying, to the surface of the metal, a coating which includes magnesium powder and an inorganic binder. In another such method, a coating that includes a magnesium alloy powder and a binder is applied to the surface of the metal. The magnesium alloy powder is selected such that it has a corrosion potential that is from about 0.01 volt to about 1.5 volt more negative than the metal's corrosion potential. Also disclosed are methods of treating a ferrous metals and magnesium alloys to improve the corrosion resistance of these materials.

Owner:NORTH DAKOTA STATE UNIV RES FOUND

Process for prparing polyaniline corrosion-resistant paint

InactiveCN1358812AIncreased corrosion potentialCorrosion Prevention and MitigationAnti-corrosive paintsEpoxyPolyamide

The present invention discloses a preparation process of polyaniline anticorrosive coating, and includes the following steps: mixing epoxy rsin, polyaniline and diluent uniformly, grinding, then mixing them with phenol aldehide amine, polyamide and diluent uniformly according to the ratio of 10-20:1, cuating on the metal surface and solidifying at room temp. so as to implement said invention. Said anticorrosive coating can form a layer of compact film on the steel surface, can raise corrosion potential of steel, reduce corrosion current and can prevent and relieve corrosion of steel, and said coating layer possesses high harndess and excellent abrasive resistance, after said coating layer is scratched, a passive film can be formed so as to can protect metal from corrosion.

Owner:XI AN JIAOTONG UNIV

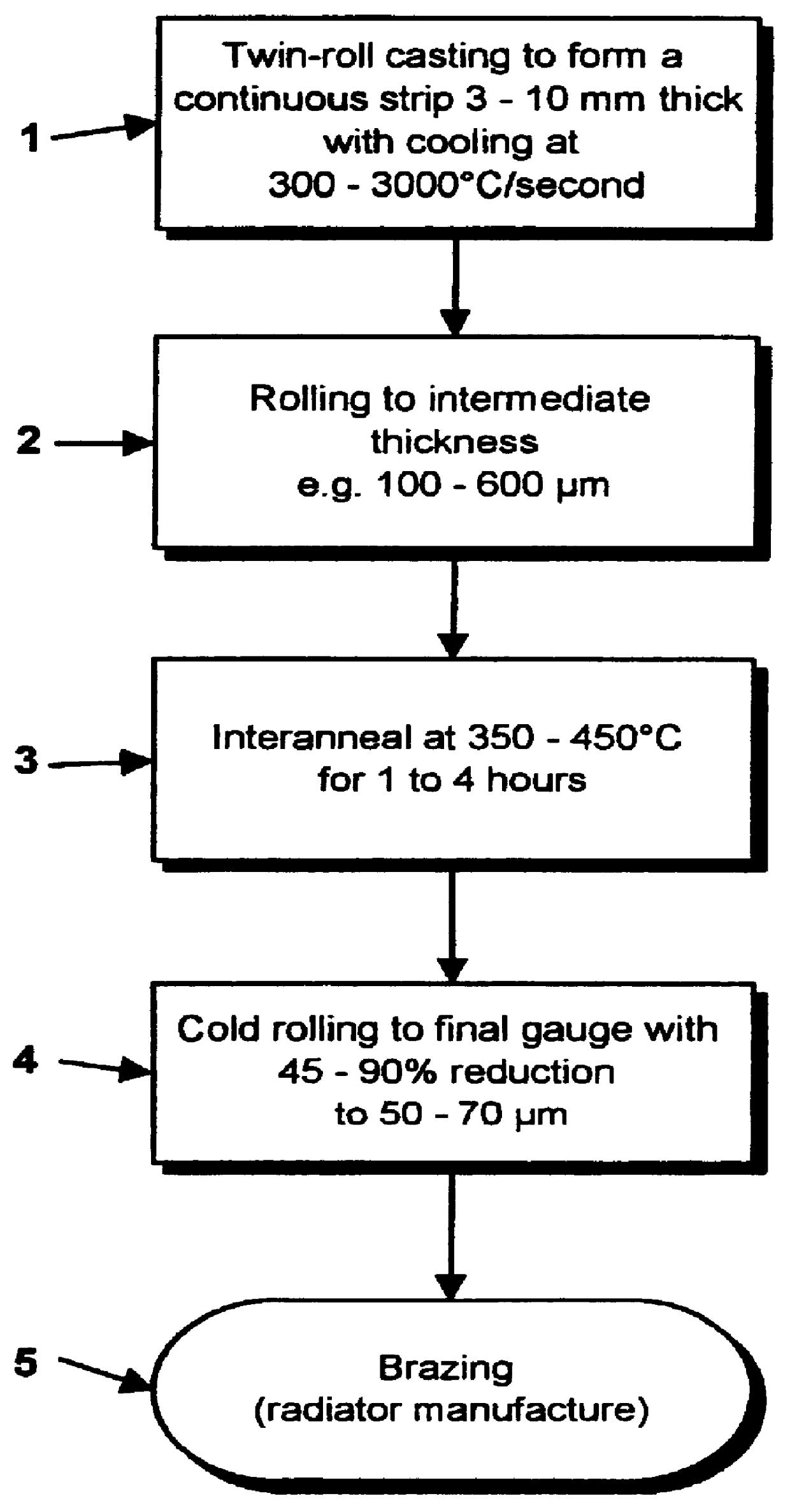

Process of producing aluminum fin alloy

InactiveUS6165291ALower (more negative) corrosion potentialImprove thermal conductivityWelding/cutting media/materialsHeat exchange apparatusMetallurgyHeat sink

An aluminum alloy fin stock of lower (more negative) corrosion potential and higher thermal conductivity is produced by a process, which comprises continuously strip casting the alloy to form a strip, cold rolling the strip to an intermediate gauge sheet, annealing the sheet and cold rolling the sheet to final gauge. Lower corrosion potential and higher thermal conductivity are imparted by carrying out the continuous strip casting while cooling the alloy at a rate of at least 300 DEG C. / second, e.g. by conducting the casting step in a twin-roll caster.

Owner:NOVELIS INC

Medical device having lithium-ion battery

A medical device includes a rechargeable lithium-ion battery for providing power to the medical device. The lithium-ion battery includes a positive electrode comprising a current collector and a first active material and a negative electrode comprising a current collector, a second active material, and a third active material. The first active material, second active material, and third active material are configured to allow doping and undoping of lithium ions. The third active material exhibits charging and discharging capacity below a corrosion potential of the current collector of the negative electrode and above a decomposition potential of the first active material.

Owner:MEDTRONIC INC

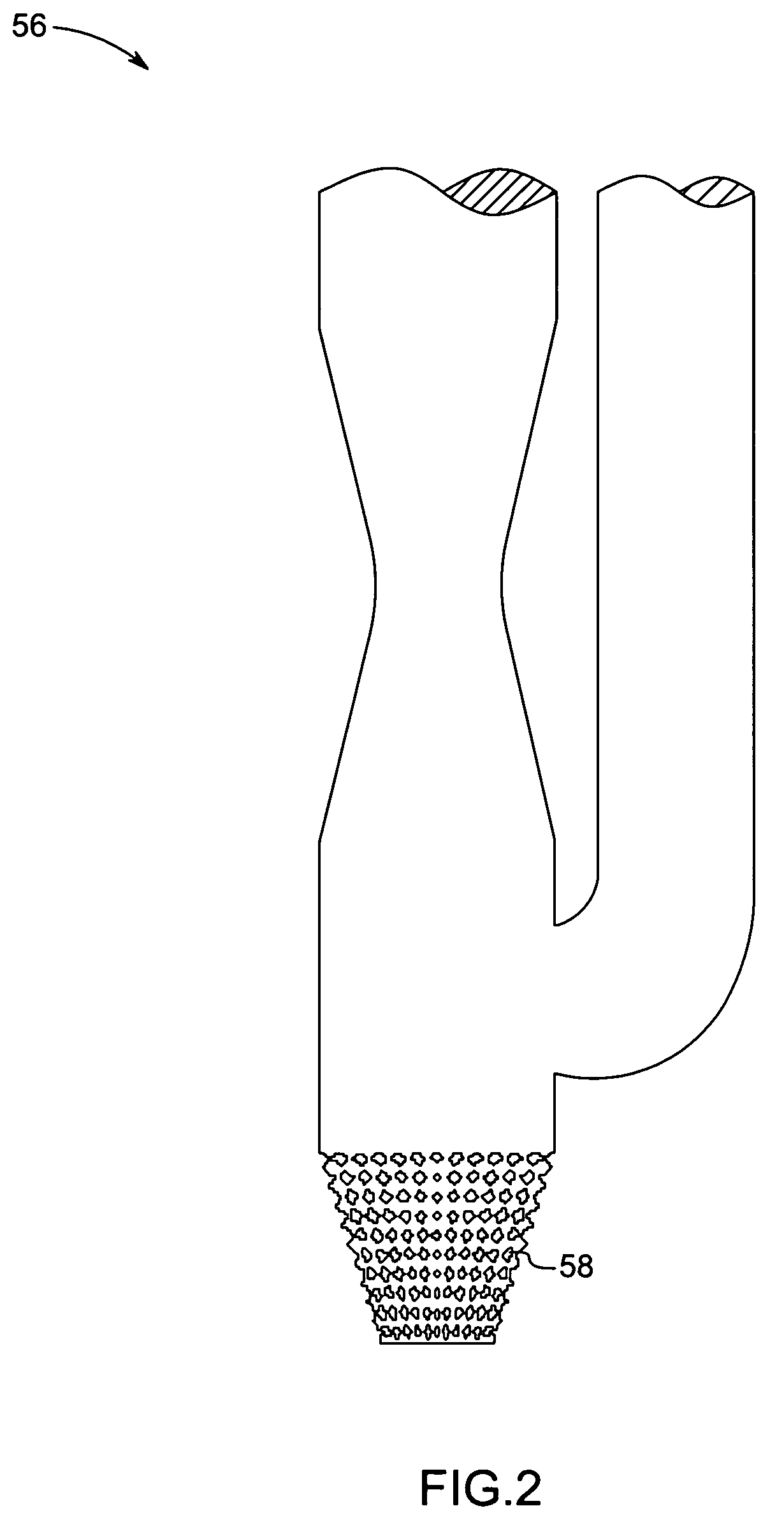

Sealing system, method of manufacture thereof and articles comprising the same

Disclosed herein is an apparatus for use downhole comprising an expandable component; a support member that has a selected corrosion rate; wherein the support member is disposed on the expandable component; where the support member comprises a plurality of particles fused together; the particles comprising a core comprising a first metal; and a first layer disposed upon the core; the first layer comprising a second metal; the first metal having a different corrosion potential from the second metal; the first layer comprising a third metal having a different corrosion potential from the first metal.

Owner:BAKER HUGHES INC

Preparation method of polyaniline water-based epoxy resin anticorrosive paint

InactiveCN105949960ANo pollution in the processImprove impermeabilityAnti-corrosive paintsMetallic material coating processesDispersityWater based

The invention particularly relates to a preparation method of a polyaniline / graphene water-based epoxy anticorrosive paint by blending a polyaniline composite material and a water-based epoxy resin, belonging to the technical field of anticorrosive paints. In order to solve the problems of lower water resistance and lower corrosion resistance of the coating due to abundant hydrophilic groups in the water-based epoxy resin paint which uses water as the solvent, the invention provides a preparation method of a polyaniline water-based epoxy resin anticorrosive paint. By using the characteristic of large specific area in the graphene, a polymerization-reduction process is utilized to prepare the large-specific-area high-dispersity polyaniline / graphene composite material, and the composite material is blended with the water-based epoxy resin to prepare the anticorrosive coating. The polyaniline / graphene composite material added into the water-based epoxy resin enhances the metallic corrosion potential, quickly conducts electrons formed in the corrosion process, and separates the cathode and anode reaction; a metal passivation layer is formed on the matrix surface to decelerate the metal corrosion; and the composite material with large specific area prolongs the seepage path of oxygen and water molecules to the carbon steel surface, and thus, has excellent barrier properties.

Owner:郭迎庆

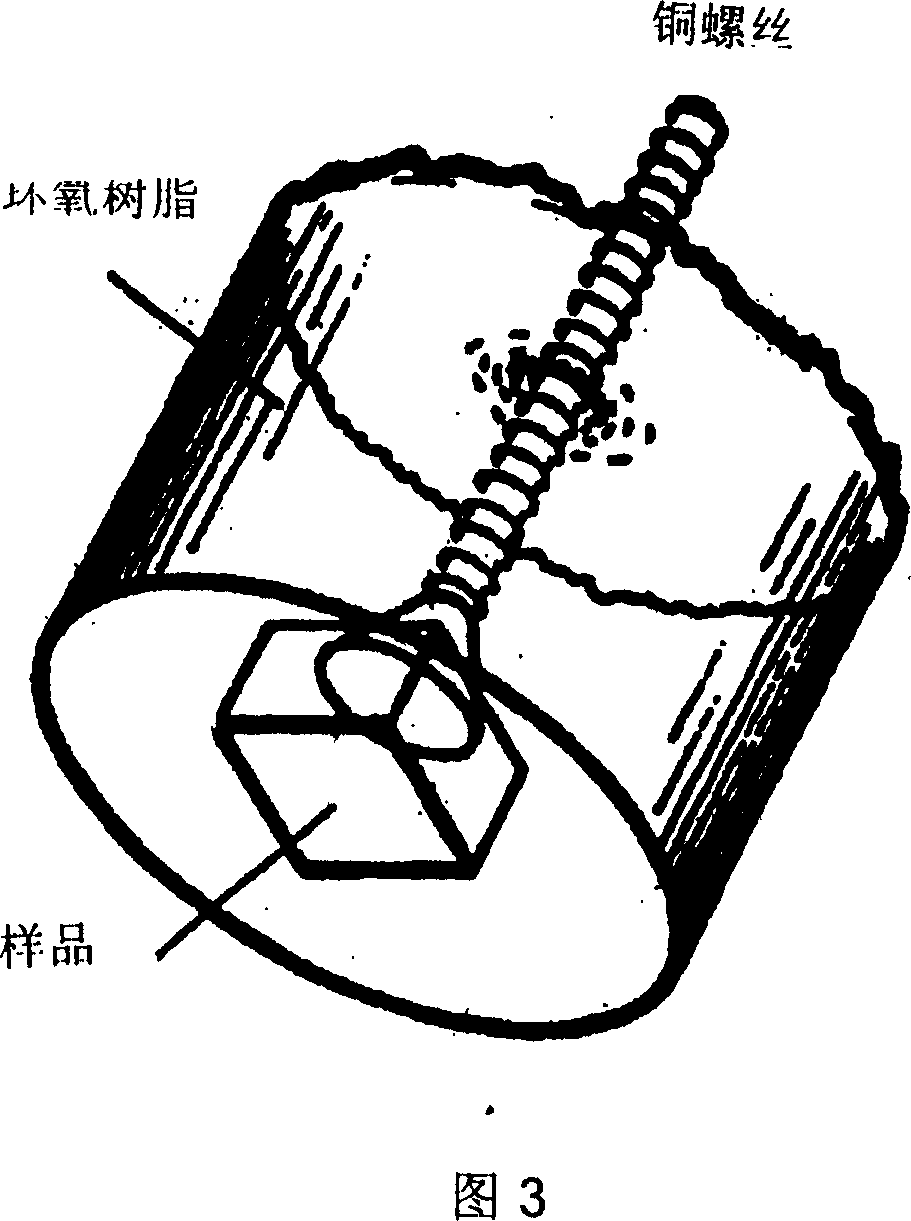

Binode polarization curve method for measuring electrochemical characteristic and corrosion resistance of metal

InactiveCN1952645AAvoid defectsUse the effect beyondWeather/light/corrosion resistanceMaterial electrochemical variablesTime informationElectricity

A method of binode polarization curve which is used to test the metallographic electrochemistry property and the corrosion resisting property is disclosed, The metal sample to be measured is immersed into the aqueous solution, the open-circuit potential that is the corrosion potential Ecorr of the sample is recorded, then the forward scan from the activating area to the inactivating area of the metal sample can be done beginning with the corrosion potential, the density of current which goes by the sample is be recorded at the same time; the scanning direction of electric potential is changed when the electric potential reaches the assigned value Et, the backward scan from the inactivating area to the activating area of the metal sample is started, a new corrosion potential E'corr is obtained, the anode polarization curve F of the forward scan and the anode polarization curve B of the backward scan that metal sample is in aqueous solution are run with the logarithm of electric potential and current density measured. The invention can make the measured results have perfect correlation with the true causticity of metal to gain one times information more than current technology. It will be the very effective tools for research of the metallographic electrochemistry property and the corrosion resisting property of metal in aqueous solution.

Owner:华宏勋

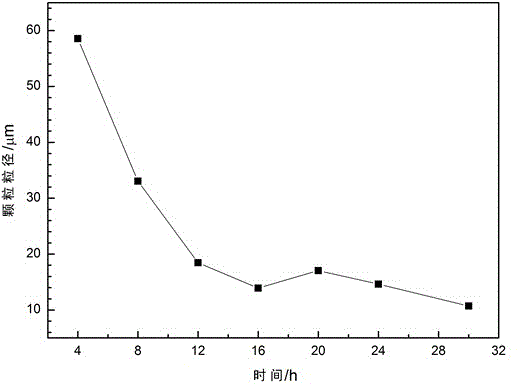

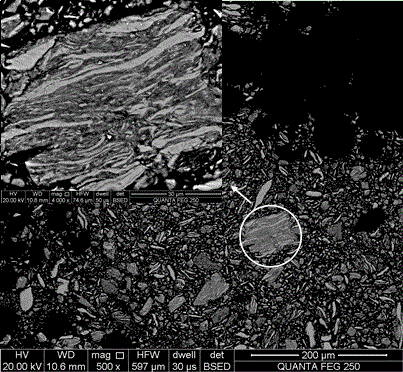

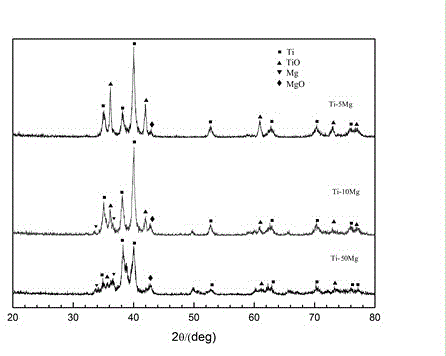

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

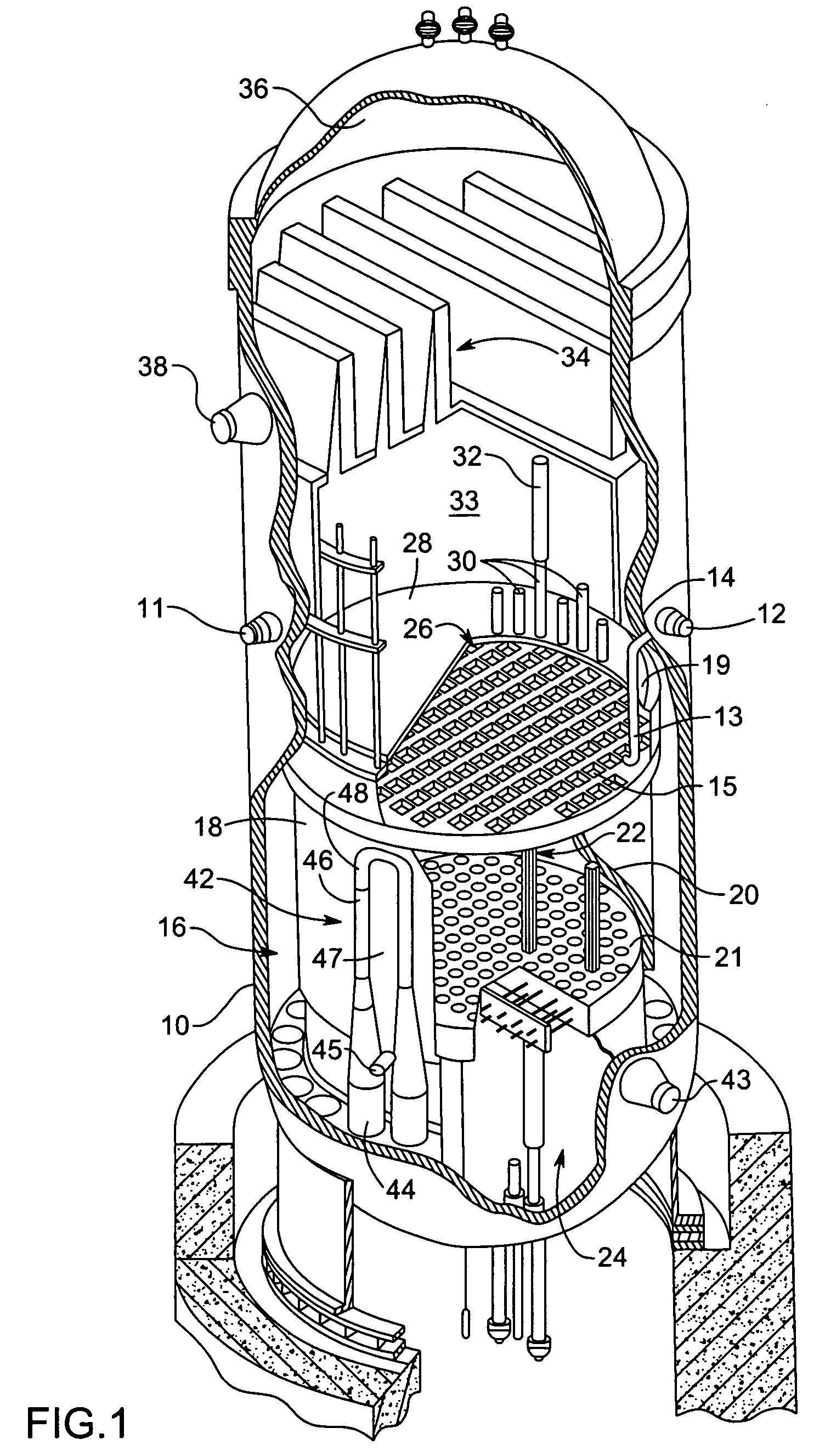

Mitigation of stress corrosion cracking of structural materials exposed to a high temperature water

InactiveUS7264770B2Reducing electrochemical corrosion potentialReduce crackingMaterial nanotechnologyEngine fuctionsStress corrosion crackingZinc

Owner:GENERAL ELECTRIC CO

Magnetoresistive head with spin valve film magnetic sensor element

InactiveUS6970332B2Improve corrosion resistanceRaise the ratioNanoinformaticsRecord information storageMagnetic reluctanceNon magnetic

An improvement in the corrosion resistance of a magnetoresistive head is aimed for, and a high magnetoresistivity ratio is maintained. In a magnetoresistive head equipped with, as a magnetic sensor element for detecting magnetic signals while in contact with a magnetic recording medium, a spin-valve film, which has a structure where an anti-ferromagnetic layer, a pinned layer in which the direction of magnetization is pinned in a predetermined direction by an exchange-coupling magnetic field at work between itself and the anti-ferromagnetic layer, a free layer in which the direction of magnetization changes in accordance with an external magnetic field, and a non-magnetic layer for magnetically isolating the pinned layer and the free layer are layered, the corrosion potential of the spin-valve film relative to a standard hydrogen electrode measured while immersed in a NaCl solution of a concentration of 0.1 mol / L is specified at +0.4 [V vs. SHE] or above.

Owner:SONY CORP

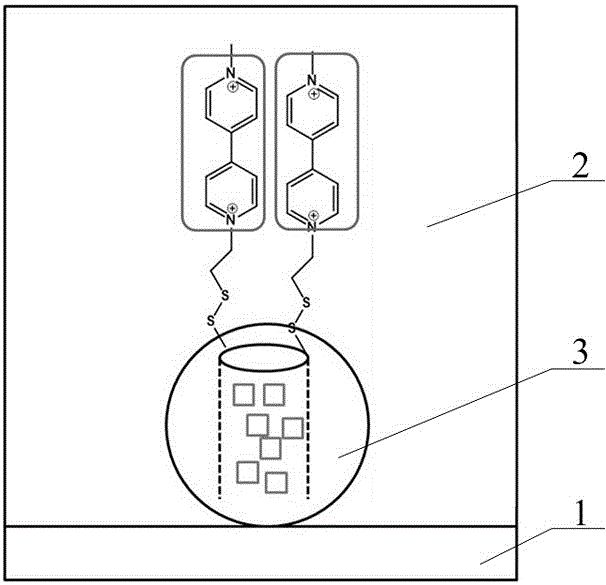

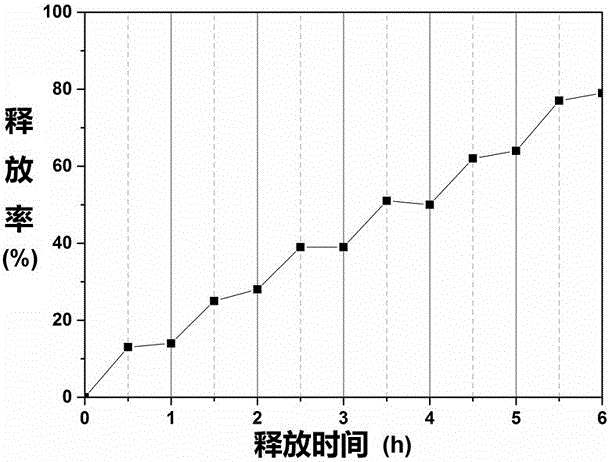

Self-corrosion potential response type self-repairing anti-corrosion coating, preparation method and application

ActiveCN105925129APermeation barrierNot easy to peel offAnti-corrosive paintsEpoxy resin coatingsSilanesMesoporous silica

The invention discloses a self-corrosion potential response type self-repairing anti-corrosion coating and belongs to the field of the metal anti-corrosion technology. The self-corrosion potential response type self-repairing anti-corrosion coating is composed of an epoxy-silane composite coating and a mesoporous silica nano-container doped in the epoxy-silane composite coating. The preparation process includes the steps that an epoxy-silane composite coating substrate is prepared; the mesoporous silica nano-container is prepared; the mesoporous silica nano-container is dispersed in the epoxy-silane composite coating and then attached to the surface of a basic material, and the self-corrosion potential response type self-repairing anti-corrosion coating is formed after high-temperature drying. The self-corrosion potential response type self-repairing anti-corrosion coating is high in sensitivity and short in response time, microcell corrosion on the surface of metal can be actively and rapidly detected, corrosion inhibitor molecules are released and adsorbed on the surfaces of corrosion microcells to generate a self-repairing effect, and good application prospects are achieved in the metal anti-corrosion technology. The invention further discloses a preparation method and application of the self-corrosion potential response type self-repairing anti-corrosion coating.

Owner:JIANGSU GUGELANSHAN PROTECTIVE FACILITIES CO LTD +2

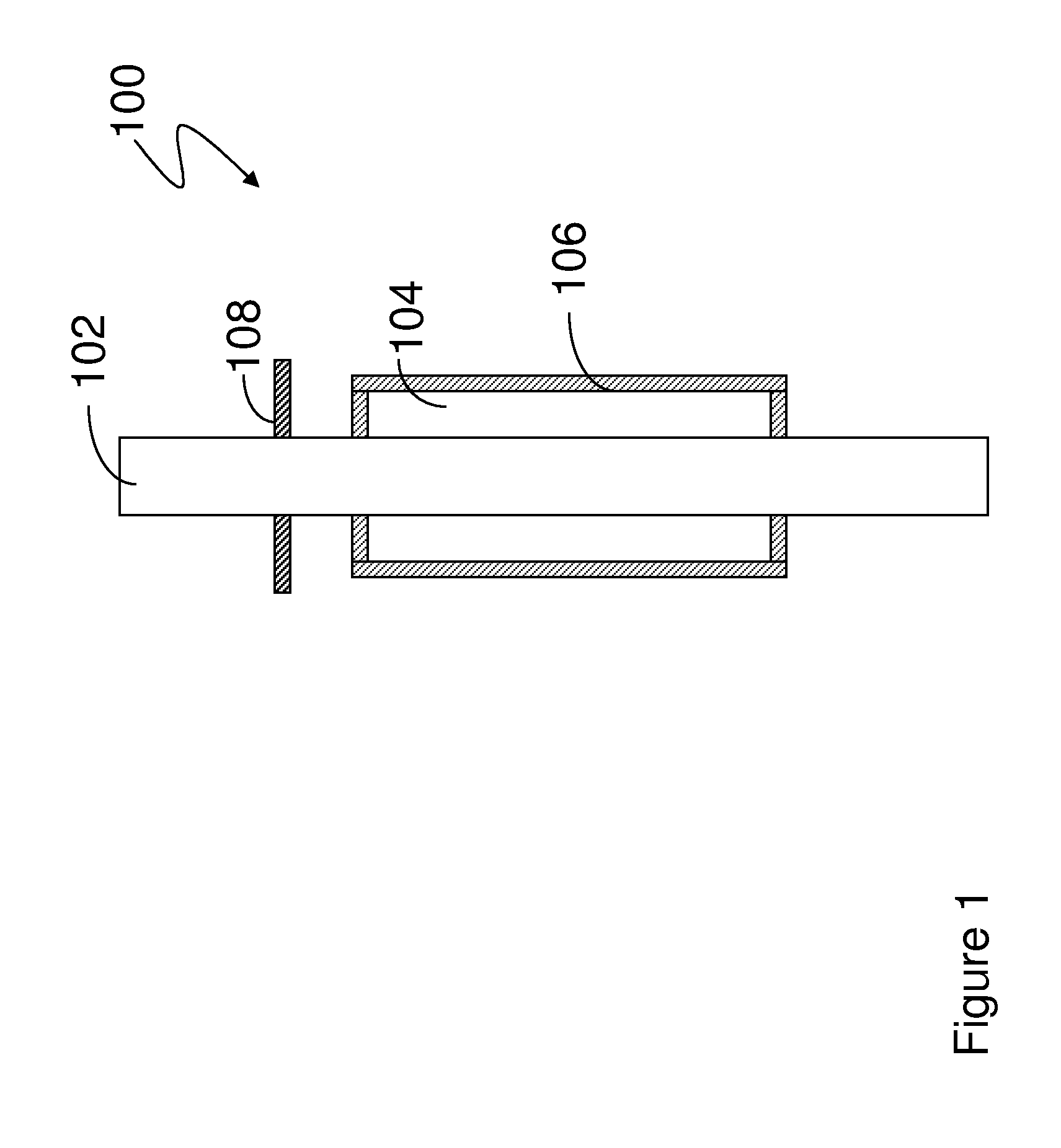

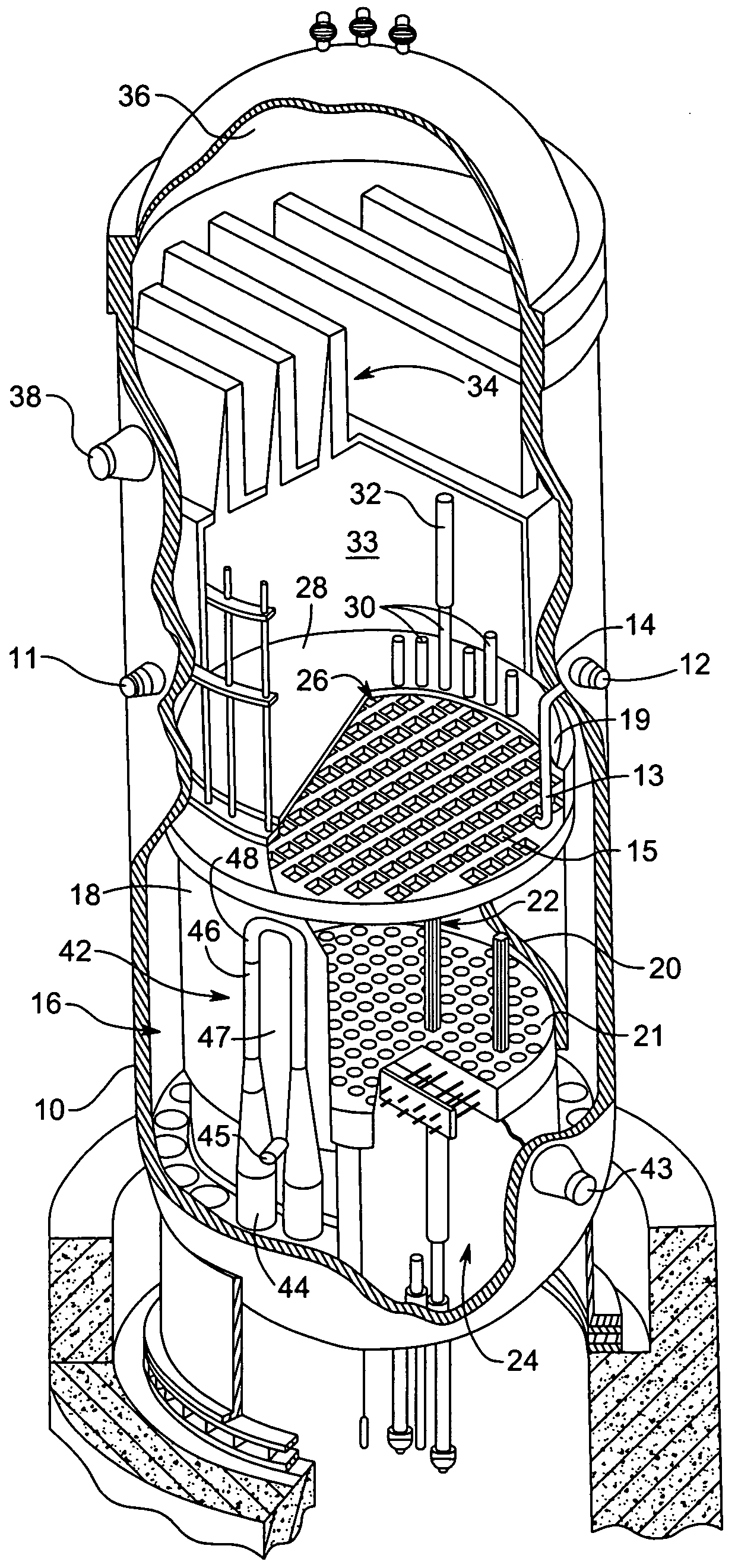

Electrochemical Corrosion Potential Sensor

InactiveUS20140069810A1Accurate measurementContinuous monitoringWeather/light/corrosion resistanceElectricityElectrochemical corrosion

An electrochemical corrosion potential sensor has a sensor unit, a lead wire and a quasi-reference electrode. A sensor unit includes a tube-shaped insulator, a tube-shaped metal casing joined to an end portion of the insulator, and a Pt electrode joined to another end portion of the insulator. A lead wire connected to the Pt electrode passes through the insulator and the metal casing. The quasi-reference electrode disposed in the metal casing is made of a less noble metal and electrically connected with the lead wire.Since an electrochemical corrosion potential sensor has the quasi-reference electrode, the measurement of the corrosion potential of a structural member of a nuclear power plant and an abnormality occurrence (water intrusion) can be accurately detected during the operation of a nuclear power plant.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

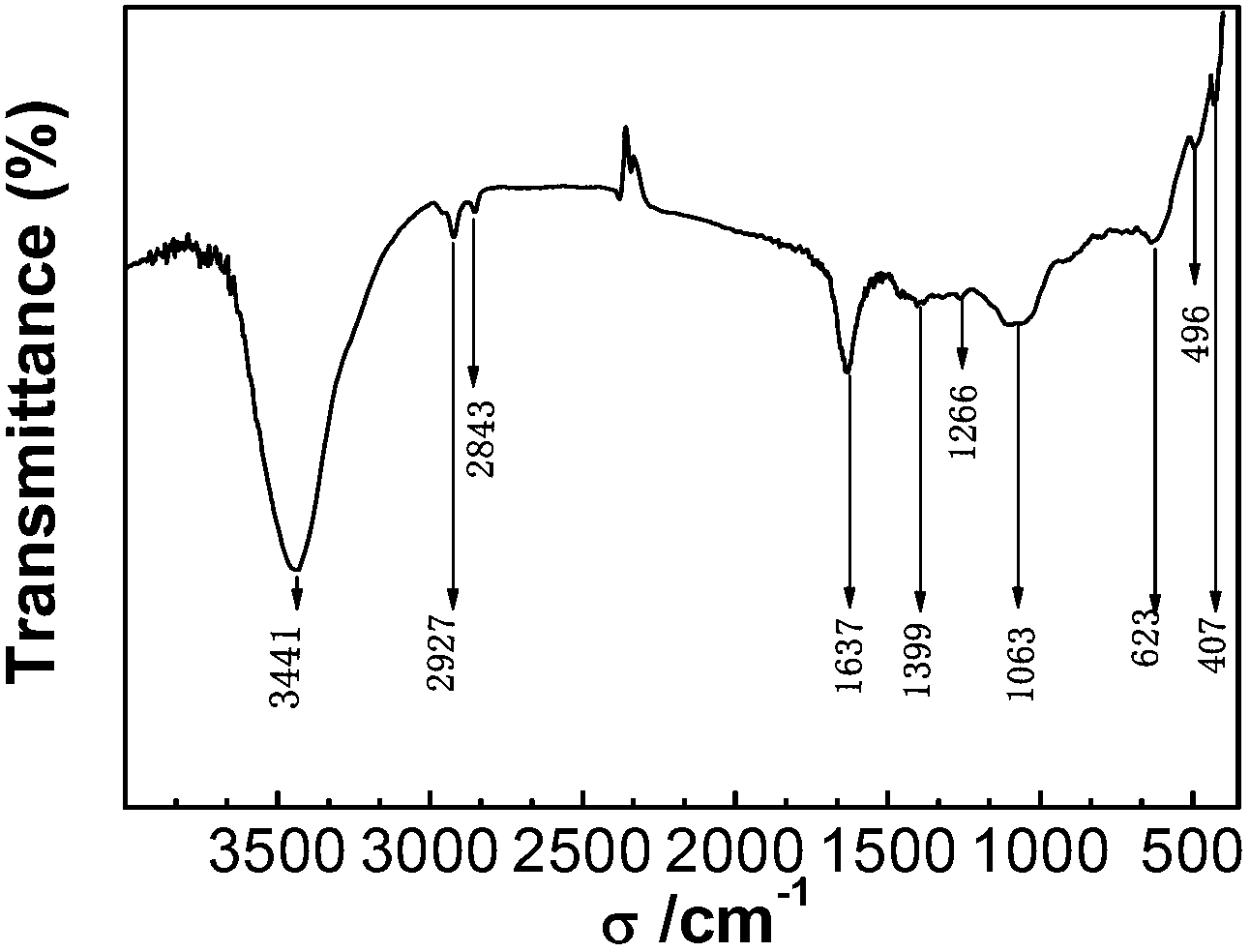

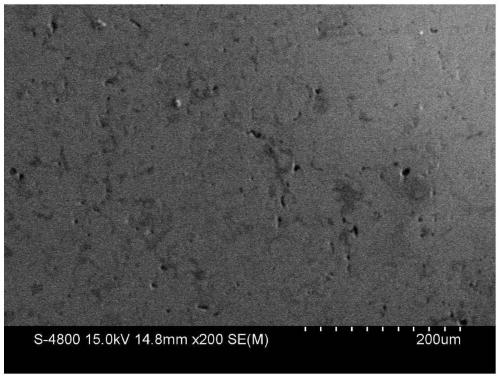

Method for preparing biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating

InactiveCN103463681AImprove corrosion resistanceConvenient researchMetallic material coating processesCalcium nitrate tetrahydrateMg alloys

The invention relates to a method for preparing a biodegradable magnesium alloy surface modification fluoridated hydroxyapatite coating. The method comprises the following steps of: pretreating a magnesium alloy substrate, wherein the adopted transfer solution is prepared from sodium dihydrogen phosphate dehydrate and calcium nitrate tetrahydrate; soaking a substrate sample obtained by pretreatment in the transfer solution for 5-100 hours, thus obtaining a calcium-phosphorus coating; soaking a calcium-phosphorus coating sample in an alkali fluoridated transfer solution for 10-48 hours, so as to obtain a fluoridated calcium-phosphorus coating, wherein the alkali fluoridated transfer solution is prepared from sodium hydroxide and sodium fluoride, the concentration of the sodium hydroxide is 3-4g / L, the concentration of the sodium fluoride is 4-5g / L, and heat treatment is not performed; performing heat treatment on the fluoridated calcium-phosphorus coating at the temperature of 300-350 DEG C for 2-5 hours, thus obtaining the fluoridated hydroxyapatite. According to performance detection, the fluoridated hydroxyapatite (FHA) coating prepared by combining a heat treatment process is shaped like a slender sheet and is divergently arranged from the center to the periphery; the electrochemical test proves that the self-corrosion potential of the substrate is improved through the FHA coating; the immersed corrosion experiment proves that an actual protective effect of the FHA coating on the magnesium alloy substrate is better than that of a fluoridated apatite (FA) coating.

Owner:TONGJI UNIV

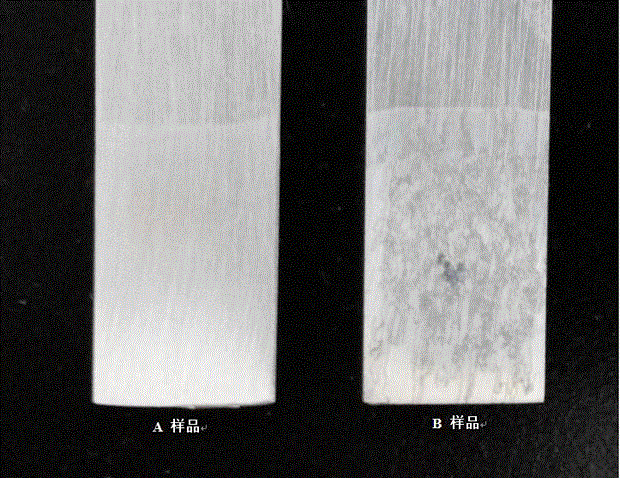

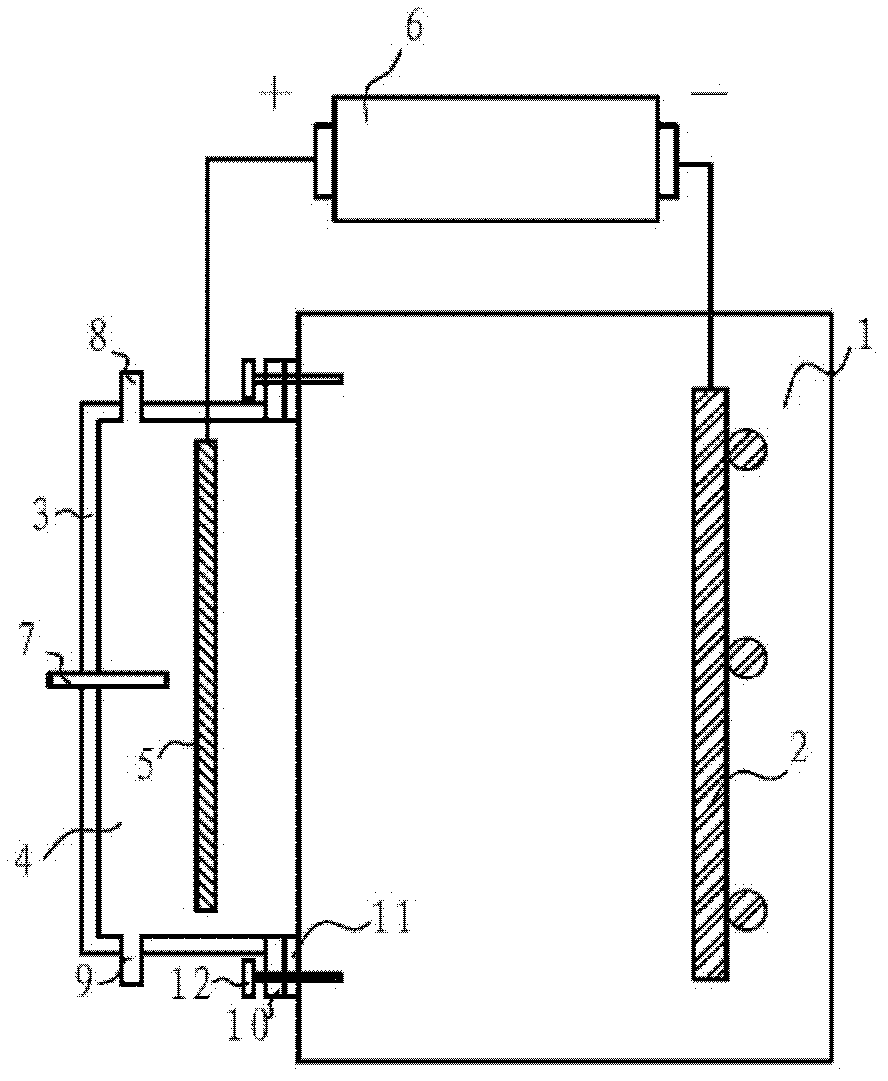

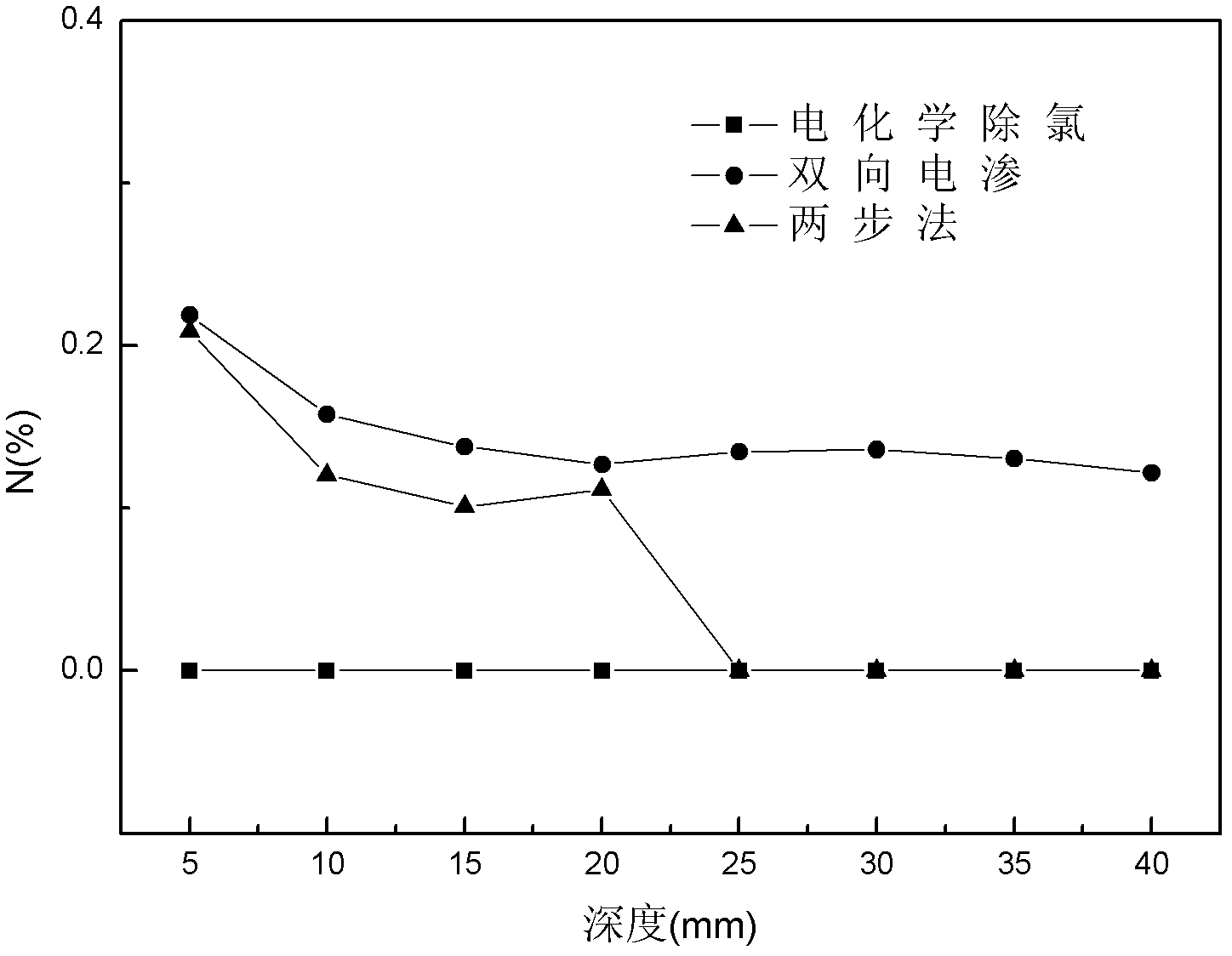

Device and method for repairing concrete structure damaged by salt through two-step process

The invention discloses a device for repairing a concrete structure damaged by salt through two-step process, including a steel bar that acts as a cathode and is disposed in concrete, an electrolytic tank whose mouth is in seal seal fit with a surface of the concrete, electrolyte disposed in the electrolytic groove, an anode immersed in the electrolyte and a direct current power supply for providing power to the cathode and the anode, wherein the electrolytic groove is provided with an electrolyte inlet, an electrolyte outlet and a pH indicator, a probe of the pH indicator penetrating througha wall of the electrolytic groove and contacting with the electrolyte. The device provided in the invention is capable of timely replacement of electrolyte which is conducive to full discharge of chloride ions, and is capable of real-time monitoring of the ph value of the electrolyte, being applicable to concrete structures of various kinds of shapes; in addition, the device has the advantages ofsimple structure, convenient operation and effective removal of the chloride ions in a concrete protective layer with the removal efficiency achieving about 60%; further, the device can raise the corrosion potential of a corroded steel bar, decrease corrosion rate, realize the repassivation and maximumly repair a concrete structure damaged by salt.

Owner:浙大宁波理工学院

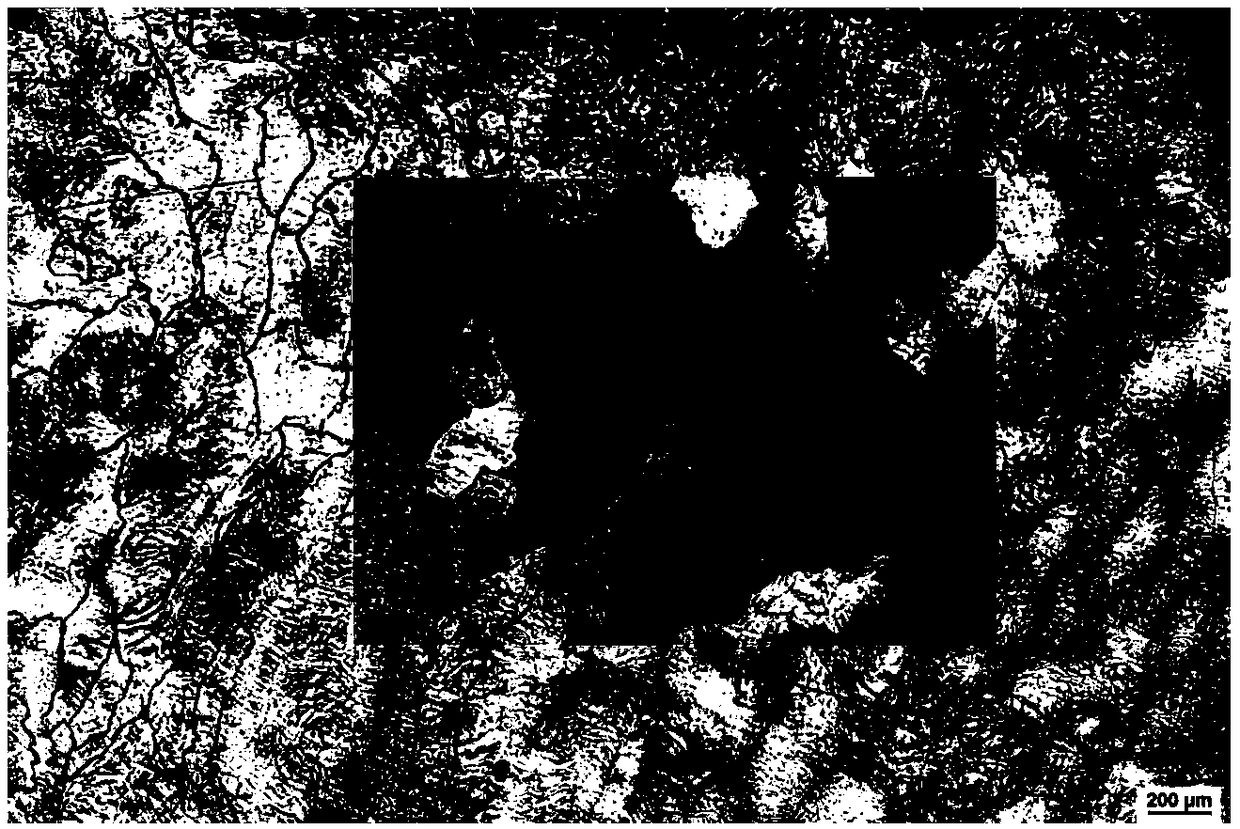

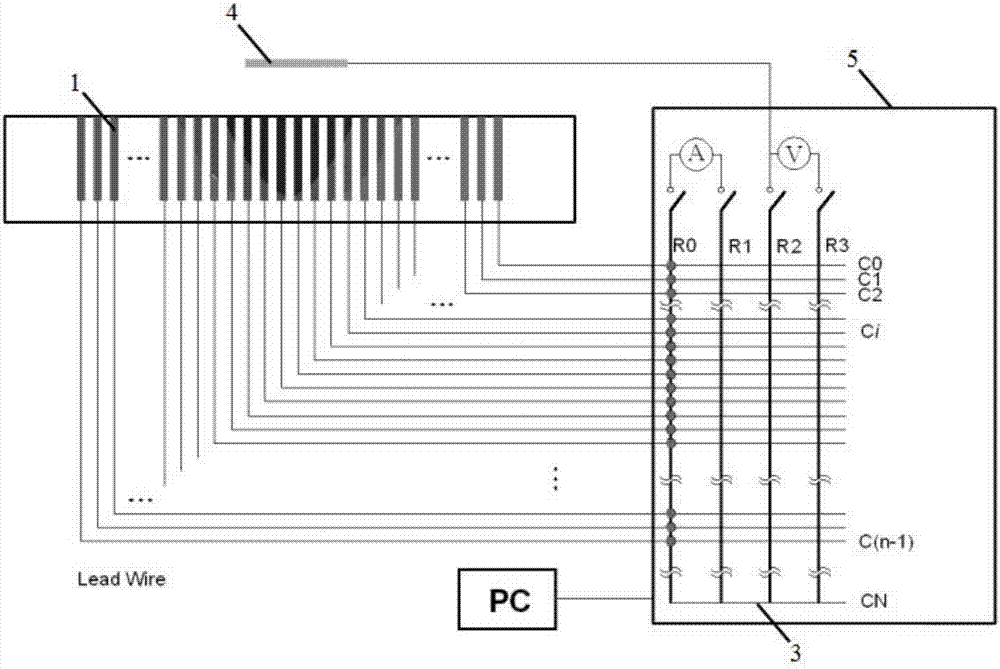

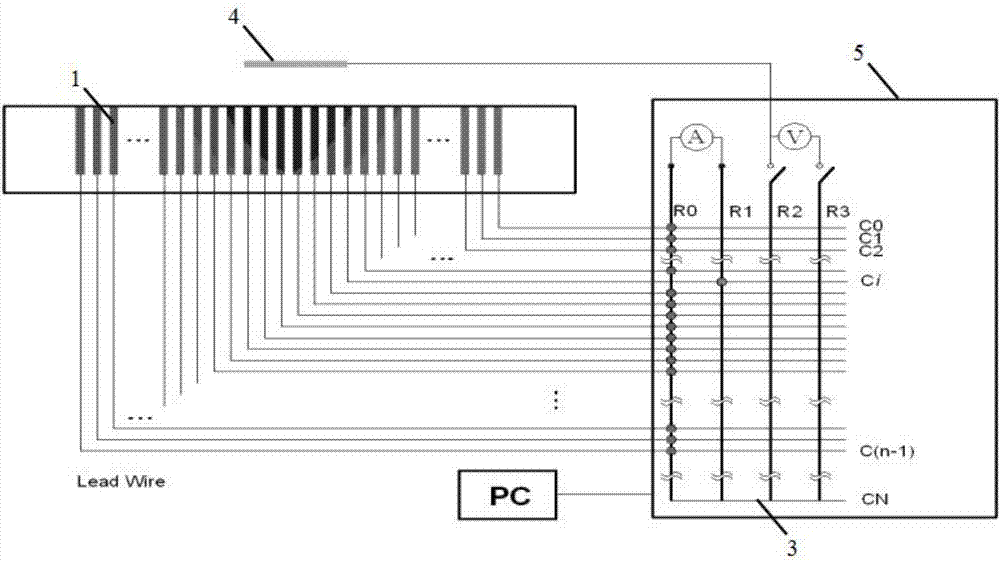

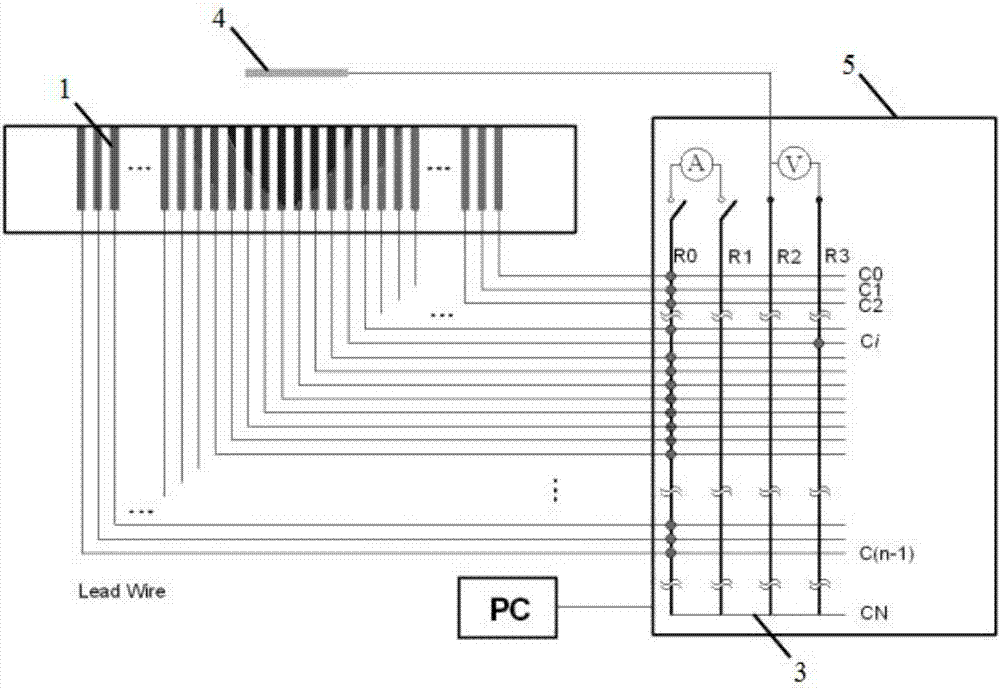

System and method for testing local corrosion of multi-electrode coupled inhomogeneous structure

InactiveCN107192665ANon-uniform stateNon-uniform densityWeather/light/corrosion resistanceSpectroscopyEngineering

The invention relates to a system and a method for testing local corrosion of a multi-electrode coupled inhomogeneous structure. Three testing systems including a classic electrochemical comprehensive testing system, a micro-area electrochemical testing system and a micro-electrode array testing system are arranged in the system; the three testing systems can be used for testing separately and any two testing systems also can be combined together; by using a micro-electrode array as a bridge and a bond, the three testing systems are coupled and combined, three tests of a classic electrochemistry test, a micro-electrode array test and a micro-area electrochemistry test can be carried out, and overall average information such as self-corrosion potential, self-corrosion current density, polarization property and electrochemical impedance spectroscopy, local distribution information such as galvanic potential and galvanic current having certain statistical characteristics, and micro-area distribution information of local cathode and anode areas in a local corrosion process of an inhomogeneous structure can be acquired and effectively associated on aspects of large scale, middle scale and small scale.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

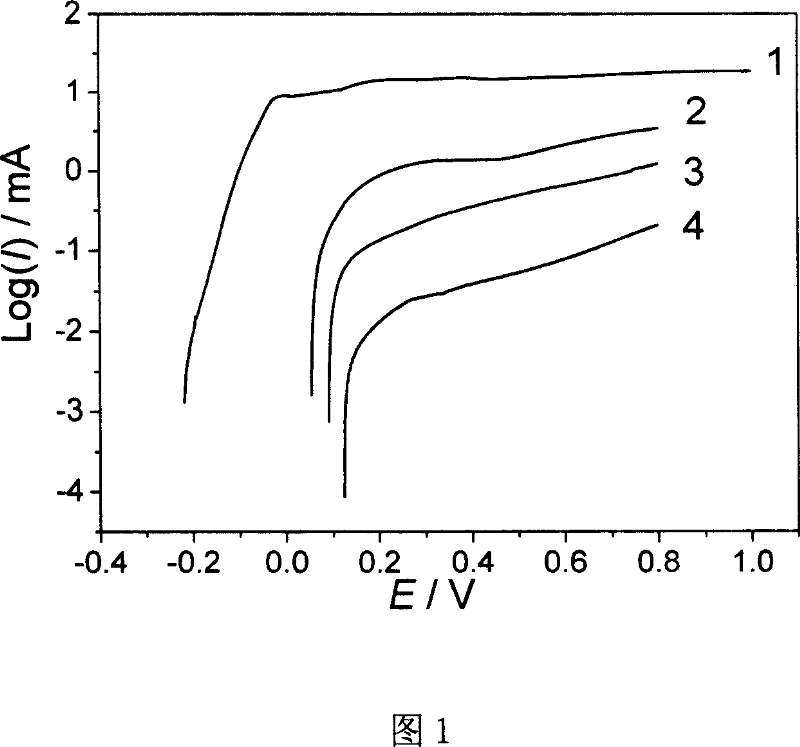

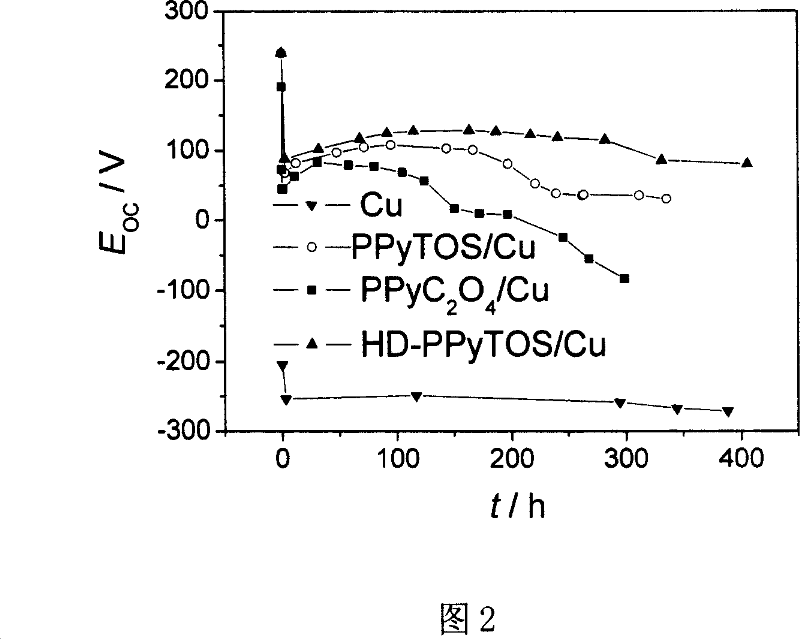

Method for preparing novel conductive composite anticorrosive coating

ActiveCN102703945AIncreased corrosion potentialNo corrosionElectrolytic organic material coatingPolypyrroleCopper electrode

The invention relates to a method for preparing a novel conductive polypyrrole / polyaniline composite anticorrosive coating. The method comprises the following steps of: dissolving p-toluenesulfonic acid into water, regulating the pH value of a solution to be an appropriate value, and adding pyrrole and aniline monomers to obtain a mixed solution; performing electrochemical synthesis by using a three-electrode system, wherein copper is taken as a working electrode, a platinum sheet is taken as an auxiliary electrode, and a reference electrode is a saturated calomel electrode; and performing electrochemical polymerization under certain electrical parameters by cyclic voltammetry to obtain a layer of conductive polypyrrole / polyaniline composite anticorrosive coating on the surface of the copper electrode. The conductive polymer coating generated on the surface of the copper has high adhesion and is uniform and compact; medium corrosion ions can be effectively hindered from penetrating the coating and permeating into the surface of a metal matrix for a long time; the composite coating effectively improves the corrosion potential of a copper matrix and reduces corrosion current; and in addition, after the prepared coating is damaged, a layer of passivating film can be quickly generated on the surface of the matrix so as to ensure that metal is free of corrosion.

Owner:常熟市通顺纺织有限责任公司

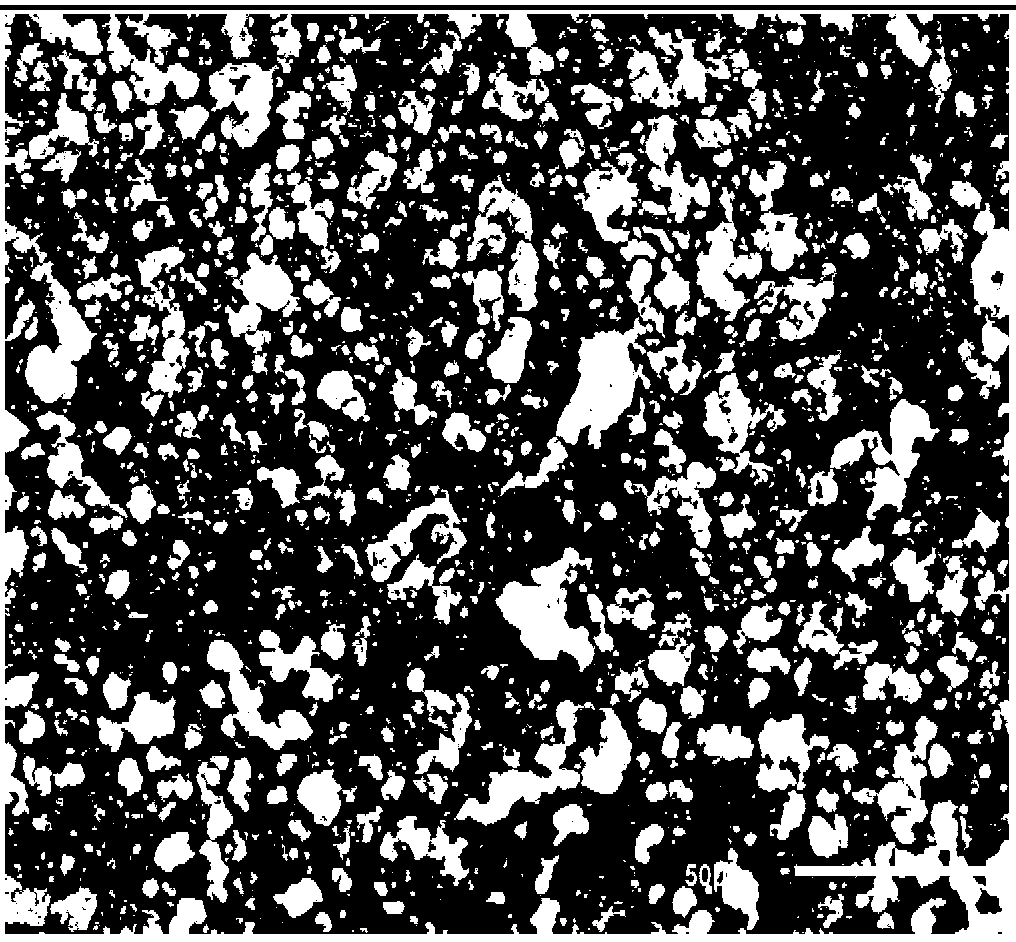

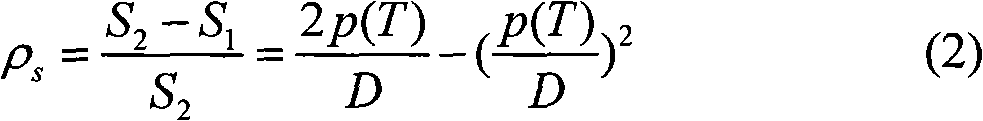

Preparation technique of high-density polypyrrole film anticorrosive coating

InactiveCN101037787AIncreased corrosion potentialNo corrosionElectrophoretic coatingsPolypyrroleMonomer

The invention discloses a process for preparing high density polypyrrole film anti-corrosion coat, wherein the solution A is produced by adding pyrrole monomer into oxalic acid radical solution; the solution B is produced by dissolving methyl benzene sulfonic acid into acetonitrile solution, then the protected copper or copper alloy is immerged into the solution A, and polymerize by an electrochemical process using cyclic voltammetry to produce polypyrrole film-modified copper or copper alloy electrode C; lastly, copper or copper alloy electrode C is immerged into the solution B, and polymerize by an electrochemical process to produce a layer of high density polypyrrole film D on the surface of copper or copper alloy electrode C. The film produced on the surface of copper by the invention is more compact than generally-synthetical polypyrrole film, can efficiently prevent corrosion ion from penetrating through the coat for a long time, and improve the corrosion potential of copper and reduce corrosion current, while the coat has higher adhesivity, but also corrosion of metal can be avoided by producing passivating film after scuffing the coat.

Owner:XI AN JIAOTONG UNIV

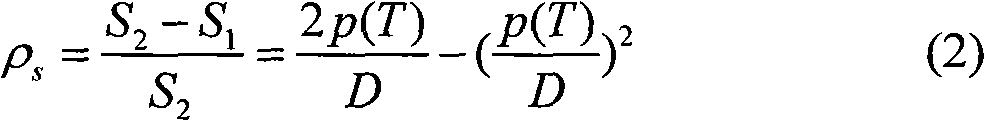

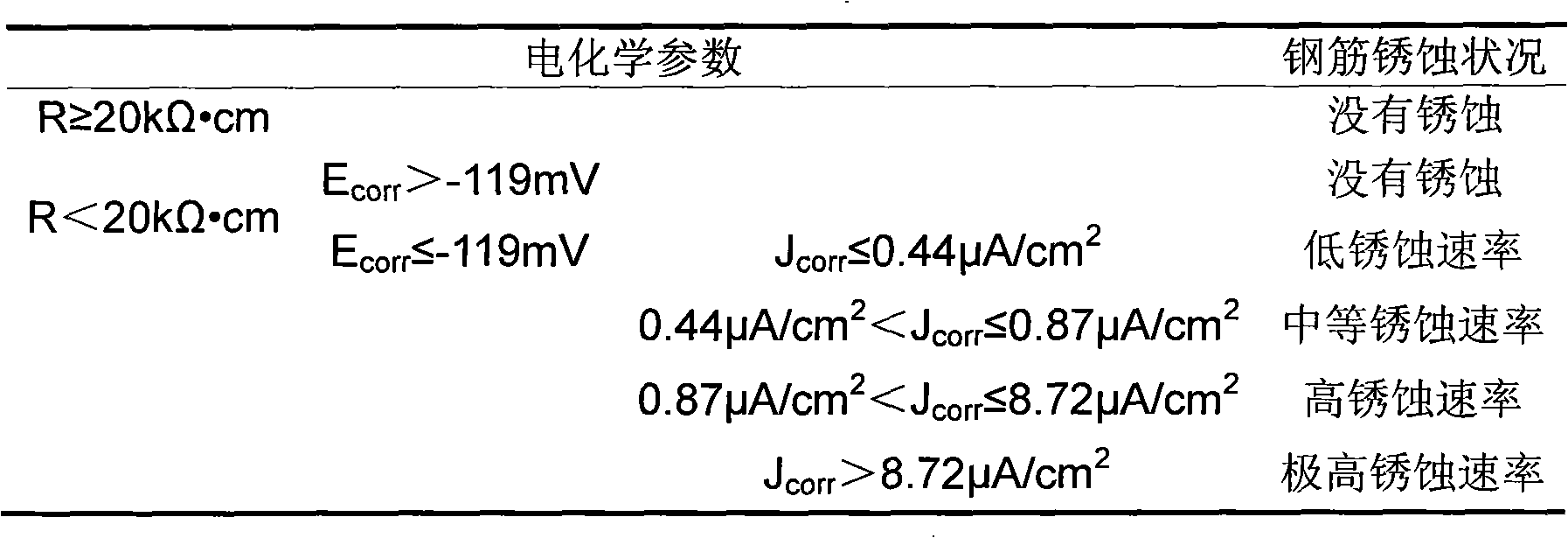

Coastal area concrete reinforcement erosion situation electrochemical test method

InactiveCN101339119AThe criteria are comprehensive and accurateWeather/light/corrosion resistanceMaterial testing goodsRebar corrosionLoss rate

The invention discloses an electrochemical test method of steel bar corrosion in the concrete of coastal area. The test method comprises the following steps: (1) under the concrete condition of the temperature of 0 to 50 DEG C and the relative humidity of 50 percent to 85 percent, the resistance rate R of the concrete is detected; if the estimated value of R is more than or equal to 20kilo-ohm, the passive film of the steel bar in the concrete is not damaged; if the estimated value of R is less than 20kilo-ohm, the second step is adopted; (2) a silver-silver chloride electrode is used for further determining the corrosion potential of the steel bar; if the estimated value of the corrosion potential of the steel bar is more than or equal to minus 119mV, the passive film of the steel bar in the concrete is not damaged; if the estimated value is less than 119mV, the passive film of the steel bar in the concrete is not damaged. The corrosion current density Jcorr of the steel bar in the concrete is further determined; the average corrosion depth and the average section loss rate of the steel bar are calculated. The guarantee rate of the estimated values is 95 percent. The electrochemical test method has the targeted characteristic and comprehensive criteria, and is in particular suitable for estimating the corrosion of the steel bar in the concrete structure without obvious cracking and rust on the surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

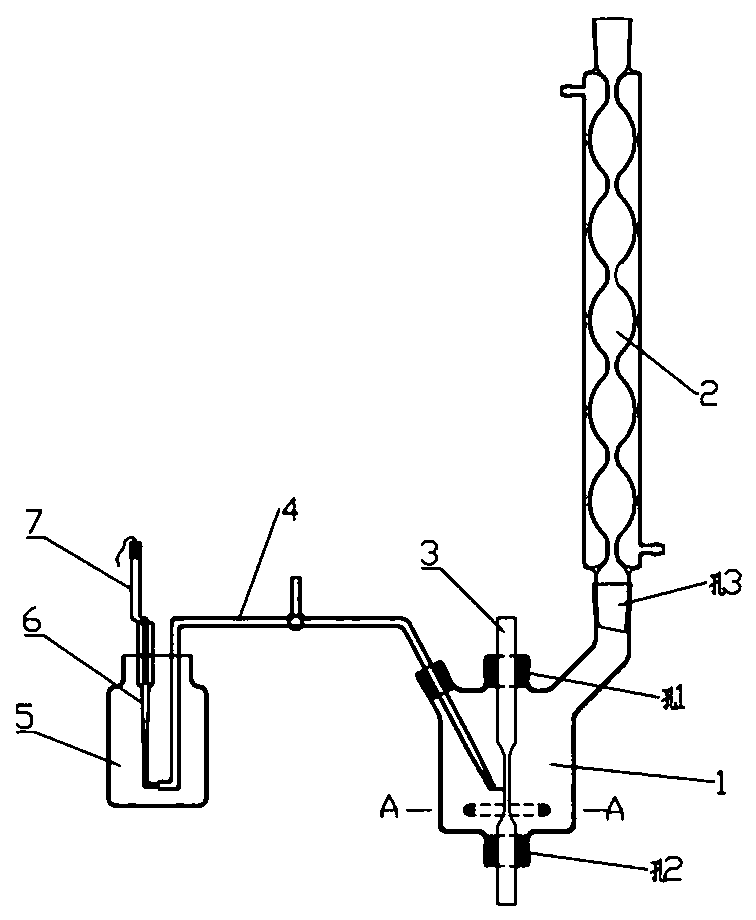

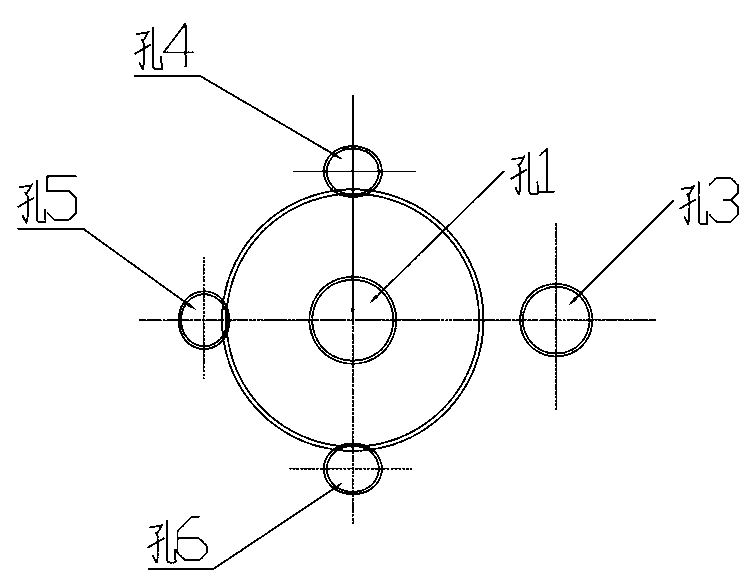

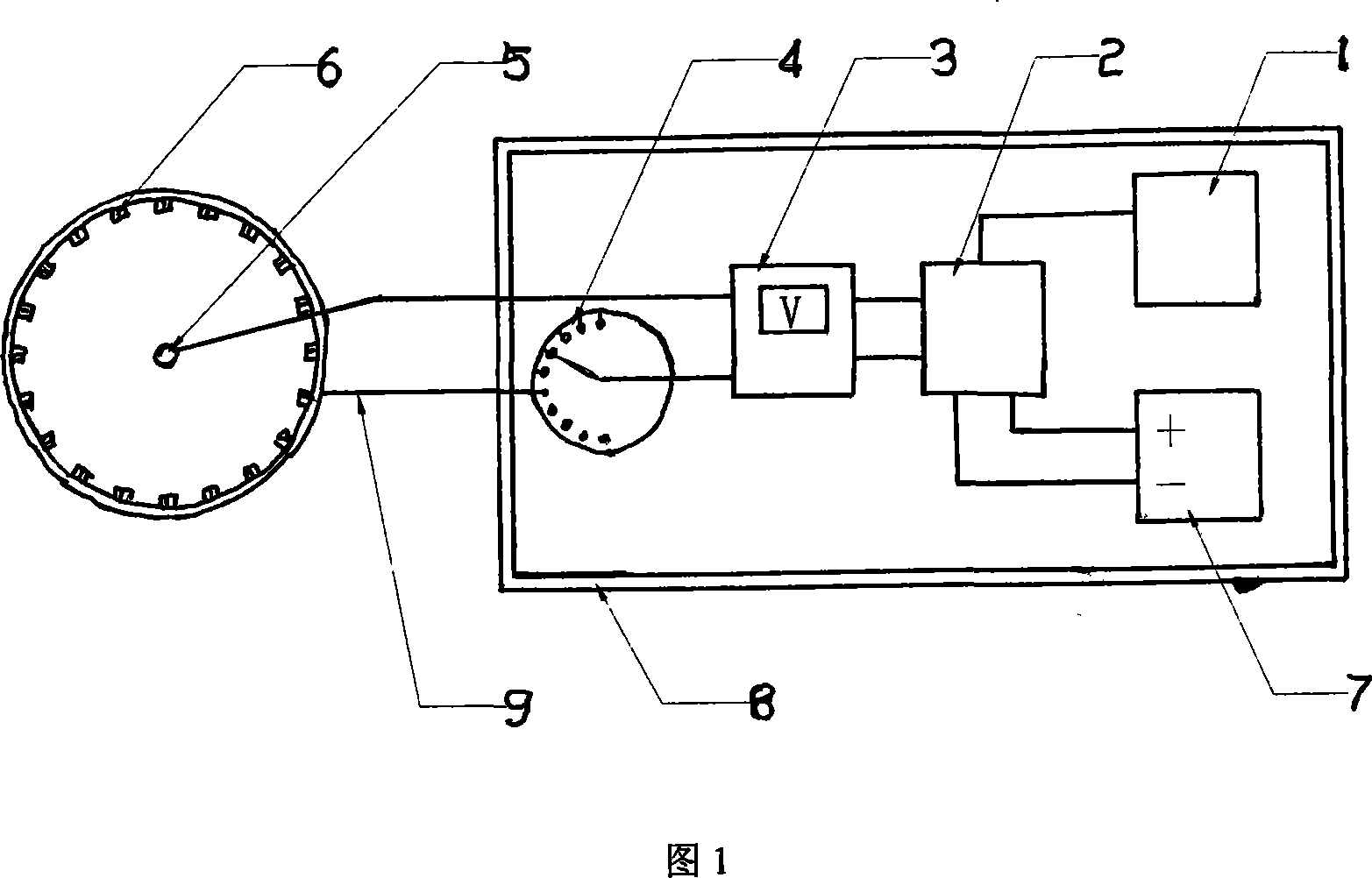

Stress corrosion test apparatus

InactiveCN102937569ATemperature controlWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesSalt bridgeTransformer

The invention discloses a stress corrosion test apparatus. The apparatus comprises a stress corrosion container (1), a spherical condenser (2), a tensile test specimen (3), a salt bridge 1 (4), a wide-mouth bottle (5), a salt bridge 2 (6), a reference electrode (7), a platinum electrode, a computer (8), an electrochemical workstation (9), a electric stove wire (10), a thermoelectric thermometer (11), a temperature controller (12), an alternating-current transformer (13), etc. The apparatus can provide tensile tests capable of being used for metals in a corrosive medium with controllable temperature and capable of being externally applied corrosion current. The temperature of the corrosion medium is controlled by the electric stove wire and a temperature-control system. The reference electrode, the platinum electrode and the tensile test specimen constitute a voltage circuit and a current circuit respectively to control the corrosion potential and current additionally applied on the test specimen or generated on a monitoring sample. A normal temperature reference electrode rather than a high temperature reference electrode can be used for the measurement of the potential by connecting the reference electrode, the wide-mouth bottle and the stress corrosion container with the salt bridges.

Owner:BEIJING UNIV OF CHEM TECH

Method and apparatus for testing metal material deep-sea corrosion potential

InactiveCN101074917ACompact structureEasy to deployWeather/light/corrosion resistanceMaterial analysis by electric/magnetic meansMicrocontrollerElectrical battery

A potential testing method of deep-sea corrosion on metal material includes preparing test device to be a unified and sealed structure, setting test device in deep-sea of selected sea area, realizing automatic measurement and automatic conversion as well as automatic storage by utilizing battery carried by itself and control of monolithic computer, using interface to guide data into computer to carry out analysis and treatment to obtain test result after recovery, enabling to carry 30-50 metal test-pieces on one test device and laying test device in deep-sea of 100-3000 metres for 1-6 months.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

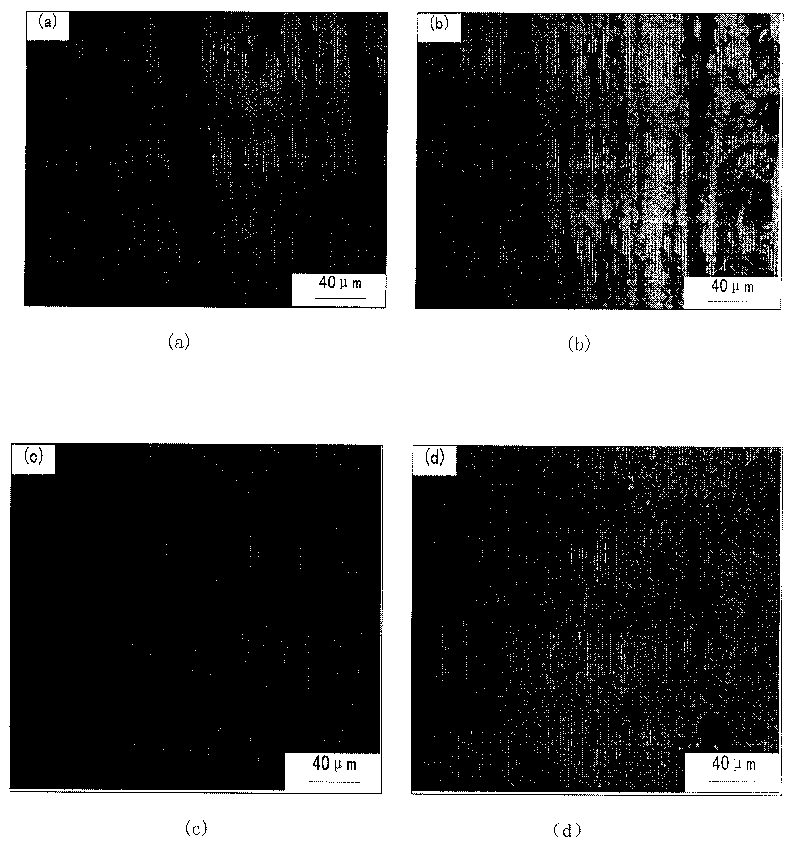

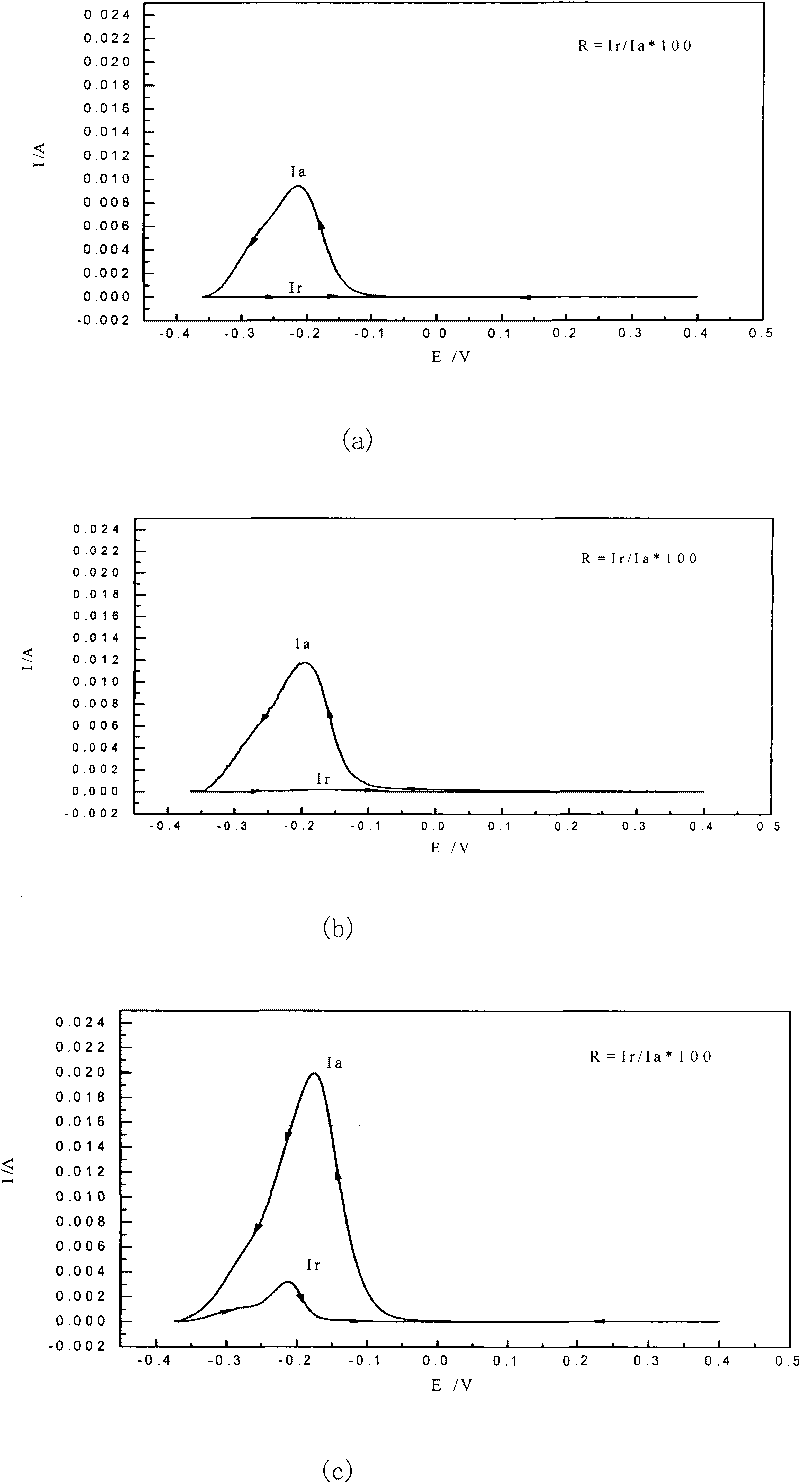

Dual-ring electrochemical dynamic potential reactivating evaluating method for diphase stainless steel intercrystalline corrosion sensitivity

InactiveCN101762454AImprove stabilityEasy to operateWeather/light/corrosion resistanceOperabilityMaterials science

The invention discloses a dual-ring electrochemical dynamic potential reactivating evaluating method for diphase stainless steel intercrystalline corrosion sensitivity, which comprises the following steps: first, pre-treating specimen; second, preparing electrochemical evaluating solution;third, establishing electrochemical evaluating system; fourth, DL-EPR testing; fifth, judging intercrystalline corrosion sensitivity. The invention adopts mixture-solution of sulphuric and hydrochloric acids as the evaluating solution, can solve the technical problems of passive potential and corrosion potential, separate the passive potential and corrosion potential according to the concrete specimen of a diphase stainless steel, thereby realizing effective and accurate judgment about the diphase stainless steel intercrystalline corrosion sensitivity, establishing the dual-ring electrochemical dynamic potential reactivating evaluating method for diphase stainless steel intercrystalline corrosion sensitivity according to the diphase stainless steel features, and further obtaining judging criterion for diphase stainless steel intercrystalline corrosion sensitivity. The method has simple process, high sensitivity, good stability, high operability, economic property and environmental-protection.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Detection and evaluation method of simulation acceleration metal acid atmospheric environment corrosion

InactiveCN106841027AThe detection method is simpleThe evaluation method is simpleWeather/light/corrosion resistanceMetallic materialsSurface roughness

The invention discloses a detection and evaluation method of simulation acceleration metal acid atmospheric environment corrosion. The method comprises the steps of preparing test specimens, wherein the size and the surface roughness of the test specimens must be identical; 2, preparing a simulation acid atmospheric environment corrosion solution, wherein a test solution needed by a high-low-temperature alternation damp and heat experiment test and electrochemical polarization curve corrosion is prepared; 3, determining a corrosion condition, wherein the high-low-temperature alternation damp and heat experiment test is conducted on the specimens in sequence; 4, determining evaluation indexes, wherein a weight increment, a corrosion velocity, a surface topography and a corrosion potential are adopted as corrosion performance indexes. According to the detection and evaluation method of the simulation acceleration metal acid atmospheric environment corrosion, through the high-low-temperature alternation damp and heat experiment test, a simple, convenient, fast and efficient detection and evaluation method of the simulation acceleration metal acid atmospheric environment corrosion is designed, the method is high in practicability, the corrosion which occurs in an outdoor acid atmospheric environment can be better represented, and a method is provided for a related metal material corrosion performance study.

Owner:HEBEI IRON AND STEEL

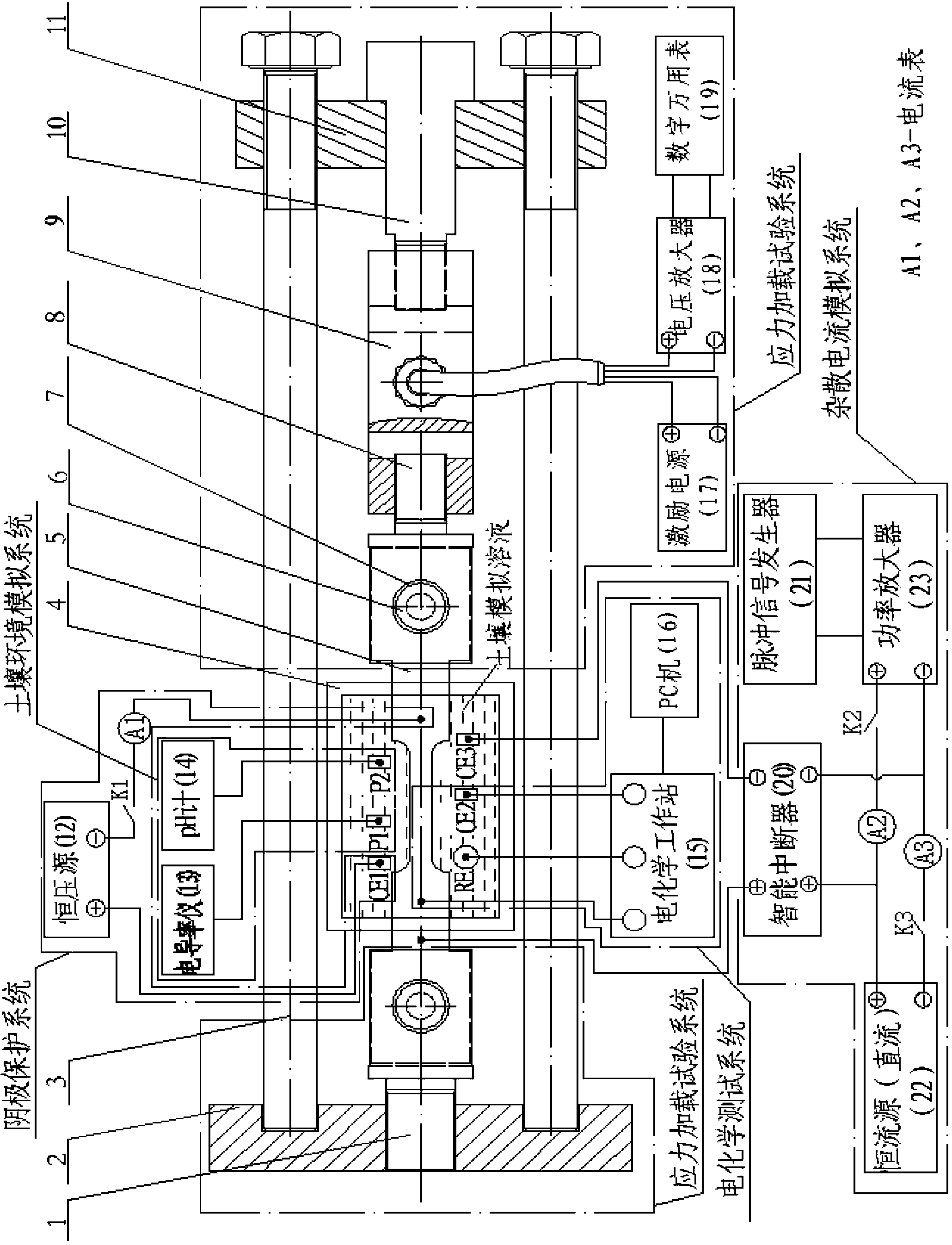

Method for stray current corrosion test of buried steel pipeline under tensile stress action

InactiveCN103411878ACapable of measuring weightlessnessWeather/light/corrosion resistanceAlternating currentSteel pipeline

The invention relates to a method for the stray current corrosion test of a buried steel pipeline under the tensile stress action, and belongs to the material corrosion and protection fields. A system used by the method comprises a stress loading test system, a soil environment simulation system, a stray current simulation system, a cathode protection system and an electrochemical test system. The stress loading test system generates a pressure required by a sample test, the soil environment simulation system stimulates the soil environment in which a buried metal is positioned to prepare soil solutions having different pH values and conductivities, the stray current simulation system generates direct current, alternate current and direct and alternate mixed stray currents, the cathode protection system provides a cathode protection potential for the sample, and the electrochemical test system tests the corrosion potentials of the sample under different influence factors. The system used by the method can measure the weight loss, can obtain the corrosion morphology, can generate the direct current, alternate current and direct and alternate mixed stray currents, can provide the stress required by the test according to the practical running condition, can stimulate the cathode protection, and can realize the corrosion rule experiments under different influence factors.

Owner:BEIJING UNIV OF TECH

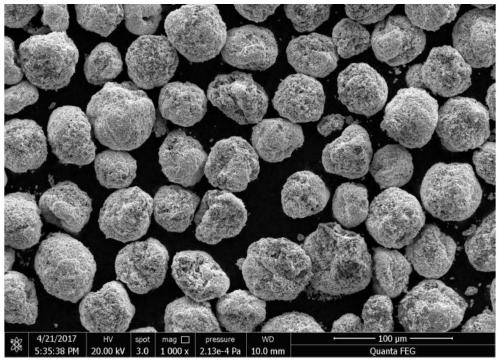

Amorphous composite coating and preparation method thereof

InactiveCN109778105AImprove wear and corrosion resistanceReduce wearMolten spray coatingThermal sprayingSlurry

The invention discloses an amorphous composite coating and a preparation method thereof. The amorphous composite coating comprises the following steps that composite powder consisting of graphene oxide powder and metal powder are added into a mixed solution consisting of a binder, a dispersant and deionized water, ultrasonic oscillation and mechanical stirring are carried out to obtain mixed slurry, the mixed slurry is subjected to spray granulation and thermal reduction to obtain graphene-metal composite powder; the surface of a substrate is pre-treated and uniformly sprayed with a nickel-coated aluminum bonding bottom layer; and graphene-metal composite powder and iron-based amorphous alloy powder are used as feed powder, and thermal spraying is carried out on the surface of the substrate through multi-channel powder feeding to obtain a graphene-metal-iron-based amorphous composite coating with high wear resistance and corrosion resistance. Compared with a single amorphous coating, the wearing capacity of the graphene-metal-iron-based amorphous composite coating is lowered by 73% and the corrosion potential is increased substantially.

Owner:SHANGHAI OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com