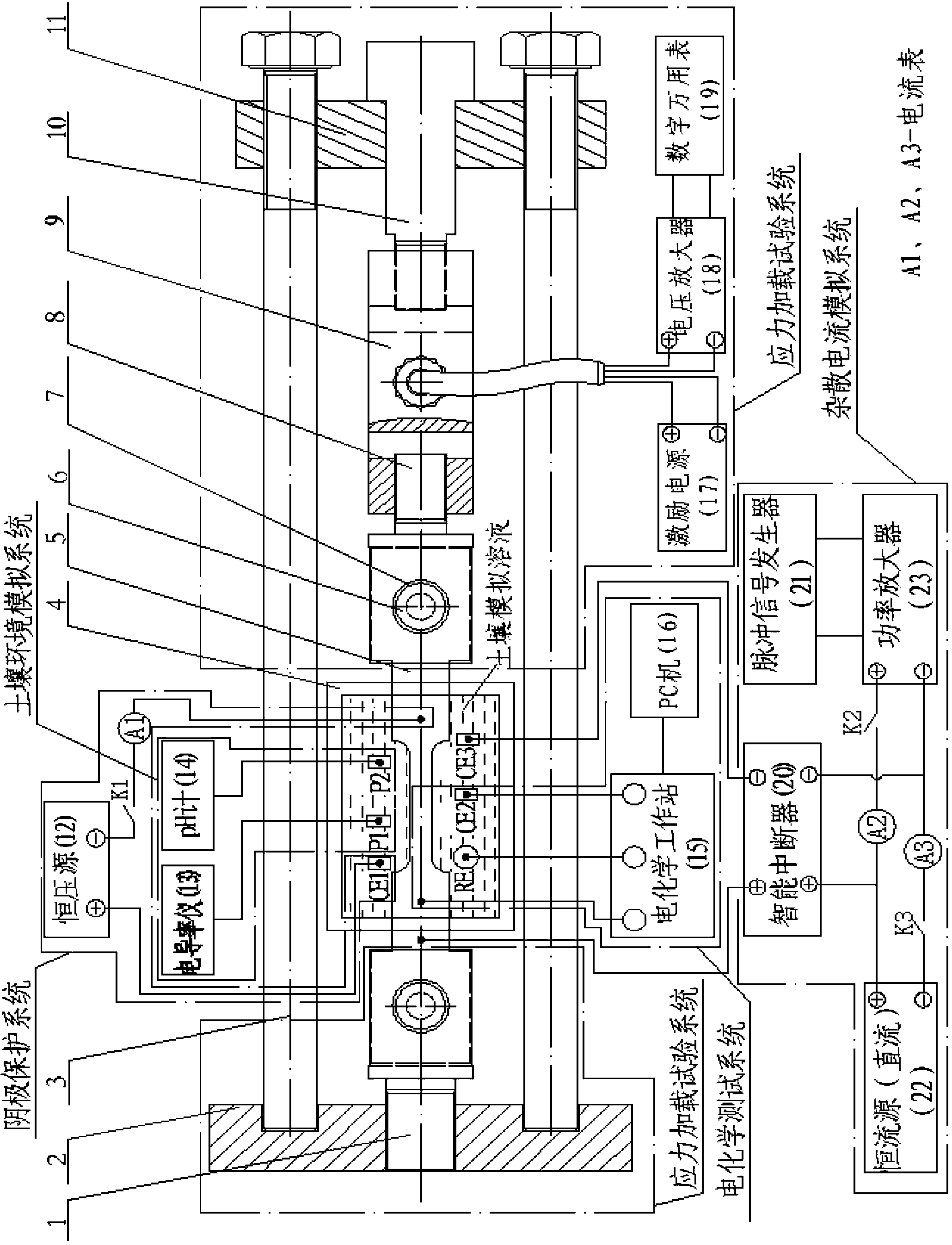

Method for stray current corrosion test of buried steel pipeline under tensile stress action

A stray current and tensile stress technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of inability to carry out stray current, small tensile stress, corrosion experiments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] exist figure 1 In the specific structure of the stray current corrosion test system for buried steel pipelines under the action of tensile stress shown in the present invention, after the stress loading test system is built, use a wrench to simultaneously rotate two long hexagon head bolts 3 through screw transmission. Axial tensile stress is generated, and the pulling force can be changed by adjusting the amount of rotation, and the long hexagon head bolt 3 is stopped rotating until the specified pulling force is observed on the digital multimeter 19 . In the experiment, if it is necessary to adjust the tensile stress of the sample 5, it is only necessary to rotate the long hexagon head bolt 3.

[0036] Build a soil environment simulation system, a stray current simulation system, a cathodic protection system, and an electrochemical test system. Use the soil environment simulation system to configure the required soil solution, and pour the soil solution into the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com