Method and apparatus for testing metal material deep-sea corrosion potential

A metal material, deep sea corrosion technology, applied in measurement devices, analytical materials, weather resistance/light resistance/corrosion resistance, etc., to achieve the effect of saving test costs, simple and compact structure, and easy deployment and recycling operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

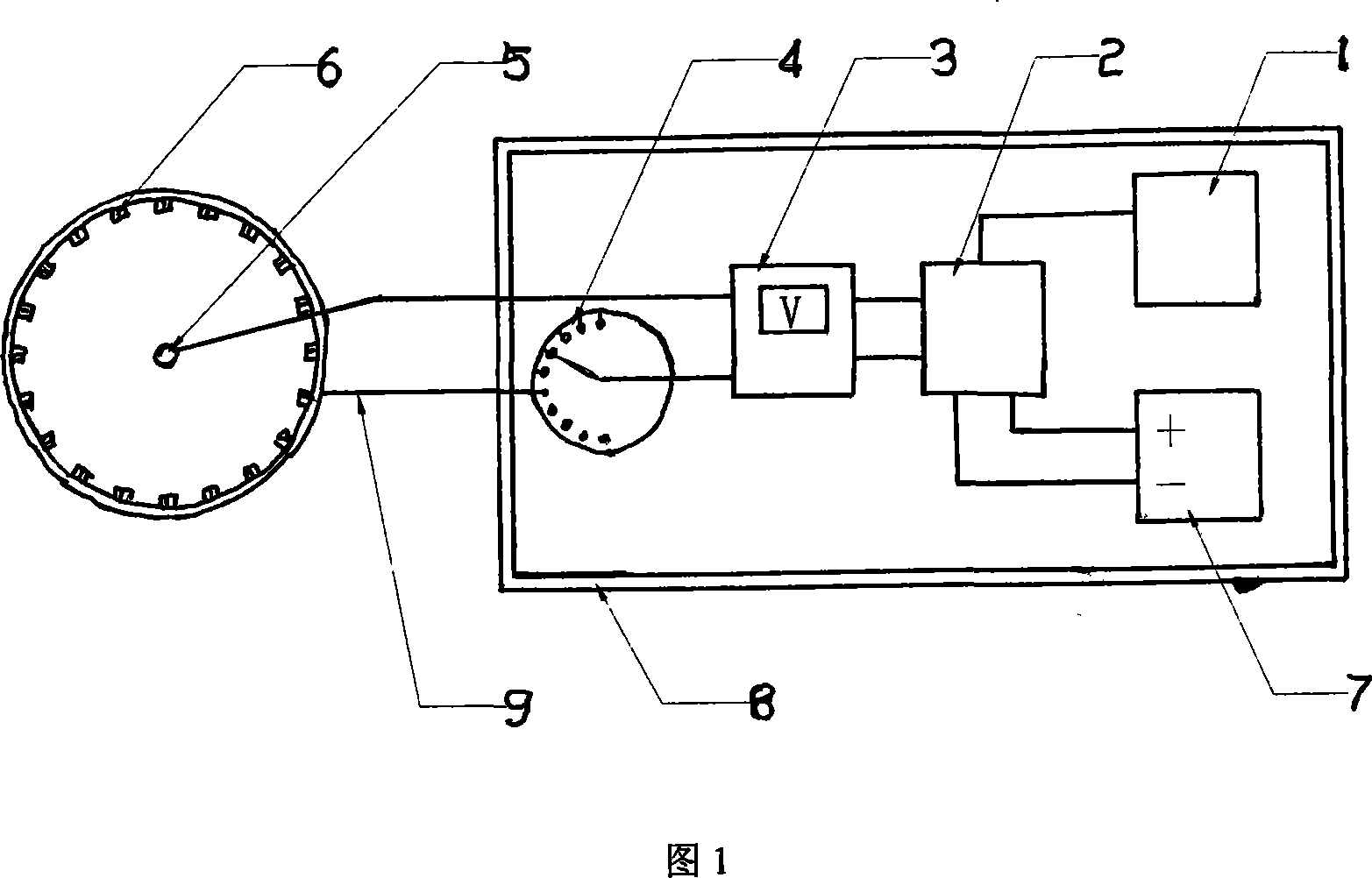

[0019] The main structure of the equipment device implemented in the present invention is composed of a data memory 1, a master controller 2, a potential measurement meter 3, a converter 4, a reference electrode 5, a sample to be tested 6, a battery 7, a pressure-resistant housing 8 and a voltage-resistant multimeter. The core wires 9 are electrically connected and assembled to form a single-body sealing system for automatic testing.

[0020] The instrument device of the present invention is manufactured in separate parts, sealed and assembled in a laboratory before the test, and then put into the sea for a real test after the test.

[0021] The potential measuring table of the implementing instrument of the present invention is completed by a conventional circuit, and is fixed in the pressure-resistant casing 8 after testing that various functions meet the requirements. Due to the low power consumption and low heat generation of the measurement circuit, the temperature in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com