Ground net corrosion detection method and system

A corrosion detection and grounding grid technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of corrosion current density error, difficulty in accurately measuring the metal corrosion state of the ground grid, submersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

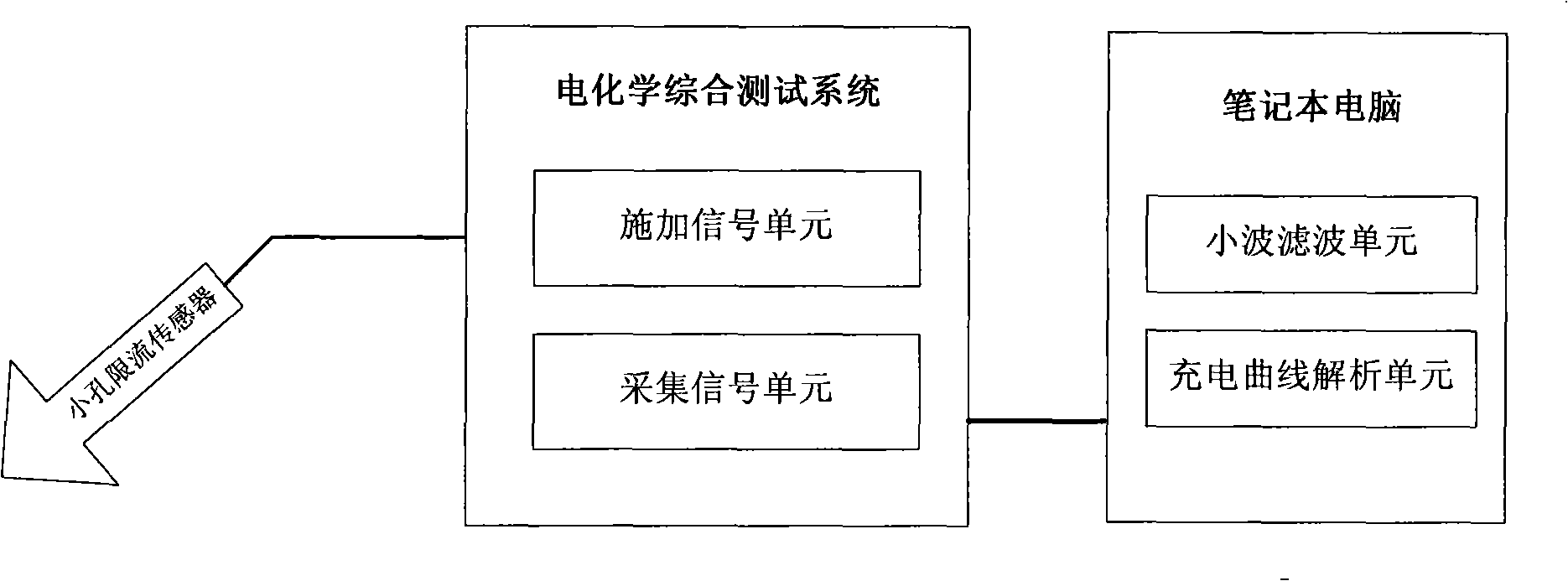

[0036] Such as Figure 8 , 9 As shown, this embodiment provides a grounding grid corrosion state detection system with an electrochemical sensor, wherein the electrochemical sensor is called a small hole current limiting corrosion electrochemical sensor, referred to as a small hole current limiting sensor.

[0037] 1. Small hole current limiting sensors include:

[0038] 1) As a jacket for the tapered front end (common carbon steel);

[0039] 2) insulating layer 501 (polytetrafluoro tape);

[0040] 3) M2.5 screw holes (514, 515) located on the jacket, and equipped with corresponding screws and fixed plastic tubes so as to be detachably connected to the insulating cylindrical shell body 504 (threaded connection is also available);

[0041] 4) A polyvinyl chloride pipe with a diameter of 15 mm as an insulating cylindrical shell;

[0042] 5) Auxiliary electrode (1Cr13SS);

[0043] 6) Reference electrode (Cu / CuSO4);

[0044] 7) As the screw hole of the auxiliary electrode te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com