Method for testing electrochemical performance of polar plate anode based on novel material PPTC

A new type of material and testing method technology, applied in the direction of material electrochemical variables, analysis materials, measuring devices, etc., can solve the problems of low accuracy of button batteries, cumbersome production, complicated operation methods, etc., and improve the electrochemical detection rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

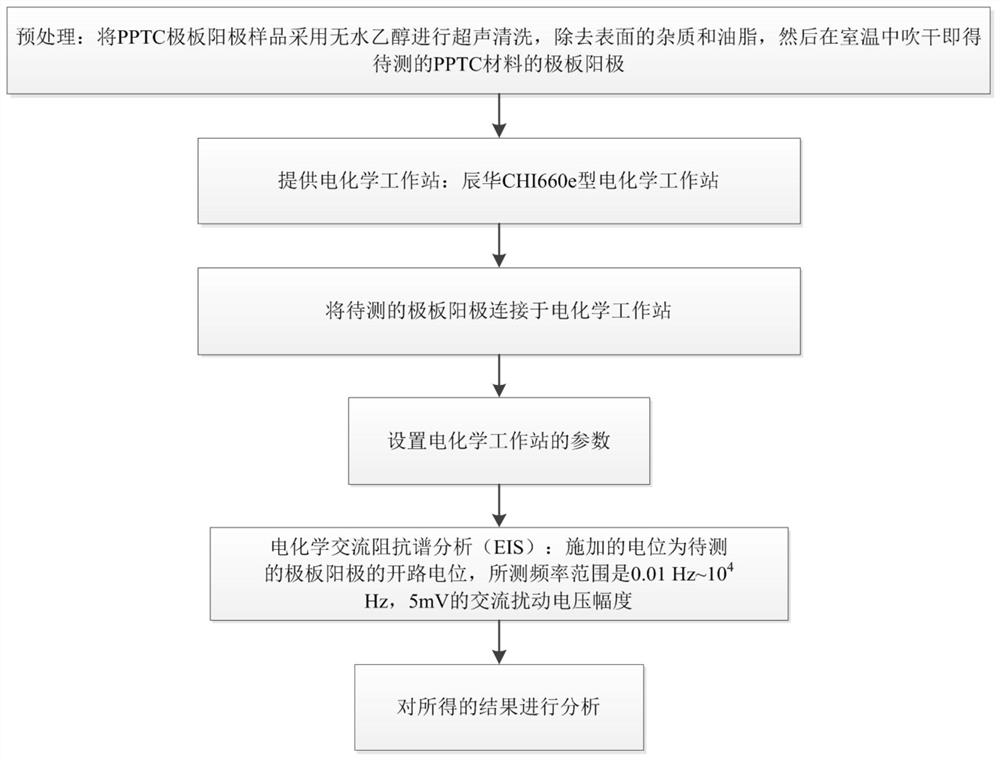

[0053] Such as figure 1 , the characterization method in the step (5) is electrochemical impedance spectroscopy (EIS), wherein the applied potential is the open circuit potential of the plate anode obtained in the step (1), and the measured frequency range is 0.01 Hz~10 4 Hz, AC disturbance voltage amplitude of 5mV.

[0054] According to the second aspect of the present invention, the present invention also proposes the application of the testing method of the electrode plate anode electrochemical performance based on the novel material PPTC of the preceding embodiment, according to an embodiment of the present invention, the application includes:

[0055] The electrochemical performance of the anode plate based on the polymer semiconductor material PPTC and the anode material of the traditional Pb-Ca-Sn alloy plate was analyzed by the method of the previous embodiment.

[0056] Figure 5 , at 25 o Electrochemical AC impedance spectroscopy (Nyquist diagram) of Pb-Ca-Sn allo...

Embodiment 2

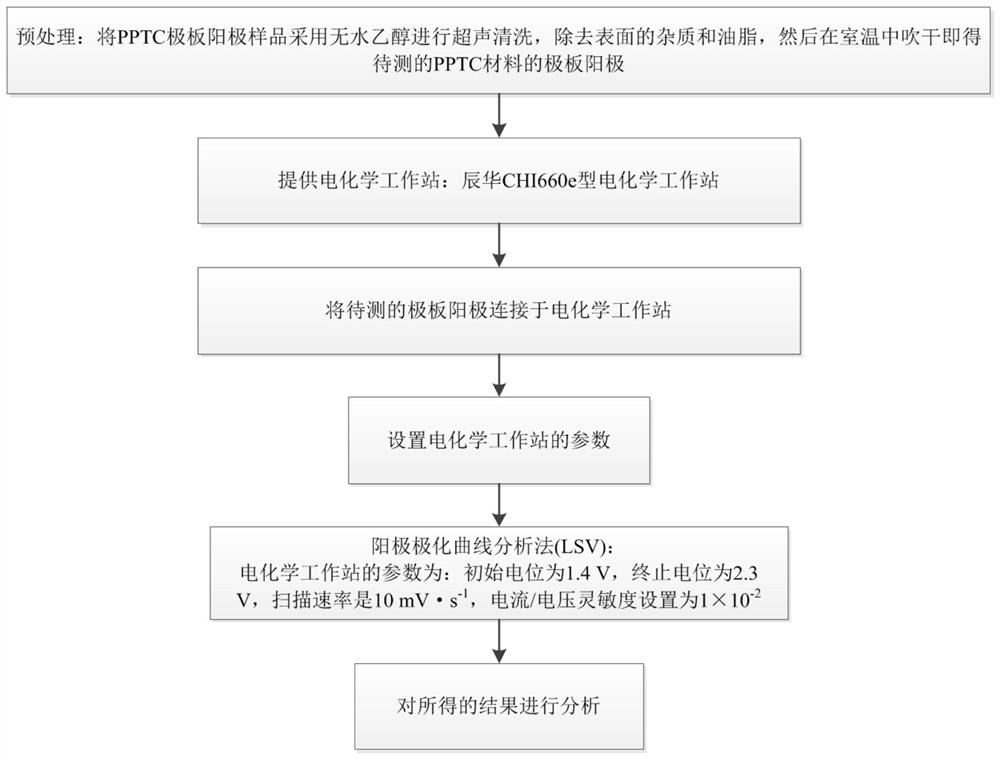

[0062] Such as figure 2 , the characterization method in step (5) is anodic polarization curve analysis (LSV), wherein, the setting of step (4) sets the parameters of the electrochemical workstation to be: the initial potential is 1.4V, the termination potential is 2.3V, and the scan rate is 10mV·s -1 , the current / voltage sensitivity is set to 1×10 -2 .

[0063] According to the second aspect of the present invention, the present invention also proposes the application of the testing method of the electrode plate anode electrochemical performance based on the novel material PPTC of the preceding embodiment, according to an embodiment of the present invention, the application includes:

[0064] The electrochemical performance of the anode plate based on the polymer semiconductor material PPTC and the anode material of the traditional Pb-Ca-Sn alloy plate was analyzed by the method of the previous embodiment.

[0065] Such as Figure 8 As shown, the anodic polarization cur...

Embodiment 3

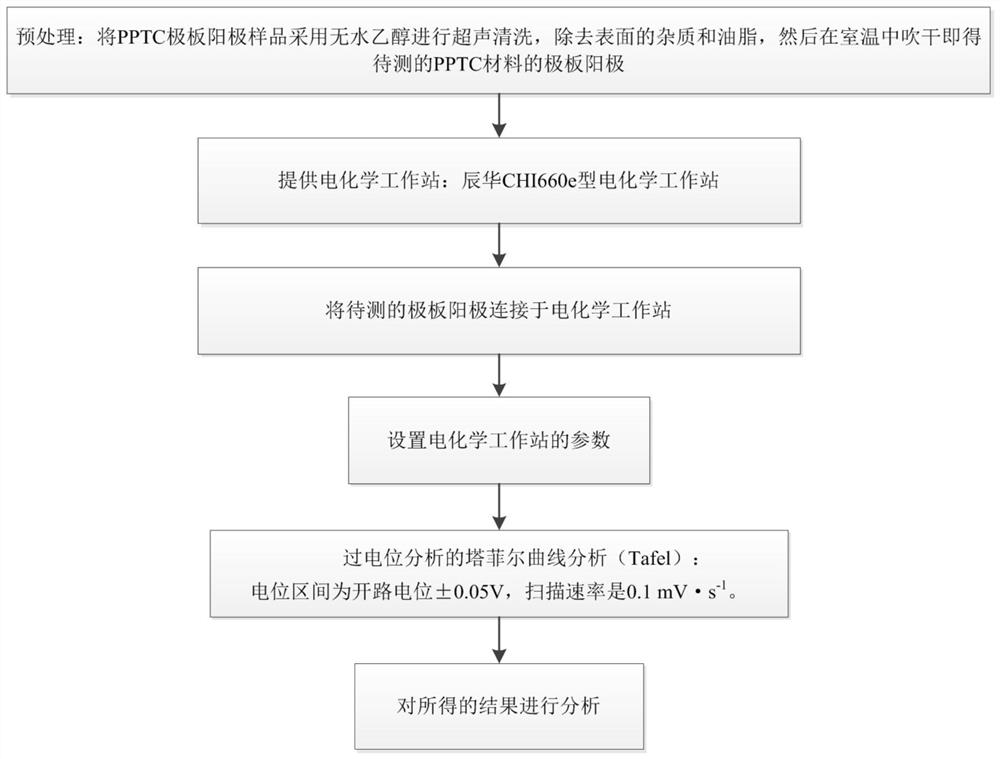

[0070] Such as image 3 As shown, the characterization method in step (5) is the Tafel curve analysis (Tafel) of overpotential analysis, wherein the parameters in step (4) are: the potential interval is the open circuit potential ± 0.05V, and the scan rate is 0.1mV s -1 .

[0071] The characterization method in step (5) is Mott-Schottky curve analysis (mott-schottky) of flat-band potential analysis, wherein the parameters in step (4) are: the potential range is -0.50V~5.0V.

[0072] According to the second aspect of the present invention, the present invention also proposes the application of the test method for the electrochemical performance of the plate anode based on the novel material PPTC of the previous embodiment. According to an embodiment of the present invention, the application includes:

[0073] The electrochemical performance of the anode plate based on the polymer semiconductor material PPTC and the anode material of the traditional Pb-Ca-Sn alloy plate was ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com