The high nickel copper anode adopts the process of periodic reverse current electrolysis

A reverse current, periodic technique used in metalworking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

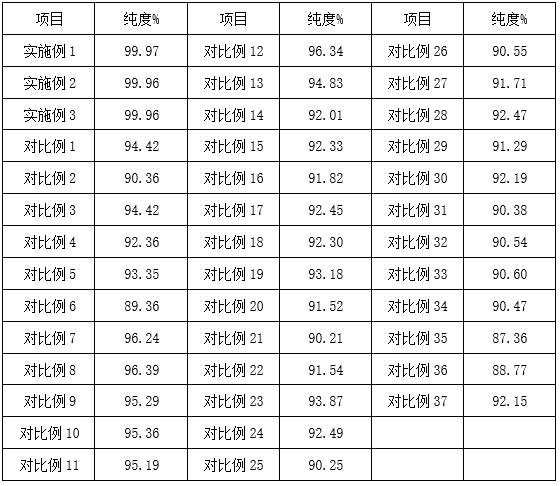

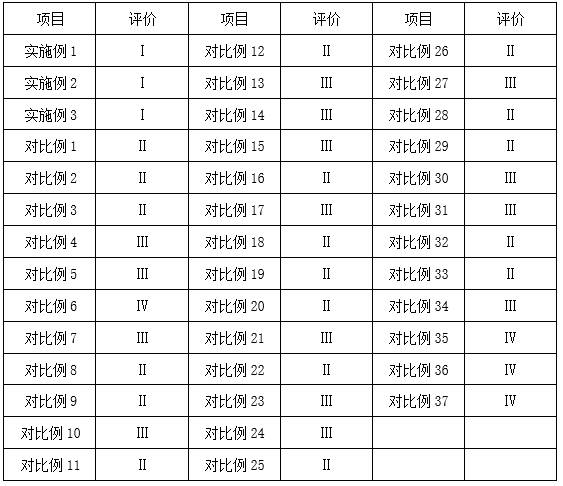

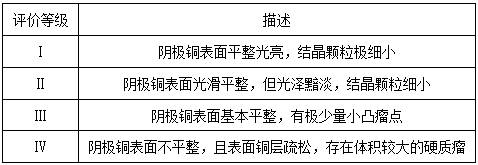

Examples

Embodiment 1

[0041] The specific operation process of the periodic reverse current electrolysis process for the high-nickel copper anode plate is as follows:

[0042] 1) Put the high-nickel copper anode plate with clean surface without oil pollution into the electrolytic cell, then put the modified cathode plate into the cathode area of the electrolytic cell, add the electrolyte, and connect the power source for electrolysis;

[0043] 2) One cycle of the current is 205s forward current, 6s no-current time, and 9s reverse current time. During no-current, microwave vibration is used to oscillate the solution particles in the electrolytic cell evenly;

[0044] 3) During the electrolysis process, the temperature of the electrolyte is kept at 64°C, and at the same time, after the electrolysis of a high nickel-copper anode sheet, the electrolyte is cyclically replaced, and the recycled electrolyte is recycled to collect the metal ions in it. ;

[0045] 4) When the thickness of a single anode ...

Embodiment 2

[0068] The specific operation process of the periodic reverse current electrolysis process for the high-nickel copper anode plate is as follows:

[0069] 1) Put the high-nickel copper anode plate with clean surface without oil pollution into the electrolytic cell, then put the modified cathode plate into the cathode area of the electrolytic cell, add the electrolyte, and connect the power source for electrolysis;

[0070] 2) One cycle of the current is 200s forward current, 8s no-current time, and 8s reverse current time. When no current is performed, microwave vibration is used to oscillate the solution particles in the electrolytic cell evenly;

[0071] 3) During the electrolysis process, the temperature of the electrolyte is kept at 66°C, and at the same time, after the electrolysis of a high nickel-copper anode sheet, the electrolyte is cyclically replaced, and the recycled electrolyte is recycled to collect the metal ions in it. ;

[0072] 4) When the electrolysis thic...

Embodiment 3

[0095] The specific operation process of the periodic reverse current electrolysis process for the high-nickel copper anode plate is as follows:

[0096] 1) Put the high-nickel copper anode plate with clean surface without oil pollution into the electrolytic cell, then put the modified cathode plate into the cathode area of the electrolytic cell, add the electrolyte, and connect the power source for electrolysis;

[0097] 2) One cycle of the current is 210s forward current, 5s no-current time, and 10s reverse current time. When no current is performed, microwave vibration is used to oscillate the solution particles in the electrolytic cell evenly;

[0098] 3) During the electrolysis process, the temperature of the electrolyte is kept at 62 °C, and at the same time, after the electrolysis of a high-nickel copper anode sheet, the electrolyte is cyclically replaced, and the recycled electrolyte is recycled to collect the metal ions in it. ;

[0099] 4) When the electrolysis th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com