High-corrosion-resistance Al-TM-RE amorphous aluminum alloy

An aluminum alloy and high corrosion resistance technology, which is applied in the field of high corrosion resistance Al-TM-RE series amorphous aluminum alloys, can solve the problems of non-replaceable on-site, difficult to meet the actual needs of engineering, and reduced protection, so as to improve the corrosion resistance etch ability, good glass forming ability, and the effect of passivation film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The compositional design of the highly corrosion-resistant Al-TM-RE series amorphous aluminum alloy provided in this example is specifically as follows: two kinds of alloy compositions are designed: alloy b and alloy c, wherein: alloy b chemical composition (molar percentage content): Al 86 %, Ni 6.0%, Co2.0%, Y 4.5%, La 0.75%, Ce 0.75%; alloy c chemical composition (molar percentage content): Al 86%, Ni6.0%, Co 2.0%, Y 4.5%, Ce 1.5%; the purity of raw material Al is ≥99.99%, and the purity of other elements is ≥99.999%. After the master alloy is prepared in a high-purity argon environment, a strip sample is prepared by a single-roll melt quenching method, and the final solidification structure is completely non-metallic. Crystalline structure with a thickness of 25-35 μm and a width of about 2.5-3.5 mm.

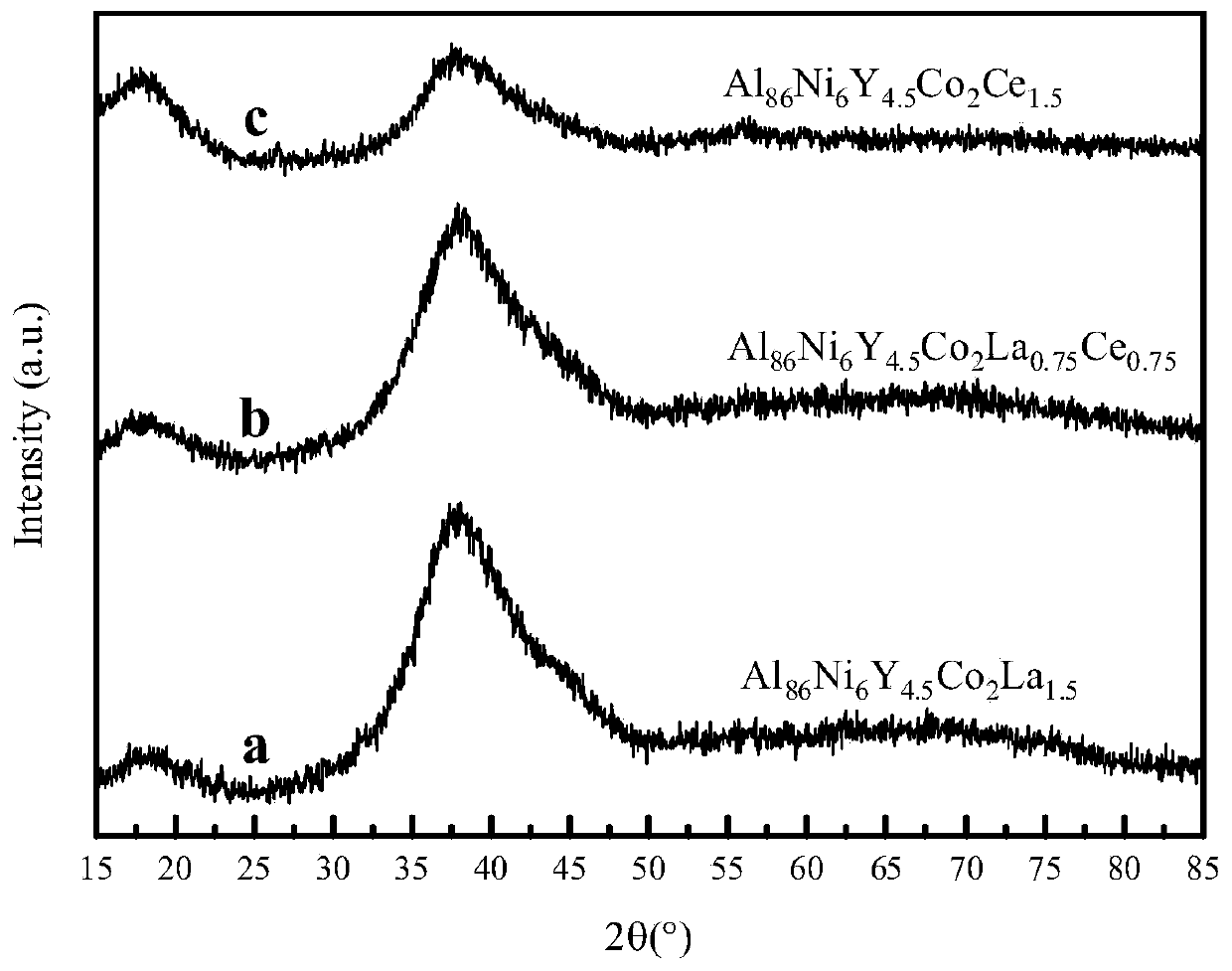

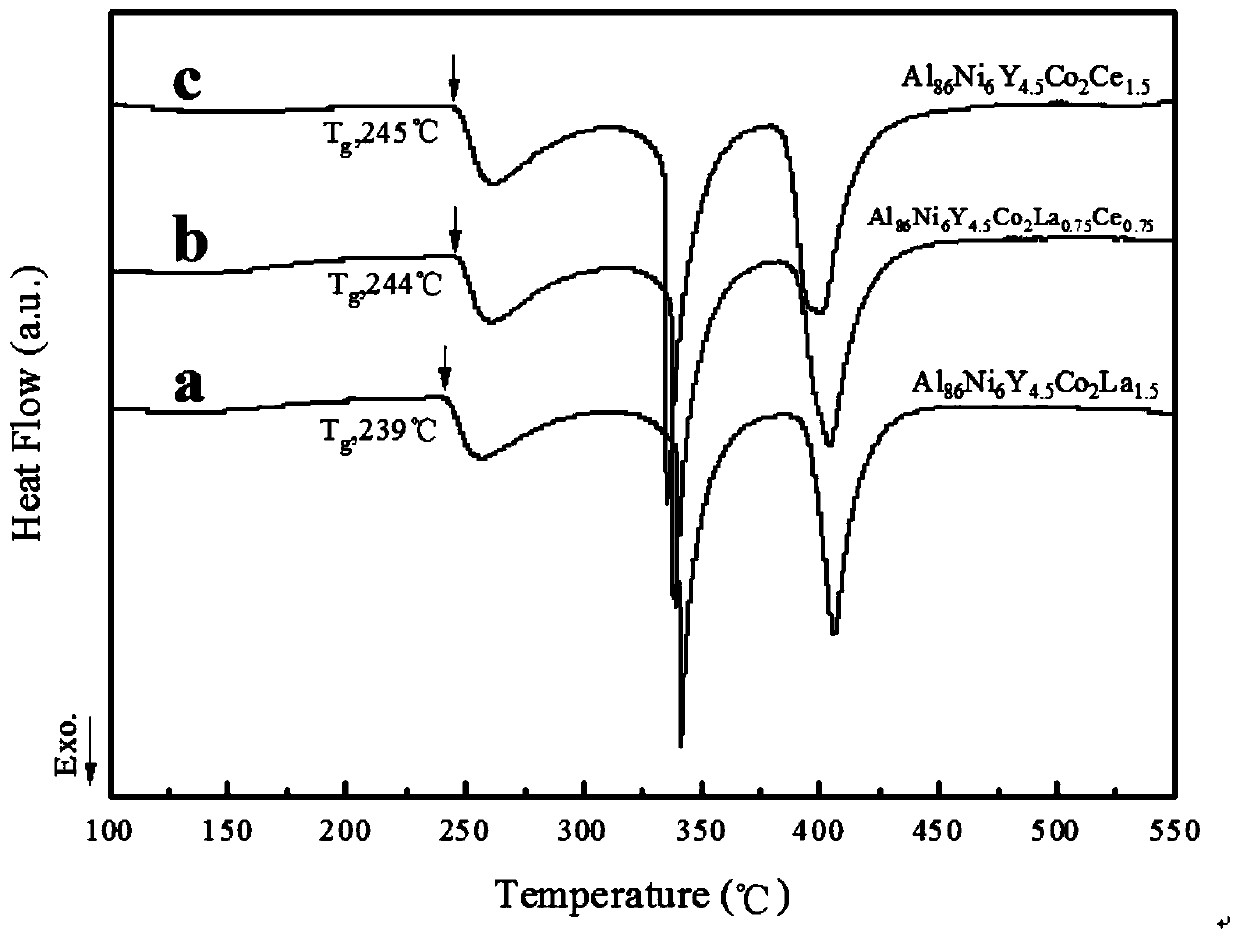

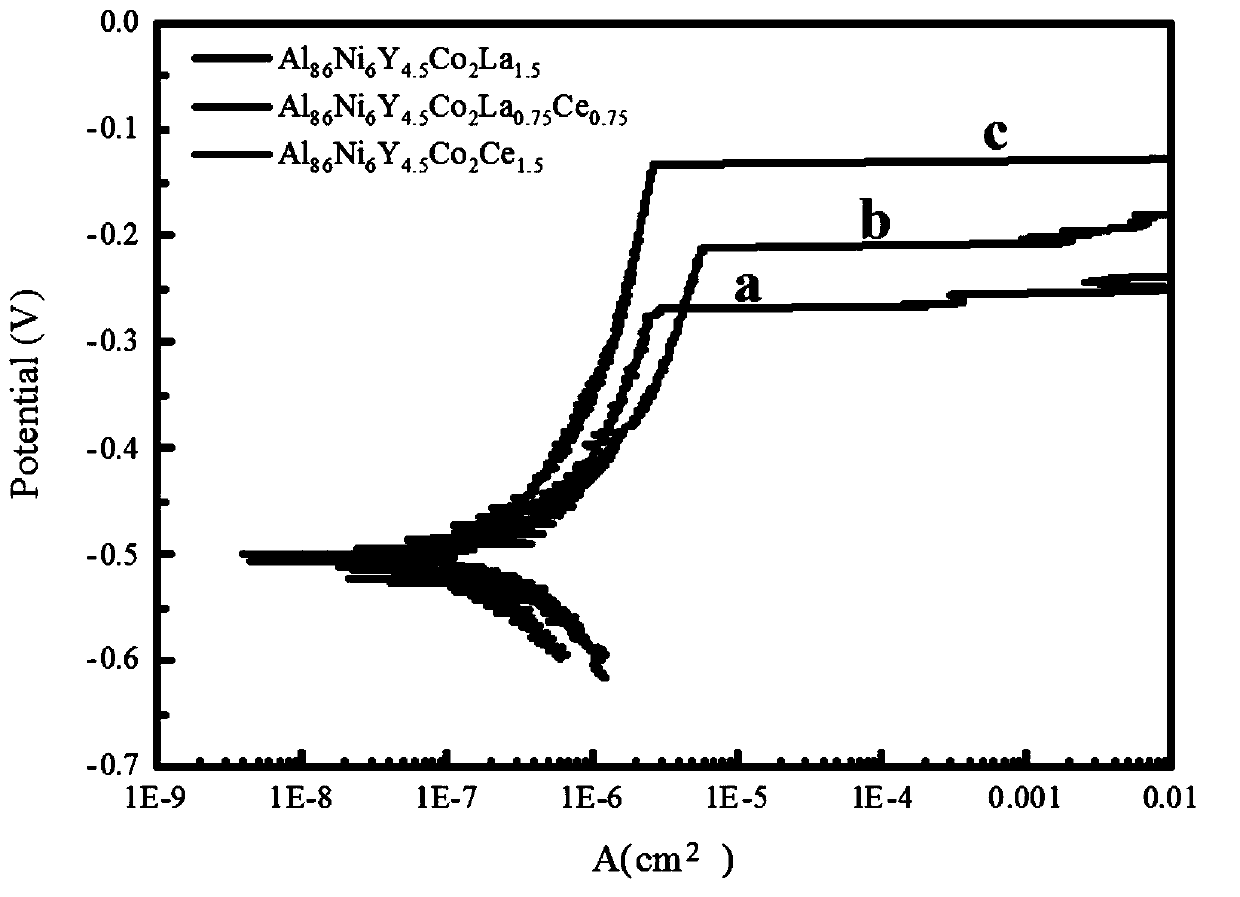

[0023] The aluminum-based strip sample designed and prepared in Example 1 has a completely amorphous structure, such as figure 1 As shown in the curves b and c in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com