Block copper-based amorphous alloy and preparation method thereof

A copper-based amorphous alloy and block technology, which is applied in the field of amorphous alloy materials, can solve the problems of poor copper-based bulk amorphous formation ability, etc., and achieve high glass formation ability, excellent mechanical properties, and uniform amorphous phase structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of bulk CuZrAl (Sn) amorphous alloy comprises the following steps:

[0034] (1) Use bulk Cu, Zr, Al, Sn metals with a purity greater than or equal to 99.9% as raw materials;

[0035] (2) Cleaning the massive Cu, Zr, Al, Sn metals, the cleaning step is specifically through surface grinding, acetone and alcohol cleaning in sequence, and finally drying for later use;

[0036] (3) According to the atomic percentage occupied by each element in the new bulk CuZrAl (Sn) amorphous alloy, it is converted into mass percentage and weighed the ingredients. The ingredients and their atomic percentage content are: 43 ~ 48at. 10 at.% Al, 0~2at.% Sn, and the rest of Cu; the raw materials are placed in a copper crucible, and the order of placement is: (from bottom to top) bulk Cu, bulk Al and Sn, bulk Zr ;

[0037] (4) Vacuumize the high-vacuum magnetron tungsten electric arc furnace to 5-10Pa, and then fill it with high-purity argon, repeating this three times;...

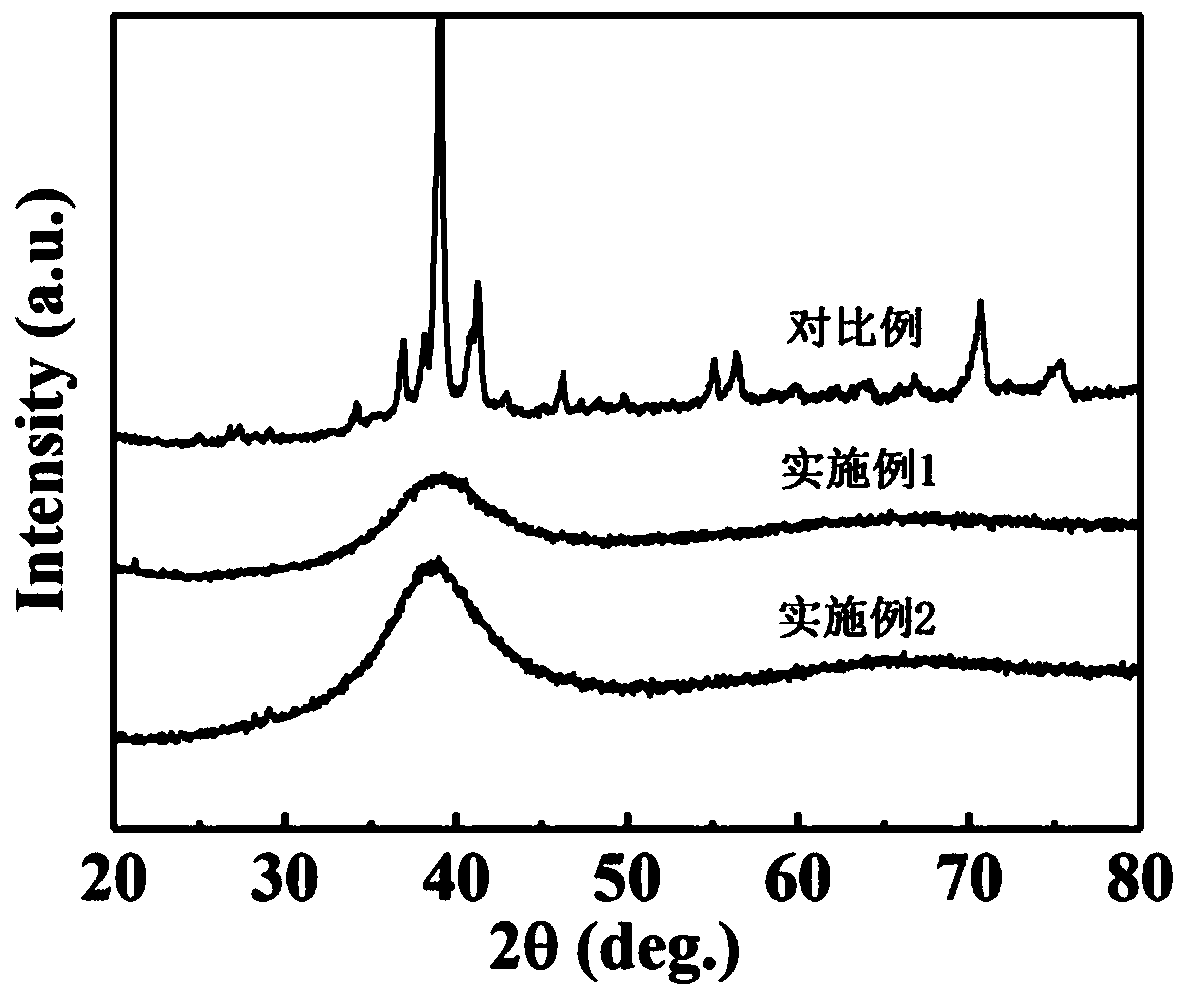

Embodiment 1

[0045] The main components of the copper-based amorphous alloy of the present embodiment are Cu, Zr, Al, and the atomic percentage (at.%) contents of each element are respectively:

[0046] Zr 45.1

[0047] Al 7.4

[0048] Cu balance

[0049] Its preparation method is:

[0050] The Cu, Zr and Al metals with industrial purity were surface polished, cleaned with acetone and alcohol in sequence, and finally dried for use; Cu 47.5 Zr 45.1 al 7.4 (at.%) converted to mass percentage Cu 41.17 Zr 56.11 al 2.72 (wt.%), carry out weighing ratio; vacuumize the high-vacuum magnetron tungsten electric arc furnace to 5-10Pa, then fill it with high-purity argon, and repeat this three times; then high-vacuum magnetron tungsten Vacuumize the electric arc furnace to 2.0~5.0×10 -3 Pa; then fill the furnace cavity with high-purity argon to 0.45-0.55MPa, melt the above-mentioned raw materials in this atmosphere, and pass in circulating water for cooling; before melting the raw materials, ...

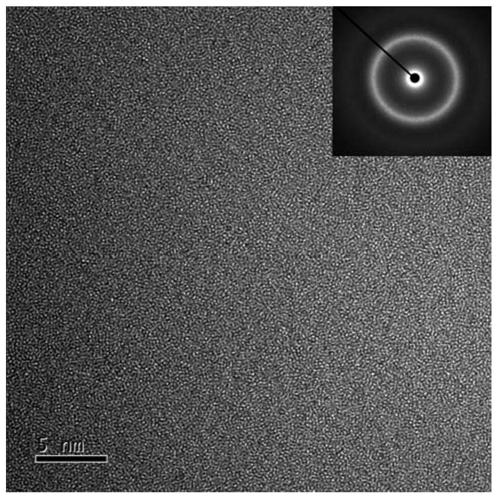

Embodiment 2

[0053] The main components of the copper-based amorphous alloy of this embodiment are Cu, Zr, Al and Sn, and the atomic percentage (at.%) contents of each element are respectively:

[0054] Zr 45.8

[0055] Al 6.4

[0056] Sn 0.5

[0057] Cu balance

[0058] Its preparation method is:

[0059] The Cu, Zr, Al, Sn metals of industrial purity are surface polished, cleaned with acetone and alcohol in sequence, and finally dried for use; Cu 47.3 Zr 45.8 al 6.4 sn 0.5 (at.%) converted to mass percentage Cu 40.53 Zr 56.34 al 2.33 sn 0.8 (wt.%), carry out weighing ratio; vacuumize the high-vacuum magnetron tungsten electric arc furnace to 5-10Pa, then fill it with high-purity argon, and repeat this three times; then high-vacuum magnetron tungsten The electric arc furnace is evacuated to 2.0-5.0×10-3Pa; then the furnace cavity is filled with high-purity argon to 0.45-0.55MPa, and the above-mentioned raw materials are smelted in this atmosphere, the smelting current is 100-25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com