Cuprous oxide nanowire array composite carbon nitride loaded copper mesh composite material and preparation method and application thereof

A nanowire array and composite material technology is applied to cuprous oxide nanowire array composite carbon nitride supported copper mesh composite material and its preparation and application fields, and can solve the problems of poor product stability, long time consumption, complicated preparation process and the like , to achieve the effect of reduced material synthesis time, simple preparation method and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. A composite carbon nitride-supported copper mesh based on cuprous oxide nanowire arrays (g-C 3 N 4 / Cu 2 (Nano wire array / copper mesh) preparation of composite nanomaterial, concrete steps are as follows:

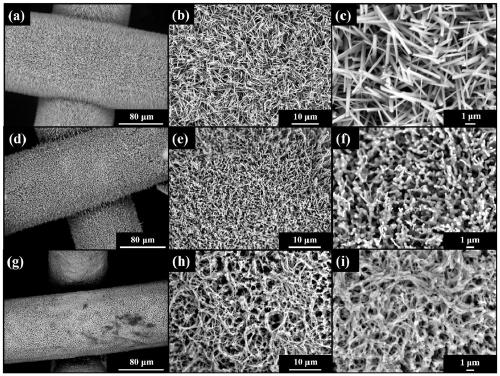

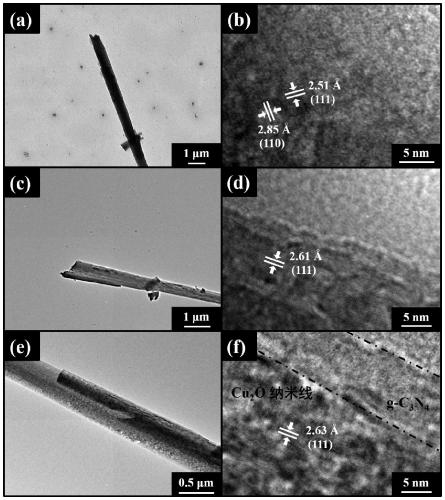

[0038] 1) Cu(OH) 2 Preparation of nanowire array / copper mesh: clean copper yarn was subjected to constant current (10mA cm -2 ) was anodized in 3mol / L sodium hydroxide solution for 700s.

[0039] 2) Cu 2 Preparation of O nanowire arrays / copper mesh: Cu(OH) 2 The nanowire array / copper mesh was annealed at 520 °C for 3 h in an argon atmosphere.

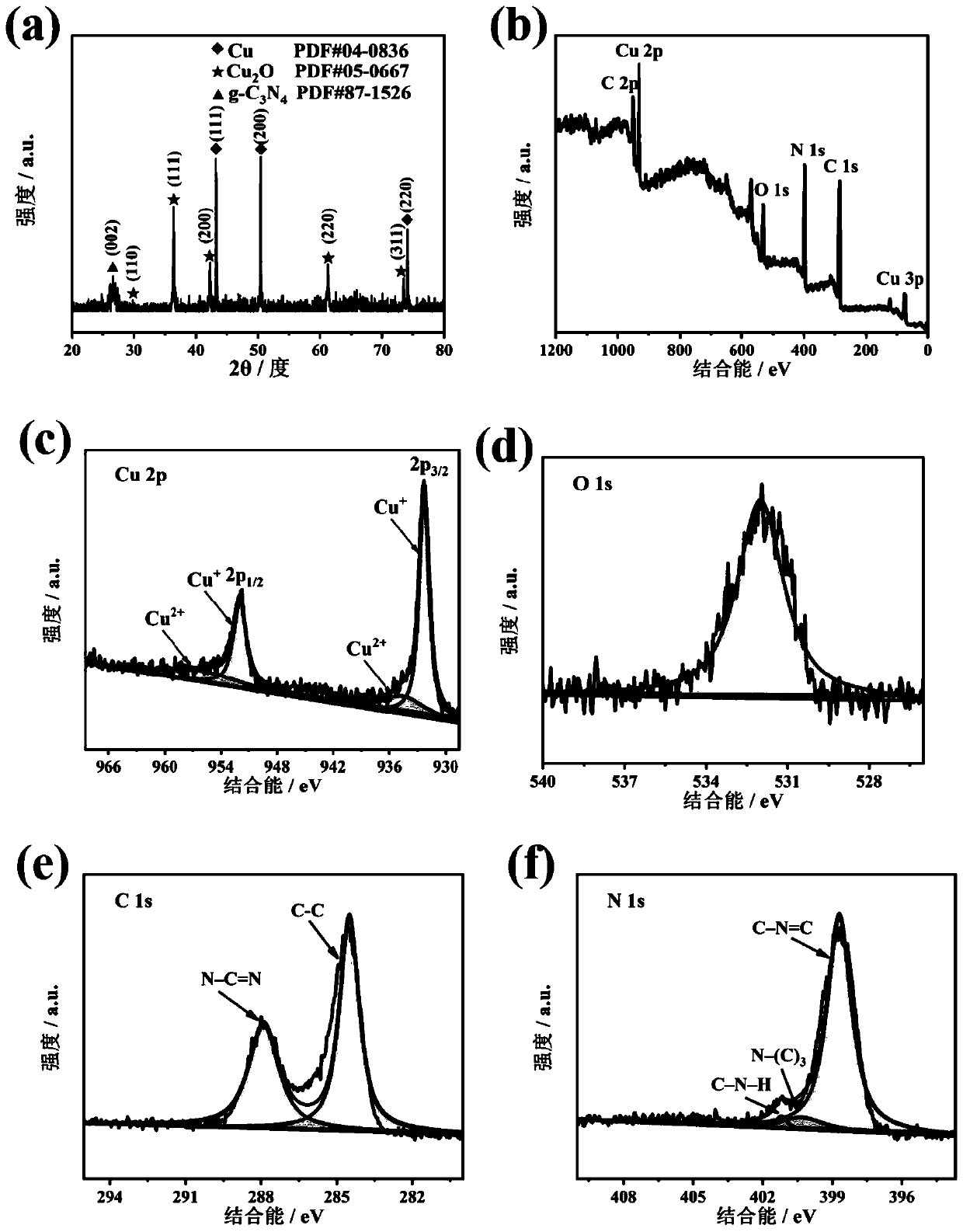

[0040] 3) g-C 3 N 4 / Cu 2 Preparation of O nanowire array / copper mesh: First, 2,4-diamino-6-phenyl-1,3,5-triazine (9 g) and cyanuric acid (6.5 g) were dissolved in 200 mL deionized water, Stir magnetically at room temperature for 24 h. Next, the mixed suspension was subjected to suction filtration to achieve solid-liquid separation. The white solid was dried in a blast oven at 60 °C for 8 h. Then, the dried whi...

Embodiment 2

[0053] A composite carbon nitride-supported copper mesh based on cuprous oxide nanowire arrays (g-C 3 N 4 / Cu 2 (Nano wire array / copper mesh) preparation of composite nanomaterial, concrete steps are as follows:

[0054] 1) Cu(OH) 2 Preparation of nanowire array / copper mesh: clean copper yarn was subjected to constant current (5mA cm -2 ) were anodized in 2mol / L sodium hydroxide solution for 500s.

[0055] 2) Cu 2 Preparation of O nanowire arrays / copper mesh: Cu(OH) 2 The nanowire array / copper mesh was annealed at 500°C for 2h in an argon atmosphere.

[0056] 3) g-C 3 N 4 / Cu 2 Preparation of O nanowire arrays / copper meshes: First, 2,4-diamino-6-phenyl-1,3,5-triazine (8 g) and cyanuric acid (5 g) were dissolved in 200 mL deionized water, at room temperature Under magnetic stirring for 24h. Next, the mixed suspension was subjected to suction filtration to achieve solid-liquid separation. The white solid was dried in a blast oven at 50 °C for 6 h. Then, the dried wh...

Embodiment 3

[0062] A composite carbon nitride-supported copper mesh based on cuprous oxide nanowire arrays (g-C 3 N 4 / Cu 2 (Nano wire array / copper mesh) preparation of composite nanomaterial, concrete steps are as follows:

[0063] 1) Cu(OH) 2 Preparation of nanowire array / copper mesh: clean copper yarn was subjected to constant current (15mA cm -2 ) were anodized in 4mol / L sodium hydroxide solution for 1000s.

[0064] 2) Cu 2 Preparation of O nanowire arrays / copper mesh: Cu(OH) 2 The nanowire array / copper mesh was annealed at 550°C in an argon atmosphere for 5h.

[0065] 3) g-C 3 N 4 / Cu 2 Preparation of O nanowire array / copper mesh: First, 2,4-diamino-6-phenyl-1,3,5-triazine (10 g) and cyanuric acid (8 g) were dissolved in 200 mL of deionized water, at room temperature Under magnetic stirring for 24h. Next, the mixed suspension was subjected to suction filtration to achieve solid-liquid separation. The white solid was dried in a blast oven at 70°C for 10 h. Then, the dried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com