Surface modification process for stainless steel

A surface modification, stainless steel technology, applied in the field of metal surface treatment, can solve the problems of high energy consumption, large processing current, unspecified degree of corrosion resistance improvement, etc., to achieve simple equipment, convenient operation, excellent corrosion resistance and other problems. Effect

Inactive Publication Date: 2008-10-22

KINGRAY NEW MATERIALS SCI & TECH

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In patent 02113351.4, the author controls a large anode polarization current (500~1500A / m 2 ) to anodize the 304 type stainless steel plate to improve the anti-corrosion performance of the stainless steel plate, but the degree of improvement of the anti-corrosion performance is not specified in the patent, and this method is only applicable to the 304 type stainless steel, the treatment current is large, and it can high consumption

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

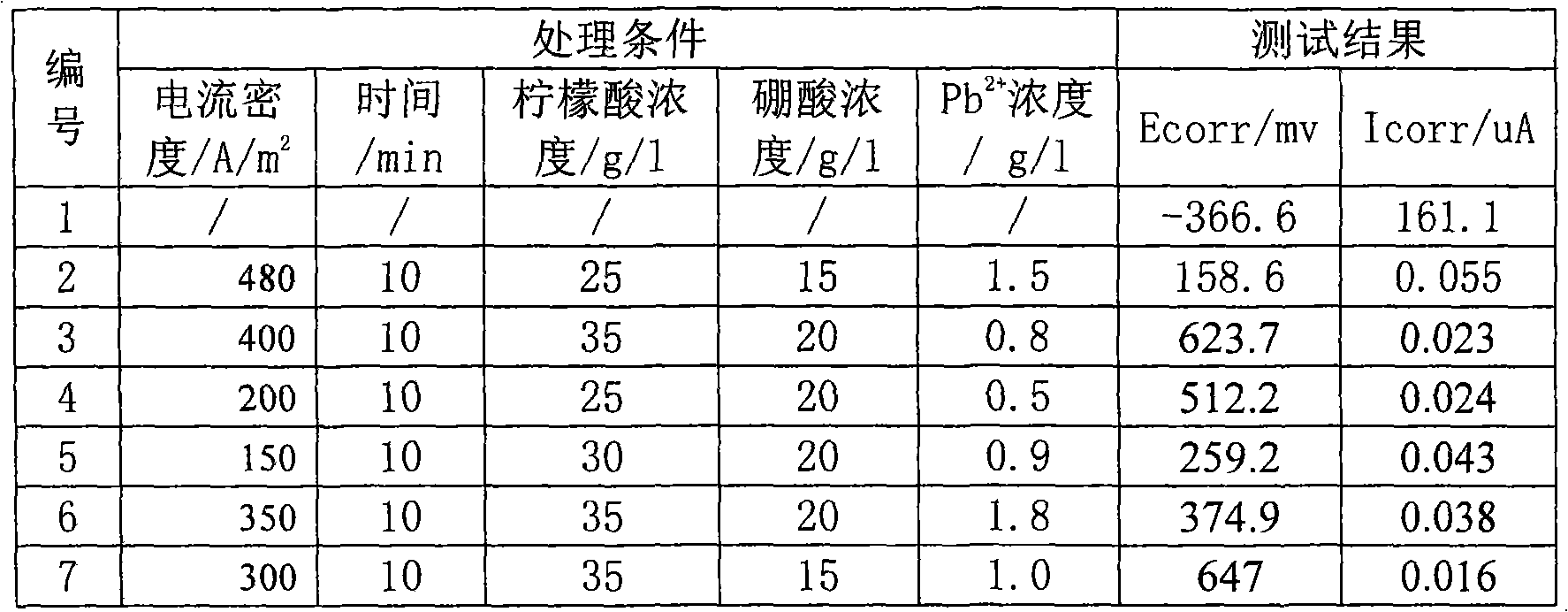

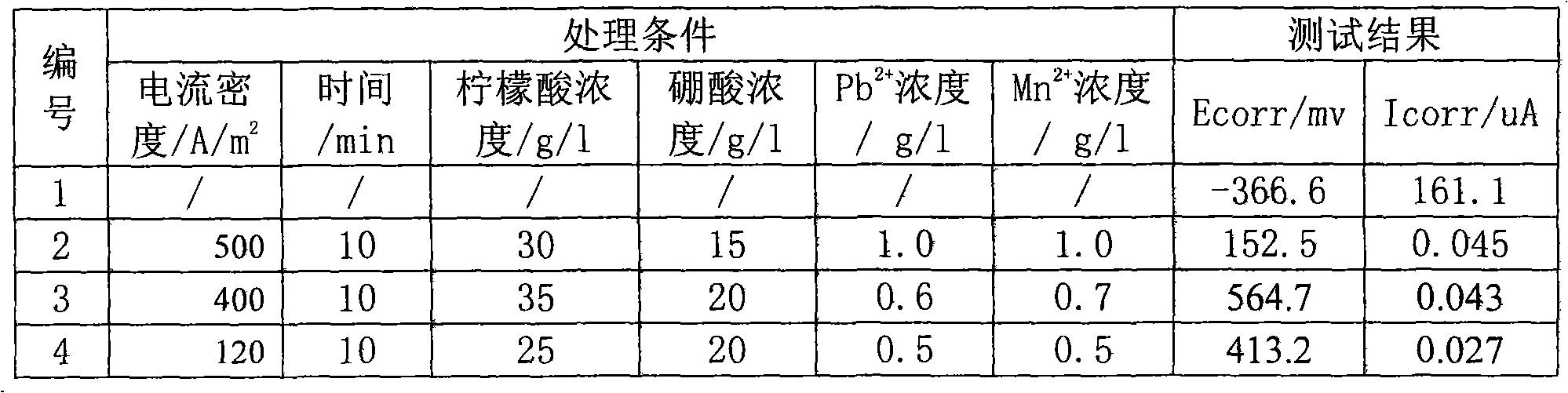

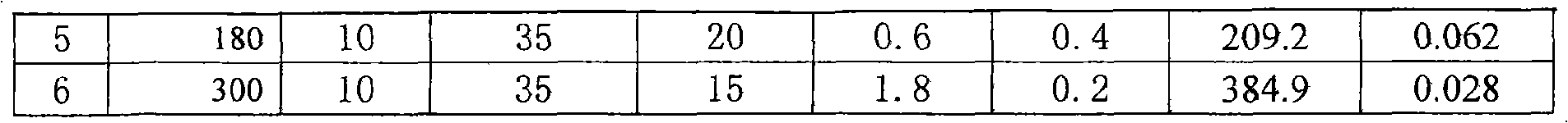

The method for modifying the surface of rustless steel belongs to the metal surface processing technique. The method comprises the steps of: pre-processing a rustless steel product through a normal method and then taking the rustless steel product as an anode to carry out anode polarization treatment, wherein the treatment process is to process the surface of the rustless steel by adding citrate and nitrate additive into electrolyte solution of citric acid and boric acid and controlling the current concentration and the polarization time. The corrosion resistance of the rustless steel product processed through the method is greatly improved while the self physical properties such as the surface color, the lustrousness, the strength, the electricity conductivity, the heat conductivity and the like are not changed. The method has simple technique and equipment and convenient operation, and is easy to industrialize.

Description

technical field The invention belongs to metal surface treatment technology and relates to a stainless steel electrochemical surface modification method. Background technique Metal surface treatment is to modify the metal surface by physical or chemical methods. In order to improve the corrosion resistance of stainless steel products, it is often necessary to use metal surface treatment technology to modify stainless steel products. The conventional surface treatment methods for stainless steel include anodic passivation, chemical oxidation and pre-oxidation. For example: anodic polarization treatment with control potential at +0.5~+0.8v passivation zone in oxyacid, in concentrated HNO 3 Medium heating oxidation treatment or pre-oxidation treatment, related patents can refer to the book "Metal Surface Treatment, Chemical and Electrochemical Surface Conversion". These conventional methods can improve the corrosion resistance of metals dozens of times. In the patent 871035...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25D11/34

Inventor 熊成礼唐三川徐光前李军

Owner KINGRAY NEW MATERIALS SCI & TECH

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com