Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Achieve the purpose of sorting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

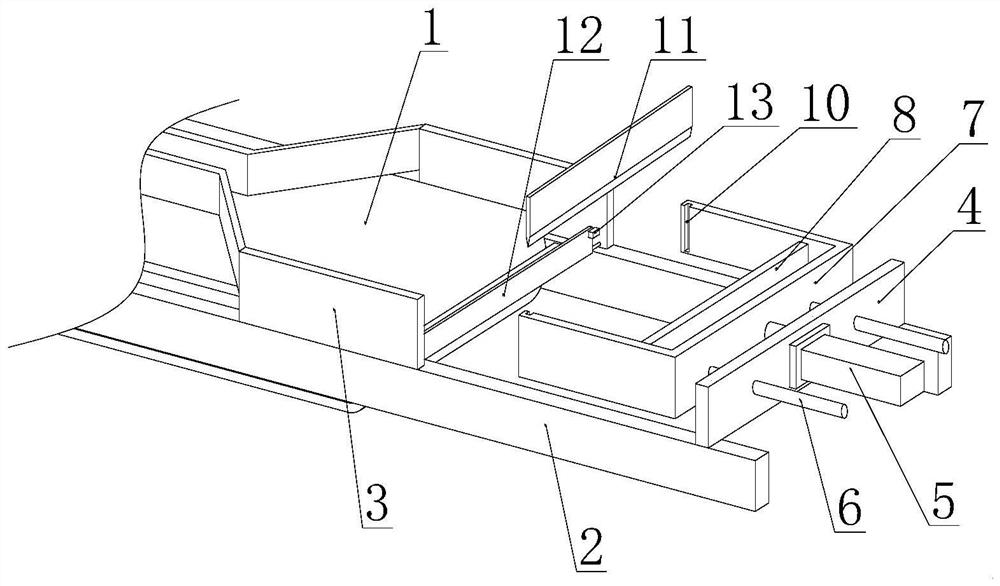

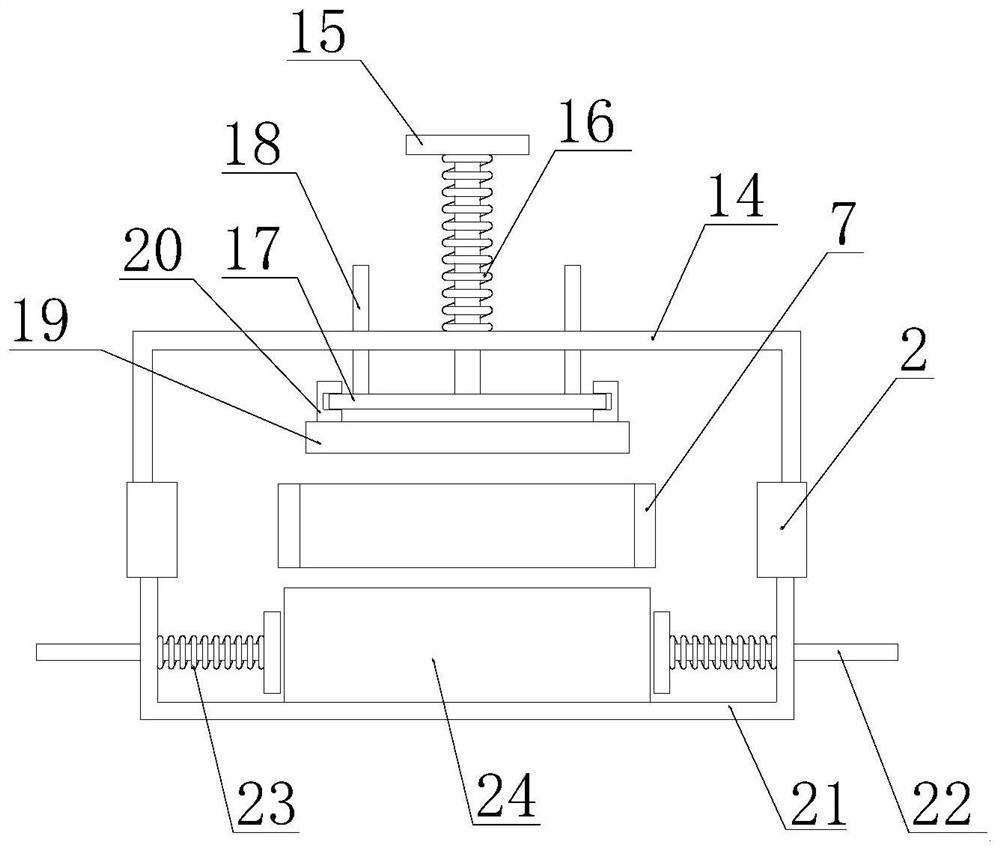

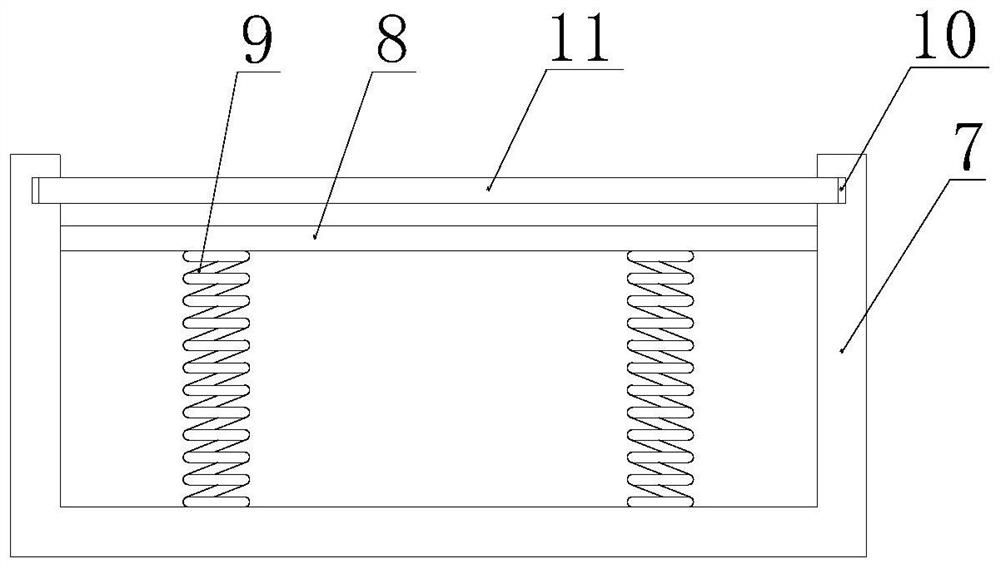

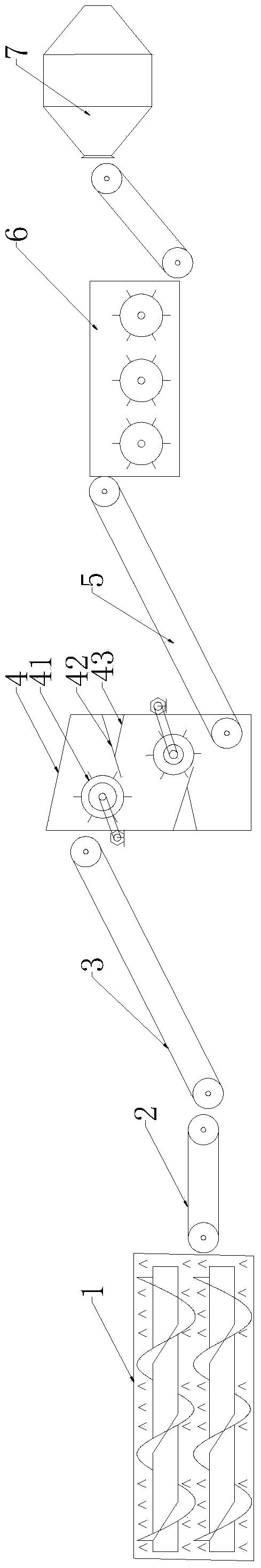

Casting sorting device

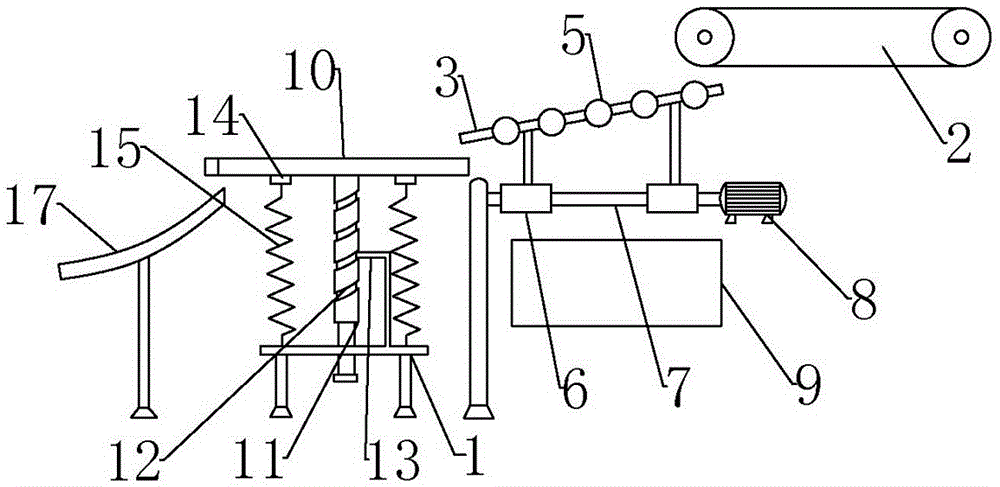

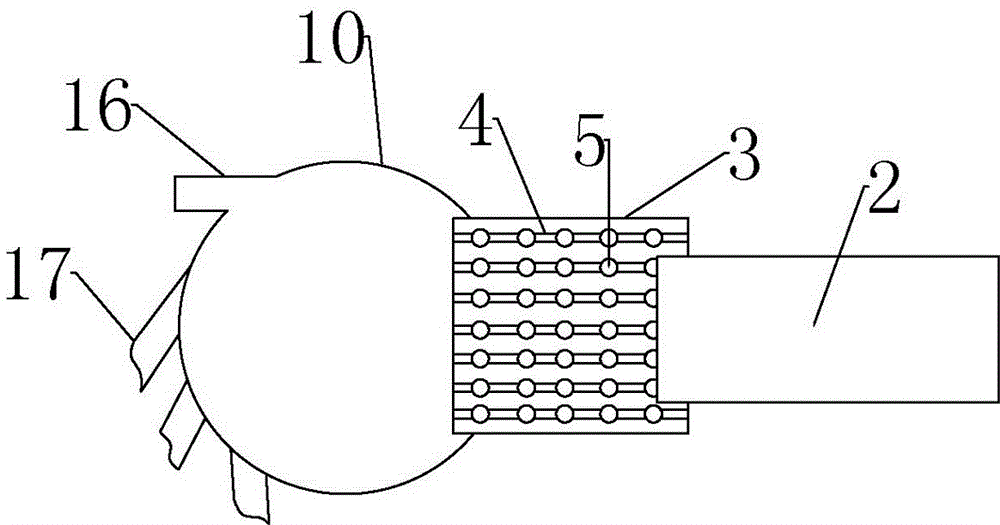

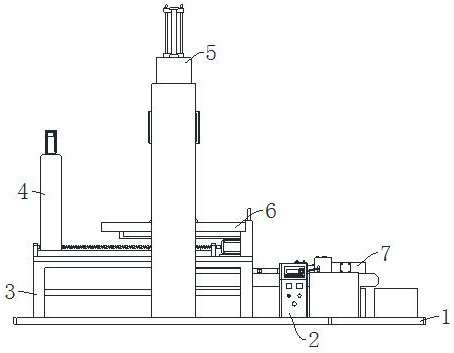

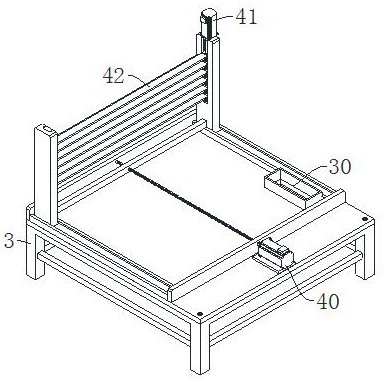

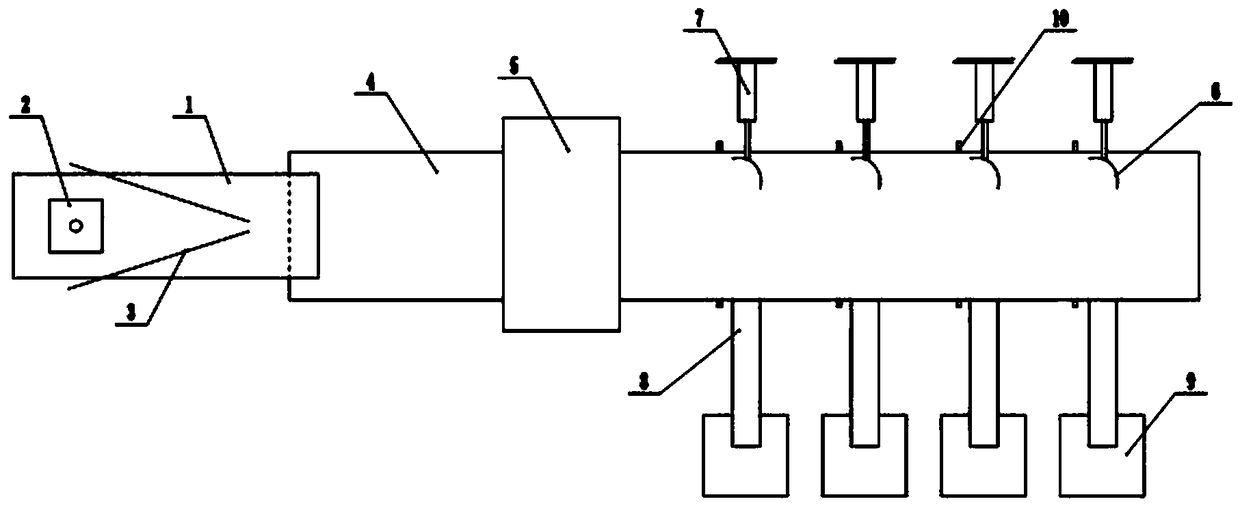

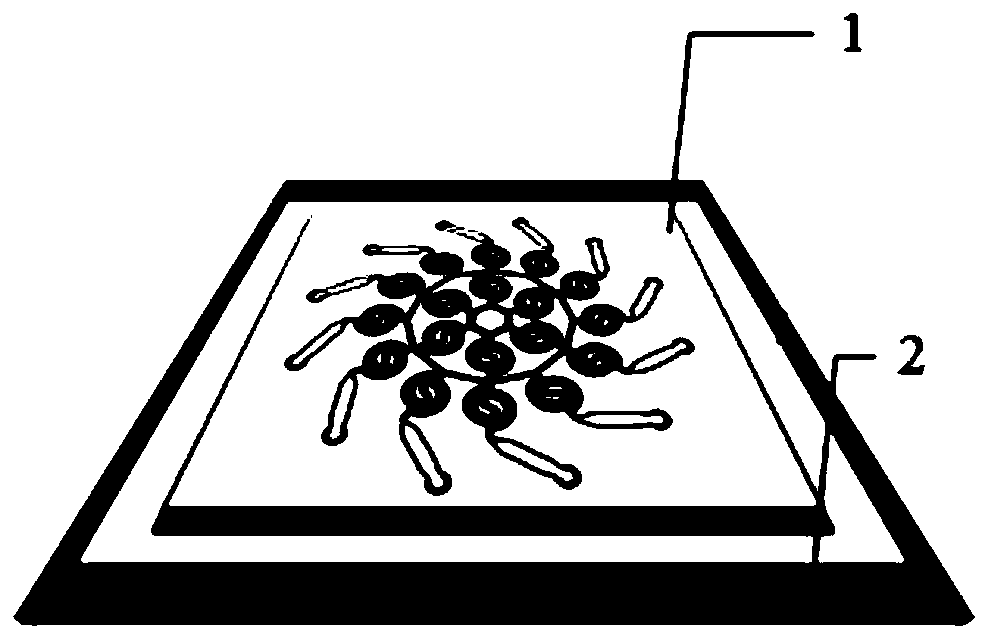

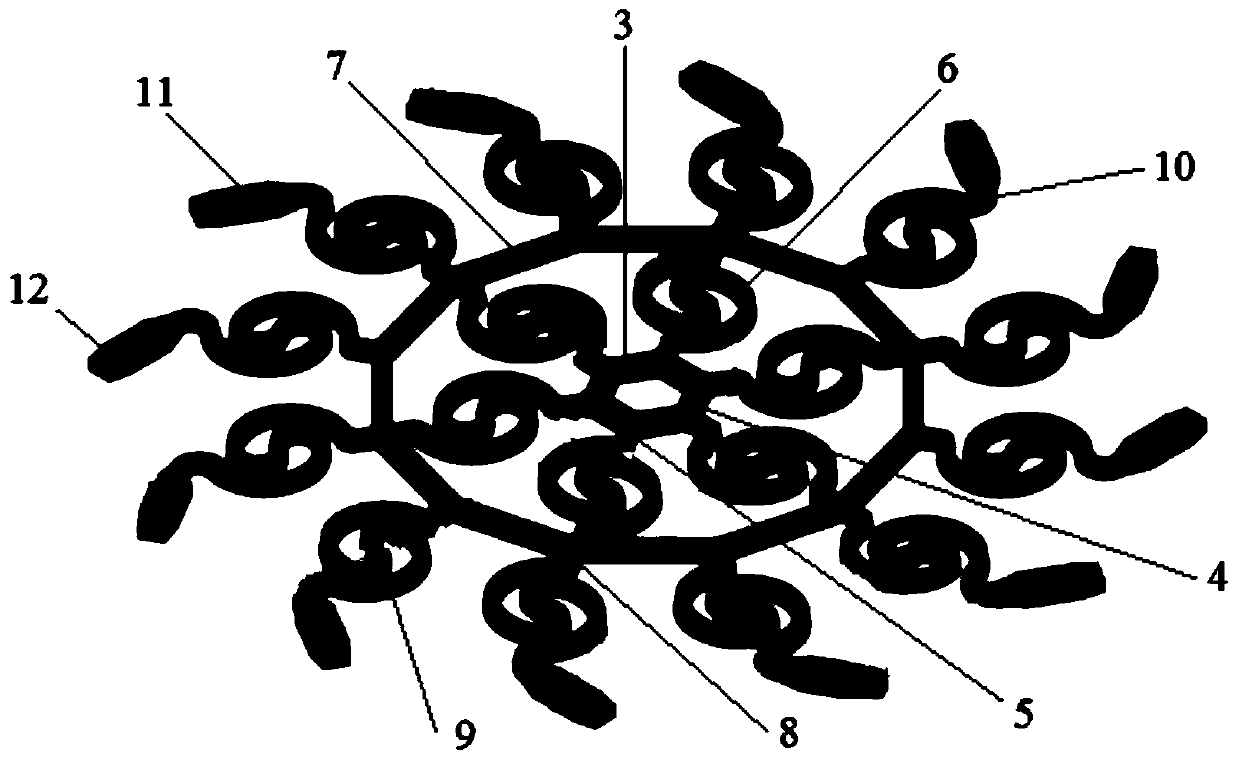

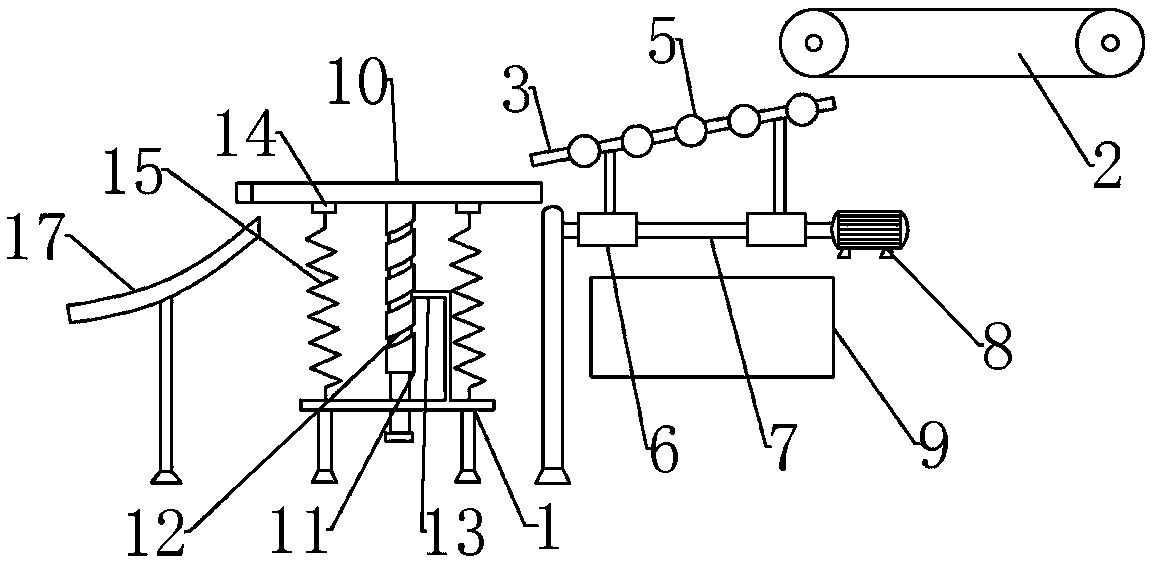

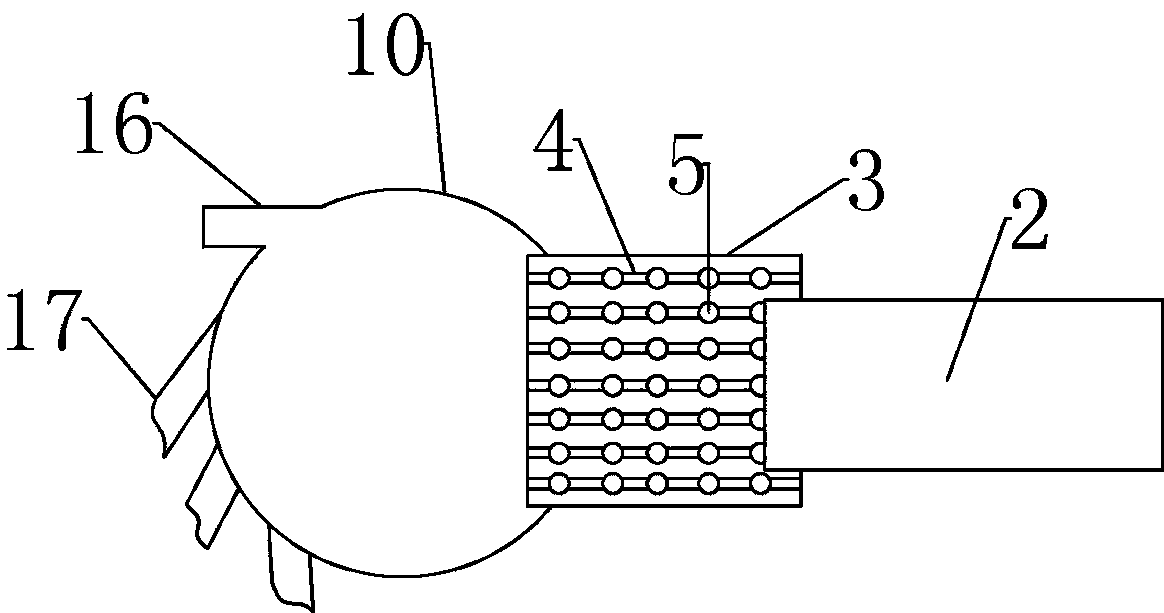

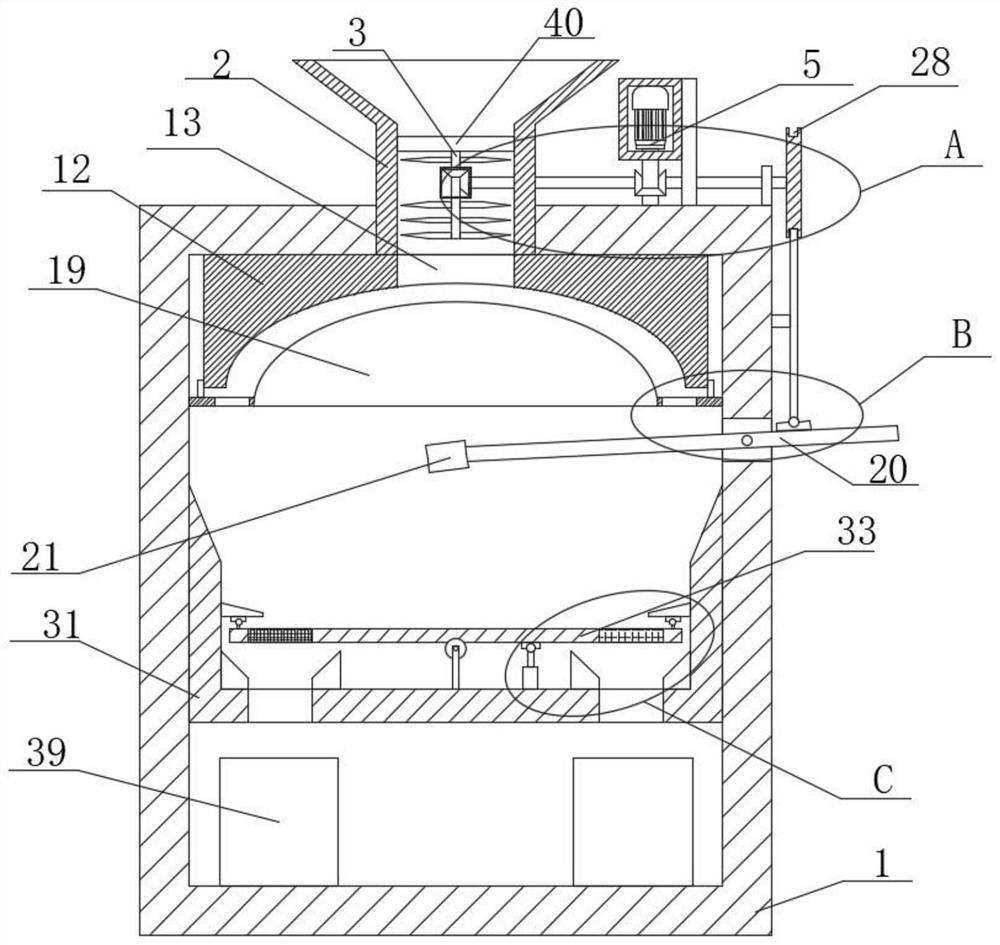

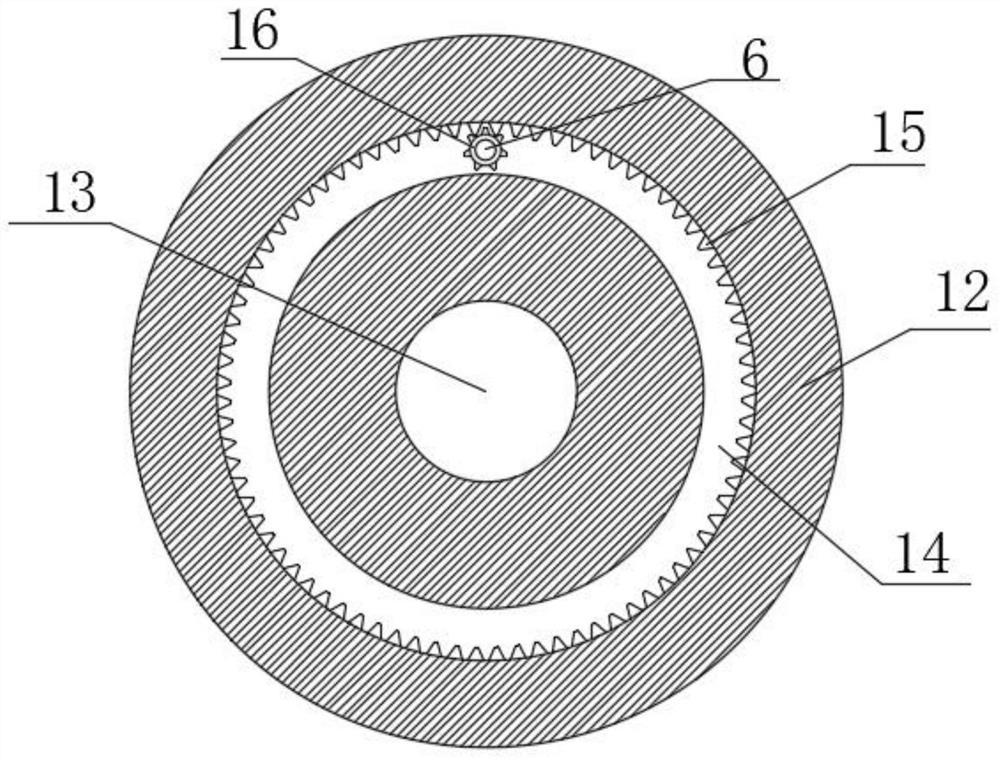

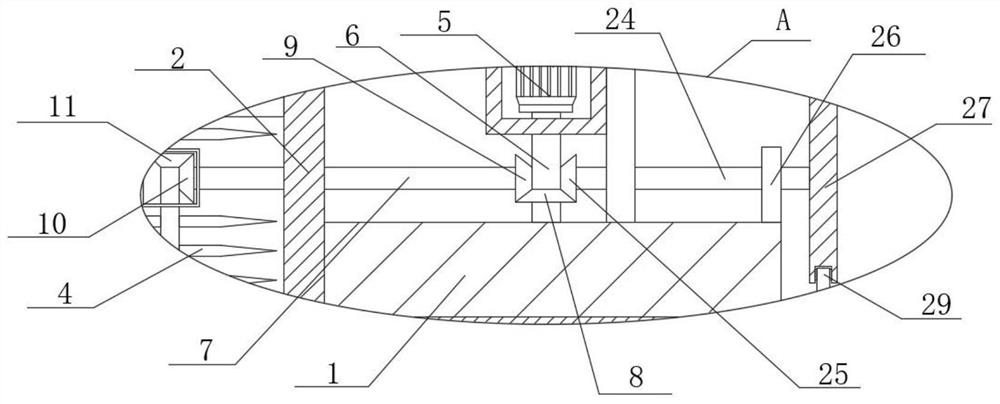

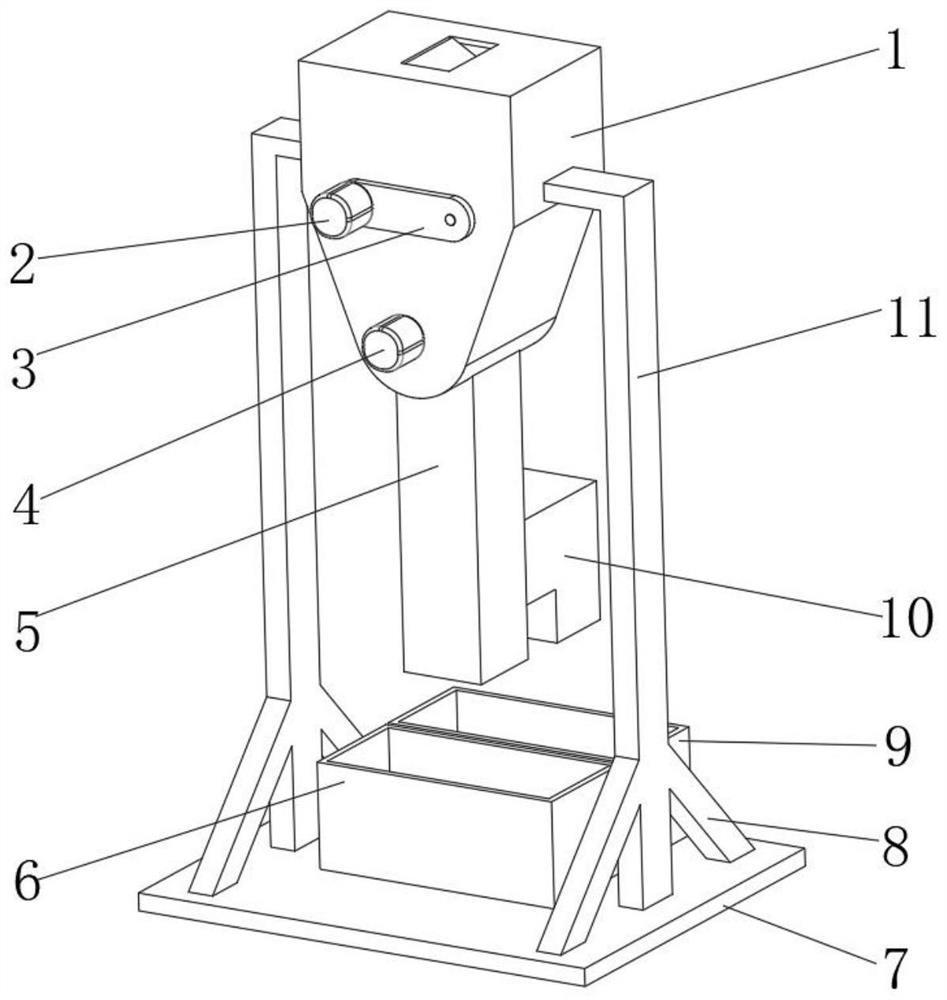

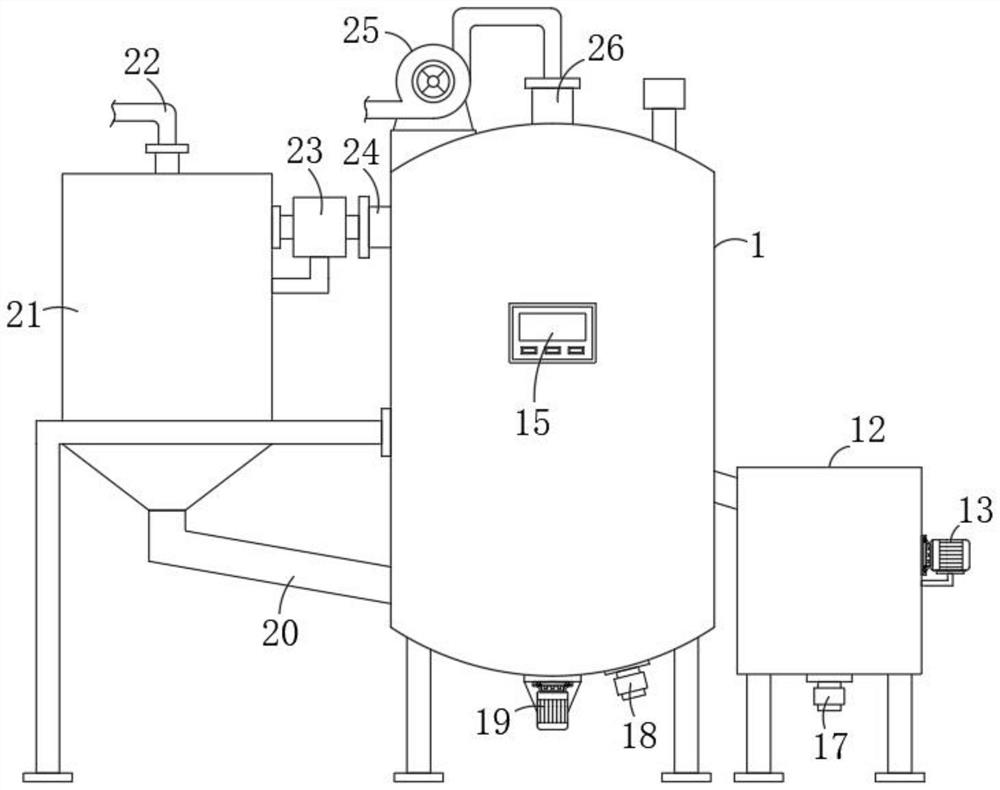

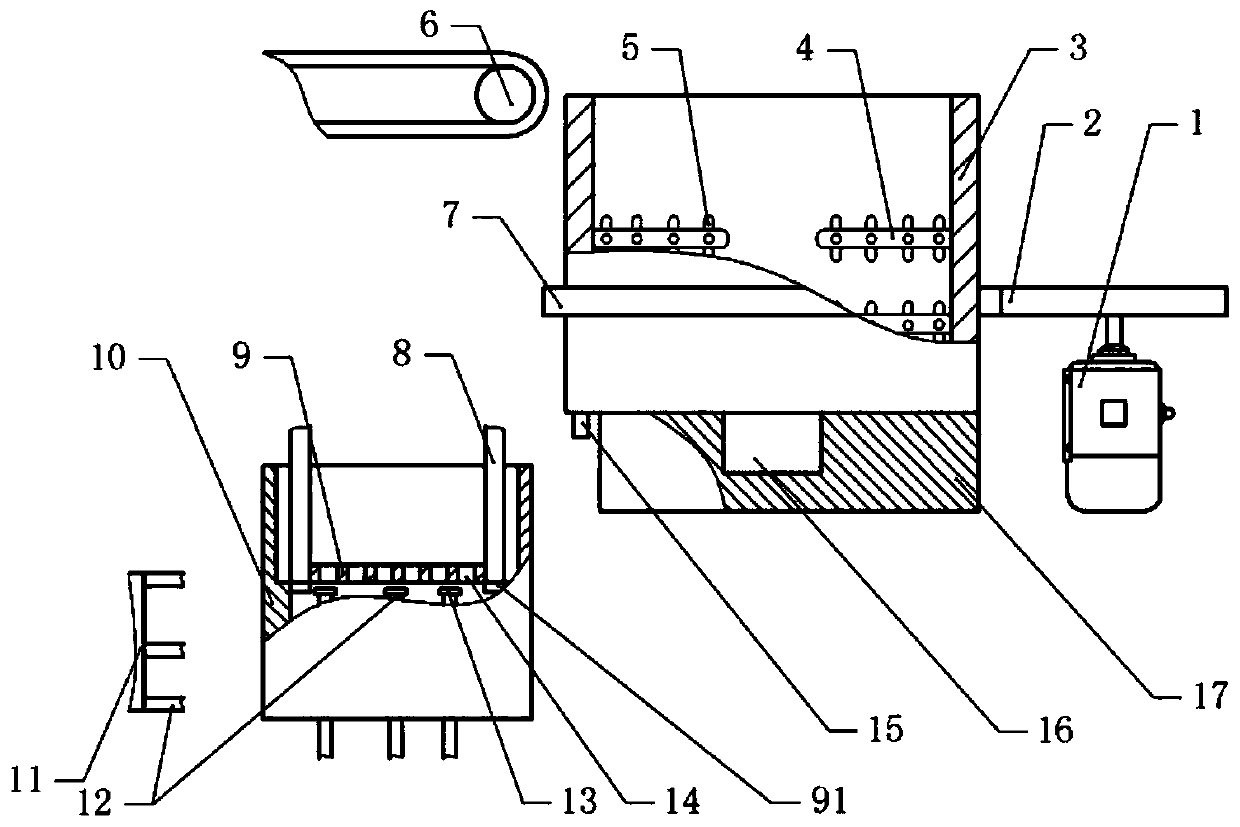

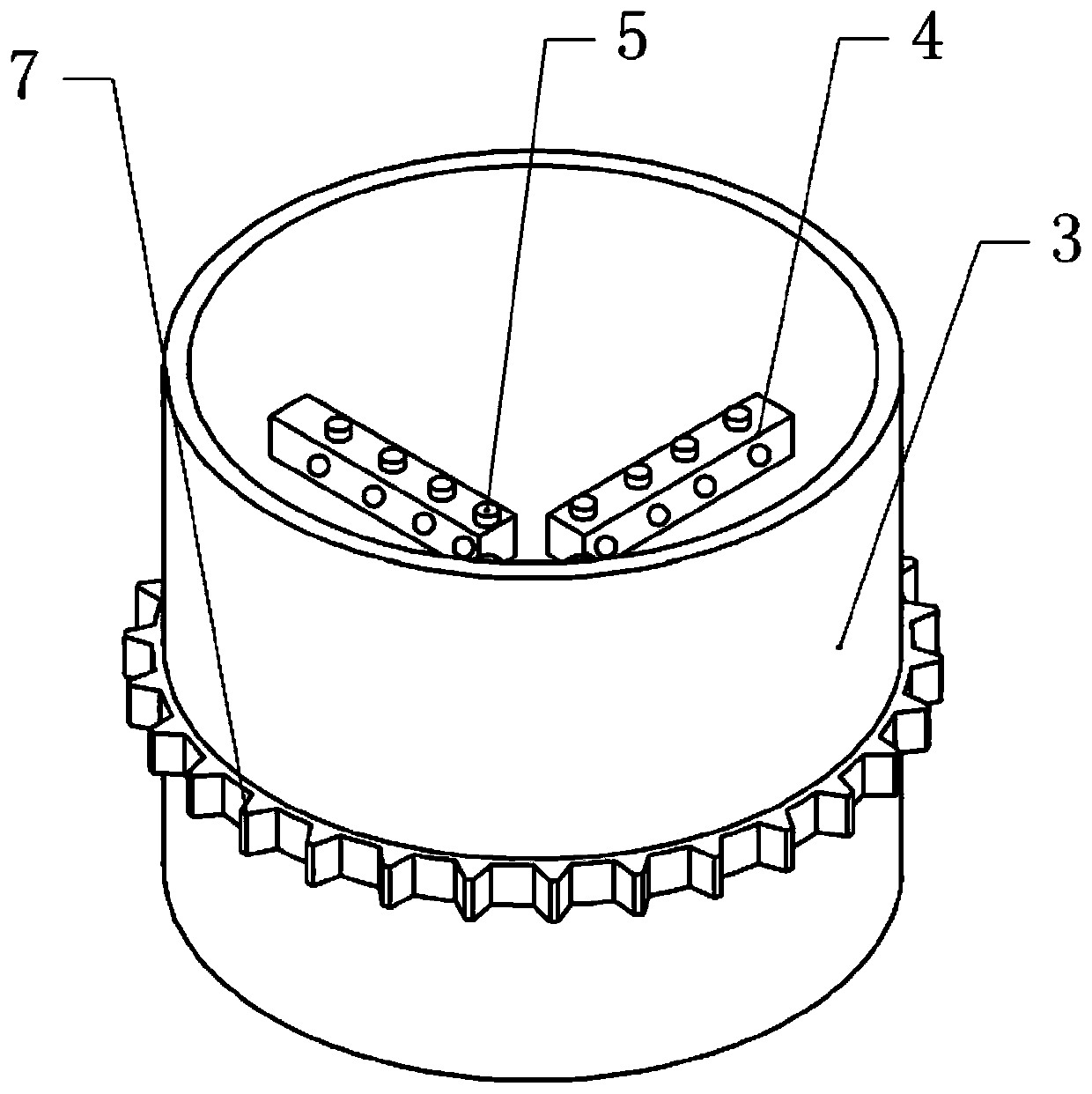

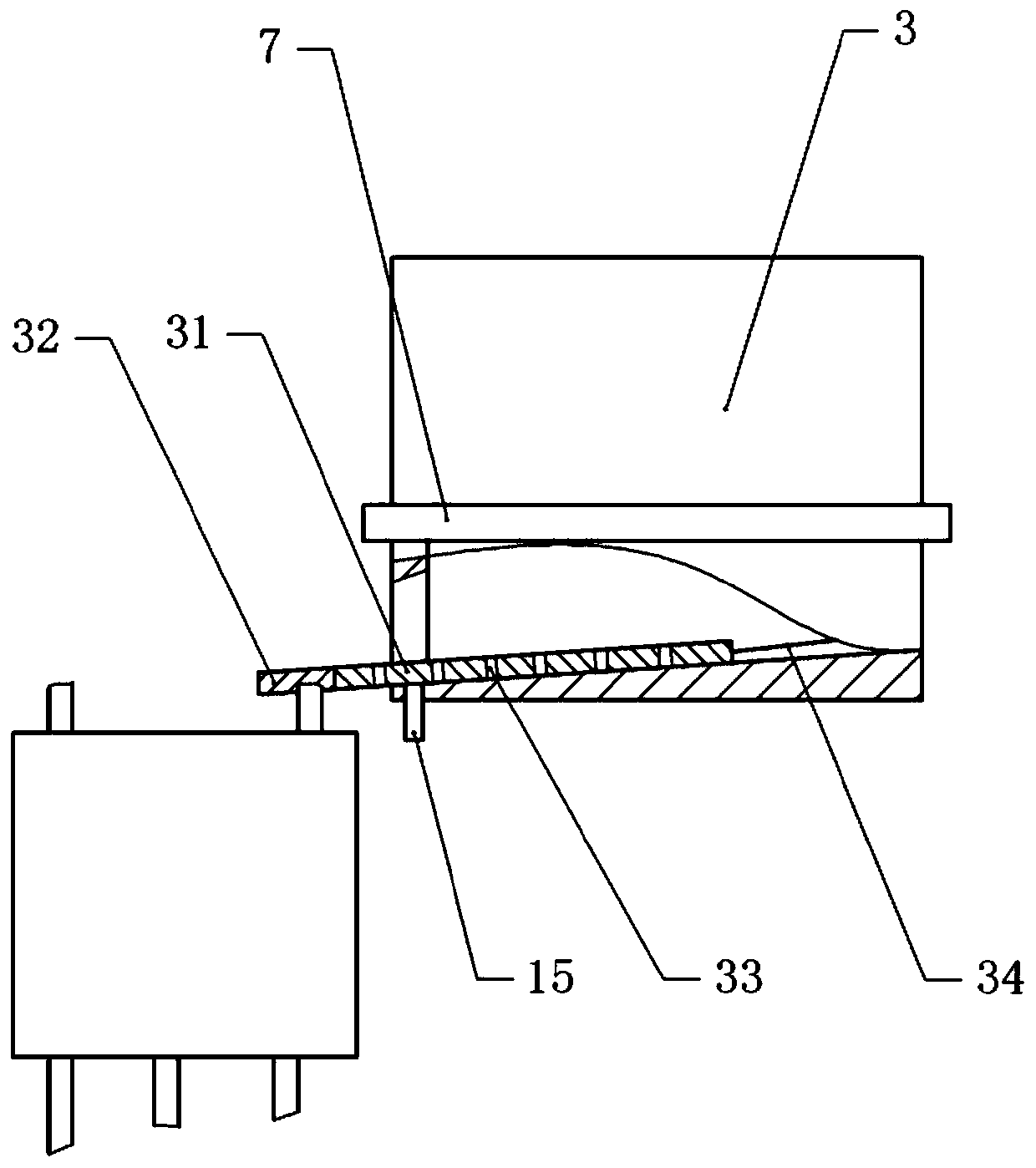

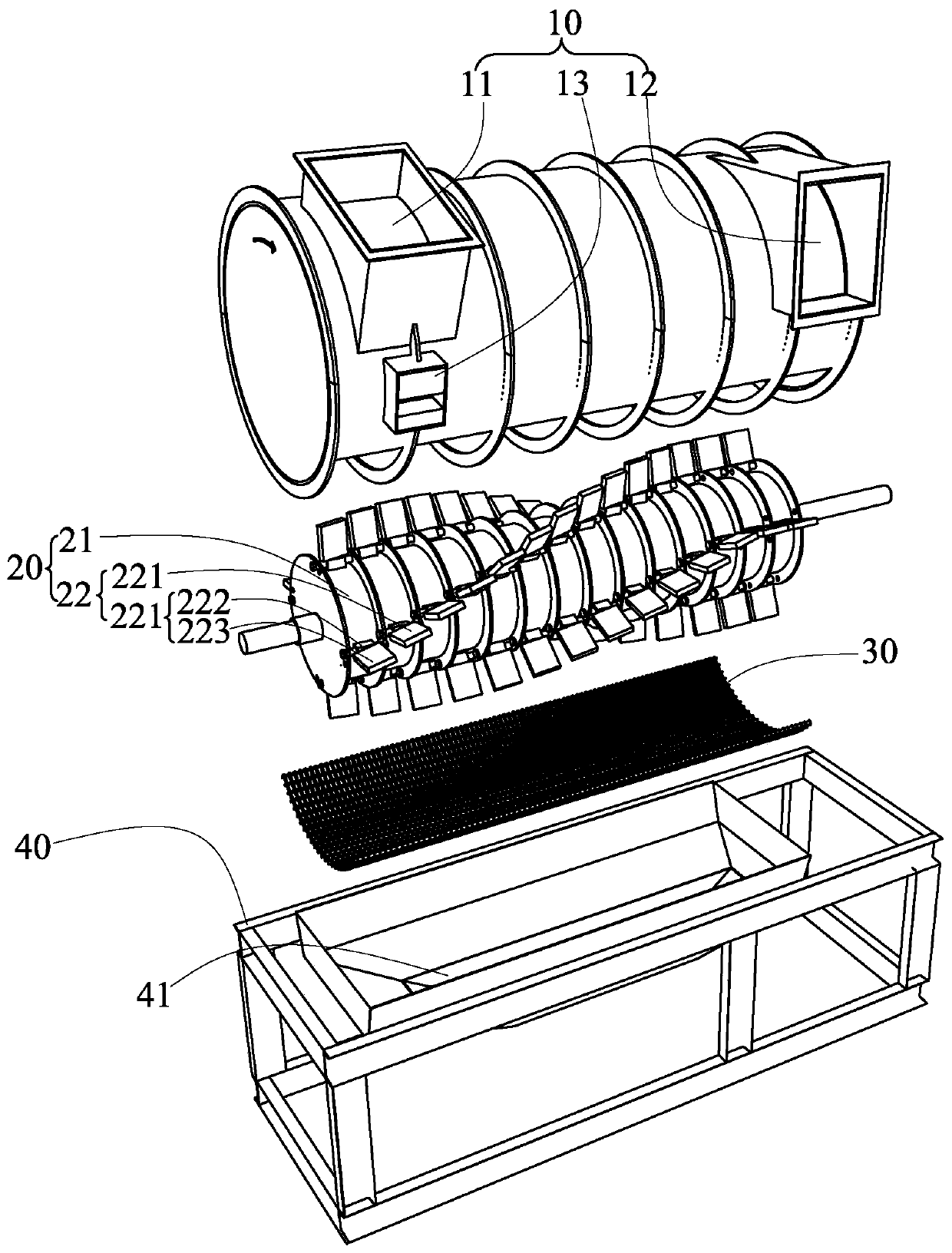

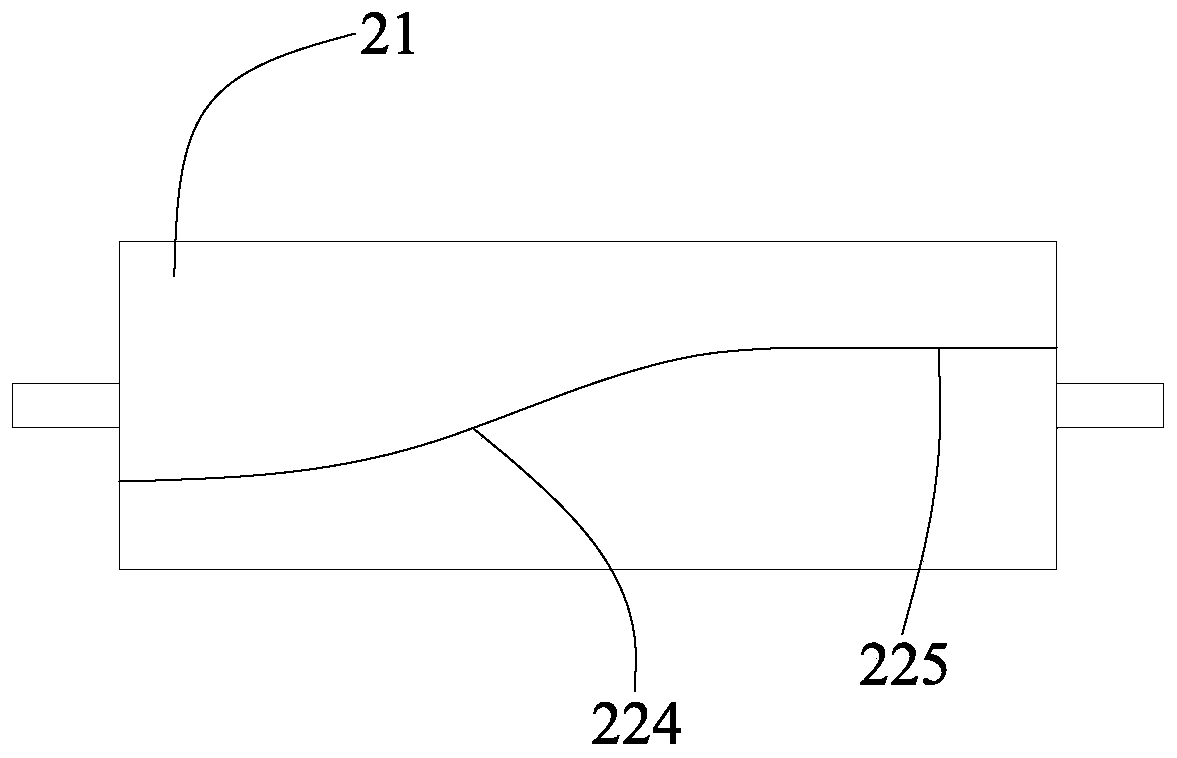

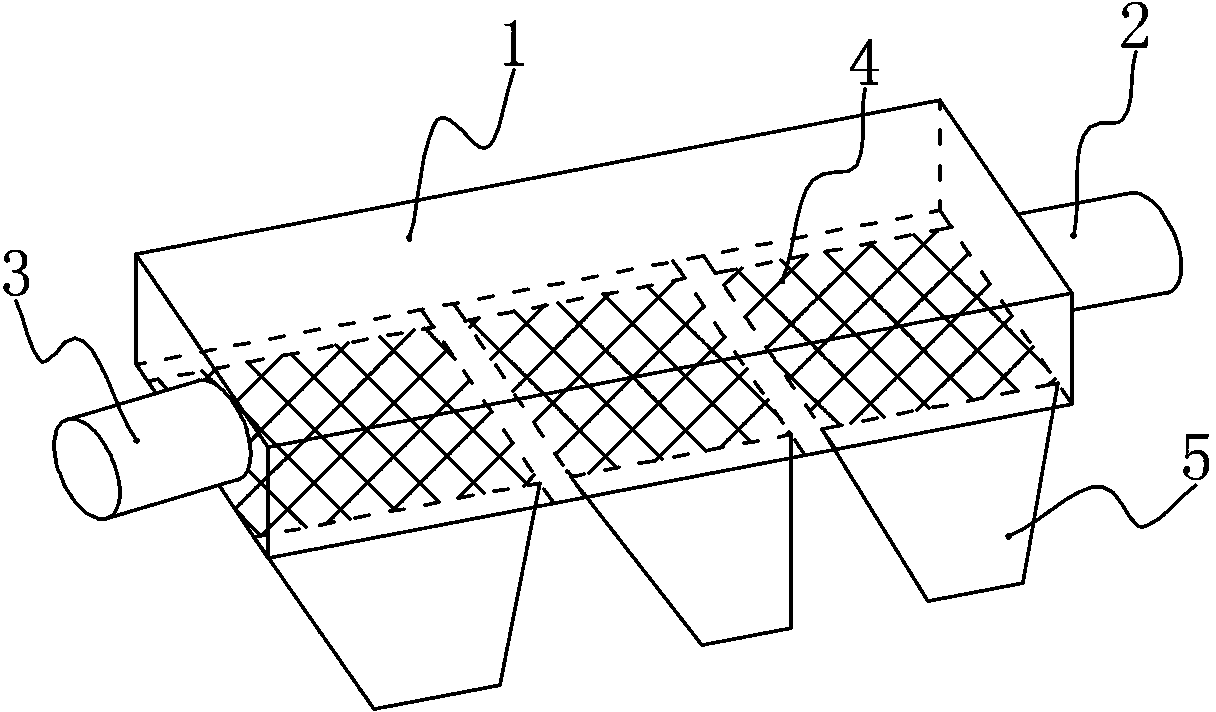

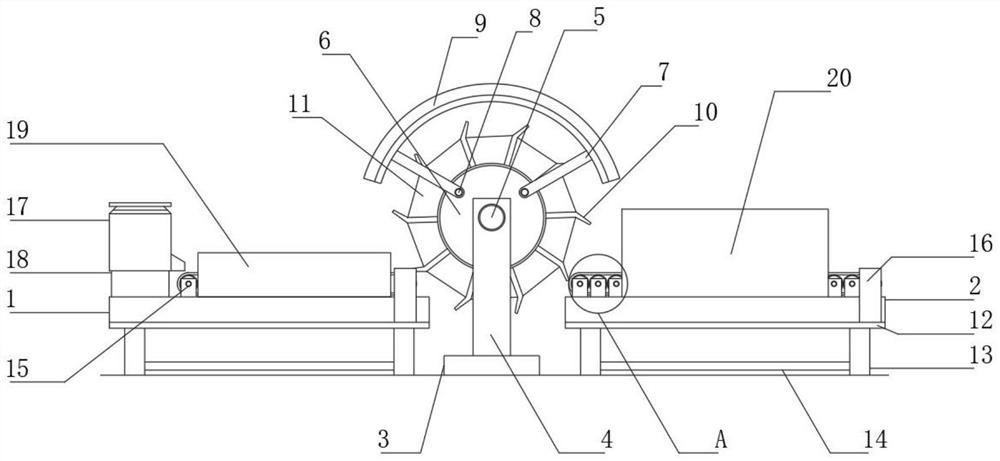

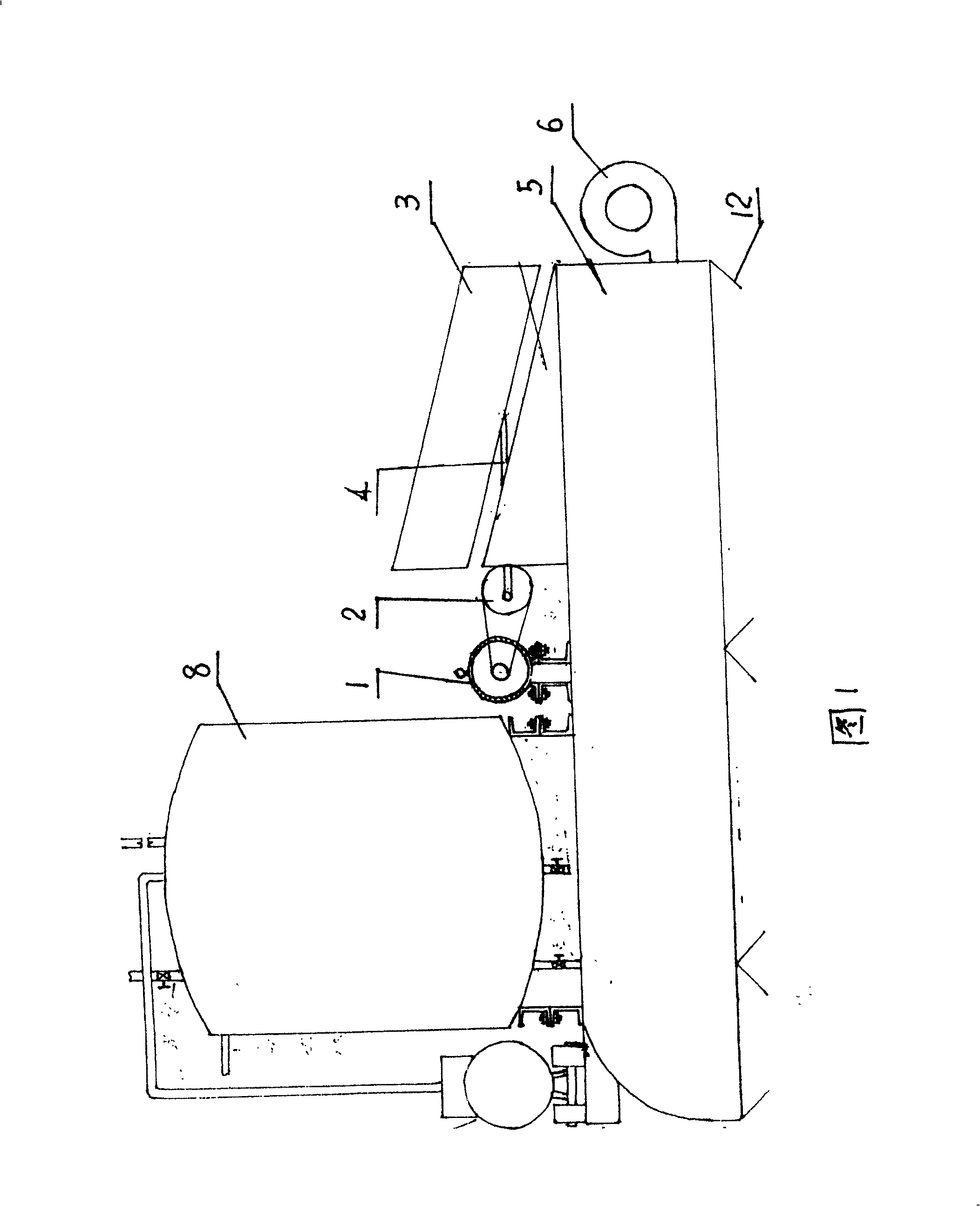

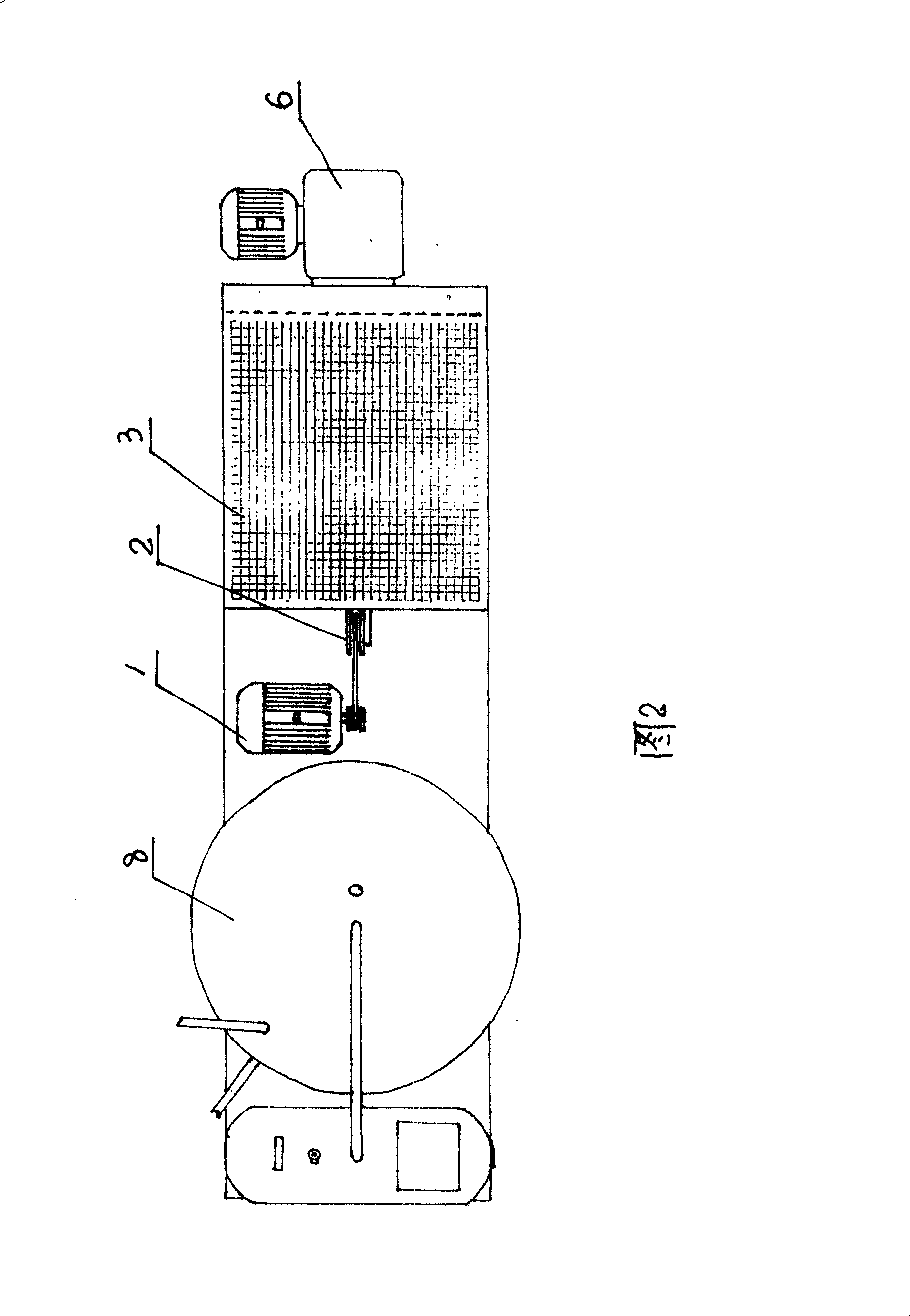

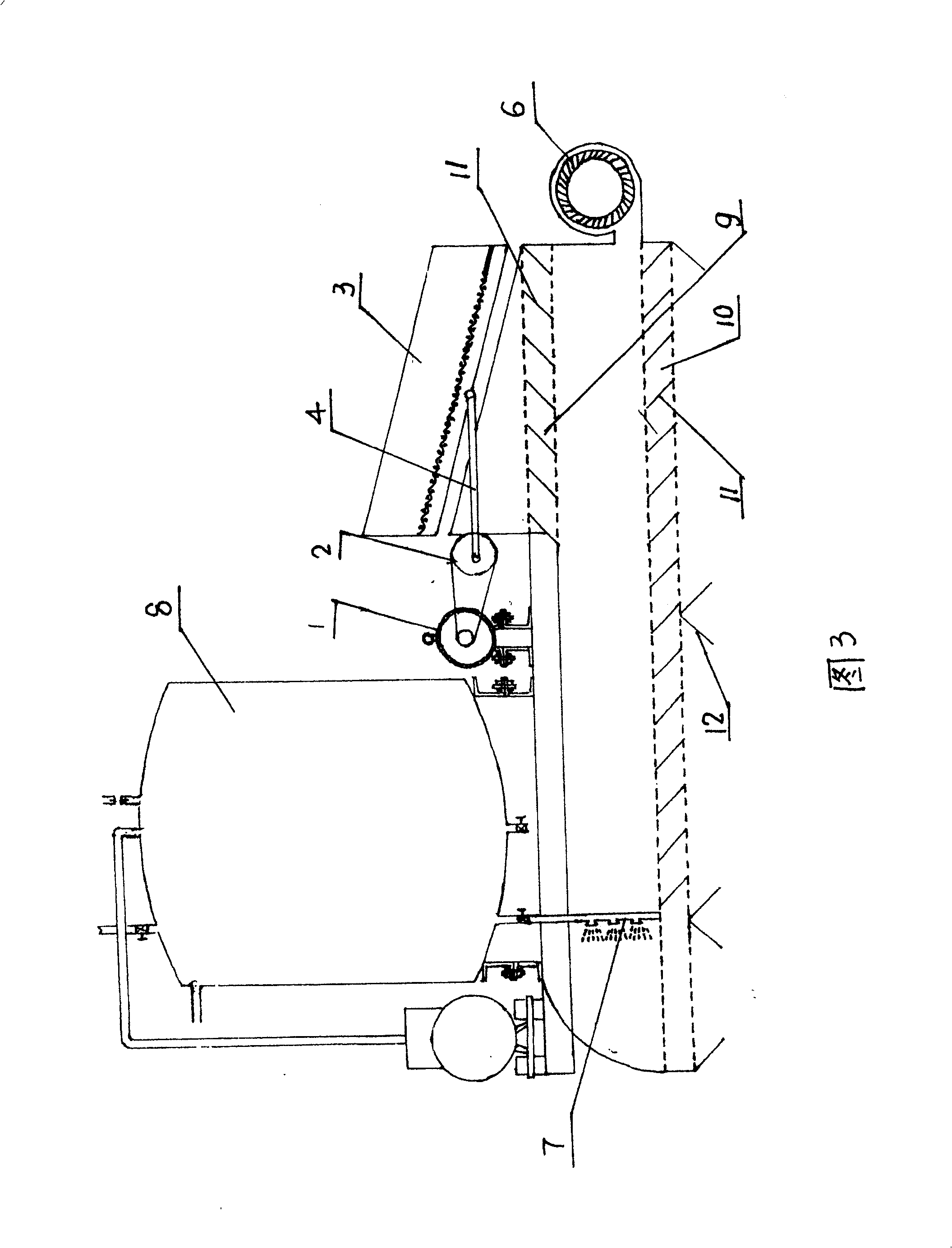

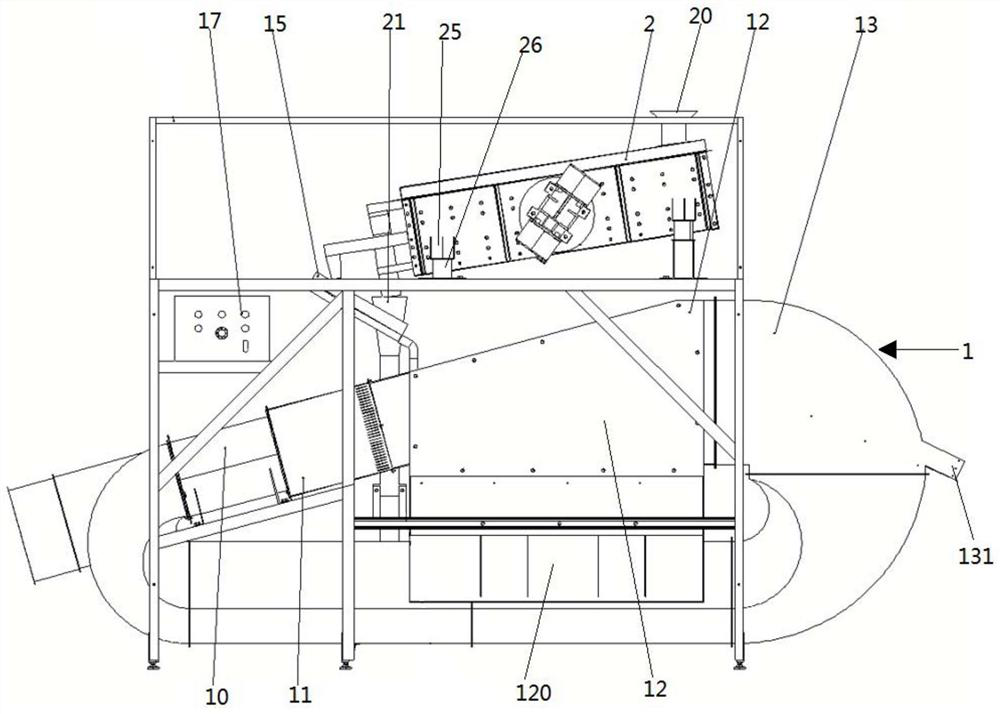

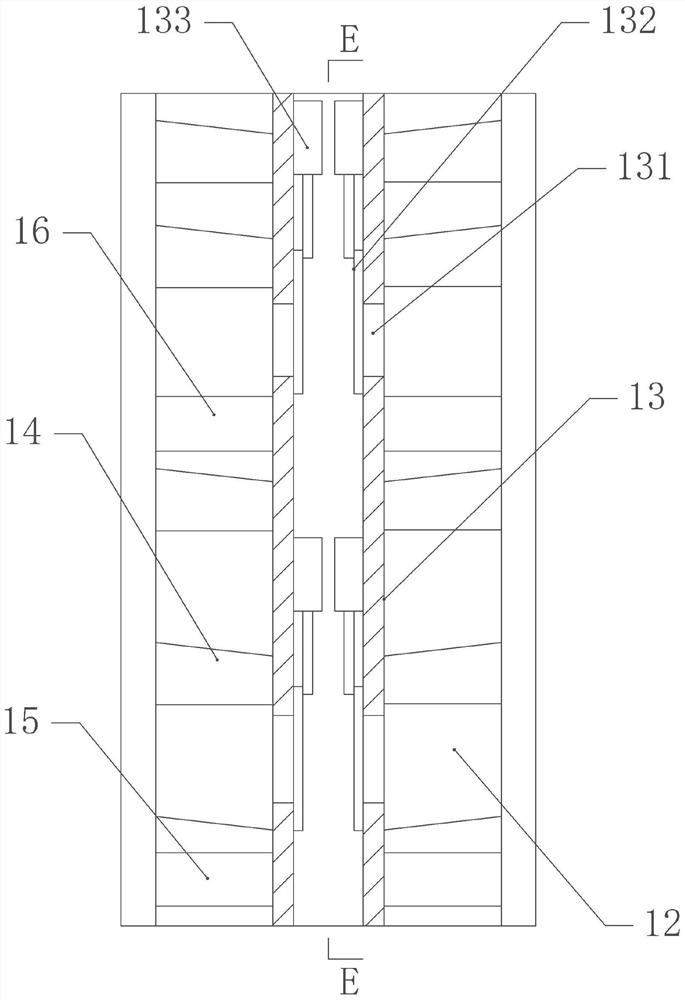

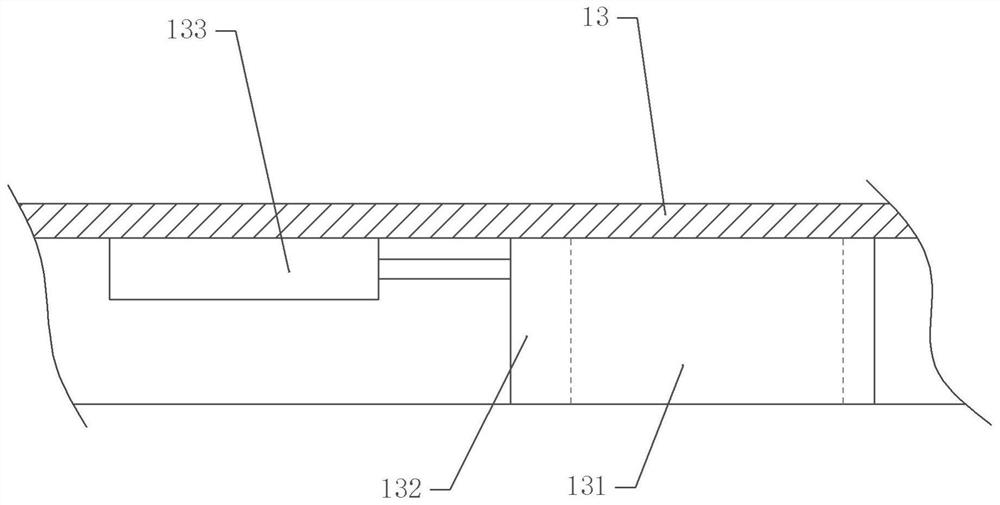

The invention discloses a casting sorting device. The casting sorting device comprises a machine frame, a conveying mechanism, a sand cleaning mechanism and a sorting mechanism. The conveying mechanism is located above one side of the sand cleaning mechanism, and the sorting mechanism is located below the other side of the sand cleaning mechanism. The conveying mechanism comprises a conveying belt. The sand cleaning mechanism comprises a frame which is connected to the machine frame in a sliding mode. The frame is obliquely arranged on the machine frame and is further connected with a plurality of connecting rods. The connecting rods are provided with a plurality of balls. The bottom side of the frame is connected with sleeves, and each sleeve is internally connected with a screw rod in a threaded mode. The screw rods are connected to the machine frame in a rotating mode. The sorting mechanism comprises a rotating disk. The rotating disk is provided with a channel opening. A plurality of sliding grooves used for communicating with the channel opening are formed in the outer side of the rotating disk. The bottom of the rotating disk is connected with a rotating rod. The rotating rod is arranged on the machine frame in a sliding mode. The rotating rod is provided with a spiral groove. A fixing rod abuts against the inside of the spiral groove. Springs are arranged between the bottom of the rotating disk and the machine frame. Compared with the prior art, sand cleaning and sorting can be conducted on castings of different weights at the same time, and working efficiency is high.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

Powder sieve with automatic controlled mesh number

InactiveCN103658012AEasy to useIncrease vibration amplitudeSievingScreeningAutomatic controlEngineering

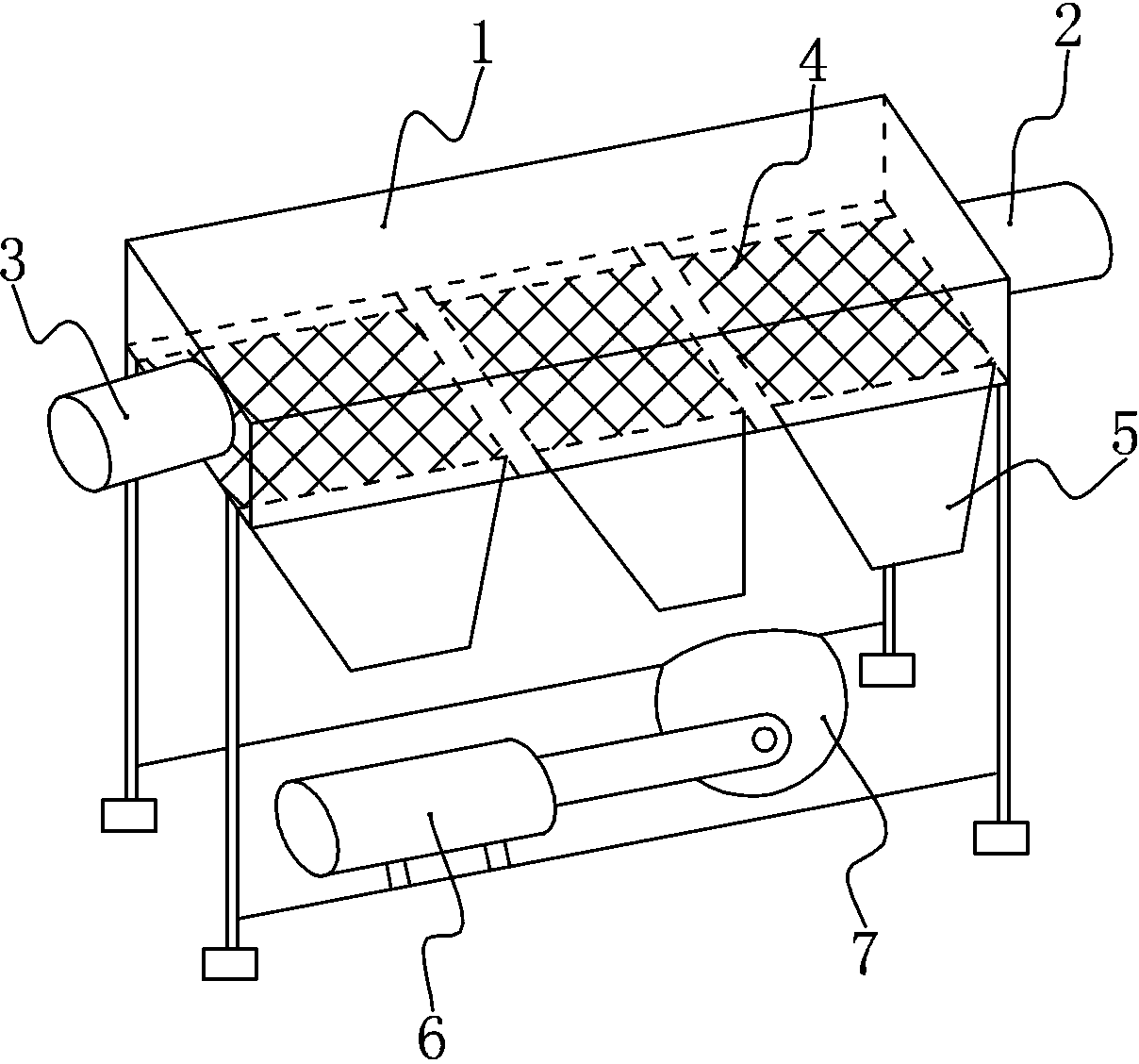

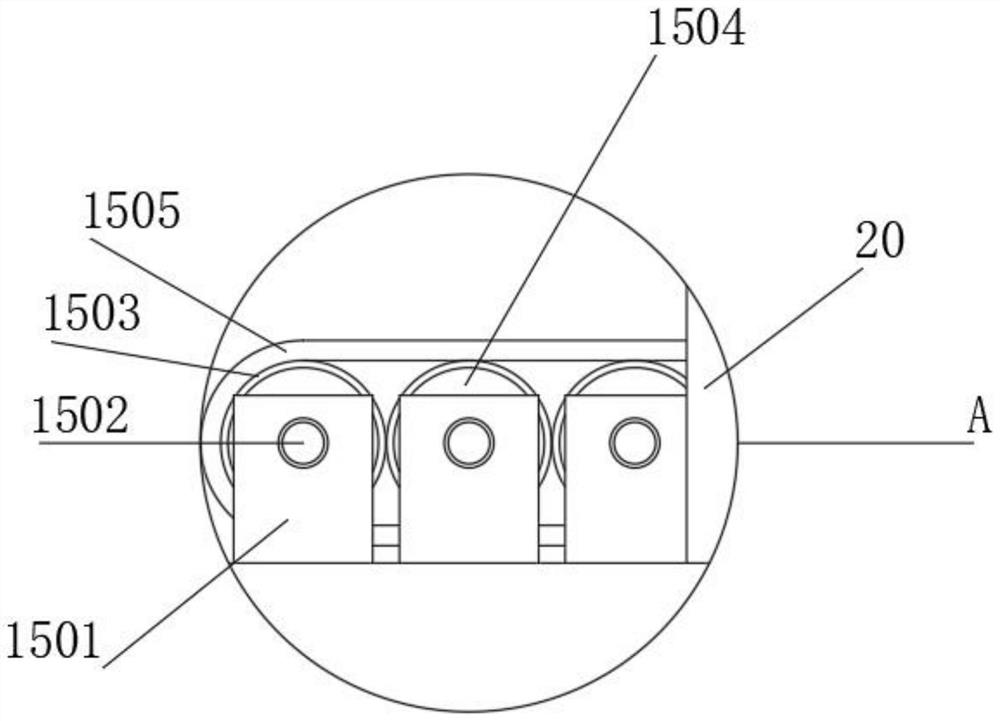

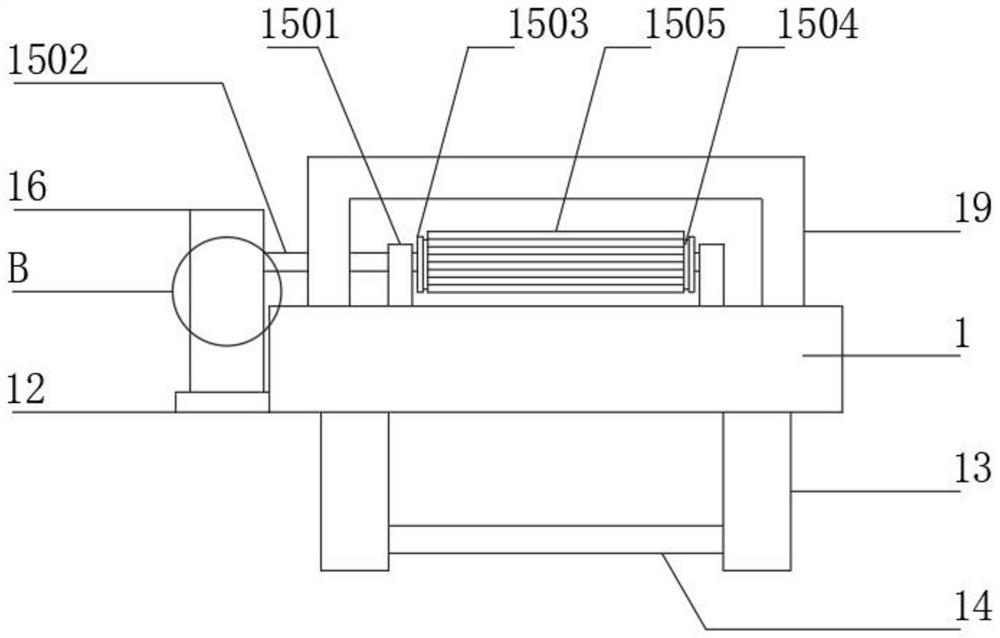

The invention discloses a powder sieve with automatic controlled mesh number. The powder sieve comprises a closed casing fixed to a vibrating support, and a feed inlet and a discharge outlet are respectively arranged on two opposite sides of the casing and located on the same straight line. The bottom surface of the casing tilts downwards from the feed inlet to the discharge outlet. At least three sorting ports of the casing are disposed on the bottom surface of the casing, and three screens are arranged at the tops of the sorting ports, are respectively superposed on the bottom surface of the casing and are respectively fastened in a chute at the bottom of the casing. The sorting ports are arranged on the bottom surface of the casing side by side. Powder raise in plants can be avoided during sieving, so that a good environment is provided for workers. Besides, the powder sieve provided with an automatic sieving device is simple in structure, low in cost and convenient to use. As the bottom surface of the casing is arranged obliquely, powder can be sieved automatically from the feeding process to the sorting process.

Owner:CHONGQING CHENGSHUO TECH

Liquid marble sorting and collecting device

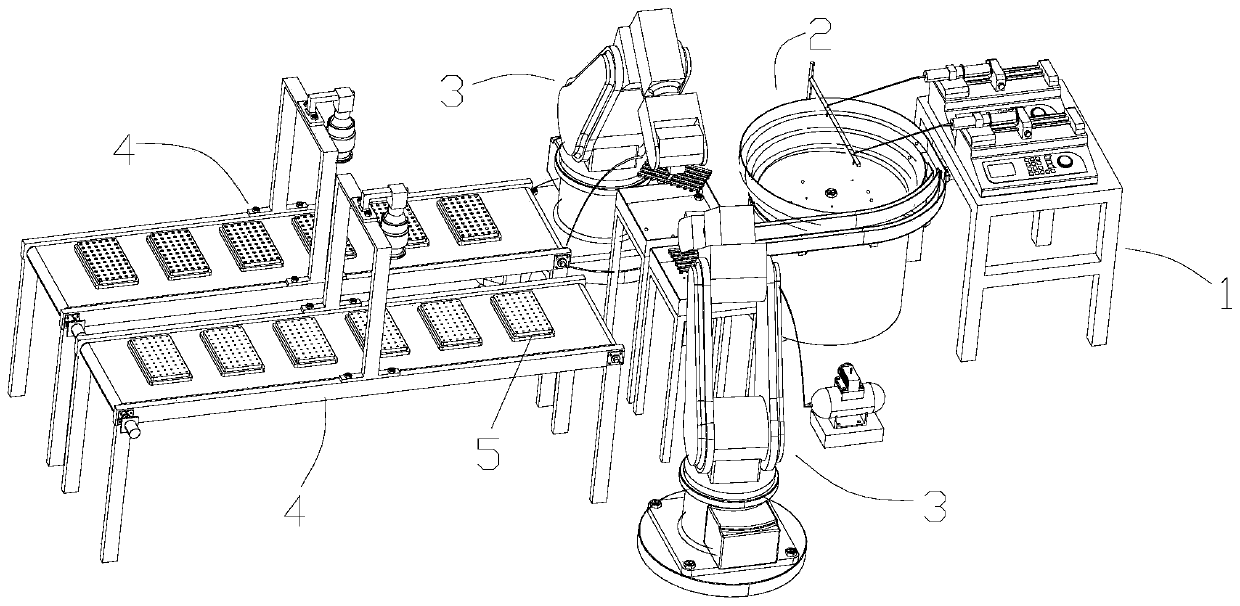

PendingCN111547505AImprove production efficiencyAchieve the purpose of sortingGranulation by liquid drop formationSortingPhysicsTransfer mechanism

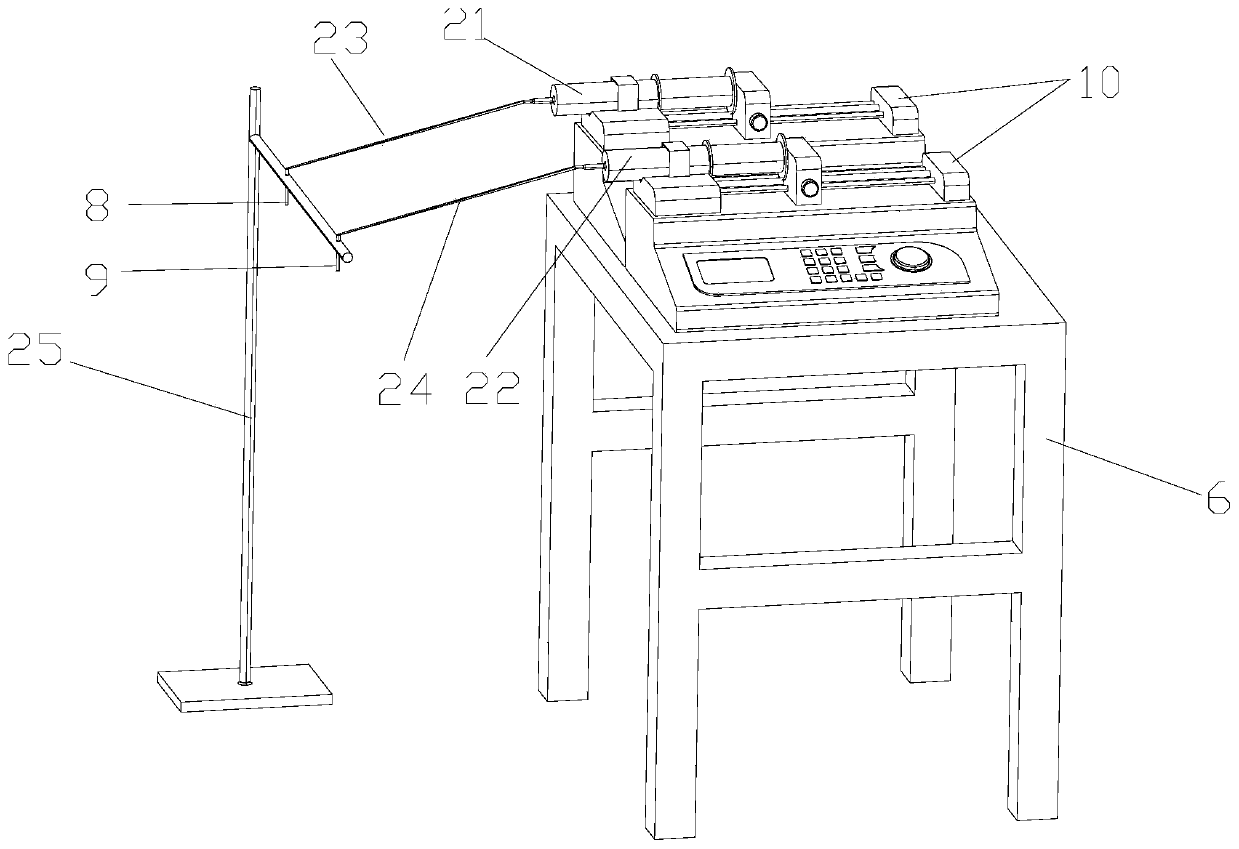

The invention discloses a liquid marble sorting and collecting device. The device comprises a liquid injection mechanism, a preparing and sorting mechanism, two collecting and transferring mechanisms,two detecting and conveying mechanisms and a plurality of marble boxes, wherein liquid drops pass through a first liquid outlet needle and a second liquid outlet needle which are different in size through two injection pumps to be dripped into a vibration disc paved with hydrophobic particles; then liquid marbles, formed by vibration wrapping, with different sizes are sorted through a sorting component; after sorting is completed, the liquid marbles with different sizes enter a first marble storage disc and a second marble storage disc through respective slide ways to be stored; the liquid marbles with corresponding sizes are sucked through suction cups on two mechanical arm assemblies correspondingly and put into the corresponding marble boxes, and the purpose of ordered collection is achieved; and finally, the detecting and conveying mechanisms carry out image acquisition, the state of the liquid marbles in the marble boxes is detected, the liquid marbles with different sizes are sorted and collected in order, and the preparation efficiency of the liquid marbles is improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

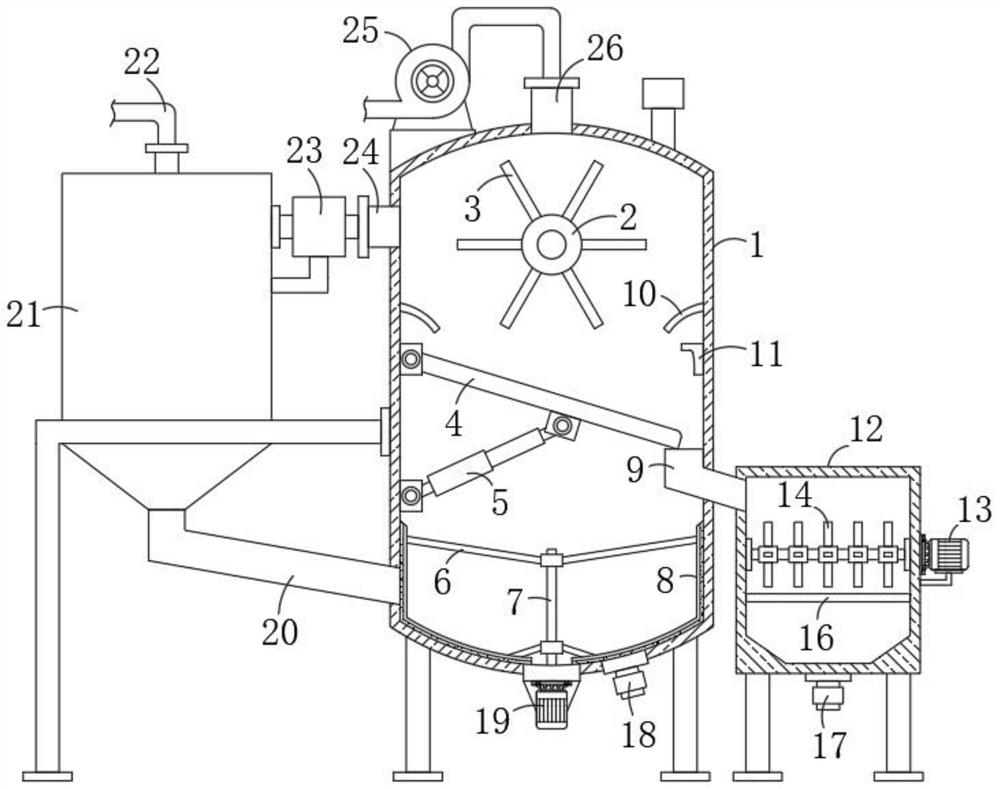

Flexible air flow powder removal method for waste ternary lithium batteries

ActiveCN110694771AImprove powder removal efficiencyAvoid powder entrainment problemsWaste accumulators reclaimingGrain treatmentsMetallurgyAluminum foil

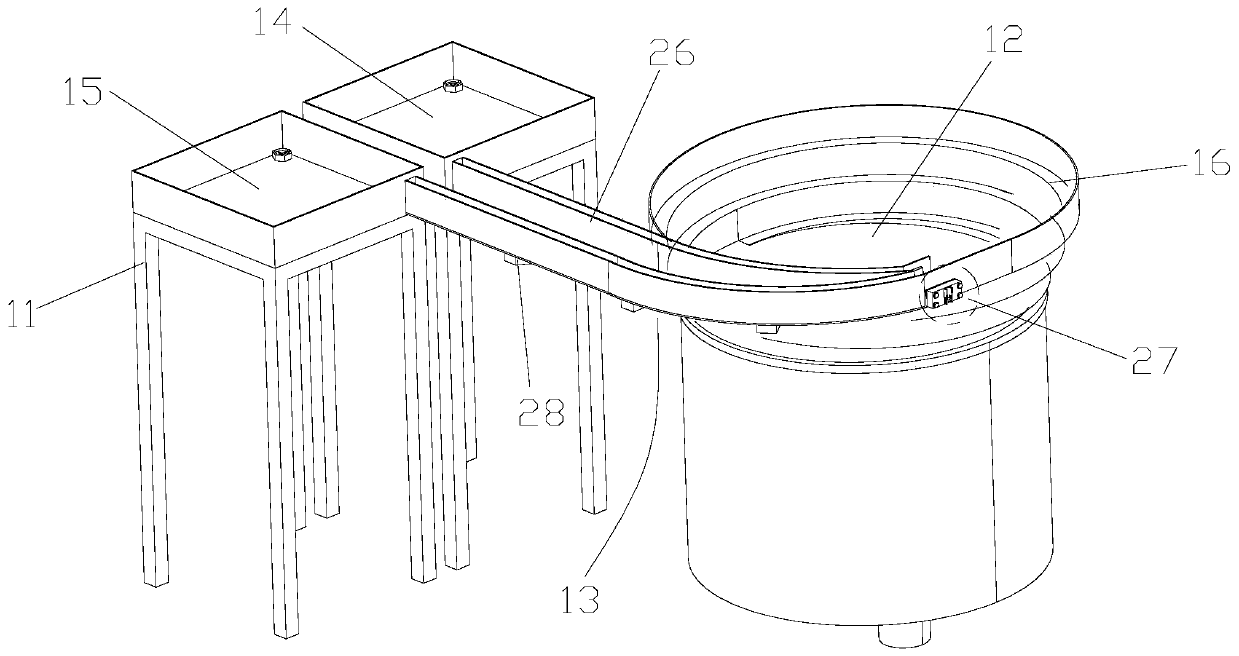

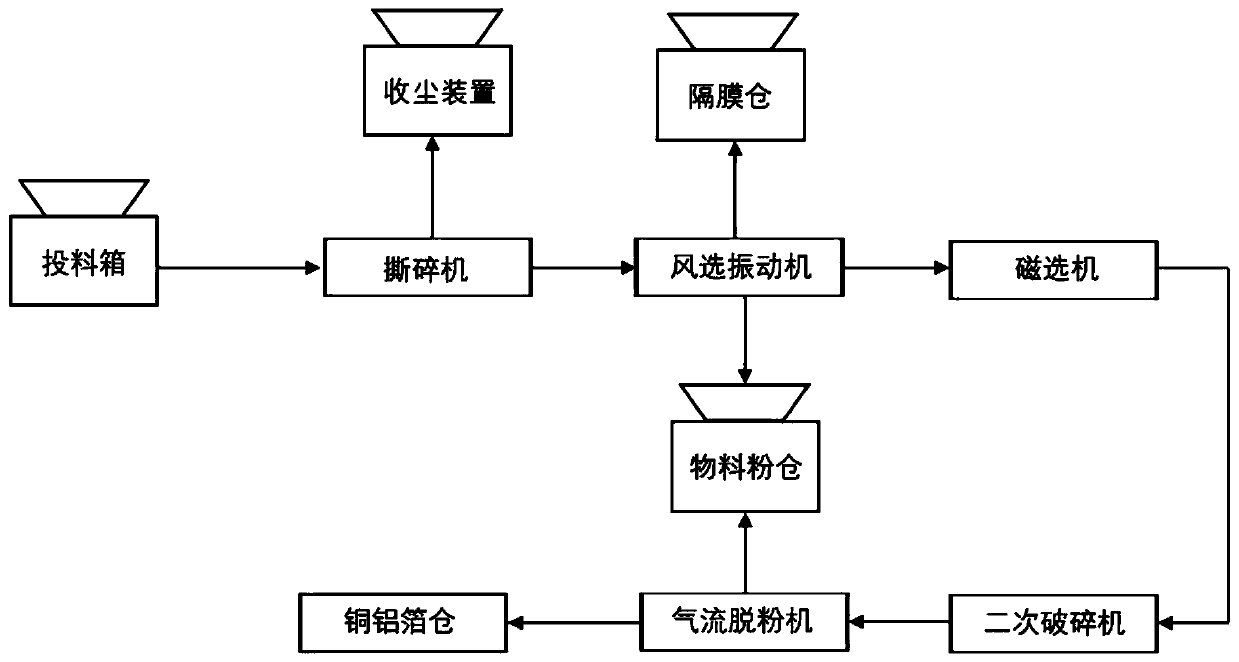

The invention relates to the technical field of material recovery of waste ternary lithium batteries, and provides a flexible air flow powder removal method for waste ternary lithium batteries. The method mainly includes the steps of putting the waste ternary lithium batteries into a battery shredder to be primarily shredded, collecting dust from volatile gas, conveying the shredded batteries intoa winnowing vibrator for primary powder separating and diaphragm winnowing, transferring winnowed diaphragms to a diaphragm bin, making screened-out powder enter a material powder bin, making screened-out crushed materials be subjected to magnetic separation and then enter a secondary crusher for fine crushing, finally making the materials enter an air flow powder remover for flexible powder removal treatment, separating out copper aluminum foil from secondarily crushed powder, and then conveying the secondary powder to the material powder bin. By means of the flexible air flow powder removalmethod, tertiary crushing and grinding do not need to be conducted on battery pole pieces, the problem that powder is carried when the battery pole pieces are rolled is avoided, the air flow powder removal speed can be flexibly adjusted, and the battery powder removal efficiency is improved.

Owner:福建常青新能源科技有限公司

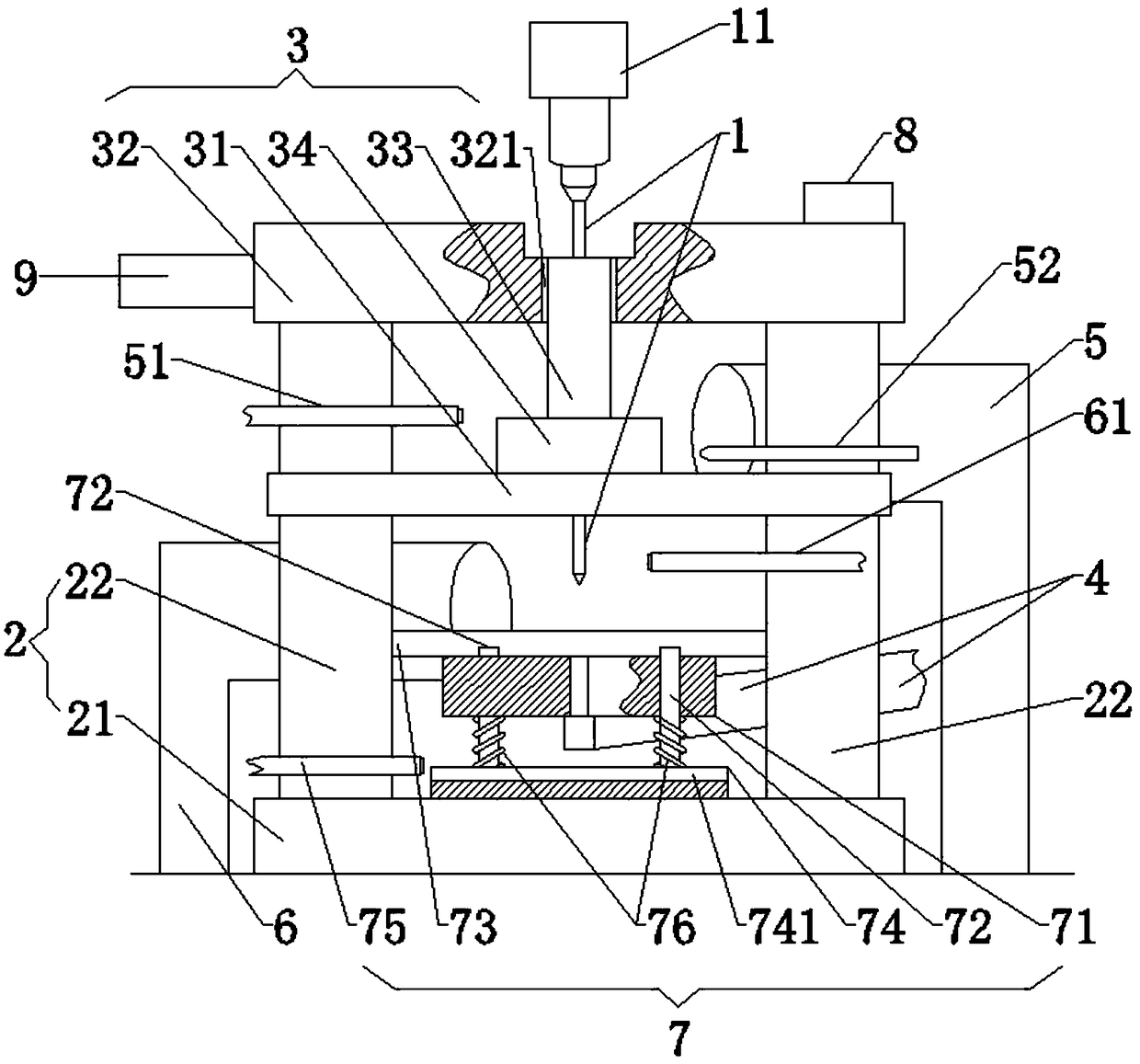

Slicing and sorting device for pumpkin finish processing and working method

ActiveCN112372732AAvoid longitudinal slice effectsImprove production and processing efficiencySortingMetal working apparatusEngineeringMechanical engineering

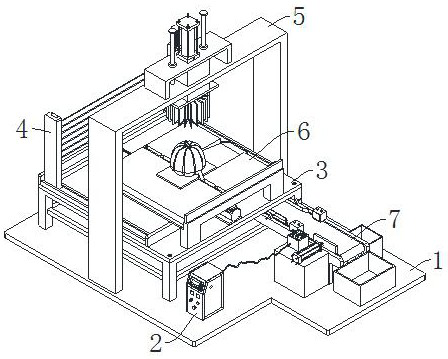

The invention relates to the technical field of pumpkin finish processing, in particular to a slicing and sorting device for pumpkin finish processing and a working method. The slicing and sorting device comprises a base, a controller, a workbench, a transverse cutting mechanism, a longitudinal cutting mechanism, a limiting mechanism and a sorting mechanism, and the controller is fixedly arrangedon one side of the top of the base. The workbench is fixedly arranged on the base and located beside the controller, the transverse cutting mechanism comprises a translation assembly, an adjusting assembly and a plurality of compression assemblies, the longitudinal cutting mechanism comprises a carrying frame, a lifting assembly and a rotating assembly, and the limiting mechanism comprises a carrying table, two clamping assemblies and two tilting assemblies. The sorting mechanism comprises a conveying belt and a detection assembly. According to the pumpkin finish processing device, pumpkin bodies to be subjected to finish processing are placed on a lifting plate, finish processing slicing and sorting can be conducted on pumpkins by operating the controller, safety, reliability, accuracy and controllability are achieved, and the pumpkin finish processing efficiency is greatly improved.

Owner:合肥市航拯工业设计有限公司

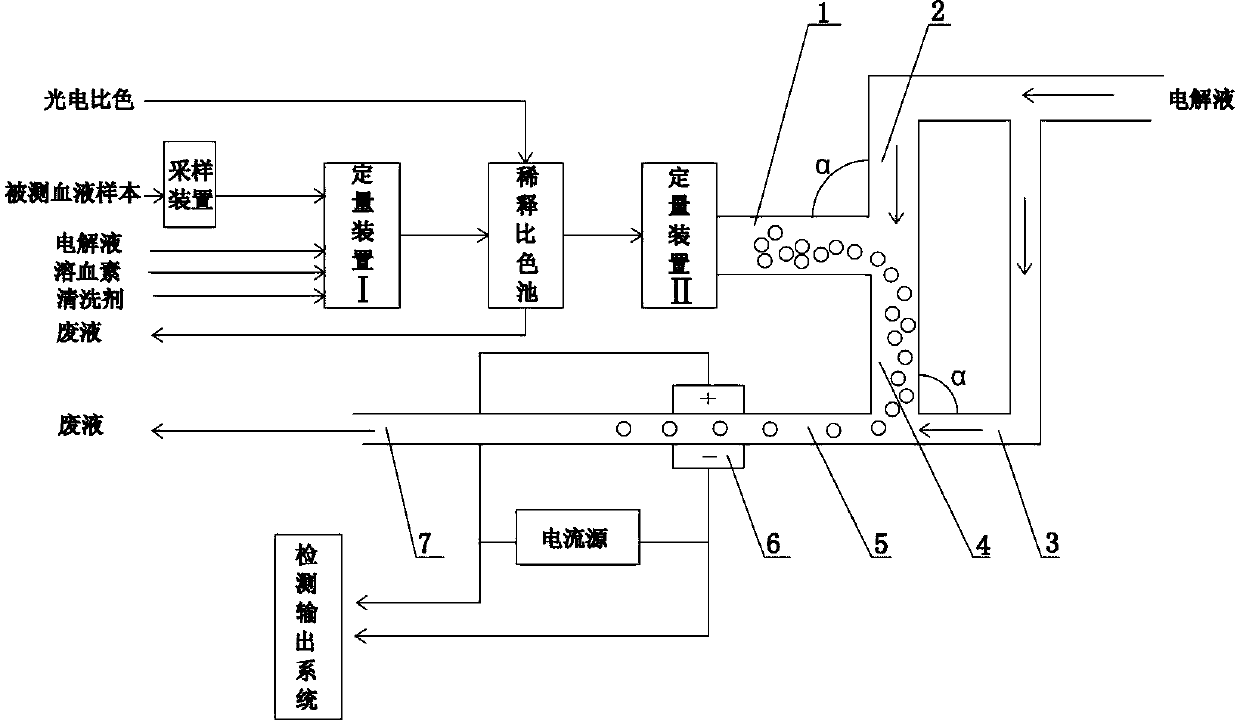

Blood cell analyzer

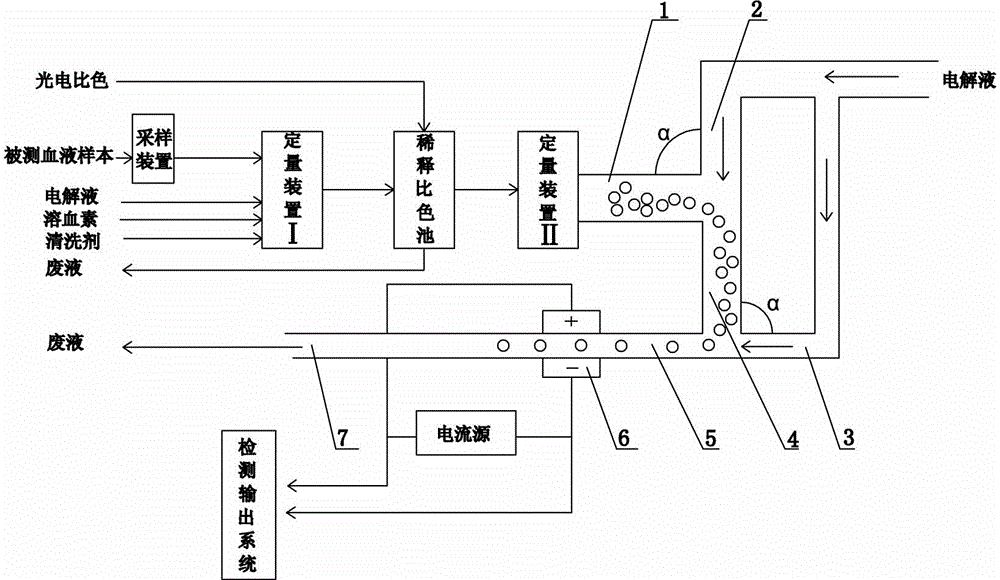

ActiveCN102981005AAchieve the purpose of sortingAvoid inaccurate test resultsMaterial analysisThree stageRed blood cell

The invention belongs to the technical field of medical detection devices, and especially relates to a blood cell analyzer. The blood cell analyzer comprises a sampling apparatus, a quantification apparatus I, a dilution colorimetric pool, a quantification apparatus II and a blood sample main tube. The blood cell analyzer is characterized in that the blood sample main tube is connected with a one-stage tangential separation sorting apparatus, the one-stage tangential separation sorting apparatus is connected with a detection electrode, or the one-stage tangential separation sorting apparatus is orderly connected with the two-stage tangential separation sorting apparatus, the three-stage tangential separation sorting apparatus until the N-stage tangential separation sorting apparatus, the N-stage tangential separation sorting apparatus is connected with the detection electrode, and the detection electrode is respectively connected with a detection analysis system and a waste liquid tube. According to the blood cell analyzer, the one-stage or multi-stage tangential separation sorting apparatus is set for carrying out one-stage, two-stage or multi-stage tangential separation sorting on the blood cells, thus, the aim of orderly sorting single blood cells is realized completely, and the problem of inaccuracy of the detection result caused by aggregation of multiple blood cells is avoided effectively.

Owner:鞍钢集团公司总医院

Miniature workpiece sorting equipment

The invention discloses miniature workpiece sorting equipment, and belongs to the technical field of miniature workpiece detection. The miniature workpiece sorting equipment comprises a material taking rod capable of doing vertical reciprocating movement, and a gravity sorting device capable of being used for pulling a workpiece to be tested, wherein the material taking rod passes through the gravity sorting device; an upper winnowing pipe capable of blowing away the workpiece to be tested is also arranged at one side of the gravity sorting device; a lower winnowing pipe capable of blowing away the workpiece to be tested is arranged under the gravity sorting device. The pulling intensity on the tubular workpiece to be tested is regulated and controlled through the gravity sorting device, the material taking rod can lift up a qualified product in an ascending process; the gravity sorting device can enable the qualified tubular workpiece to ascend and pass; then, the upper winnowing pipeblows away the workpiece to be tested, so that the sorting is convenient; a proper gravity standard block only needs to be set; drawing force does not need to be tested by a test tool; the monitoringis convenient and fast; the drawing force intensity is more standard; the measurement is not needed in each time of detection.

Owner:YINGTAN CITY RUIYUAN MINLATURE ELEMENT

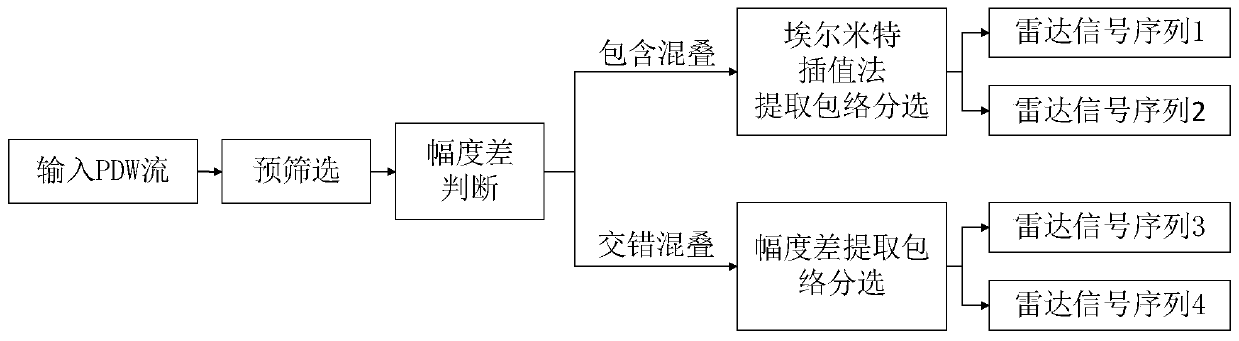

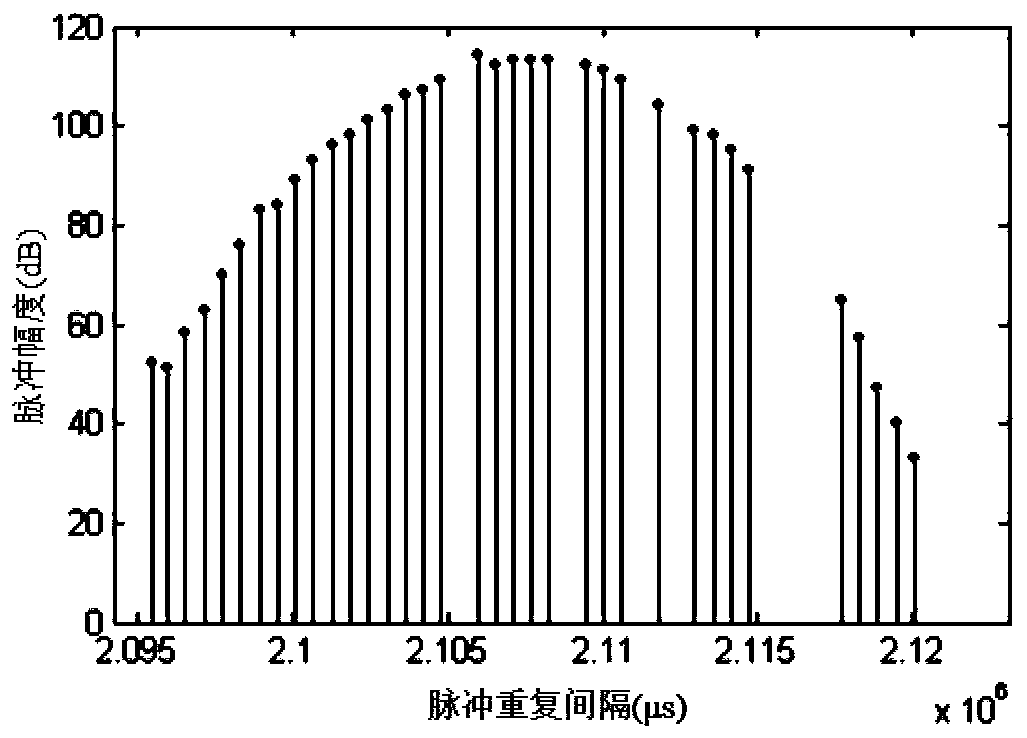

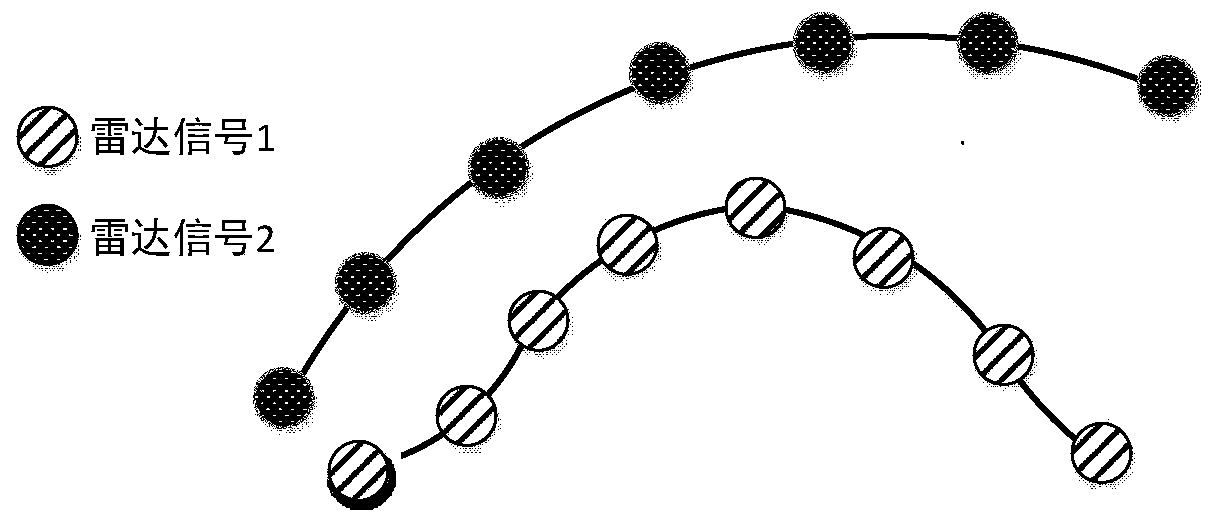

Envelope extraction algorithm for signal pulse amplitude sorting

PendingCN110263625ASorting is not easyEasy to sortCharacter and pattern recognitionRadar radiationHermite interpolation

The invention discloses an envelope extraction algorithm for signal pulse amplitude sorting. The method comprises the following specific steps of: pre-screening false pulses of a signal; modeling a Pulse Amplitude (PA) to obtain the variation characteristic of the PA; calculating an amplitude difference, and dividing PA aliasing conditions into two types according to the amplitude difference: containing aliasing and staggered aliasing; extracting the envelope of PA by using a segmented Hermite interpolation method during containing aliasing, and sorting; and during staggered aliasing, extracting the envelope of the PA by utilizing an amplitude difference algorithm and sorting to respectively obtain pure signal sequences. The envelope extraction algorithm can effectively process the aliasing radar radiation source signals under the conditions of false and missing pulses, is high in de-interlacing accuracy, and provides a more convenient and faster new method for the sorting work of the radar radiation source signals.

Owner:JILIN UNIV

Arrangement device for battery pack production and welding and use method of arrangement device

PendingCN114852721AImprove processing efficiencyReduce labor intensityFinal product manufactureWelding/cutting auxillary devicesStructural engineeringManufacturing engineering

The arrangement device for battery pack production welding comprises a conveying belt, racks are erected on the two sides of the conveying belt correspondingly, guide plates are fixedly connected to the positions, located at the tail section of the conveying belt, of the two racks correspondingly, and a supporting plate is fixedly connected between the tops of the ends, away from the conveying belt, of the two racks; a U-shaped material taking frame is movably connected to the side, close to the conveying belt, of the supporting plate, a first push plate and a limiting plate are arranged in the U-shaped material taking frame, an L-shaped flow limiting plate is rotationally connected between the ends, close to the U-shaped material taking frame, of the two flow guide plates, and a second push plate is detachably connected to the upper portion of the U-shaped material taking frame. According to the device, the U-shaped material taking frame used for receiving materials is arranged at the tail end of the battery conveying belt, the U-shaped material taking frame is in butt joint with the tail end of the conveying belt, the batteries on the conveying belt can enter the U-shaped material taking frame, the batteries are tightly connected due to mutual extrusion, and only the positions of a small number of batteries need to be manually adjusted subsequently; and the machining efficiency of battery welding is greatly improved, and the labor intensity of workers is reduced.

Owner:JIANGSU YONGCHANG NEW ENERGY TECH

Roxburgh rose sorting system based on machine vision

PendingCN109499905AAchieve the purpose of sortingImprove sorting efficiencyInvestigation of vegetal materialSortingMachine visionRecognition system

The invention discloses a roxburgh rose sorting system based on machine vision. The system comprises a detection conveyor, a machine vision recognition system is arranged on the upstream position of the detection conveyor, the machine vision recognition system is used for recognizing the colors and / or sizes of roxburgh roses, a pushing flow dividing mechanism is arranged at the downstream positionof the detection conveyor, and is suitable for pushing the roxburgh roses to different flow dividing channels according to the colors and / or sizes of the roxburgh roses, and classifying of the roxburgh roses is finished; the machine vision recognition system is used for recognizing the colors and sizes of the roxburgh roses, the pushing flow dividing mechanism sorts the roxburgh roses with the different colors and sizes out of the different flow dividing channels, and the aim of roxburgh rose sorting can be achieved. Compared with the traditional screening manner, the automatic assembly linemanner is adopted, and the roxburgh rose sorting efficiency is greatly improved.

Owner:GUIZHOU UNIV

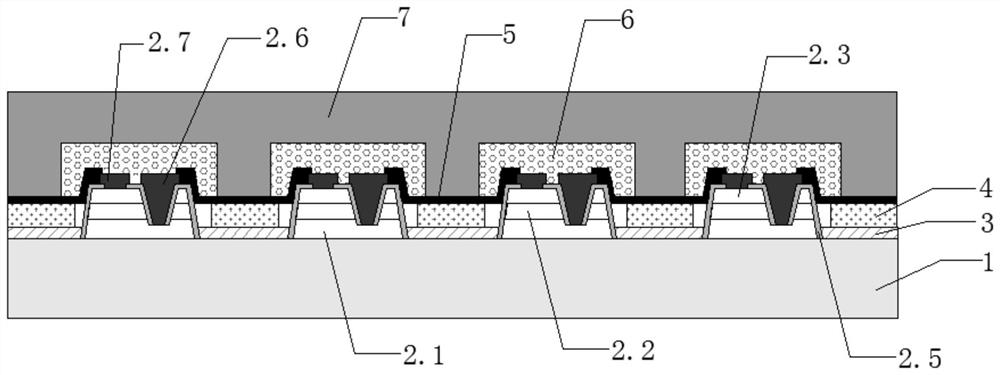

Micro device facilitating picking and testing, manufacturing, testing and transferring method and display

PendingCN112447787AReach permutationAchieve the purpose of sortingSemiconductor/solid-state device testing/measurementSolid-state devicesDisplay deviceStructural engineering

The invention provides a micro device facilitating picking and testing, a manufacturing, testing, transferring method and a display. A first sacrificial layer is arranged on the surface of a groove, and all testing electrodes are distributed above the first sacrificial layer corresponding to the groove at intervals and are far away from an LED core particle; the device also comprises multiple metal bridges, the metal bridges and the test electrodes are distributed in a crossed manner, the metal bridges are used for connecting the electrodes of two adjacent LED core particles in series, and themetal bridges are connected with the test electrodes at the corresponding grooves of the two adjacent LED core particles; the second sacrificial layer coats each LED core particle to form an independent coating unit; therefore, the integration of the LED core particles and the test structure is realized, and meanwhile, the purposes of arranging and sorting the LED core particles are achieved, sothat the perfect connection of subsequent test and transfer processes is ensured.

Owner:XIAMEN QIANZHAO SEMICON TECH CO LTD

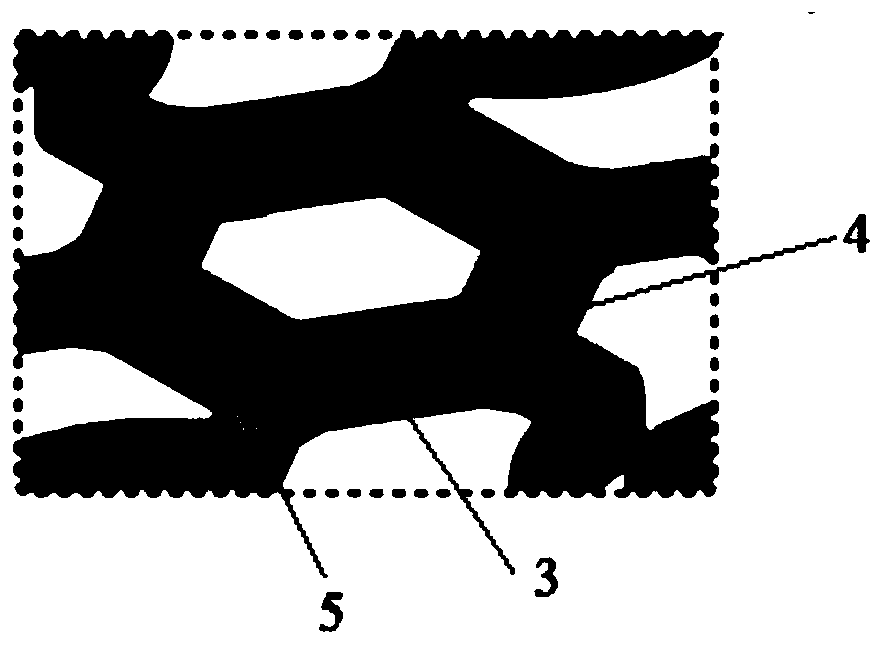

Integrated microfluidic chip for drug screening and application thereof

PendingCN109722387AFlexible switchingAvoid mutual interferenceMicrobiological testing/measurementTissue/virus culture apparatusConcentration gradientEngineering

The invention discloses an integrated microfluidic chip for drug screening. The chip is formed by a flow layer and a glass layer; the flow layer is provided with a concentration gradient structure generation region; the concentration gradient structure generation region is provided with a hexagonal fluid channel; the hexagonal fluid channel is provided with three sample introduction ports; the periphery of the hexagonal fluid channel is provided with six first micro channels; the liquid outlet ends of the first micro channels communicate with first micro-ring circle channels; the liquid outletends of the first micro-ring circle channels communicate with annular channels; the annular channels are provided with twelve second micro channels; the liquid outlet ends of the second micro channels communicate with second micro-ring circle channels; the liquid outlet ends of the second micro-ring circle channels communicate with buffering channels; and the liquid outlet ends of the buffering channels communicate with cell culture chambers. The same drug treatment can be used for two different cells through the layout with different micro-pipeline networks; and therefore, the purpose of cell sorting and drug screening can be achieved by forming drug concentration gradients to act on same or different cells.

Owner:SHANXI AGRI UNIV

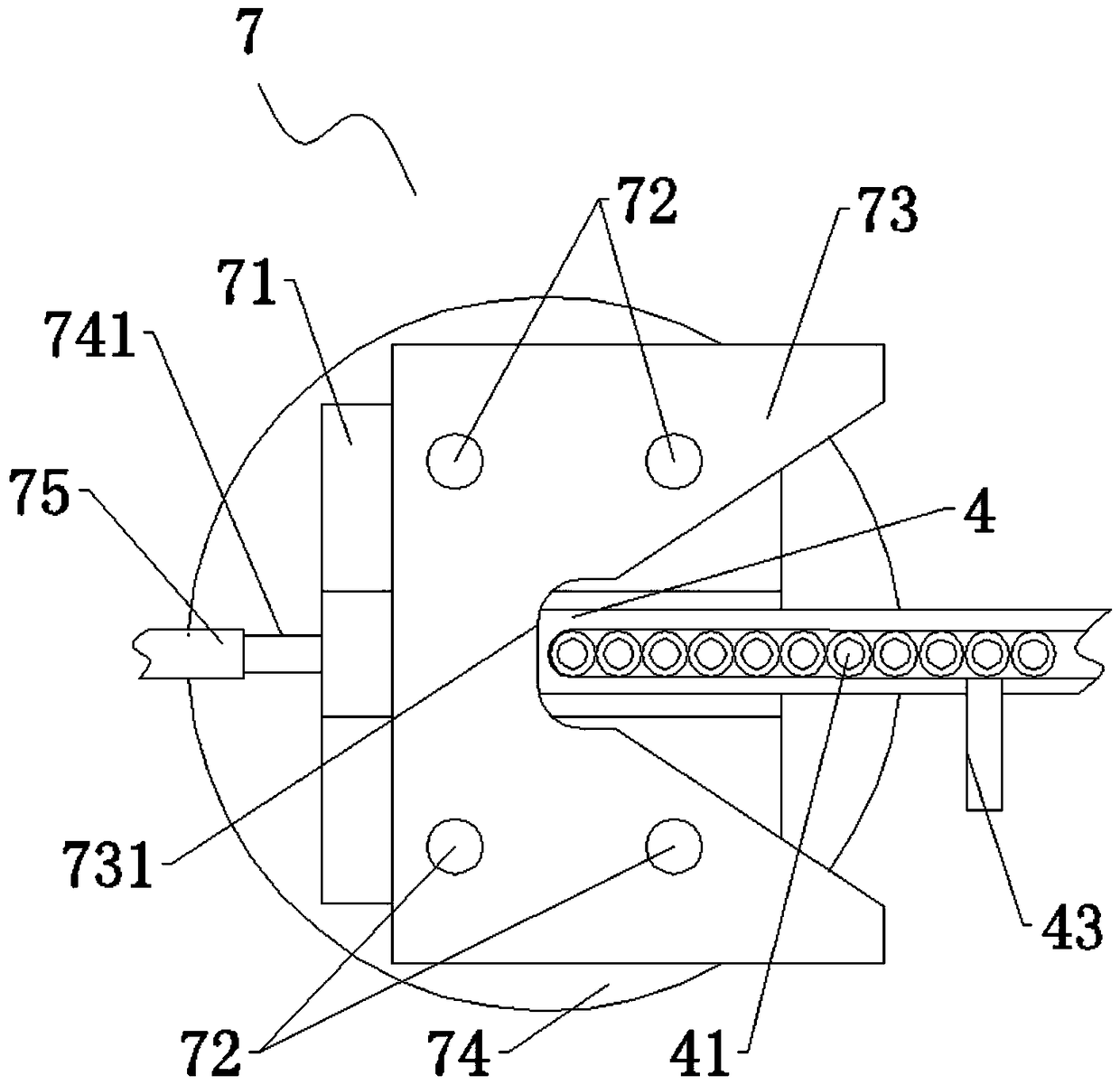

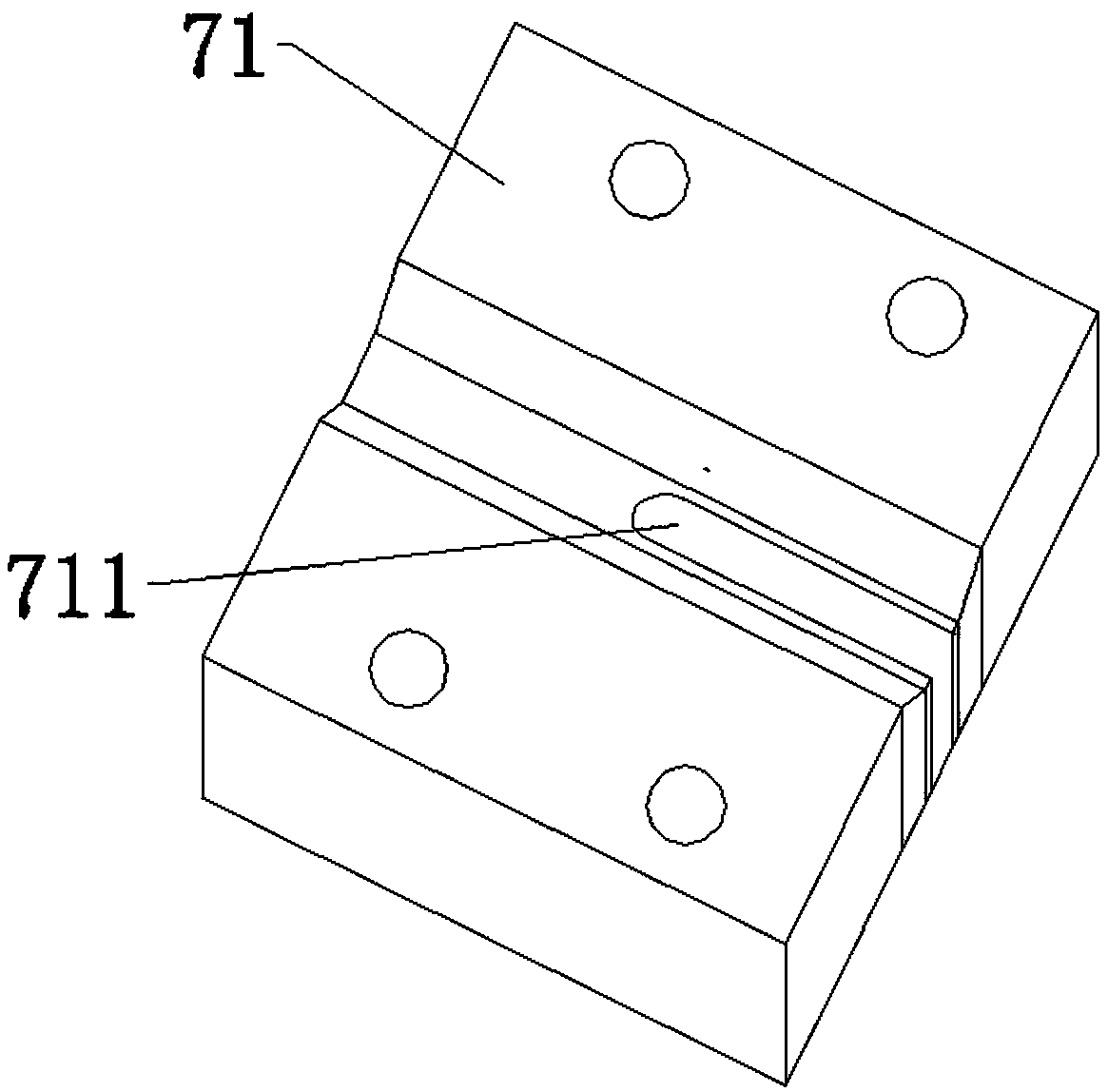

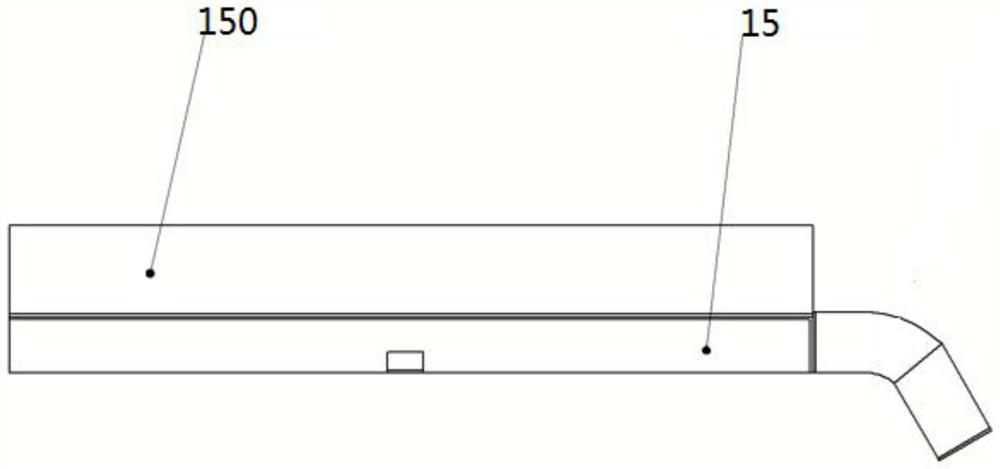

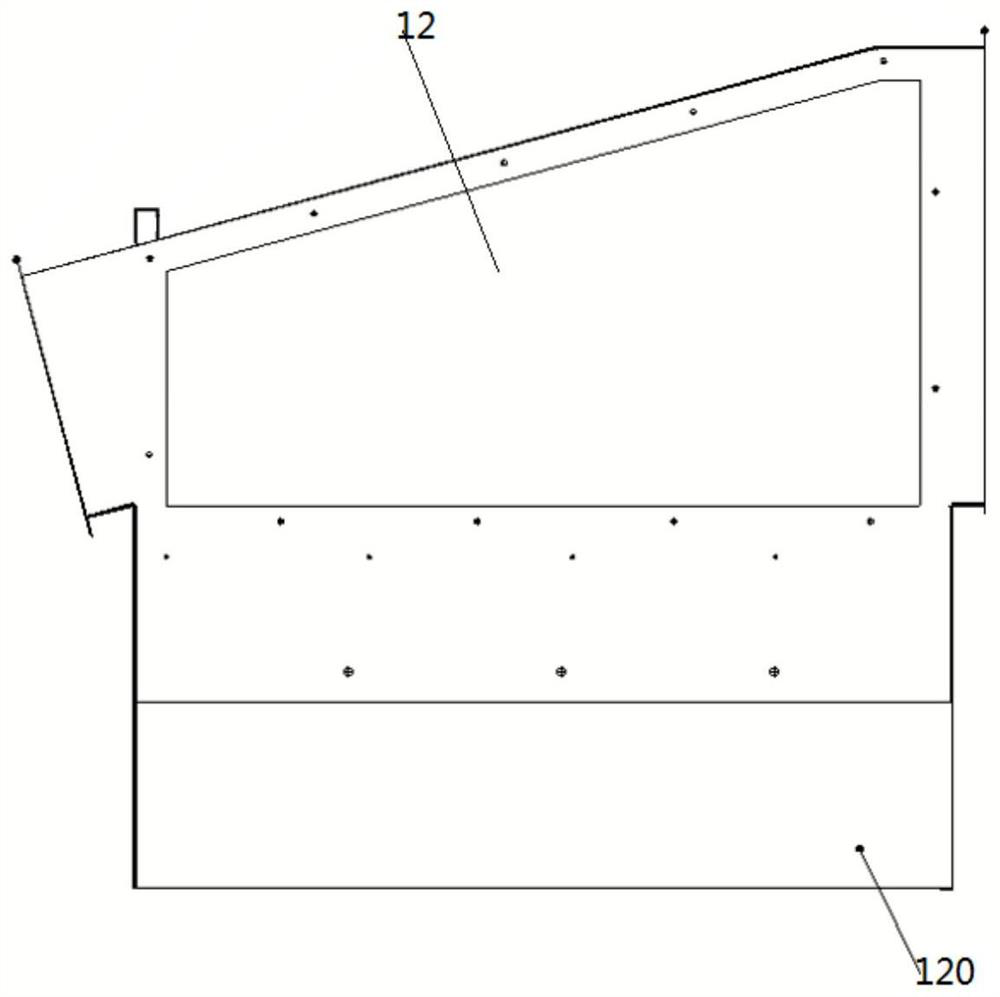

Casting sorting device

The invention discloses a casting sorting device. The casting sorting device comprises a machine frame, a conveying mechanism, a sand cleaning mechanism and a sorting mechanism. The conveying mechanism is located above one side of the sand cleaning mechanism, and the sorting mechanism is located below the other side of the sand cleaning mechanism. The conveying mechanism comprises a conveying belt. The sand cleaning mechanism comprises a frame which is connected to the machine frame in a sliding mode. The frame is obliquely arranged on the machine frame and is further connected with a plurality of connecting rods. The connecting rods are provided with a plurality of balls. The bottom side of the frame is connected with sleeves, and each sleeve is internally connected with a screw rod in a threaded mode. The screw rods are connected to the machine frame in a rotating mode. The sorting mechanism comprises a rotating disk. The rotating disk is provided with a channel opening. A plurality of sliding grooves used for communicating with the channel opening are formed in the outer side of the rotating disk. The bottom of the rotating disk is connected with a rotating rod. The rotating rod is arranged on the machine frame in a sliding mode. The rotating rod is provided with a spiral groove. A fixing rod abuts against the inside of the spiral groove. Springs are arranged between the bottom of the rotating disk and the machine frame. Compared with the prior art, sand cleaning and sorting can be conducted on castings of different weights at the same time, and working efficiency is high.

Owner:YONGCHUAN DISTRICT CHONGQING HUAYI MACHINERY CASTING CO LTD

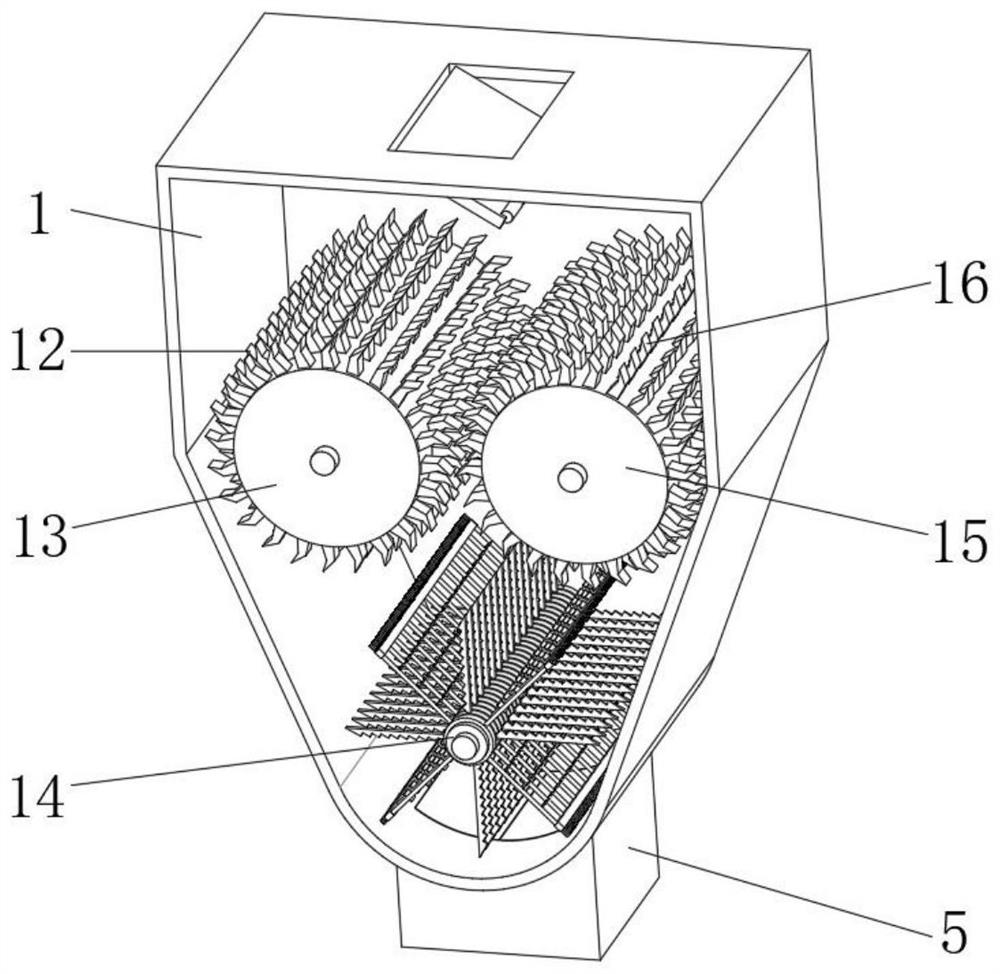

Crushing and sorting device for waste building structures

InactiveCN112871398AEnsure grinding and crushing effectAvoid accumulationGrain treatmentsElectric machineryDrive motor

The invention belongs to the technical field of waste building structure treatment equipment, and particularly relates to a crushing and sorting device for waste building structures. The crushing and sorting device aims at solving the problems that existing treatment equipment for the waste building structures cannot treat the structures in place, the crushing effect is poor, sorting of the structures is greatly influenced, and subsequent treatment of the structures is influenced. According to the scheme, the crushing and sorting device comprises a box body and a mounting frame, wherein a feeding pipe is fixedly arranged at the top of the box body, a mounting rod is fixedly arranged in the feeding pipe, a rotating rod is rotationally arranged on the mounting rod, a plurality of crushing rods are fixedly arranged on the rotating rod, a driving motor is fixedly arranged at the top of the box body, and the top end of a driving shaft is fixedly arranged on an output shaft of the driving motor. The crushing and sorting device is convenient to use, the waste building structures can be fully ground and crushed, the crushed structures can be sorted, and the subsequent treatment efficiency of the structures is effectively improved.

Owner:郁家府

Computer hard disk destroying device and operation method thereof

InactiveCN113102081AIncrease attractivenessReduce descent speedHollow article cleaningGrain treatmentsElectric machineryEngineering

The invention discloses a computer hard disk destroying device and an operation method thereof, and relates to the technical field of computer hard disk destroying devices. Waste separation is facilitated. The computer hard disk destroying device comprises a body, a base, a crushing mechanism, a smashing mechanism and a sorting mechanism, the outer walls of the two sides of the body are mounted on the outer wall of the top of the base through a mounting frame, two supporting ribs are arranged on the outer walls of the two sides of the bottom end of the mounting frame, the crushing mechanism and the smashing mechanism are arranged in the body, and a discharging opening is formed in the bottom of the body. The operation method of the computer hard disk destroying device comprises the following steps that a computer hard disk to be destroyed is put into the body in a manner of pressing a feeding door; and a first motor is controlled to work to drive a first crushing roller and a second crushing roller to preliminarily crush the hard disk. According to the computer hard disk destroying device and the operation method thereof, by arranging the sorting mechanism, the hard disk can be discharged after being crushed in the body, a first electromagnet is electrified in the discharging process, magnetic metal materials in waste can be attracted, so that the sorting purpose is achieved, and classification treatment is facilitated.

Owner:郑小元

Mixed dust removal equipment based on powder coating for plastic processing

InactiveCN112122296AImprove resource utilizationReduce manufacturing costSievingScreeningComposite materialManufacturing engineering

The invention discloses mixed dust removal equipment based on a powder coating for plastic processing, and relates to the technical field of powder coating production and processing. The mixed dust removal equipment based on the powder coating for plastic processing comprises a machine body, wherein a dust inlet pipe is connected to the middle of the top end of the machine body, and a dust suctionfan is arranged on one side of the top of the machine body; a first discharging valve is connected to one side of the bottom end of the machine body, and a screening plate is hinged to the middle ofthe interior of the machine body; and a rotating drum is movably arranged inside the machine body and located above the screening plate, and six blade plates distributed in an annular array mode are fixed to the outer circumferential face of the rotating drum. According to the mixed dust removal equipment based on the powder coating for plastic processing, through the arrangement of the screeningplate, screening holes and an electric push rod, floating dust can be screened, so that the powder coating is conveniently recovered in a classified mode, then the recycling of the powder coating is facilitated, the resource utilization rate is effectively improved, the production cost is greatly reduced, and the production benefit is favorably increased.

Owner:JUYE JINHUA PLASTIC POWDER

Bag food sorting method and device

The invention relates to the technical field of screening, and discloses a bagged food separation method and device. The bagged food device comprises a vertical separation barrel and a drive piece used for driving the separation barrel to rotate. Multiple separation shafts are hinged in the separation barrel. The periphery of each separation shaft is fixedly connected with lugs. A sliding plate isarranged at the bottom in the separation barrel. Water holes are formed in the sliding plate. A discharge port is arranged on the side wall of the separation barrel. A baffle used for closing the discharge port is hinged to the sliding plate. A fixing hole is formed in the lower portion of the baffle. A fixing piece penetrating through the bottom of the separation barrel is arranged below the fixing hole. The fixing piece and the fixing hole are detachably connected. The bagged food separation method and device are simple in structure, and bagged food can be separated so that the bagged foodwhich is not well packaged can be discharged.

Owner:重庆好弟兄食品有限公司

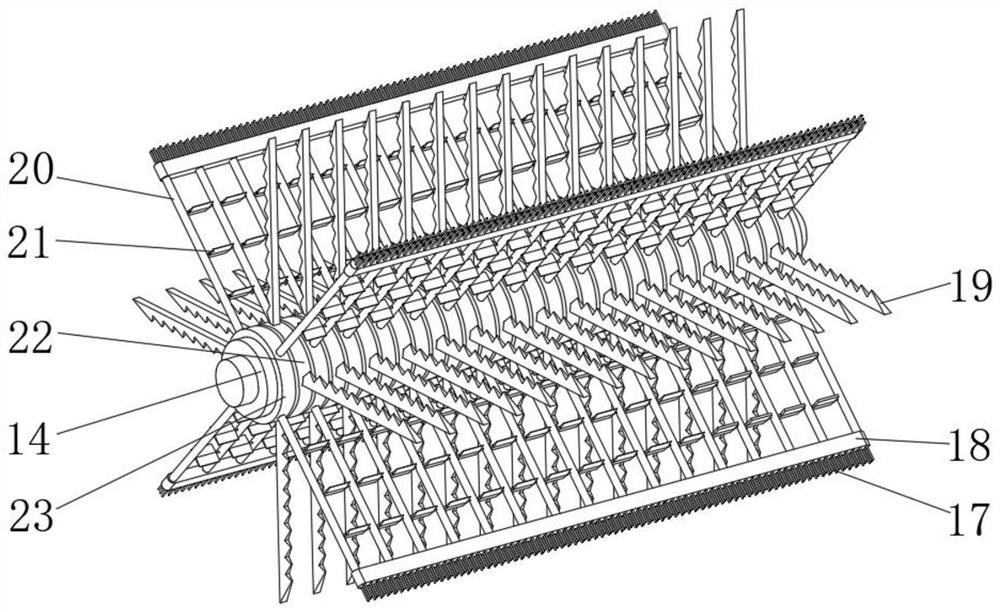

Plastic film dry cleaning machine

PendingCN110883981AEasy dischargeFacilitate strippingPlastic recyclingPlastic filmStructural engineering

The invention provides a plastic film dry cleaning machine. The plastic film dry cleaning machine comprises a material barrel, a plastic film sorting mechanism, a material sorting screen and a discharging frame. The plastic film sorting mechanism comprises a rotary barrel and multiple material beating rows. Each material beating row comprises multiple material beating devices. Each material beating device comprises an erecting rod and a beating block. A spiral section and a straight section are arranged in the arrangement direction of the multiple beating blocks around the axial arrangement direction of the rotary barrel. The multiple beating blocks are spirally arranged around the axial direction of the rotary barrel on the spiral section. The arrangement direction of the multiple beatingblocks and the axial direction of the rotary barrel are arranged in parallel on the straight section. As the plastic film dry cleaning machine is provided with the plastic film sorting mechanism, plastic films are beaten and drawn-thrown in the rotating process, thus, attachments attached to the plastic films can be stripped in the beating and drawing-throwing processes, and then the effect of washing the plastic films is achieved.

Owner:浙江青草地环境科技有限公司

Conveying automatic loose sorting device

ActiveCN110641965ABreak the balanceAvoid jammingConveyorsConveyor partsElectric machineryStructural engineering

The invention relates to a conveying automatic loose sorting device which comprises a mounting plate; mounting plate is fixedly provided with a drive device and a rubbing assembly connected with the drive device; the rubbing assembly comprises a first rubbing plate and a second rubbing plate; the first rubbing plate and the second rubbing plate are fixed on two different line track sliders respectively; the line rail sliders are connected with linear guide rails respectively; the two wire track sliders are connected with each other through a swing arm; one and only one of the two line rail sliders is connected with one end of a line rail slider connecting rod, and the other end of the connecting rod is connected with an eccentric block; the drive device drives the eccentric block and the connecting rod to move to enable the linear rail sliders to move on the linear guide rails respectively; and the first rubbing plate and the second rubbing plate perform rubbing through the swing arm along with the linear rail sliders respectively. For the conveying automatic loose sorting device provided by the invention, by driving the two rubbing plates by the drive motor to perform rubbing backand forth, the rubbing action is realized to break through the balance of objects on a conveying line, and the objects are prevented from forming jamming and blockage at a discharge hole, so that thepurpose of sorting is achieved, convenience is provided to object detection at a rear section, and manual detection is replaced.

Owner:BEIJING FOCUSIGHT TECH

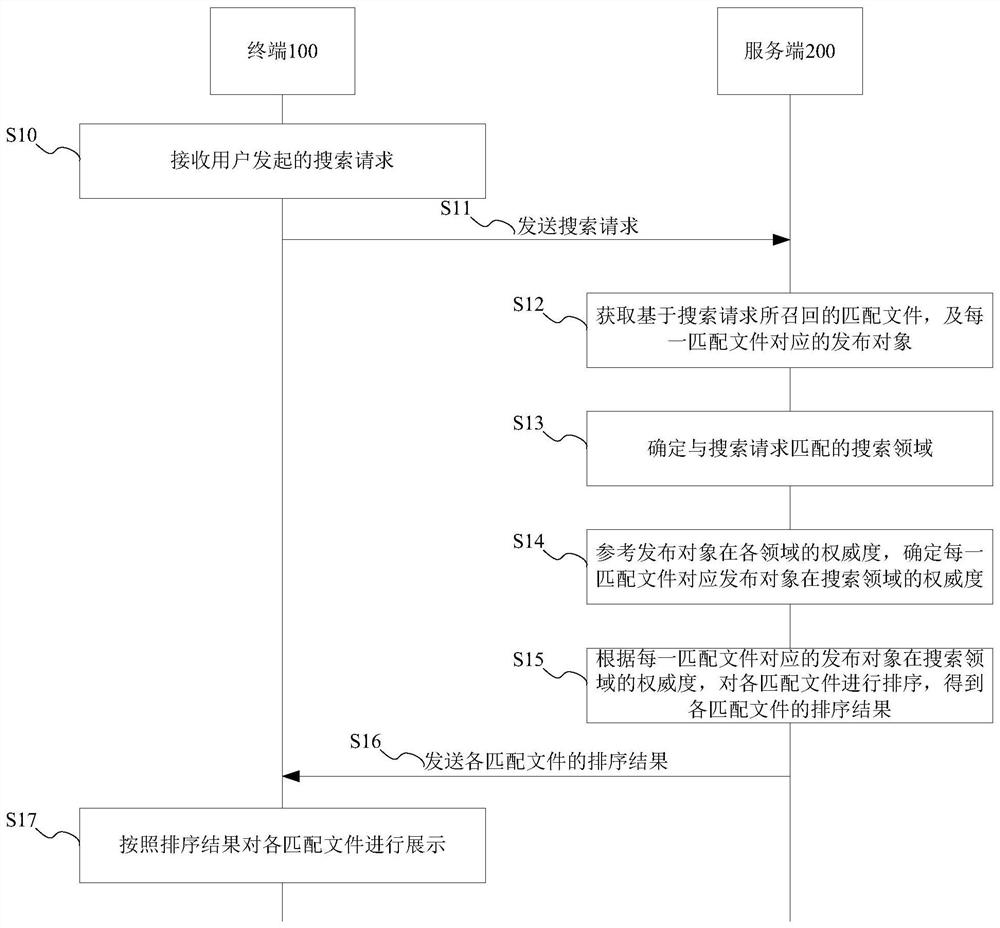

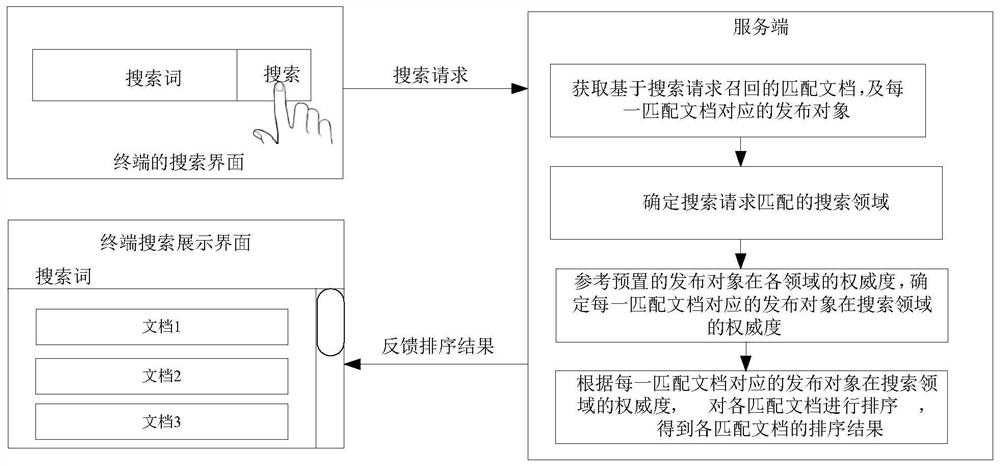

Sorting method, device, equipment, storage medium and search system for searching files

ActiveCN109144953BAchieve the purpose of sortingFile metadata searchingSpecial data processing applicationsEngineeringCollation

Embodiments of the present application provide a sorting method, device, device, storage medium, and search system for searching files. This application counts the authority of publishing objects in various fields in advance, and determines the search field that matches the search request, and then aims at recalling The matching files determine the authority of the published object in the search field. The authority can represent the quality of the matching files. Therefore, sorting the matching files based on the authority can achieve the purpose of sorting according to the quality.

Owner:TENCENT TECH (SHENZHEN) CO LTD

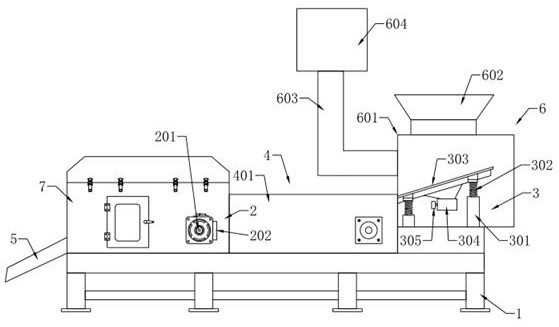

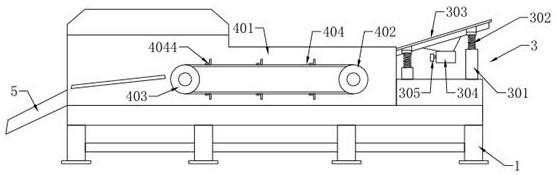

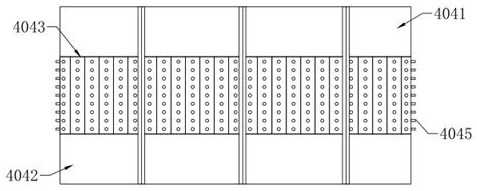

Novel copper-aluminum sorting machine

InactiveCN111822143AImprove separation efficiencyAchieve the purpose of sortingMagnetic separationTransmission beltElectric machinery

The invention discloses a novel copper-aluminum sorting machine, which comprises a supporting rack, wherein a feeding mechanism is fixedly mounted on one side above the supporting rack, the feeding mechanism comprises a supporting column, a spring is fixedly inserted into the upper part of the supporting column, a material guide plate is fixedly welded above the spring, a vibration motor is fixedly connected to the lower part of the material guide plate through a bolt, the output end of the vibration motor is connected with an eccentric block, a sorting assembly is arranged on one side of thefeeding mechanism, the sorting assembly comprises a machine shell, a belt conveying roller and an eccentric magnetic roller are arranged in the machine shell, a conveying belt is connected between thebelt conveying roller and the eccentric magnetic roller in a transmission manner, a driving mechanism is connected to the eccentric magnetic roller, and the supporting rack is provided with a cover shell at one side of the machine shell. The copper-aluminum sorting machine is reasonable in design and high in separation efficiency, adopts a high-strength permanent magnet material as the magnetic source, and is stable and durable in magnetic performance and easy to maintain.

Owner:广东忠能科技集团有限公司

Powder sieve with controllable mesh number

The invention discloses a powder sieve with controllable mesh number. The powder sieve comprises a closed casing provided with a feed inlet, a discharge outlet, at least three sorting ports and three screens. The feed inlet and the discharge outlet are respectively arranged on two opposite sides of the casing and located on the same straight line. The bottom surface of the casing tilts downwards from the feed inlet to the discharge outlet. The sorting ports of the casing are disposed on the bottom surface of the casing, and the three screens are arranged at the tops of the sorting ports, are respectively superposed on the bottom surface of the casing and are respectively fastened in a chute at the bottom of the casing. The sorting ports are arranged on the bottom surface of the casing side by side. Powder raise in plants can be avoided during sieving, so that a good environment is provided for workers. Besides, the powder sieve provided with an automatic sieving device is simple in structure, low in cost and convenient to use. As the bottom surface of the casing is arranged obliquely, powder can be sieved automatically from the feeding process to the sorting process.

Owner:CHONGQING CHENGSHUO TECH

Handkerchief paper packaging machine based on energy conservation and environmental protection

InactiveCN114030681ASmooth rotationGuaranteed normal operationPaper article packagingConveyorsEnvironmental resource managementEnergy conservation

The invention discloses a handkerchief paper packaging machine based on energy conservation and environmental protection. The handkerchief paper packaging machine comprises a conveying unit and a packaging unit. According to the handkerchief paper packaging machine based on energy conservation and environment protection, by arranging fixing frames, a connecting shaft and an electric control piece, the sorting disc can rotate between the fixing frames more stably, the sorting disc can operate normally, the sorting purpose is achieved. By arranging a supporting frame, a fixing screw and a material blocking plate, materials are prevented from falling off in the moving process, so that unnecessary waste is avoided. Meanwhile, sterilization lamps are arranged, sterilization treatment can be conducted on the outer portions of the materials, sorting discs and sorting material plates are arranged, the handkerchief paper on the market at present is mostly designed into ten small bags, and therefore the sorting discs can quantitatively complete conveying, manual sorting is replaced and material waste is avoided. Compared with the previous arrangement, the investment of manpower and material resources is greatly reduced, and the machine is more energy-saving and environment-friendly. A protection plate is mounted.

Owner:常德长岭机械制造科技有限公司

Environment friendly dedusting griddle employed wind and water

InactiveCN100446865CReduce dust contentImprove product qualitySievingGas current separationAtmospheric airEngineering

The invention provides the dust elimination environment protection ore screen. The ore screen comprises shaker screen composed by rack, motor, eccentric wheel, and steel-wire screen, dust elimination sorting canister installed on the bottom of shaker screen, winding device installed on the front of dust elimination sorting canister, sprinkler installed on the back of dust elimination sorting canister, feed inlets installed in the upper dust elimination sorting canister and shaker screen, and blanking inlets. Using the device to sort stone or ore, the dust is separated and prevented from polluting environment. Using the device to produce stone or ore, the dust content is low and the product quality is high.

Owner:赵凤臣

Combined type circulating airflow separation equipment

PendingCN114101060AGuaranteed stabilityEfficient sortingSievingGas current separationSmall footprintMechanics

According to the combined type circulating airflow separation equipment, the vibrating screen on the upper side of the circulating cavity can achieve preliminary screening of materials and clear away large and small impurities, meanwhile, the obliquely-arranged vibrating screen can enable screened materials to fall into the circulating box through gravity, energy can be saved, and the occupied area of the combined type circulating airflow separation equipment can be reduced; the power section provides a certain wind speed for materials to be screened, the rectification section rectifies airflow entering the winnowing section into uniform airflow, the situation that the separation effect is affected due to the fact that the materials interact with one another and a negative pressure area is generated in the winnowing section is avoided, the materials are evenly separated according to different specific gravities of the materials, and therefore the purpose of separation is achieved. The rotary air duct ensures the stability of air flow in the circulating cavity, and meanwhile, dust in the materials can be prevented from being directly discharged, so that environmental pollution is avoided; the device is simple in structure and small in occupied area, meanwhile, materials can be efficiently screened in a high-quality mode, and high applicability and universality are achieved.

Owner:XINGTAI TIANYUANXING FOOD EQUIP

Blood cell analyzer

ActiveCN102981005BAchieve the purpose of sortingAvoid inaccurate test resultsMaterial analysisThree stageMedicine

The invention belongs to the technical field of medical detection devices, and especially relates to a blood cell analyzer. The blood cell analyzer comprises a sampling apparatus, a quantification apparatus I, a dilution colorimetric pool, a quantification apparatus II and a blood sample main tube. The blood cell analyzer is characterized in that the blood sample main tube is connected with a one-stage tangential separation sorting apparatus, the one-stage tangential separation sorting apparatus is connected with a detection electrode, or the one-stage tangential separation sorting apparatus is orderly connected with the two-stage tangential separation sorting apparatus, the three-stage tangential separation sorting apparatus until the N-stage tangential separation sorting apparatus, the N-stage tangential separation sorting apparatus is connected with the detection electrode, and the detection electrode is respectively connected with a detection analysis system and a waste liquid tube. According to the blood cell analyzer, the one-stage or multi-stage tangential separation sorting apparatus is set for carrying out one-stage, two-stage or multi-stage tangential separation sorting on the blood cells, thus, the aim of orderly sorting single blood cells is realized completely, and the problem of inaccuracy of the detection result caused by aggregation of multiple blood cells is avoided effectively.

Owner:鞍钢集团公司总医院

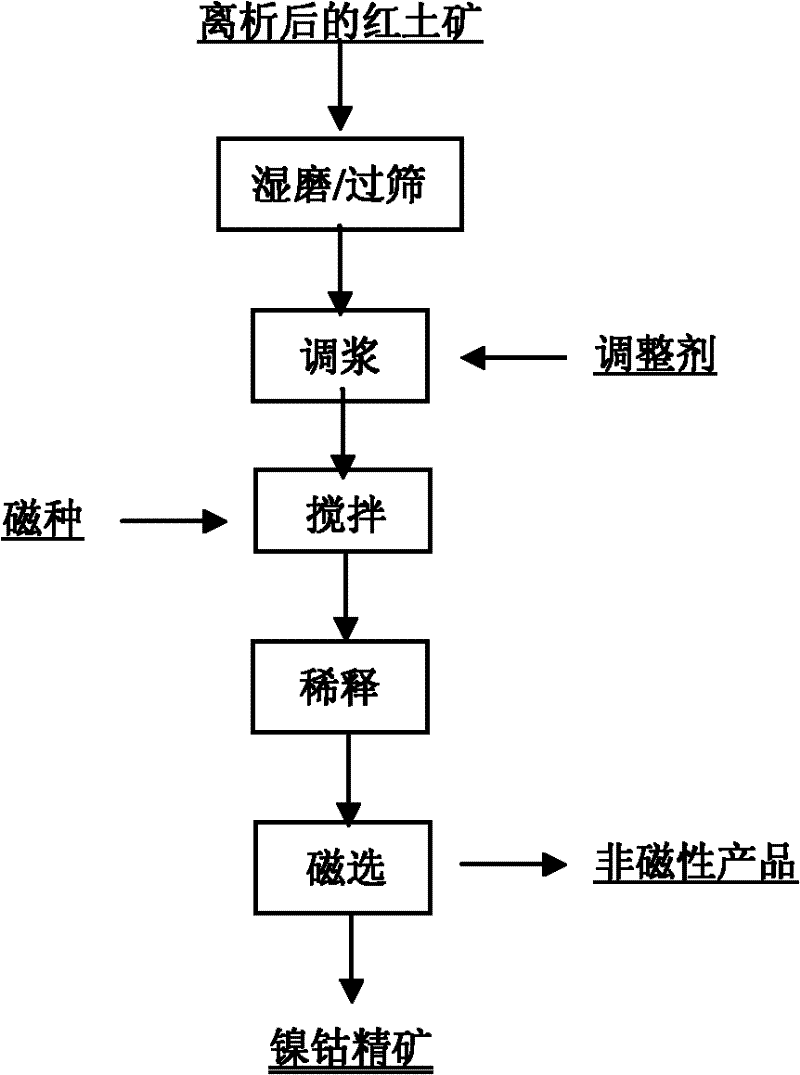

Magnetic separation method for gathering rich nickel and cobalt from chloridized and separated low-grade laterite

ActiveCN101912815BImprove cohesionInhibit aggregationMagnetic separationMagnetic separatorEconomic benefits

The invention discloses a magnetic separation method for gathering rich nickel and cobalt from chloridized and separated low-grade laterite, comprising the following steps of: carrying out wet grinding and sieving on the chloridized and separated low-grade laterite, and then adding water and a modifier to carry out size mixing; then adding magnetic seeds to be stirred for a period of time; and adding water for diluting, and then carrying out magnetic separation on a permanent-magnetic roller strong magnetic separator, wherein obtained ore concentrates are nickel and cobalt rich products. Compared with the prior art, the magnetic separation method enhances the yield of the nickel and the cobalt and the grades of the ore concentrates, thereby enhancing the economic benefit; in addition, theinvention solves the problems of lower grade and low nickel yield of the ore concentrates obtained by chloridizing and separating the low-grade laterite, the yield of the nickel is more than 90 percent, and the yield of the cobaltis is more than 80 percent.

Owner:CENT SOUTH UNIV

A visual sorting system applied to pineapple collection

ActiveCN113894054BAchieve the purpose of sortingReduce shipping costsSortingControl engineeringControl theory

The invention belongs to the technical field of pineapple harvesting and sorting, and proposes a visual sorting system applied to pineapple collection, which includes a lifting bracket and sorting empty tubes fixed on the lifting bracket, and both sides of the sorting empty tubes are provided with Elevate the conveyor belt, on which a number of inclined lifting baffles are fixed; on the conveyor belt, a detection module and a retest module are arranged in sequence along its conveying direction, both the detection module and the retest module include a support body, and a camera is fixedly connected to the support body , the supporting body is fixedly connected with a driving part, and the output shaft of the driving part is fixedly connected with a driving shaft; a number of sorting components are arranged on both sides of the sorting empty pipe along the conveying direction of the conveyor belt. The opening on the pipe and the power part fixed on the sorting empty pipe, the output shaft of the power part is fixedly connected with a closing plate for closing the opening. The invention quickly sorts pineapples, improves the sorting efficiency and reduces the labor force of operators.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

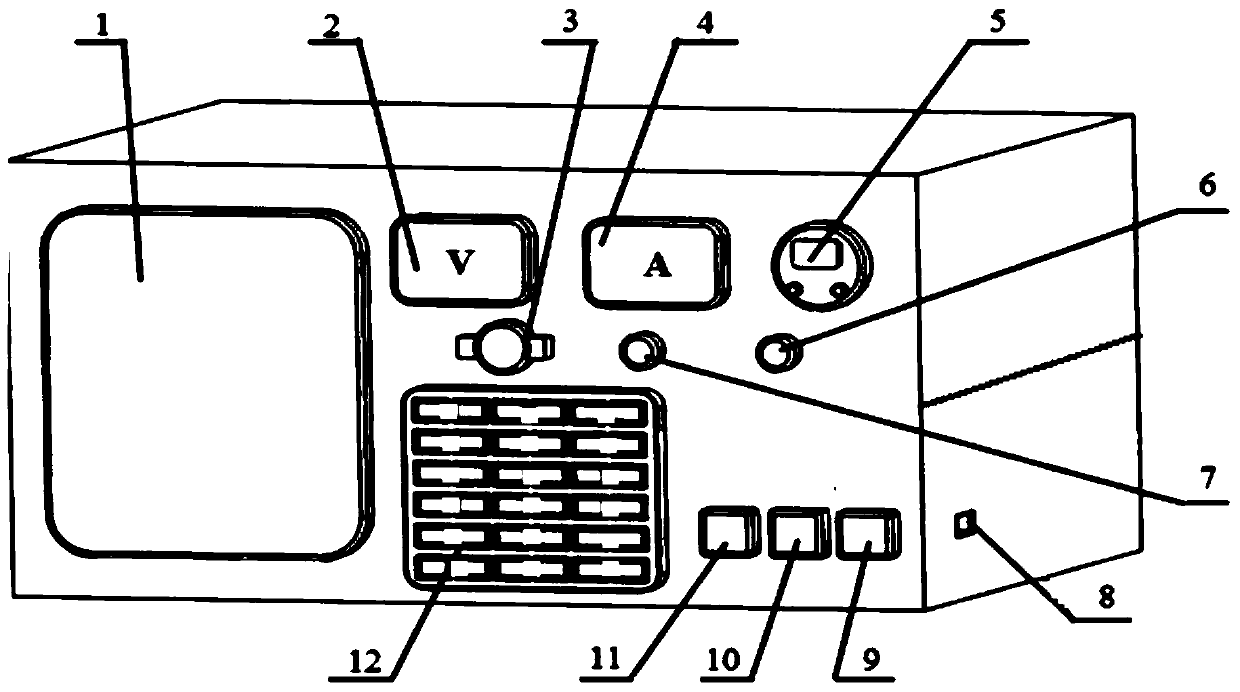

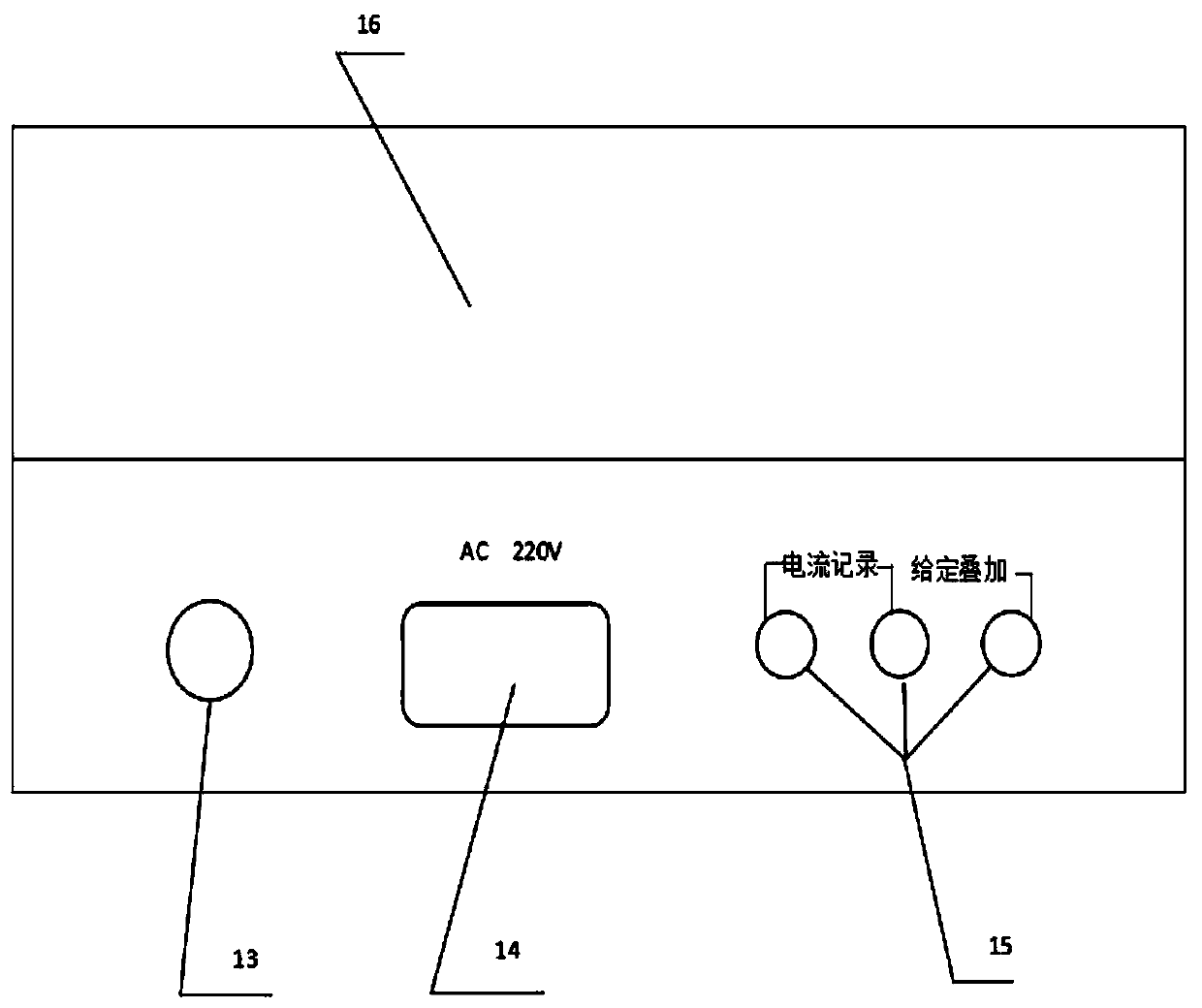

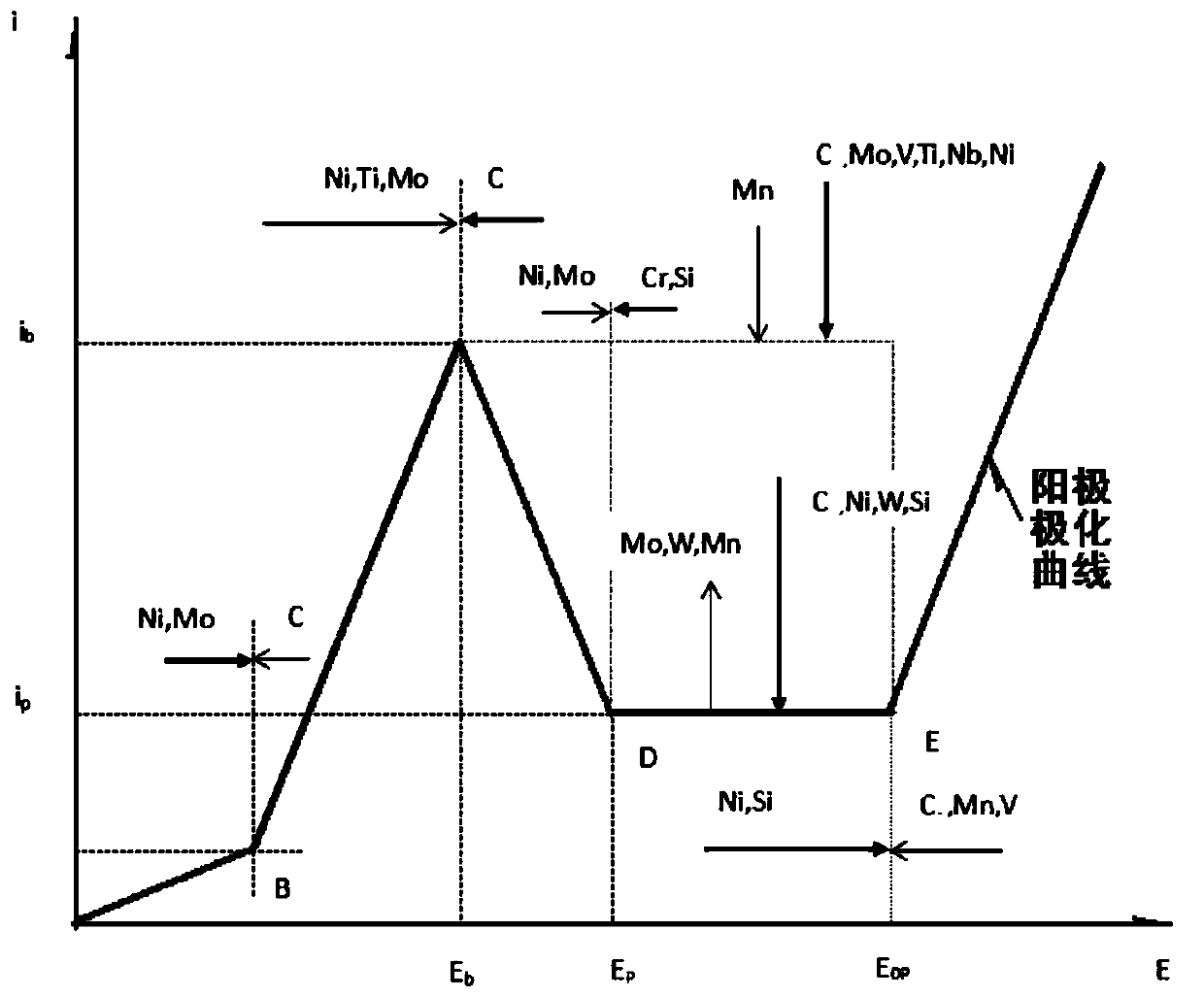

Electrochemical method and device for sorting structural steel grades

ActiveCN107607606BAchieve the purpose of sortingLow costMaterial electrochemical variablesLiquid-crystal displayHemt circuits

An electrochemical method and device for sorting structural steel grades. The main purpose is to provide an electrochemical method capable of quickly and accurately sorting structural steel grades and a device for realizing the method. It is characterized in that: the main step of the method is to measure and obtain the anodic polarization curve of the unknown brand structural steel in a special electrolyte solution by performing electrochemical experiments on the structural steel of the unknown brand, and analyze the characteristic parameters of the anodic polarization curve, and then Compared and identified with the standard anodic polarization curve characteristic parameters of known grades of structural steel in the standard sample database, the grade of the steel is finally identified; the device includes an electrochemical test module and a polarization curve identification module; the electrochemical The test module includes a three-electrode electrolytic cell, a test circuit and a motor stirring circuit; the polarization curve identification module includes an 89C51 chip, an analog-to-digital conversion chip and a liquid crystal display circuit.

Owner:NORTHEAST GASOLINEEUM UNIV

Peel-off household waste sorting machine

ActiveCN105536969BEfficient recyclingRealize resourcesGas current separationSolid waste disposalLitterResource utilization

The invention relates to a stripping type household garbage separator. The separator comprises a separation conveying belt, a primary smashing mechanism, a scraper mesh-type screening and conveying mechanism, a rotary screen and a winnowing mechanism which are sequentially arranged from downstream to upstream. The separator has the advantages that multiple smashing and screening mechanisms are arranged so that kitchen residues, fruit peel, vegetables and the like in household garbage can be effectively recycled, classified utilization of the garbage is achieved, and the subsequent garbage handling amount is reduced; light objects, difficult to recycle, such as plastic bags in the household garbage are punctured, and after garbage contained in the plastic bags is released, the plastic bags are separated out by wind; by means of the conveying belt with an inclination angle, heavy objects contained in the plastic bags are separated through gravity, and finally resource utilization, reduction and harmlessness of the household garbage are achieved.

Owner:黑龙江神工环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com