Casting sorting device

A sorting device and casting technology, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of low work efficiency, time-consuming, labor loss, etc., and achieve the goal of improving quality, enhancing friction effect, and improving sorting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

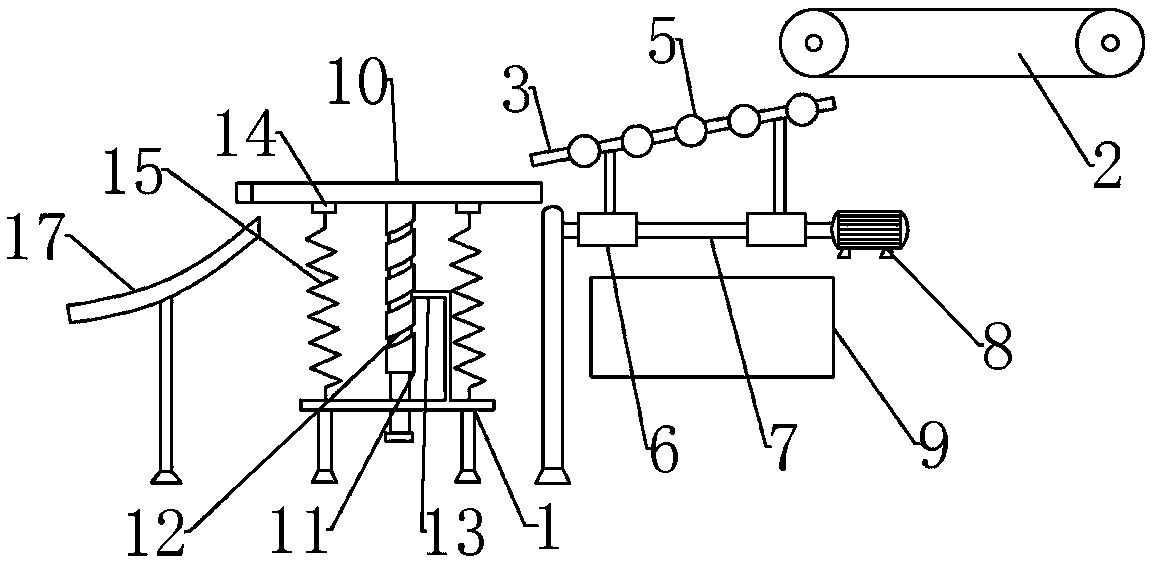

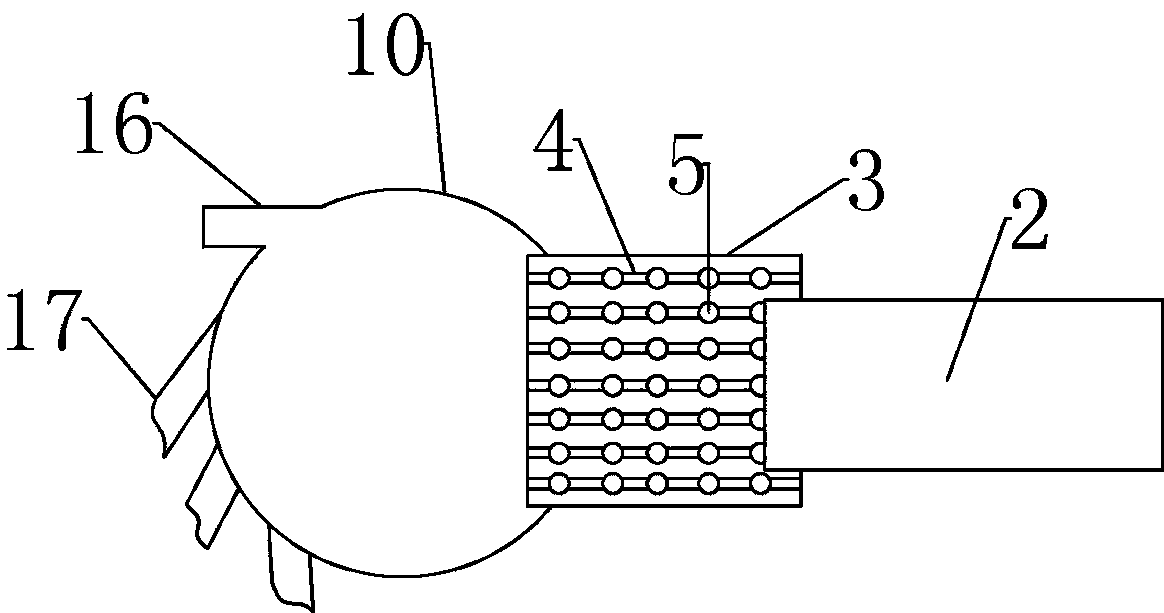

[0016] The reference signs in the drawings of the description include: frame 1, conveyor belt 2, frame 3, connecting rod 4, rubber ball 5, sleeve 6, screw mandrel 7, servo motor 8, collection box 9, rotating disc 10, rotating rod 11. Spiral groove 12, fixed rod 13, block 14, spring 15, channel opening 16, chute 17.

[0017] Example basic reference figure 1 with figure 2 Shown: Casting sorting device, including frame 1, conveyor belt 2 is rotatably installed on frame 1, there is a direction frame 3 slidingly installed on frame 1 on the lower left side of conveyor belt 2, frame 3 is installed obliquely, and frame 3 There are several connecting rods 4 welded between the upper and lower side walls, and several rubber balls 5 are clamped on the connecting rods 4. Two shafts are welded on the bottom side of the frame 3, and the lower ends of the shafts are welded with sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com