Arrangement device for battery pack production and welding and use method of arrangement device

A technology for arranging devices and battery packs, applied to primary batteries, battery pack components, welding equipment, etc., can solve the problems of increasing the labor intensity of staff and reducing production efficiency, and achieves improved scope of application, improved processing efficiency, and reduced labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

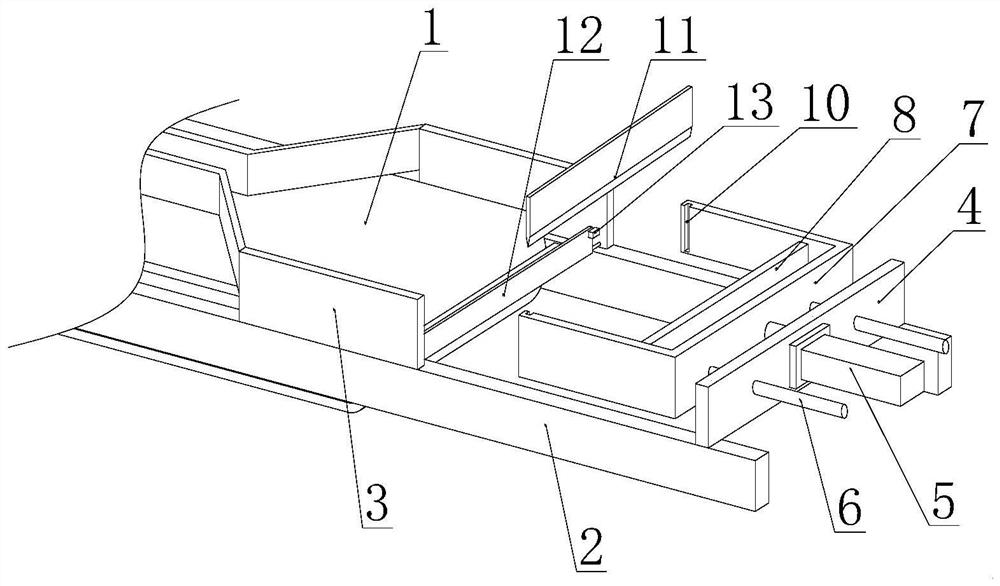

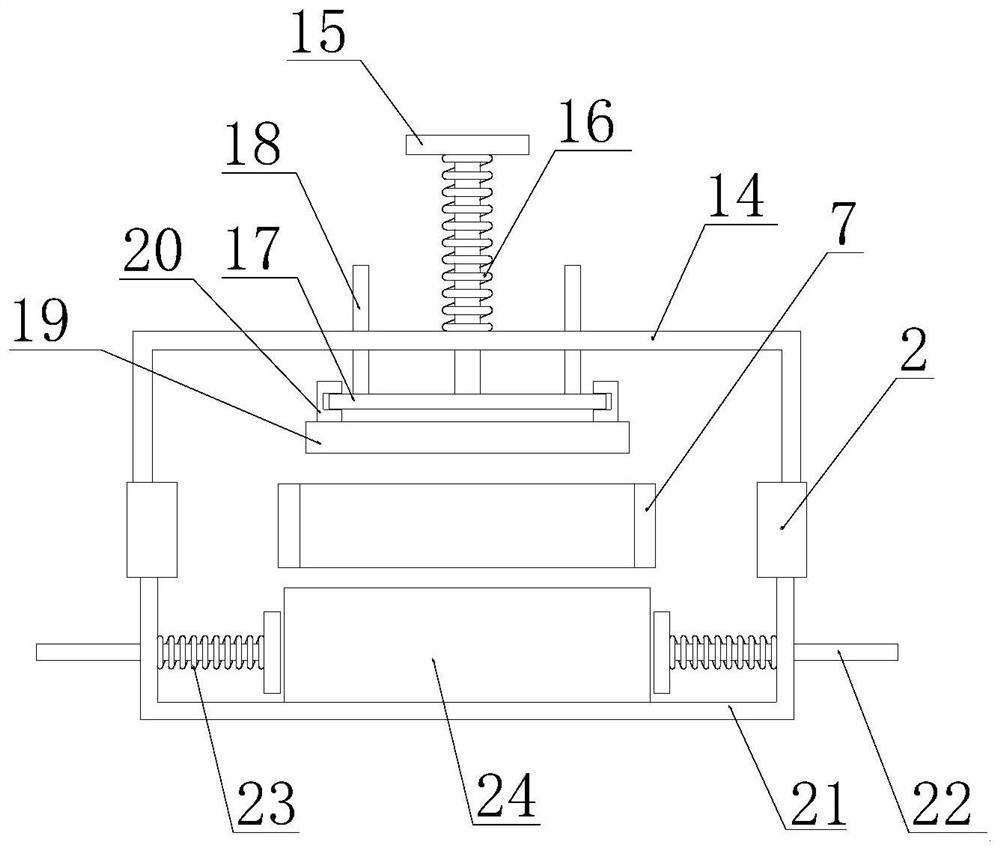

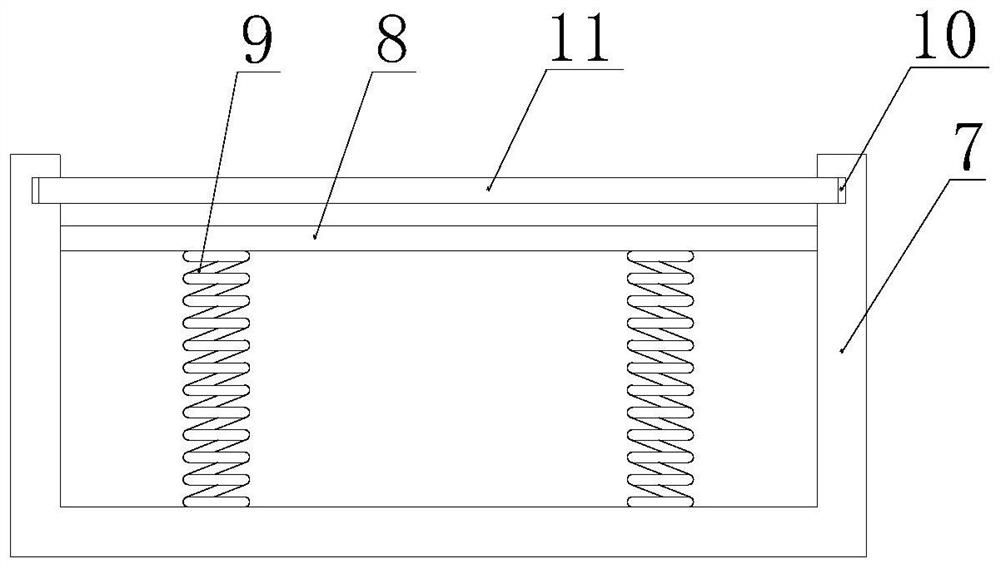

[0024] like Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: an arrangement device for production and welding of battery packs, comprising a conveyor belt 1, and racks 2 are erected on both sides of the conveyor belt 1, and the two racks 2 are located at the end of the conveyor belt 1 A deflector 3 is fixedly connected to each section position, a support plate 4 is fixedly connected between the tops of one end of the two racks 2 away from the conveyor belt 1, and a U-shaped reclaimer frame is movably connected to the side of the support plate 4 close to the conveyor belt 1. 7. The inside of the U-shaped reclaiming frame 7 is provided with a No. 1 push plate 8 and a limit plate 11, and an L-shaped flow restricting plate 12 is rotatably connected between one end of the two deflectors 3 close to the U-shaped reclaiming frame 7. A second push plate 19 is detachably connected to the upper part of the U-shaped reclaiming frame 7 , and a materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com