Powder sieve with automatic controlled mesh number

A technology of mesh size and powder, applied in the field of automatic powder separation equipment, can solve the problems of inaccurate control, inconvenient use, poor production environment of the factory building, etc., and achieve the effect of convenient use, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

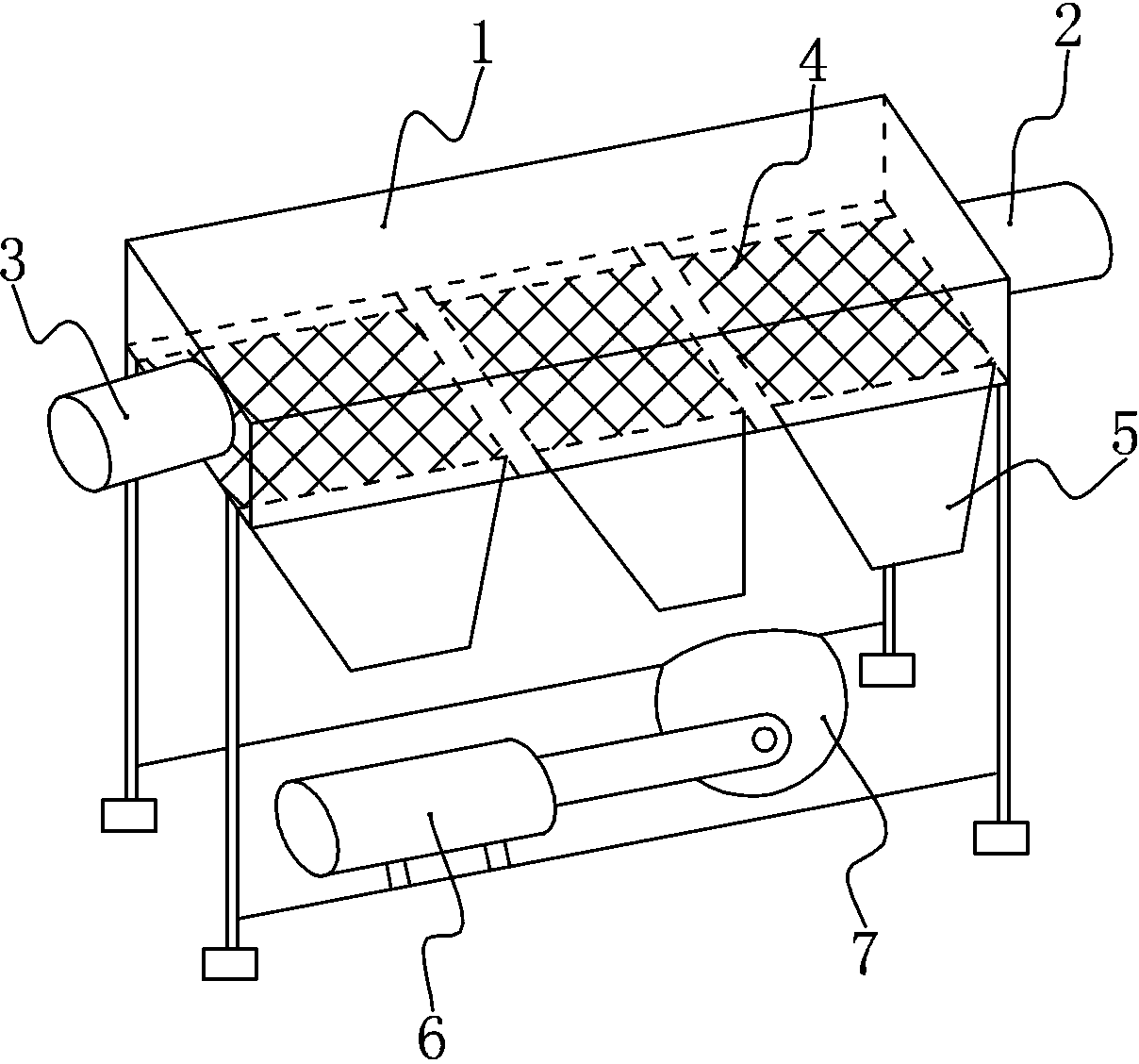

[0012] Such as figure 1 As shown, the present invention is an automatic control sieve for powder mesh, installed on a vibrating frame, comprising a closed shell 1, on which is provided a feed port 2, a discharge port 3, a material selection port 4 and a sieve The net 5, the feed port 2 and the discharge port 3 are respectively arranged on two opposite sides of the housing 1, and the feed port 2 and the discharge port 3 are located on a straight line; the bottom surface of the housing 1 starts from the feed port 2 to the discharge port 3 are set obliquely downward; the material selection port 4 of the shell 1 is set on the bottom surface of the shell 1, and the screen 5 is set on the top of the material selection port 4, and the screen 5 is divided into three pieces, which are stacked separately On the bottom surface of the casing, the three screens 5 are respectively clamped in the chute at the bottom of the casing 1; there are three material selection ports 3, which are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com