External corrosion proof technology of oil field oil water well annular tube

A technology for oil-water wells and casings, which is applied in the field of anti-corrosion technology for oil-water well casings in oil fields. It can solve the problems of liquid epoxy coal tar pitch anti-corrosion layer insulation performance, low mechanical properties, restrictions on industrialization, and high cost of aluminum anodes. Bare metal area, improved anti-corrosion reliability, high effect of anti-corrosion reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

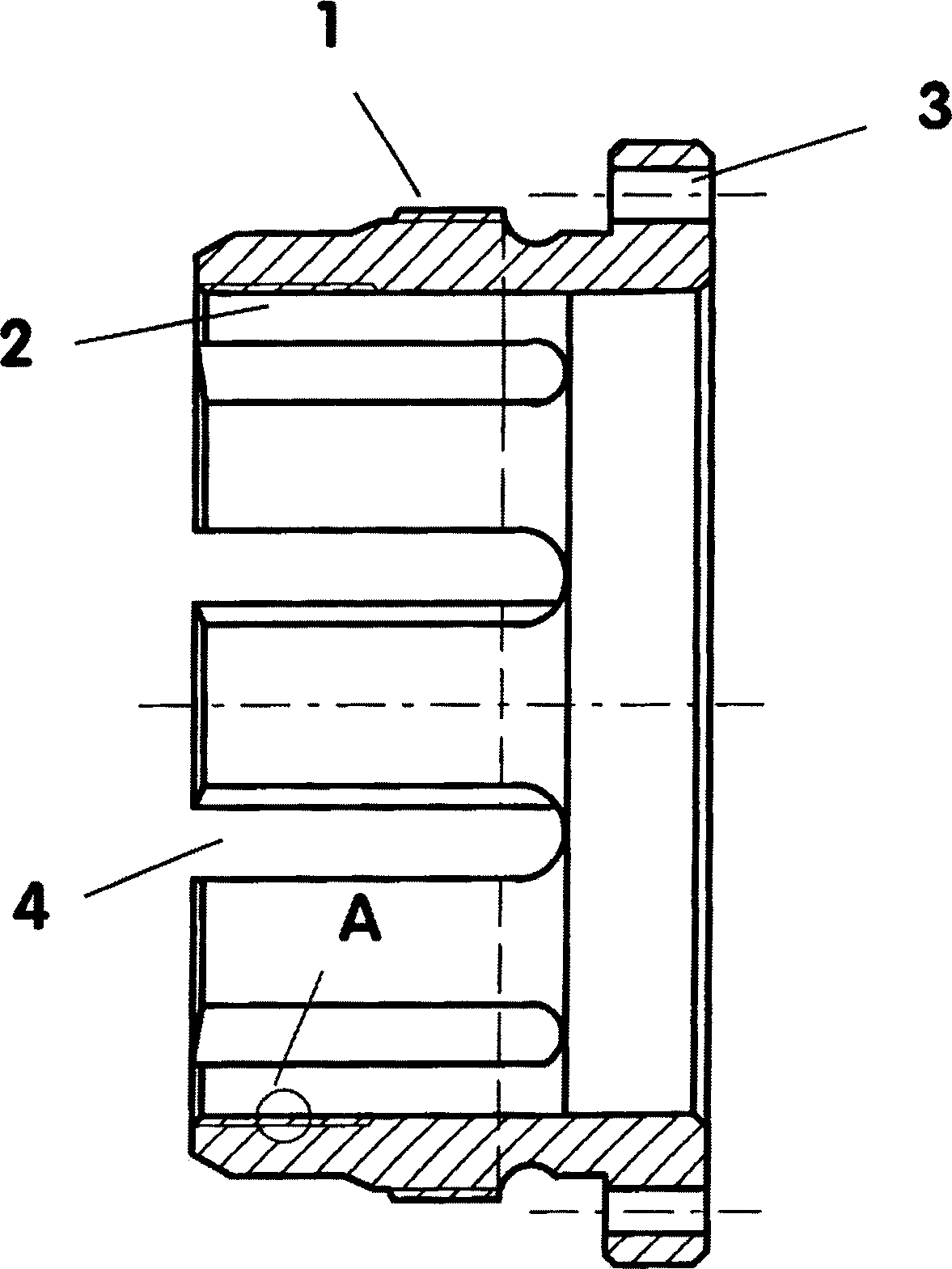

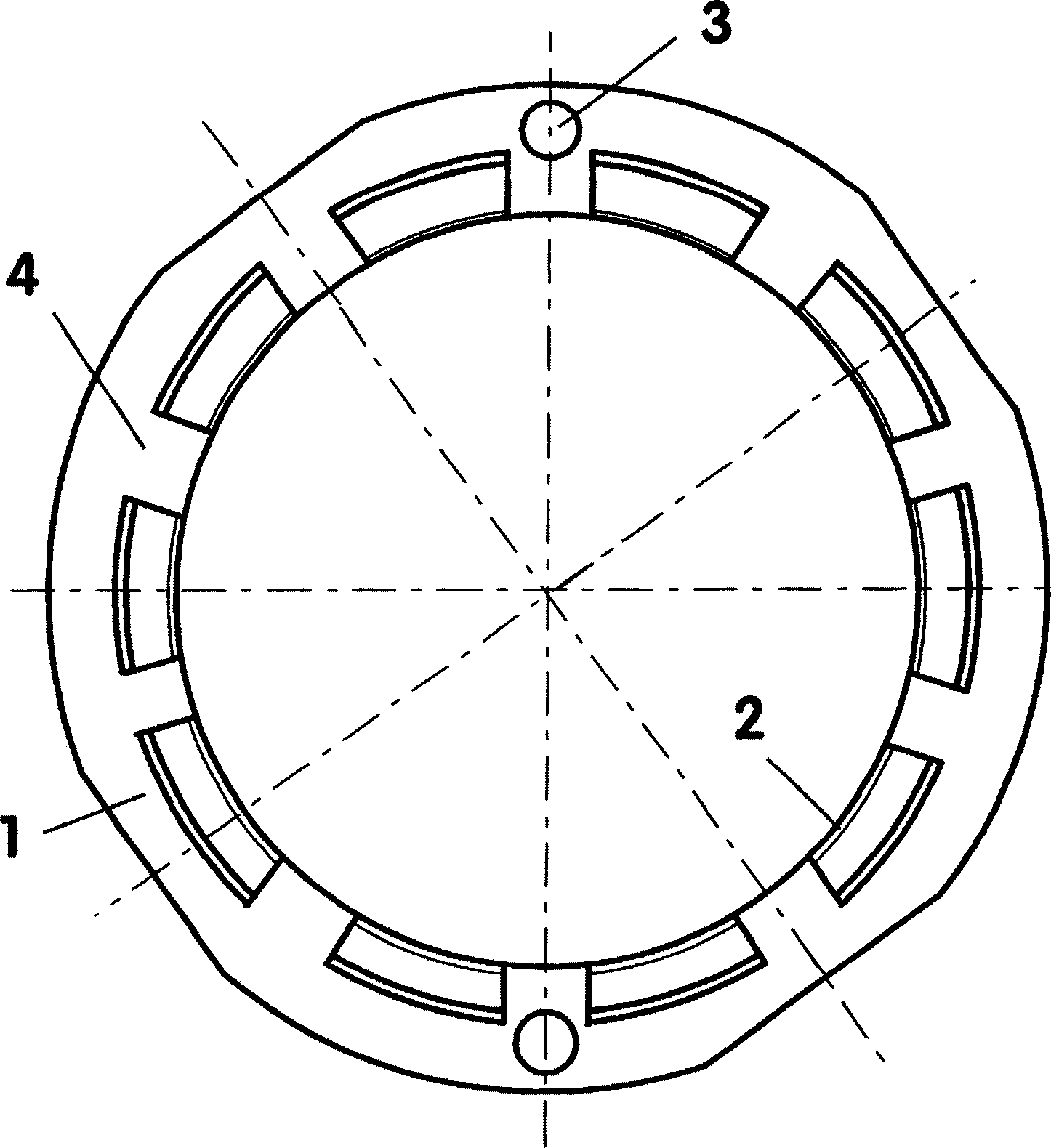

[0032] According to the well depth of Changqing Xifeng Oilfield, the present invention designs an epoxy cold-wrapped zinc anode casing anticorrosion process scheme that meets the anticorrosion requirements of this area. In 2003, 315 wells were popularized and applied in Changqing Xifeng Oilfield. The specific implementation plan includes the following 7 steps:

[0033] Al

Cd

Fe

Cu

Pb

Si

Zn

0.55

0.072

0.0023

0.005

0.0044

<0.01

margin

[0034] 2. Casing inspection: For the casings that have passed the oilfield quality inspection, check the pipes one by one for deformation, bending, pits, micropores and other defects on the surface before anti-corrosion construction. Defective pipes must not be used.

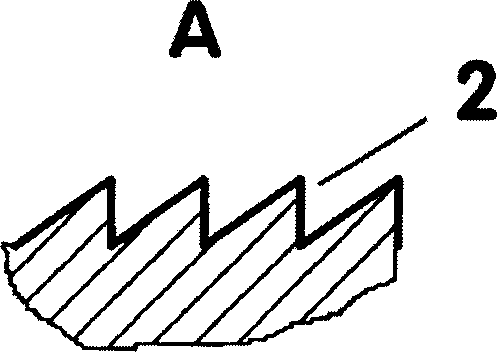

[0035] 3. Casing epoxy cold wrapping construction: first reserve 500mm from the end face of the casing female coupling and pin to the pipe body without winding, as hoisting and tong construction, and...

Embodiment 2

[0043] The prototype of this technology was tested in 1993 in the casing bracelet type aluminum sacrificial anode plus epoxy coal tar pitch coating external anti-corrosion process. At that time, the anti-corrosion materials used were aluminum anode and epoxy coal pitch. With the progress of material technology, now The mechanical and corrosion resistance of the epoxy cold-wrapped anti-corrosion layer have been greatly improved, and the zinc anode is more suitable for the environment of the corrosive medium of the Luohe River in Changqing.

[0044] In July 1993, two wells (Xinhua 38-13: from the original Hua 38-13 well) were constructed in the Huachi and Lingnan operation areas of Changqing Oil Production No. Plane 4 meters, Xinnan 29-22 well: 10 meters away from the original Nan 29-22 well), these two wells are still in normal production for 10 years (design life 27-34 years). Compared with the original well and the renewal well, the Xinhua 38-13 well has exceeded the life of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com