Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

106results about How to "Uniform pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Purification of gases using multi-composite adsorbent

InactiveUS6358302B1Low costMaximum performanceNitrous oxide captureGas treatmentSorbentNitrogen oxide

Owner:BOC GRP INC

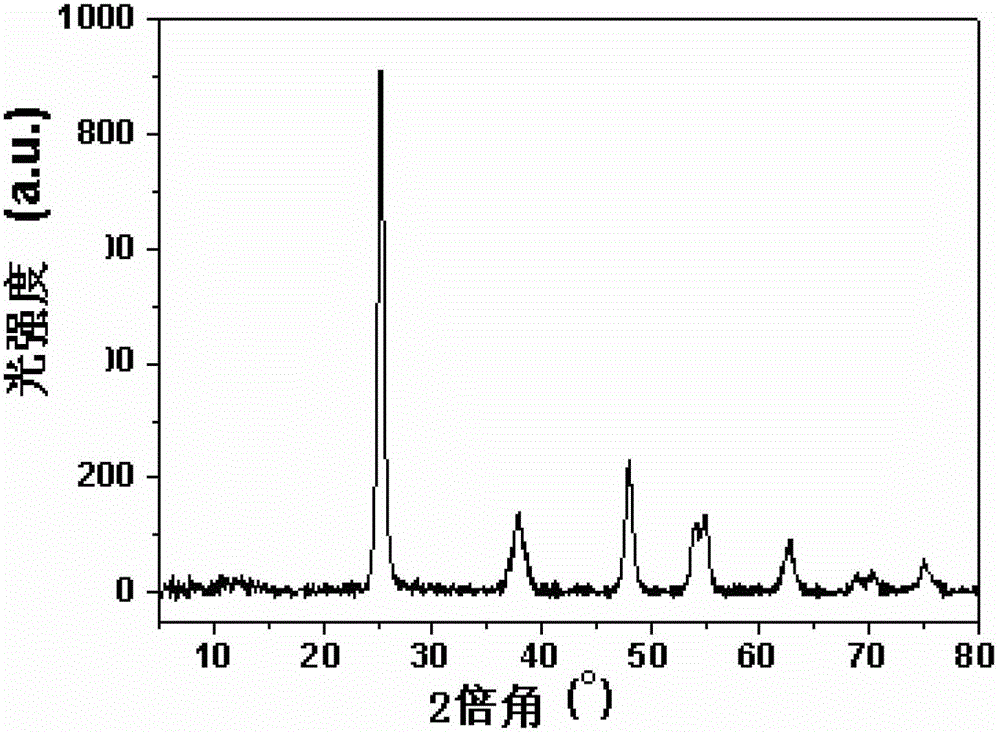

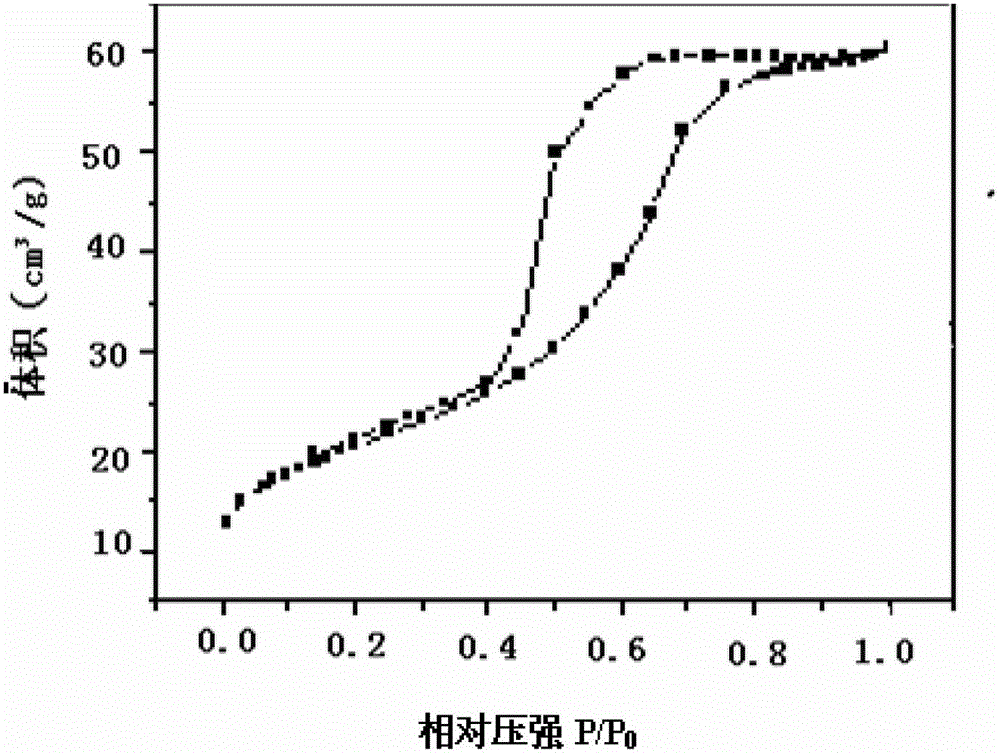

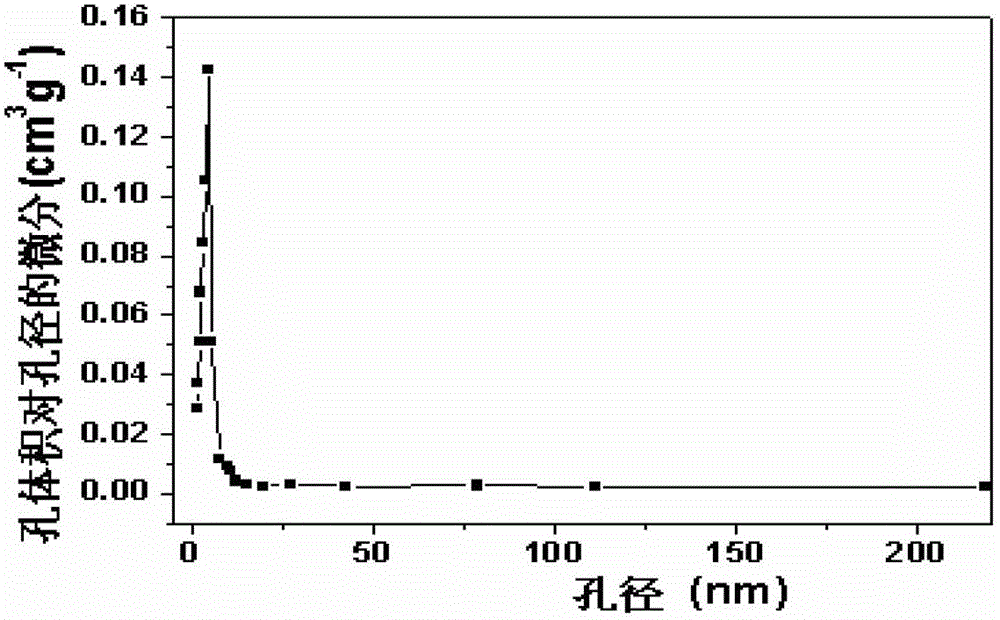

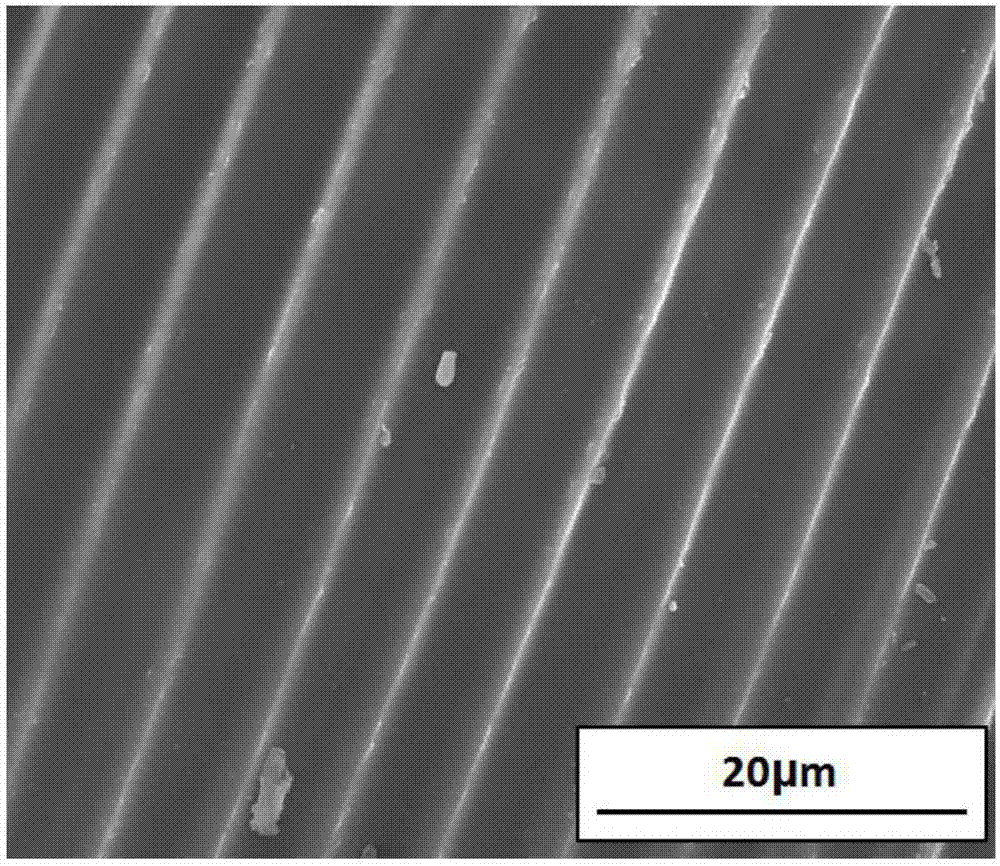

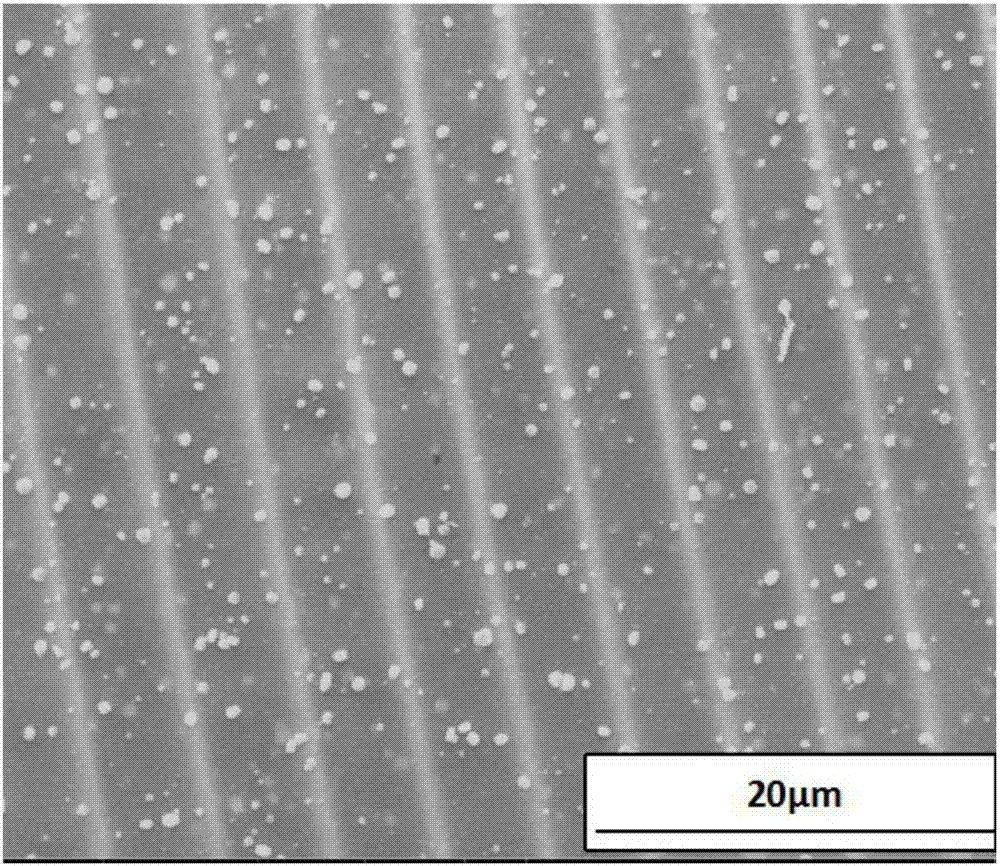

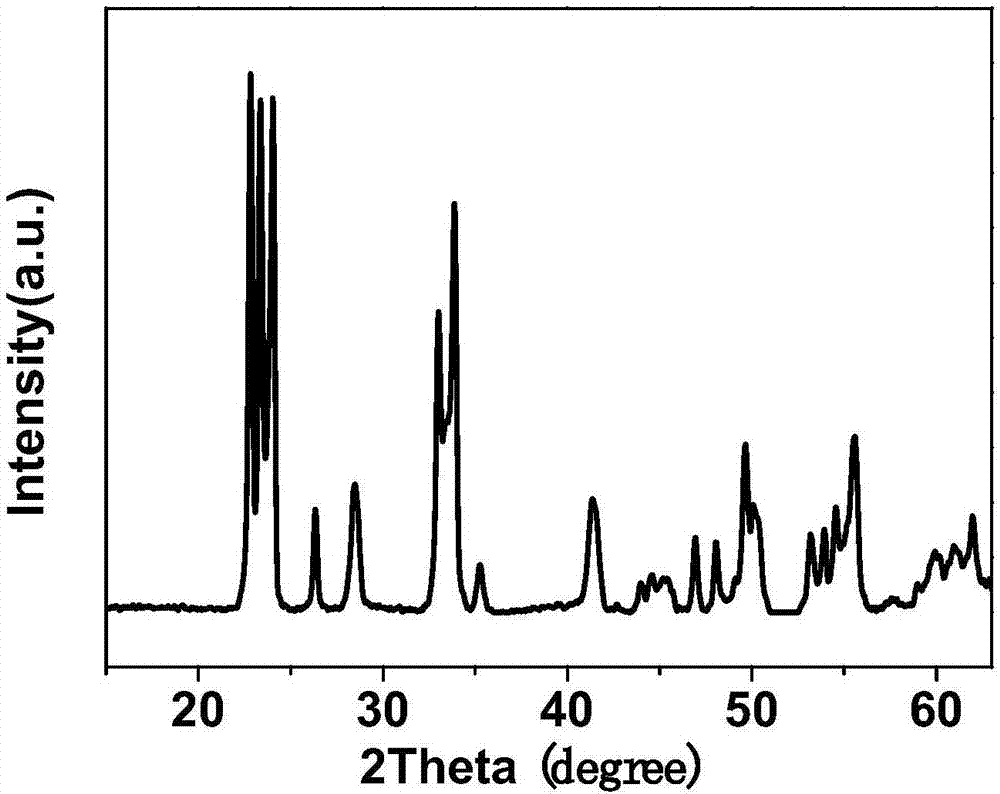

Preparation method of ordered mesoporous titania/silver photocatalyst

InactiveCN102744059AImprove photocatalytic activityGood dispersionMetal/metal-oxides/metal-hydroxide catalystsWastewaterMunicipal sewage

The invention discloses a preparation method of ordered mesoporous titania / silver photocatalyst, relating to a preparation method of titania / silver and aiming to solve the technical problems of small specific surface area, poor orderliness and low photocatalytic activity of mesoporous titania / silver photocatalyst prepared by prior arts. The preparation method comprises the steps of silver solution preparation, titanium precursor preparation, titania / silver gel preparation, and heat treatment. The inventive photocatalyst has specific surface area of 120-160 m<2> / g, has the advantages of uniform mesopores and high catalytic activity; can be applied to photocatalysis field, and water treatment field of lake, ocean, municipal sewage and industrial sewage.

Owner:HEILONGJIANG UNIV

Mesoporous silica particles and preparation method thereof

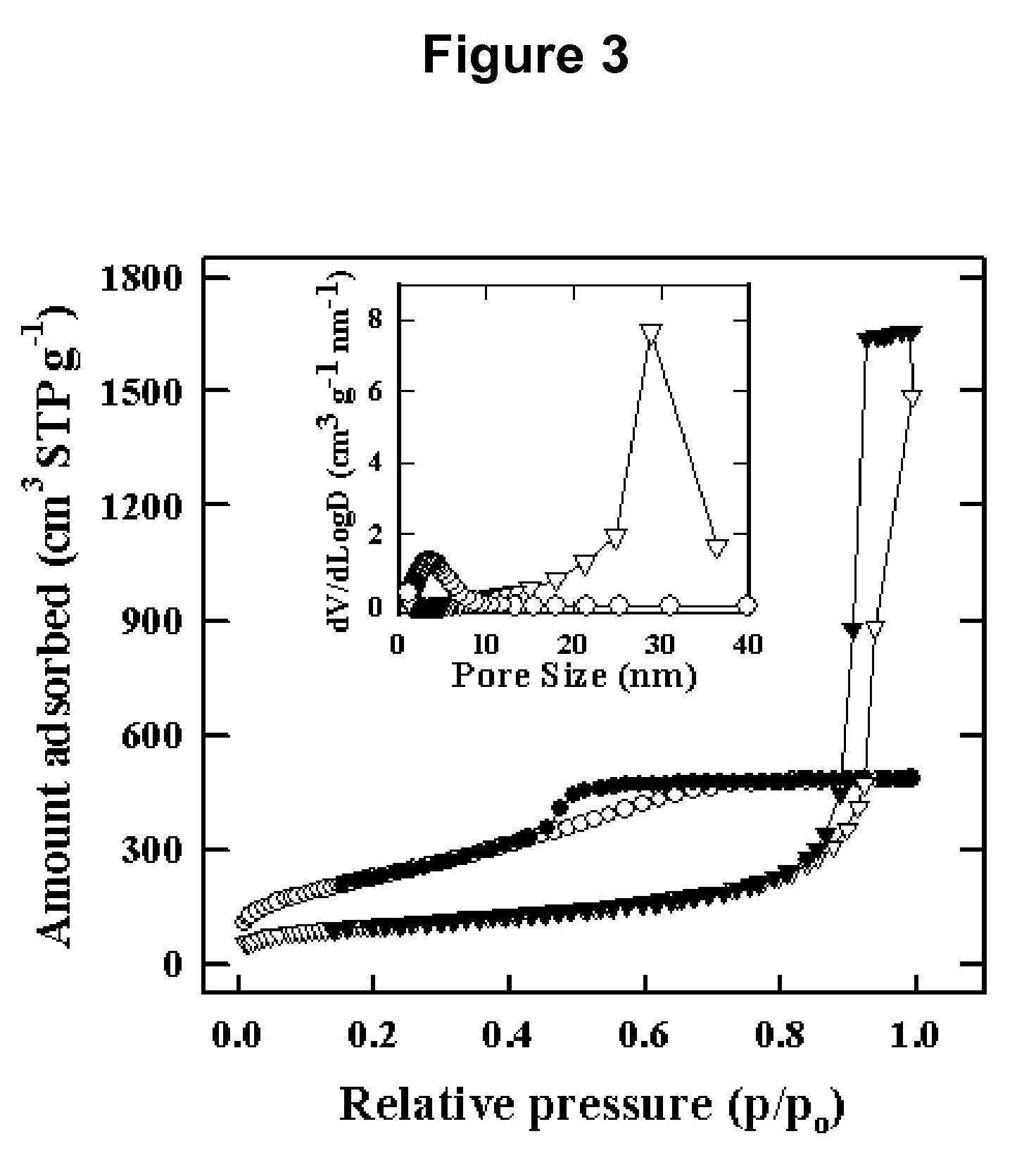

InactiveUS20080286187A1Large average pore sizeHigh pore volumeAluminium compoundsSilicaSilica particleDielectric

Disclosed are mesoporous silica particles and a preparation method thereof, particularly, a method of preparing mesoporous silica particles, including mixing a silica precursor, an alkylamine-based surfactant, and a phosphoric acid-based cosurfactant, thus preparing a mixture solution (a mother liquor); adding or not adding the mixture solution with an acid solution, and conducting stirring, thus providing mesoporous silica particles; and thermally treating the mesoporous silica particles. These mesoporous silica particles are prepared using a phosphoric acid-based cosurfactant for stabilizing the surface of the particles to prevent the aggregation thereof, thereby uniformly distributing the particles. Through a hydrothermal reaction, the mesoporous silica particles have various pore sizes, a large surface area, and a high pore volume, and thus are widely used in catalysts, adsorbents, low dielectrics, and separation and purification processes, and are useful as templates for the preparation of novel porous materials, including porous carbon.

Owner:KOREA ATOMIC ENERGY RES INST

Silicon carbide-based, porous structural material being heat-resistant and super lightweight

InactiveUS20050020431A1Improve wettabilityEasy to produceCeramic shaping apparatusCeramicwareSlurryAtmosphere

The present invention provides a silicon carbide-based heat-resistant, ultra lightweight, porous structural material having the same shape as that of a spongy porous body and also provides a process for readily producing the material. In the process of the present invention, slurry containing silicon powder and a resin is applied to the framework of the spongy porous body by an impregnation method in such a manner that interconnected pores of the porous body are not plugged with the slurry; the resulting porous body is carbonized at a temperature of 900° C. to 1320° C. in vacuum or in an inert atmosphere; the resulting porous body is subjected to reactive sintering at a temperature of 1320° C. or more in vacuum or in an inert atmosphere, whereby silicon carbide having high wettability to molten silicon is produced and open pores due to a volume reduction reaction are formed in one step; and molten silicon is infiltrated into the resulting porous body at a temperature of 1300° C. to 1800° C. in vacuum or in an inert atmosphere, whereby the silicon carbide-based heat-resistant, ultra-lightweight, porous structural material is produced.

Owner:NAT INST OF ADVANCED IND SCI & TECH

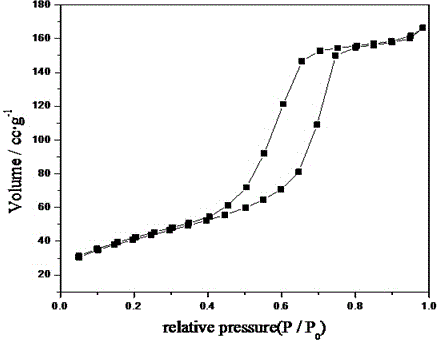

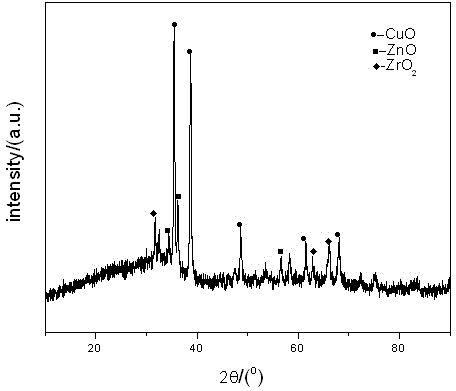

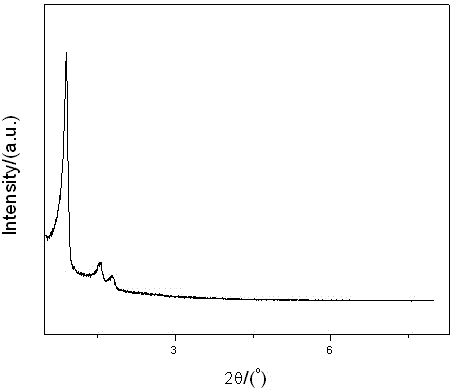

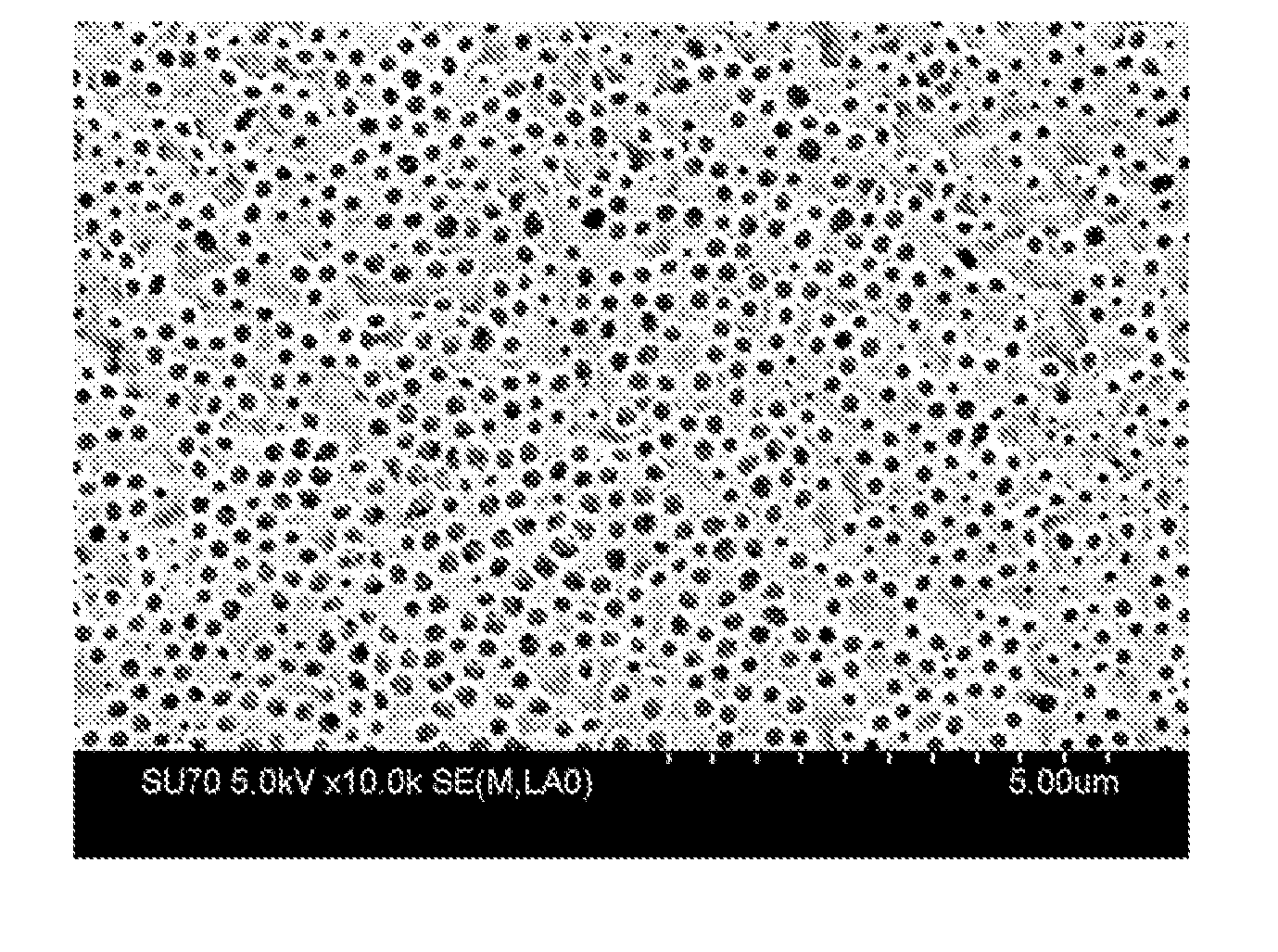

Preparation method for Cu-Zn-Zr mesoporous catalyst

ActiveCN104001517ALarge specific surface areaUniform poresOrganic compound preparationHydroxy compound preparationSolventZircon

The invention relates to a preparation method for a Cu-Zn-Zr mesoporous catalyst, which belongs to the technical field of catalyst preparation. The method comprises the following steps: uniformly mixing a copper salt, a zinc salt and a zircon salt so as to obtain a mixed salt solution; adding powder of a mesoporous template SBA-15 into the mixed salt solution prepared in the previous step so as to obtain a catalyst mixed salt solution; evaporating all the solvents in the catalyst mixed salt solution prepared in the previous step so as to obtain a catalyst mixed salt and repeating dipping twice to three times according to the above-mentioned steps so as to obtain a final dipped catalyst mixed salt; and roasting the final dipped catalyst mixed salt so as to obtain a roasting product and washing and drying the roasting product so as to obtain the Cu-Zn-Zr mesoporous catalyst. The Cu-Zn-Zr mesoporous catalyst prepared by using the method has a high specific surface area, narrow pore size distribution and uniform pore channels and shows high catalytic activity during synthesis of methanol through carbon dioxide hydrogenation at low temperature.

Owner:KUNMING UNIV OF SCI & TECH

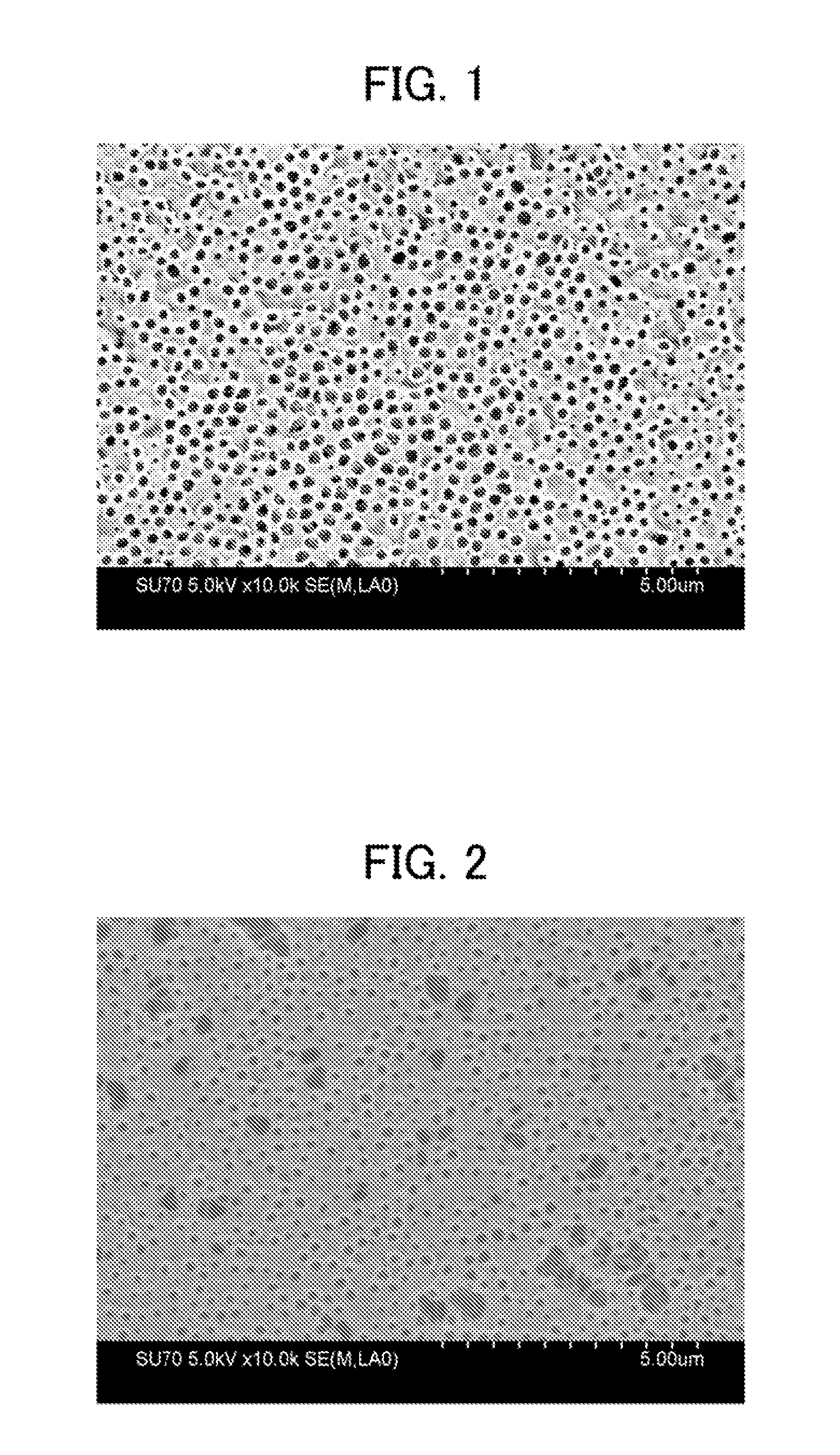

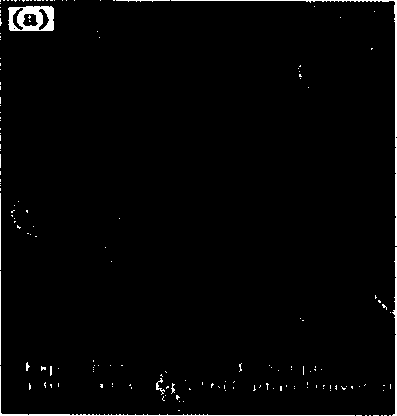

Method for producing porous polyimide film, porous polyimide film and separator using same

ActiveUS20160072110A1Excellent electrical propertiesEasy to moveSecondary cell gas removalSolid electrolyte fuel cellsComposite filmPolyamic acid

A method for producing a porous polyimide film comprises: forming a first un-burned composite film wherein the first film is formed on a substrate using a first varnish that contains (A1) a polyamide acid or a polyimide and (B1) fine particles at a volume ratio (A1):(B1) of from 19:81 to 45:65; forming a second un-burned composite film wherein the second film is formed on the first film using a second varnish that contains (A2) a polyamide acid or a polyimide and (B2) fine particles at a volume ratio (A2):(B2) of from 20:80 to 50:50 and has a lower fine particle content ratio than the first varnish; burning wherein an un-burned composite film composed of the first film and the second film is burned, thereby obtaining a polyimide-fine particle composite film; and a fine particle removal step wherein the fine particles are removed from the polyimide-fine particle composite film.

Owner:TOKYO OHKA KOGYO CO LTD

Method of using nano zeolite molecular sieve assemble material as affinity chromatography filler to separate functional protein molecules

InactiveCN1431497AUniform poresLow costIon-exchange process apparatusComponent separationChromatographic separationProtein molecules

In the invention, with being fixed in macropore-micropore multistage ordered zeolite structure through the ion exchnage process, the transition metal ions are as the affiliation active spots where the distinctive combination is occurred with the functional biomacromolecules possesisng the sequential histidine structure. Then, using the gradient elution through the buffer solution to reach the goal of enrich and separation. The carrier provides the advantages of even pore passages, good mechanical and chemical stability, easy to modify the surfaces etc. The diatomaceous earth is as the moldingboard and the molecular sieve of nano Beta zeolite wit surface being modified is as affinity chromatography filler. With the column being filled with the said materials, the satisfying result for separating the functional protein molecules is obtained in different leaching systems.

Owner:FUDAN UNIV

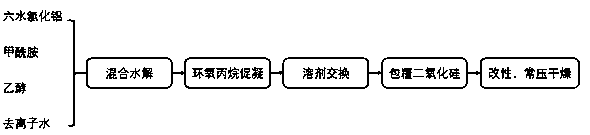

Ordinary pressure preparation method for aluminium oxide composite aerogel rapped by silicon dioxide

InactiveCN109621849AUniform poresReduce manufacturing costAerogel preparationColloidal chemistry detailsVolumetric Mass DensitySilicon dioxide

The invention discloses an ordinary pressure preparation method for aluminium oxide composite aerogel wrapped by silicon dioxide. According to the method, cheap inorganic aluminium salt is taken as araw material, aluminium oxide wet gel is prepared through a collosol-gel method, a framework of the wet gel is wrapped by a silicon dioxide layer, and the effects of surface modification and anti-sintering at the high temperature are achieved; then the aluminium oxide composite aerogel wrapped by the silicon dioxide is obtained through steps of hydrophobic modification and normal-pressure drying.The prepared composite aerogel has the advantages of being lower in density, capable of resisting high temperature and high in temperature preservation performance and can be widely applied to the fields of aerospace, industrial furnaces and the like which need heat insulation under the high temperature condition.

Owner:ZHEJIANG UNIV OF TECH

Polyvinylidene fluoride hollow fiber micropore filter membrane and preparation method of same

ActiveCN107096396AReasonable microstructureEliminate finger holesMembranesSemi-permeable membranesFiberMicropore Filter

The invention discloses a preparation method of a polyvinylidene fluoride hollow fiber micropore filter membrane. The preparation method includes the steps of: preparing a film casting liquid; preparing a core liquid; preparing an outer solidifying liquid; performing spinning; performing rinsing replacement; and performing thermal treatment. The method is used for preparing the PVDF hollow fiber micropore filter membrane through combination of thermally induced phase separation and solution phase conversion; compared with the solution phase conversion method, finger-like holes are eliminated, and the microstructure of the membrane is more reasonable; and compared with the thermally induced phase separation method, the method simplifies operations, is free of solvent extraction and reduces cost; in the film casting liquid, inorganic additives, such as nano glass powder or nano silicon carbide, are added, so that strength of membrane filaments is enhanced, and especially, pressure resistance and wear resistance of the membrane filaments are improved. The method can be used for preparing internal-pressure or external-pressure membrane filaments having a skin layer. The microstructure under the skin layer is also in a network structure or a particle stacking structure. The membrane filaments have good separation performance and high flux.

Owner:开源环保(集团)有限公司

Microwave integrated machine for production of aerogel material and method for continuous production of aerogel material

ActiveCN109529735AAvoid sparkingAvoid accidentsAerogel preparationEnergy based chemical/physical/physico-chemical processesMicrowaveThermal insulation

A microwave integrated machine for production of an aerogel material and a method for continuous production of the aerogel material are disclosed. The invention belongs to the technical field of aerogel material production and especially relates to a microwave integrated machine and an efficient production method for continuous production of the aerogel material by using the microwave technique. The invention aims to solve the technical problem that existing aerogel preparation methods have long production period and the internal skeleton structure is collapsed and the thermal insulation performance is reduced. The method of the invention comprises the following steps: preparing a wet aerogel material, letting the wet aerogel material enter a solvent replacement device and then enter a hydrophobic modification device, and drying to obtain the aerogel material; letting the evaporated solvent gas enter a shell and tube condenser, condensing for gas-liquid separation, recycling the solvent, returning an inert gas to the equipment for recycling so as to complete a production period. According to the method, each solvent replacement only takes more than ten minutes, and each hydrophobicmodification only takes more than ten minutes. Thereby, production efficiency is greatly improved.

Owner:江西宏柏新材料股份有限公司

Porous oxide and preparation method thereof

The invention provides a porous oxide and a preparation method thereof. The preparation method comprises the following steps of mixing an inorganic salt solution with a polymer solution, so as to obtain a precursor solution; carrying out freezing treatment and drying treatment on the precursor solution in sequence, so as to obtain a porous-structure predecessor; carrying out calcination on the porous-structure predecessor, so as to obtain the porous oxide. According to the preparation method, through the assistance of a polymer, the polymer is closely combined with an inorganic salt together; the growth of an ice crystal is impeded; a porous precursor is formed; the polymer is removed in a high-temperature calcination process; the inorganic salt is decomposed into an oxide and grows by using the porous precursor as a template, so as to obtain a porous oxide material which has a macroscopic three-dimensional structural feature and is uniform in pore canal.

Owner:NORTHEAST NORMAL UNIVERSITY

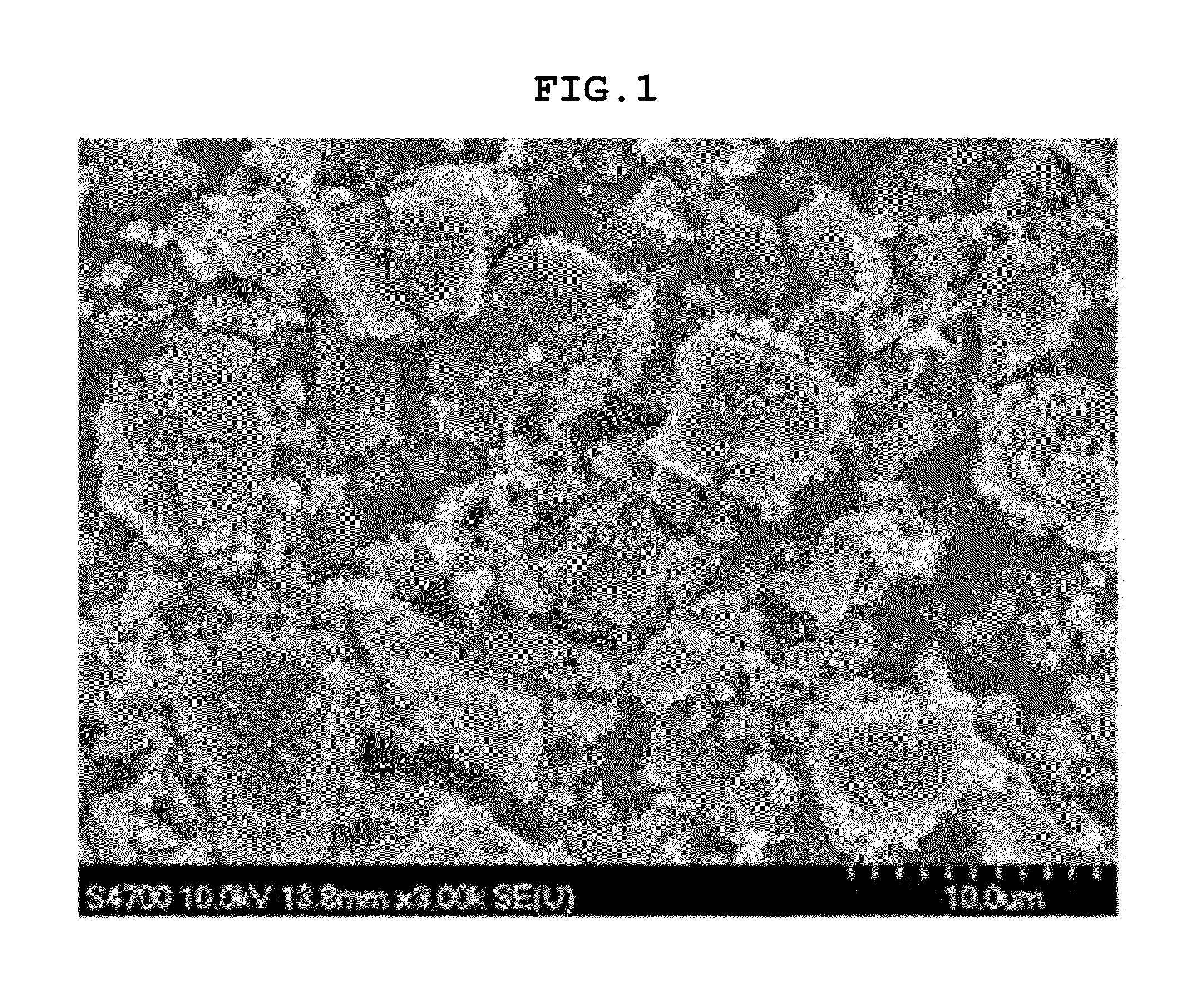

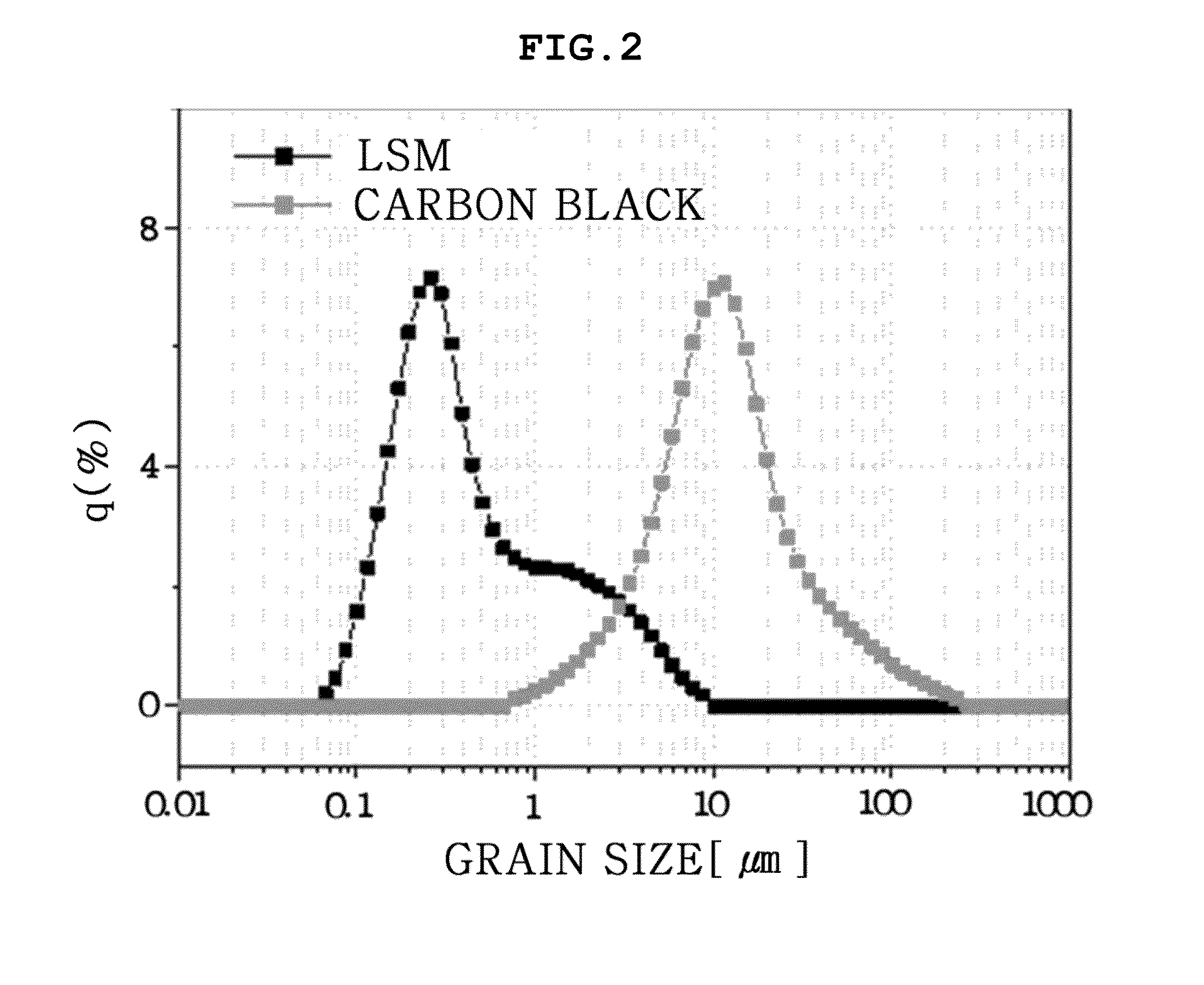

Electrode paste for solid oxide fuel cell, solid oxide fuel cell using the same, and fabricating method thereof

InactiveUS20140170523A1High porosityUniform poresCell electrodesConductive materialPorosityFuel cells

Disclosed herein are an electrode paste for a solid oxide fuel cell in an anode supported type in which an anode, an electrolyte layer, and a cathode are sequentially stacked, including a raw material powder, a dispersant, a binder, a solvent, and a liquid pore-forming material, a solid oxide fuel cell using the same, and a fabricating method thereof. The electrode paste for the solid oxide fuel cell may form uniform pores in the electrode and may provide high porosity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

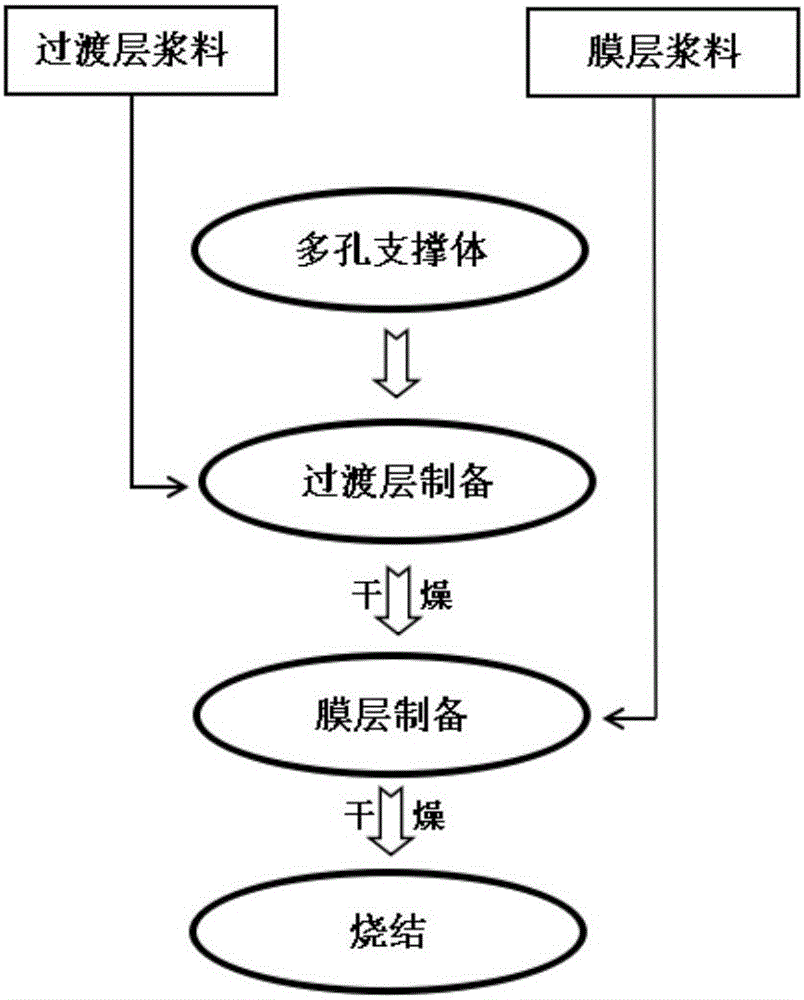

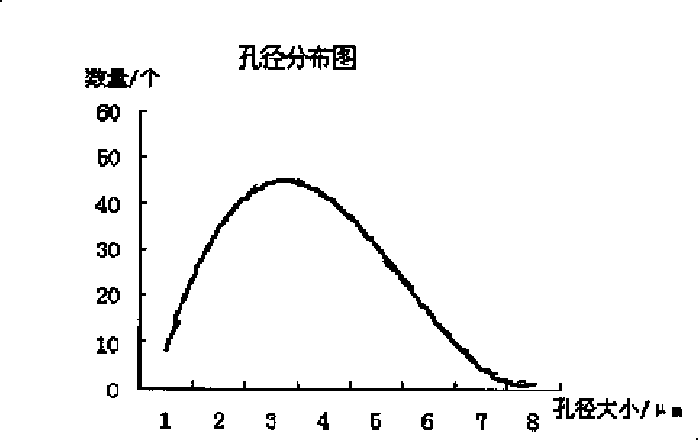

Porous ceramic film and preparation method thereof

ActiveCN106747346AUniform poresAperture adjustableSemi-permeable membranesCeramicwarePolyvinyl alcoholSlurry

The invention discloses a porous ceramic film and a preparation method thereof and belongs to the technical field of porous ceramic films. The porous ceramic film is of a multistage structure and comprises a film layer, a transition layer and a porous supporting body; the film layer is prepared by sintering low-activity nanometer particles with dense sphere and a middle transition phase; the transition layer is prepared by sintering conventional irregular micro-powder; and the film layer and the transition layer are sintered by one time under the same condition. The preparation method comprises the following steps: enabling the transition layer particles and the film layer particles to disperse in a polyvinyl alcohol (PVA) aqueous solution to obtain transition layer slurry and film layer slurry; depositing the transition layer on the surface of the porous supporting body by using a dipping-pulling method, and drying; preparing the film layer on the surface of the transition layer by using the dipping-pulling method, and drying to obtain a ceramic film green body; and finally, obtaining the porous ceramic film through one-step sintering. The porous ceramic film has very good effect on treating suspended matters and can be used in the fields of printing and dyeing material recovery, beverage clarification, powder preparation, oil-water separation and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for producing blowing up electrolyte and high specific surface area aluminum electrolytic capacitor electrode foil

InactiveCN101210342ALess pollutionIncrease specific volumeAnodisationElectrolytic capacitorsAluminium chlorideElectrolysis

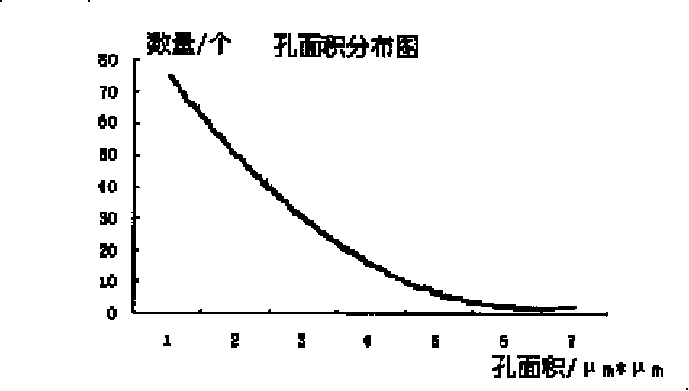

The invention relates to a pitting electrolyte and a production method of an electrode foil with high specific surface area for an aluminum electrolytic capacitor. The pitting electrolyte mainly contains aluminum chloride and sulfuric acid solution. The production method comprises a first pre-treatment step, a second anode oxidization step, a third acid pickling step, a fourth corrosion pitting step, a fifth hole expansion step and a sixth post-treatment step. The invention has simple process, convenient operation and less environment pollution. The electrode foil for the aluminum electrolytic capacitor produced by the invention has optimal normal distributions in hole diameter distribution, hole area and minimal hole pitch distribution, thus achieving uniform pitting capable of controlling the corrosion start point and greatly improving the specific capacity of the electrode foil for the aluminum electrolytic capacitor. Accordingly, the prepared aluminum electrolytic capacitor has a specific surface area of 10% to 15% and a specific capacity up to 0.70 to 0.75 muF / cm<2>.

Owner:XINJIANG JOINWORLD CO LTD

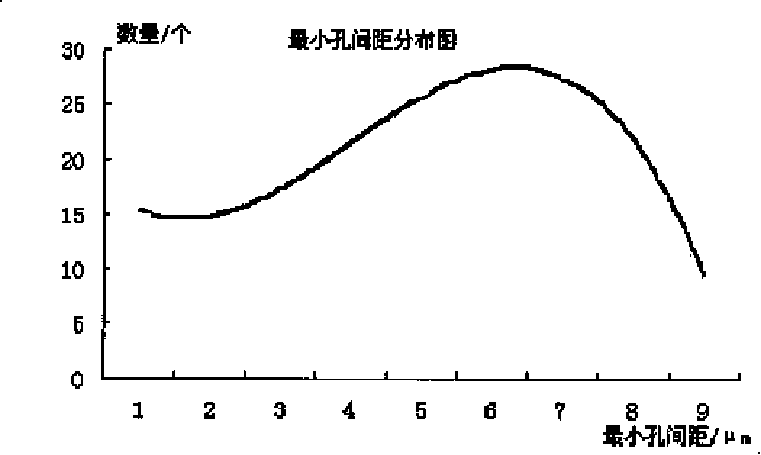

Mesoporous ruthenium nanoparticles for targeted therapy of colorectal cancer as well as preparation method and application of mesoporous ruthenium nanoparticles

ActiveCN109589407AControl reduction potentialFacilitate depositionPowder deliveryEnergy modified materialsSilicon dioxideCoordination complex

The invention discloses mesoporous ruthenium nanoparticles for targeted therapy of the colorectal cancer as well as a preparation method and application of the mesoporous ruthenium nanoparticles. Thepreparation method comprises the following steps: (1), dissolving ruthenium trichloride in a perchloric acid solution, then adding a nonionic surfactant, and mixing uniformly to obtain a mixed solution I; (2), adding amino-modified colloidal silicon dioxide nanoparticles into the mixed solution I, and ultrasonically mixing to obtain a uniform mixed solution II; (3), adding a sodium borohydride solution into the mixed solution II, performing an ultrasonic reaction, and after completion of the reaction, washing by using water and centrifuging to obtain an intermediate product; (4), dispersing the intermediate product in a hydrofluoric acid solution, then washing by using water and drying to obtain the mesoporous ruthenium nanoparticles for the targeted therapy of the colorectal cancer. The ruthenium nanoparticles prepared according to the preparation method provided by the invention have large specific surface area, can be loaded with a ruthenium complex and a coupled bispecific antibodyand are applied to targeted resistance to the colorectal cancer in combination with photothermal and immunotherapy.

Owner:JINAN UNIVERSITY

Water-repellent porous silica, method for preparation thereof and use thereof

InactiveUS6852299B2Uniform poresLow dielectric constantMaterial nanotechnologyPigmenting treatmentSilicon dioxideElectron

Water-repellent porous silica having uniform pores, which comprises silica skeleton wherein fluorine atoms are fixed through covalent bonds and which has an alkali metal content of not more than 10 ppb, is synthesized. By the water-repellent porous silica, a water-repellent porous silica film having uniform pores, which is applicable to a light functional material or an electron functional material, a process for preparing the same and uses thereof can be provided.

Owner:MITSUI CHEM INC

Preparation method of microcapsule antibacterial functional finishing agent

InactiveCN110344257AUniform pore sizeAperture ruleBiochemical fibre treatmentMesoporous silicaSilicon dioxide

The invention provides a preparation method of a microcapsule antibacterial functional finishing agent. According to the microcapsule antibacterial functional finishing agent, mesoporous silica coatedwith polyurethane serves as a wall material, aloin, lemon essential oil, vanilla oil and Chinese mugwort oil serve as core materials, and the weight ratio of the wall material to the core materials is 1:(1-5). A fabric finished by the finishing agent has good antibacterial effect, a combination action of the finishing agent and the fabric is high, and the antibacterial effect is more durable through sustained-release effect of a microcapsule. Antibacterial components used by the finishing agent are provided with natural extracts, safe and free from toxicity, and good health states of skins can be kept. The finishing agent has important application values in the field of textile.

Owner:SUZHOU INST OF TRADE & COMMERCE

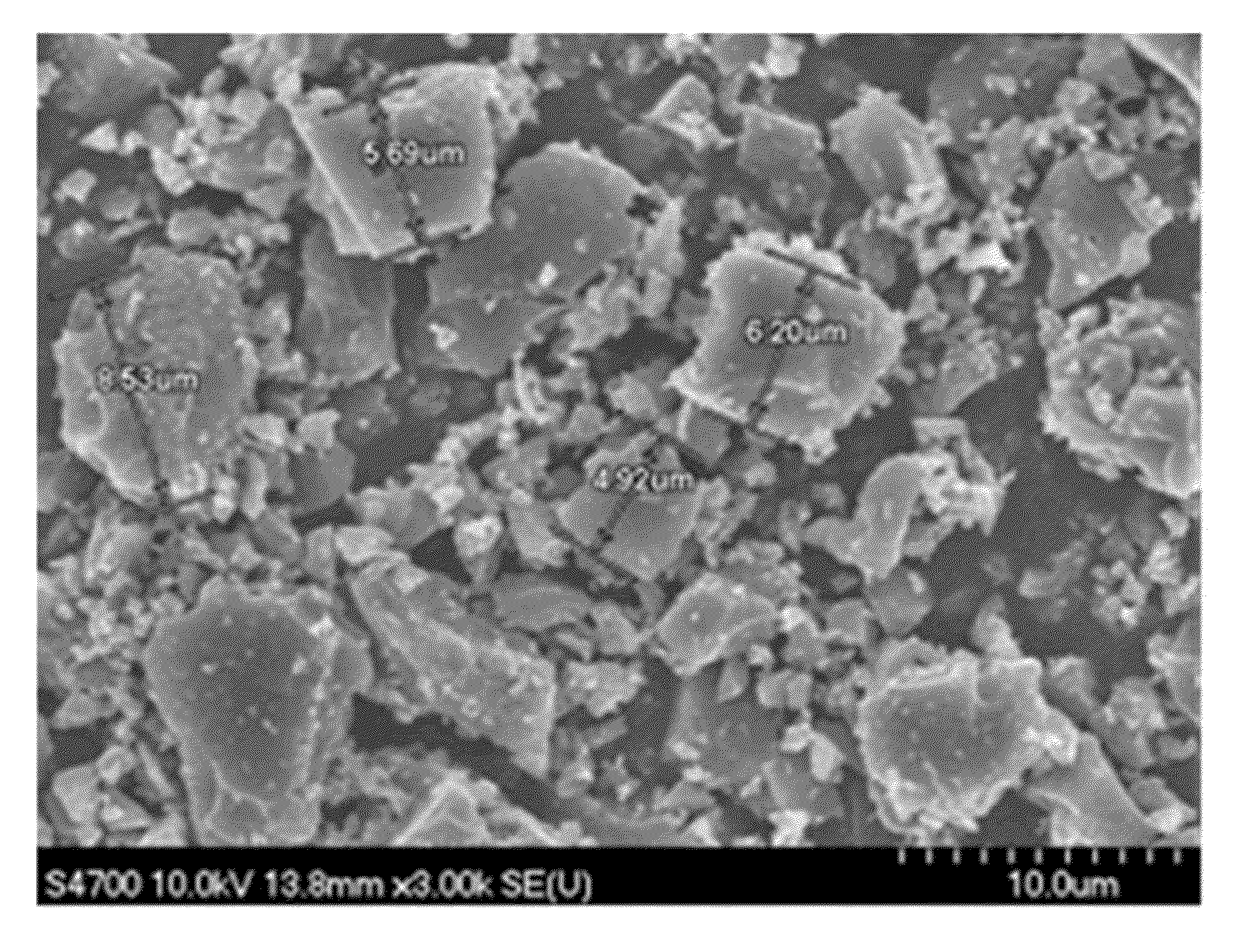

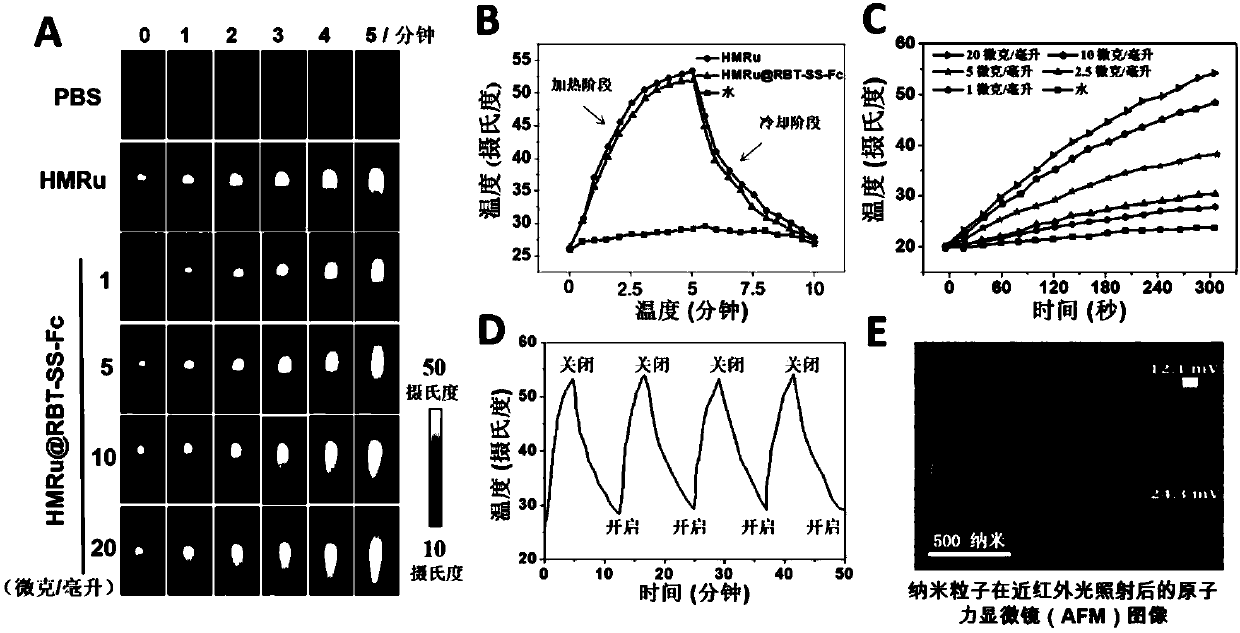

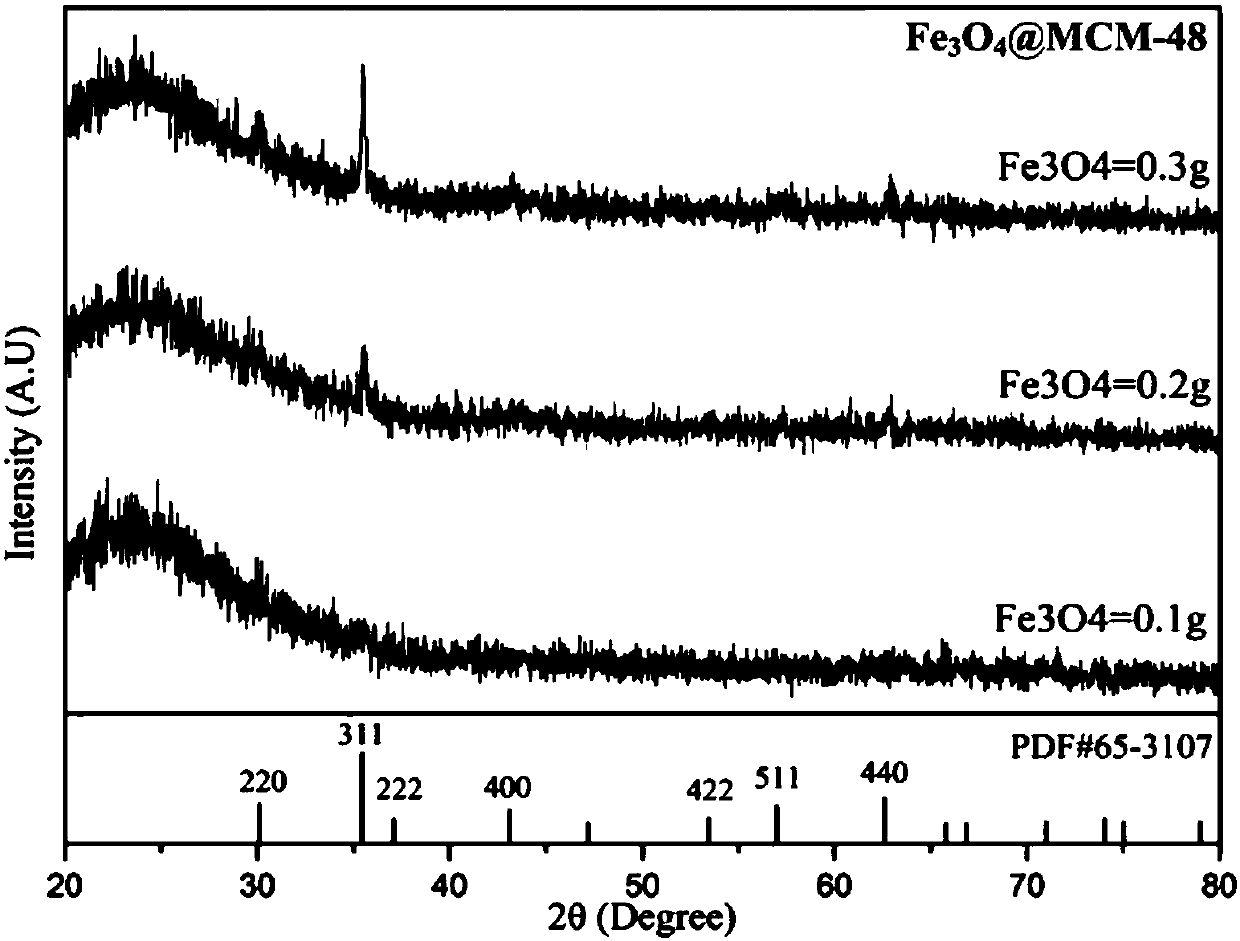

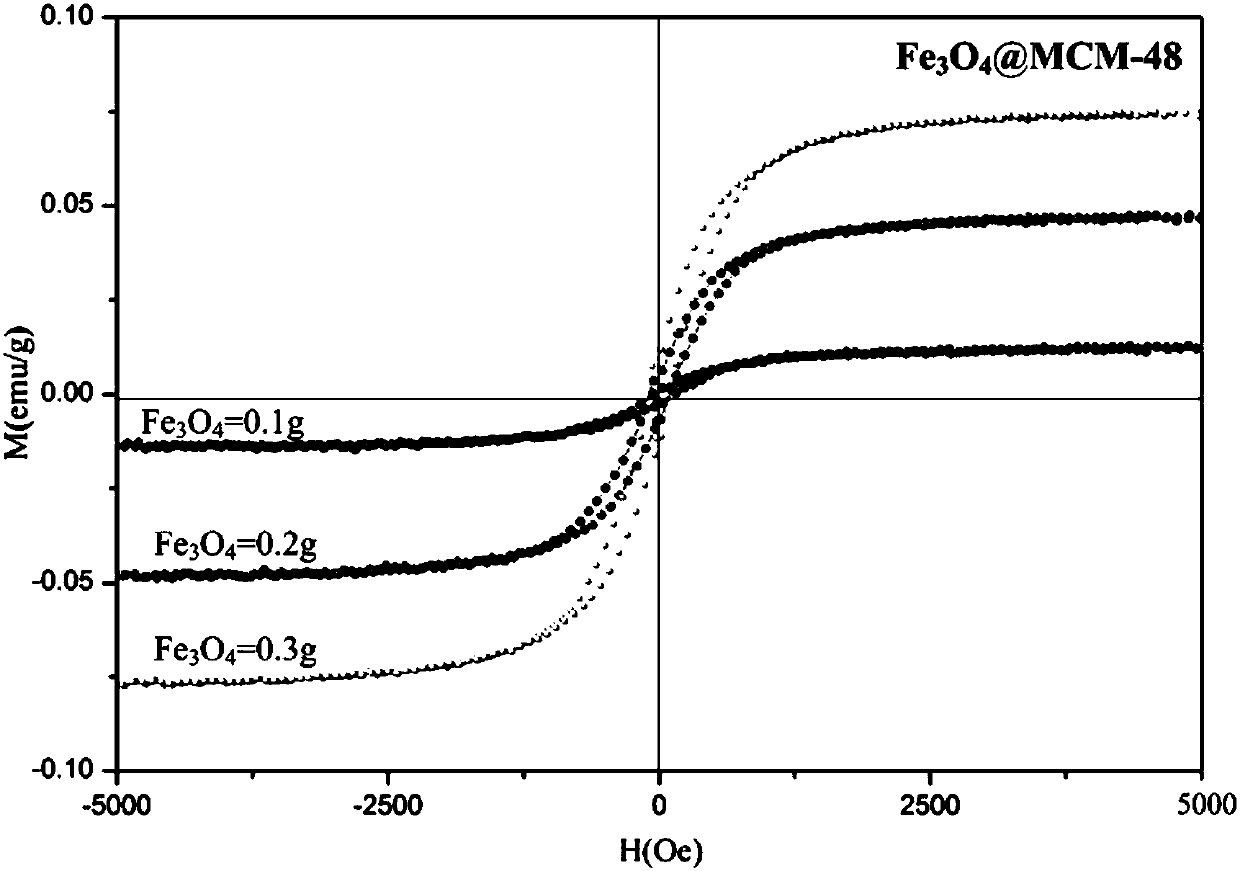

Preparation method of magnetic ordered mesopore Fe3O4@MCM-48 composite adsorbing material

ActiveCN107803180AStrong guidanceLow toxicityOther chemical processesAlkali metal oxides/hydroxidesMolecular sieveMaterial synthesis

The invention belongs to thel field of magnetic composite material synthesis technology, and particularly discloses a preparation method of a magnetic ordered mesopore Fe3O4@MCM-48 composite adsorbingmaterial. The preparation method includes steps of combining a ferrite Fe3O4 grain and a mesoporous molecular sieve MCM-48; roasting in a muffle furnace at 450-650 DEG C, so as to obtain the Fe3O4@MCM-48 magnetic mesopore composite adsorbing material with a core-shell structure. The method is low in cost, low in toxicity, simple in operation, gentle in condition, and short in consumed time; the prepared material has magnetism and the mesoporous duct of the molecular sieve; the preparation method has huge prospect in absorption and separation, and drug carrier.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Medium/low temperature mesoporous nitrogen oxide and dioxin removal catalyst and preparation method thereof

InactiveCN110368923ALarge specific surface areaEffective co-removalDispersed particle separationCatalyst activation/preparationActive componentMetal particle

The invention discloses a medium / low temperature mesoporous nitrogen oxide and dioxin removal catalyst and a preparation method thereof. According to the catalyst, a mesoporous carbon-silicon composite material is adopted as a carrier, and one or more of vanadium pentoxide, tungsten oxide, cerium oxide and manganese oxide are adopted as active components. The catalyst disclosed by the invention iscapable of effectively achieving synergetic removal of NOx and dioxin within a medium / low temperature range of 180-300 DEG C, and in addition, the catalyst disclosed by the invention has the advantages of being large in specific surface area, ordered in pore height, small in active metal particle size and uniform in active metal particle size distribution.

Owner:LONGKING COALOGIX ENVIRONMENTAL PROTECTION TECH SHANGHAI CO LTD

Cadmium selenide quantum dot and nanoporous carbon composite material and preparation method therefor

The invention provides a cadmium selenide quantum dot and nanoporous carbon composite material and a preparation method therefor. The cadmium selenide quantum dot and nanoporous carbon composite material is formed by cadmium selenide quantum dots and nanoporous carbon in a compounding manner; the cadmium selenide quantum dots are grown on the surface of the nanoporous carbon in an in-situ manner; and the nanoporous carbon is obtained by calcining a zeolite imidazate type coordination polymer under protection of an inert gas. The nanoporous carbon disclosed by the invention has the advantages of large specific surface area, uniform pore channels, and large pore channel dimensions; and when the composite material is formed by the nanoporous carbon and the cadmium selenide quantum dots, the dispersity of the cadmium selenide quantum dots can be improved, the crystal particle dimensions of the cadmium selenide quantum dots can be controlled, and generation of small-dimensional cadmium selenide quantum dots can be reduced, so that the photocatalytic efficiency and the service life of the composite material are obviously improved and prolonged.

Owner:CHANGCHUN UNIV OF TECH

An efficient catalyst for catalytic incineration of VOC waste gas and a preparing method thereof

InactiveCN108906069ASimple preparation processReduce energy consumptionHeterogenous catalyst chemical elementsCatalyst activation/preparationManganeseCerium

An efficient catalyst for catalytic incineration of VOC waste gas and a preparing method thereof are disclosed. The method includes (1) fully stirring active metal salt solutions according to a certain ratio to obtain a mixture solution, then adding a proper amount of activated carbon, stirring the mixture for 2-6 h, then adding activated alumina and cerium dioxide powder as a catalyst carrier, stirring the mixture overnight, and finally stirring and drying the mixture at a constant temperature to obtain mixture powder, with the active metals being two or more selected from copper, manganese,cobalt, antimony and lanthanum; (2) mixing the dried mixture powder and a pore forming agent, adding the mixture into a ball mill, performing ball milling for 4-8 h, then adding a binder, fully mixingthe materials, and performing extrusion molding to obtain a catalyst precursor; and (3) roasting the catalyst precursor at 350-750 DEG C for 2-6 h. The method is simple in process and low in energy consumption, and the obtained catalyst is low in cost, high in poisoning resistance, wide in applicability, free of secondary pollution, long in service lifetime and high in catalysis efficiency.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Silicon carbide based, porous structural material being heat-resistant and super-lightweight

InactiveUS20070032371A1Easy to produceUniform poresCeramic shaping apparatusCeramicwareHeat resistanceStructural material

A process for producing a silicon carbide-based heat-resistant, ultra-lightweight, porous structural material having the shape of a spongy porous body.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Reinforced polyvinylidene fluoride hollow fiber micropore filter membrane and preparation method of same

ActiveCN107096395AReasonable microstructureEliminate finger holesSemi-permeable membranesMembranesFiberMicropore Filter

The invention discloses a preparation method of a reinforced polyvinylidene fluoride hollow fiber micropore filter membrane. The preparation method includes the steps of: preparing a film casting liquid; preparing a support body; preparing an outer solidifying liquid; performing spinning; performing rinsing replacement; and performing thermal treatment. The method is used for preparing the PVDF hollow fiber micropore filter membrane through combination of thermally induced phase separation and solution phase conversion; compared with the solution phase conversion method, finger-like holes are eliminated, and the microstructure of the membrane is more reasonable; and compared with the thermally induced phase separation method, the method simplifies operations, is free of solvent extraction and reduces cost; in the film casting liquid, inorganic additives, such as nano glass powder or nano silicon carbide, are added, so that strength of membrane filaments is enhanced, and especially, pressure resistance and wear resistance of the membrane filaments are improved.

Owner:开源环保(集团)有限公司

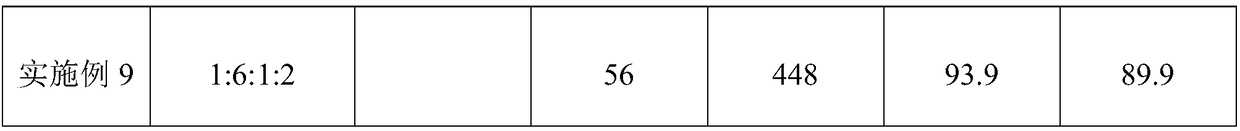

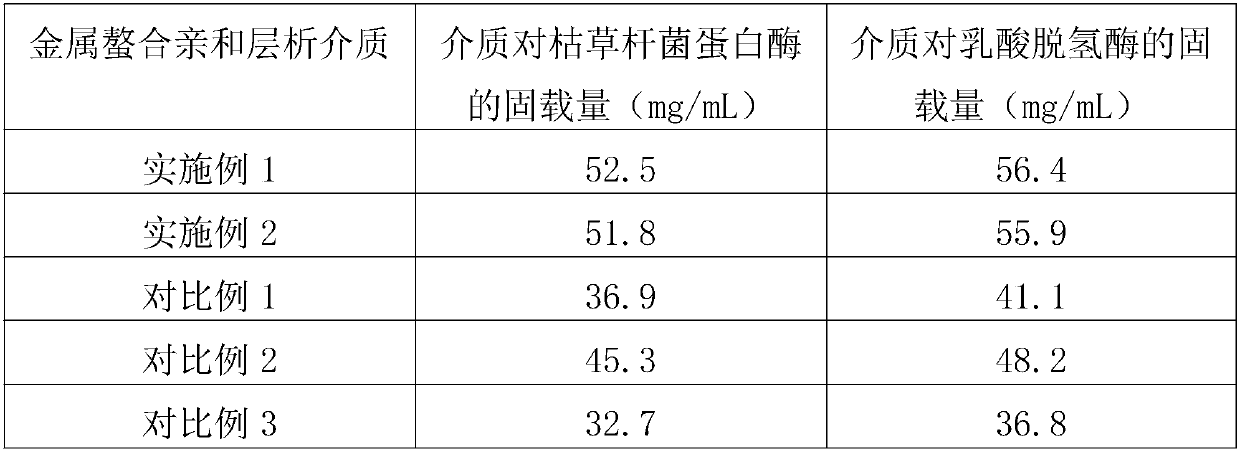

High carrying capacity metal chelating affinity chromatography medium

ActiveCN107754769AIncrease protein loadIncreased metal loadingOther chemical processesSolid sorbent liquid separationIonCarrying capacity

The invention relates to a high carrying capacity metal chelating affinity chromatography medium. Silica gel microspheres are adopted as a core; pores are formed inside the silica gel microspheres; carboxymethyl chitosan oligosaccharide molecules are adhered to the surfaces and the pores of the silica gel microspheres; a part of the carboxymethyl chitosan oligosaccharide molecules are complexed with first metal ions to form a first layer of metal chelating; the rest part of the carboxymethyl chitosan oligosaccharide molecules are bonded with allyl glycidyl ether; the allyl glycidyl ether is connected with aglycone; and the aglycone is complexed with second metal ions to form a second layer of metal chelating. By adopting the medium, double metal layers are successfully immobilized on the surface of the medium, the carrying capacity of the metal affinity chromatography medium is effectively increased, and the medium is simple in improvement method, low in production cost and beneficialto large-scale popularization and application.

Owner:SUZHOU BOJIN BIOLOGICAL TECH

Preparation method of mesoporous lithium vanadium phosphate cathode material

ActiveCN108461751AHigh specific capacityHigh mesoporous structurePhosphatesCell electrodesPhosphateElectrolyte

The invention discloses a preparation method of a mesoporous lithium vanadium phosphate cathode material. The method comprises the following steps: (1) preparing a mixed solution from a vanadium source, a phosphorus source, a template agent and oxalic acid according to a ratio, and drying the mixed solution to obtain a dried mixture; (2) calcining the dried mixture obtained in the step (1) under inert atmosphere, then adding an alkaline solution and removing the template agent, washing and drying to obtain mesoporous vanadium phosphate; and (3) mixing mesoporous vanadium phosphate obtained inthe step (2) with a lithium source according to a mass ratio of 1 to (0.1-5), then adding the mixture to deionized water to prepare a solution with a lithium ion concentration of 0.01-10mol / L, duringand calcining under inert atmosphere, then removing unreacted lithium elements by using deionized water, and drying the solution to obtain mesoporous lithium vanadium phosphate. The mesoporous lithiumvanadium phosphate prepared by the method has uniform pores; the contact area between the mesoporous lithium vanadium phosphate and electrolyte is increased; the electron transmission distance is shortened, so that the lithium battery conductivity and the material utilization rate are improved.

Owner:GUANGDONG TEAMGIANT NEW ENERGY TECH CORP

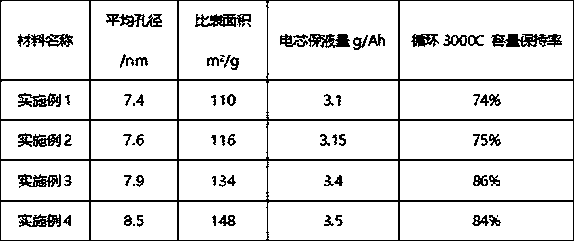

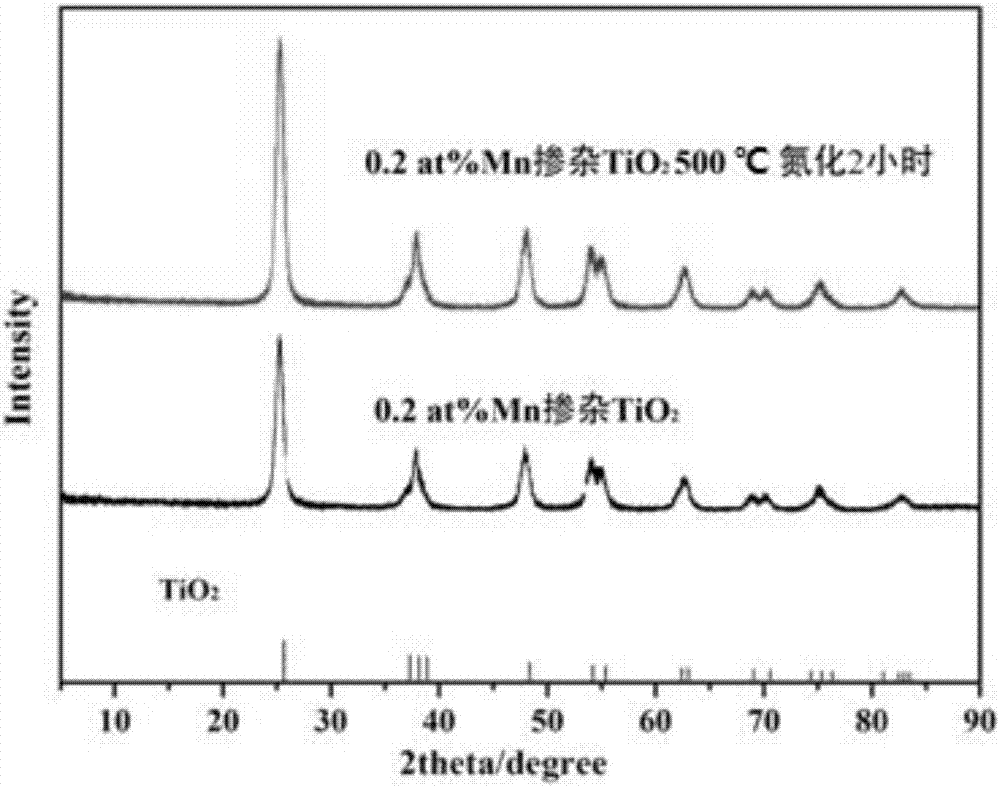

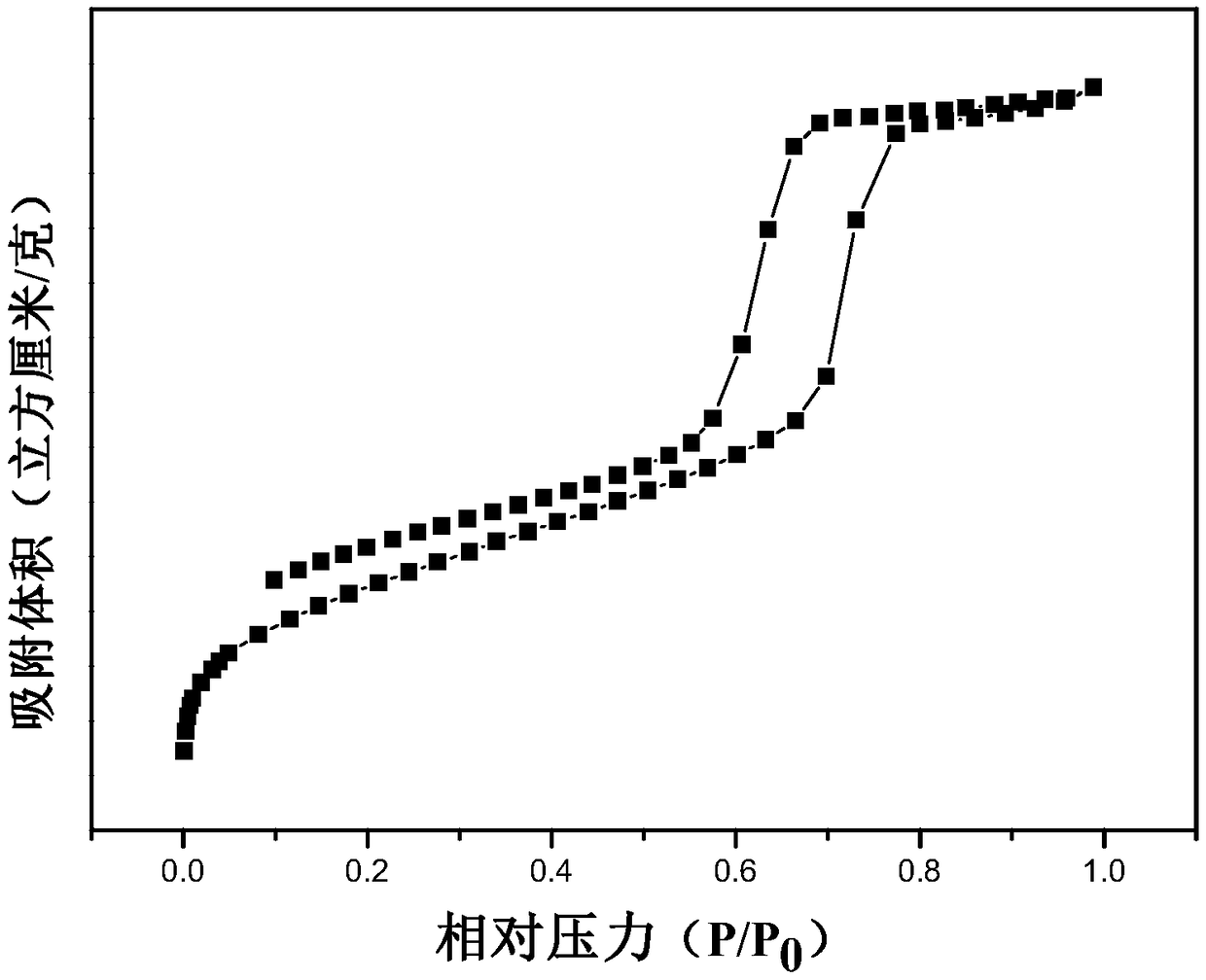

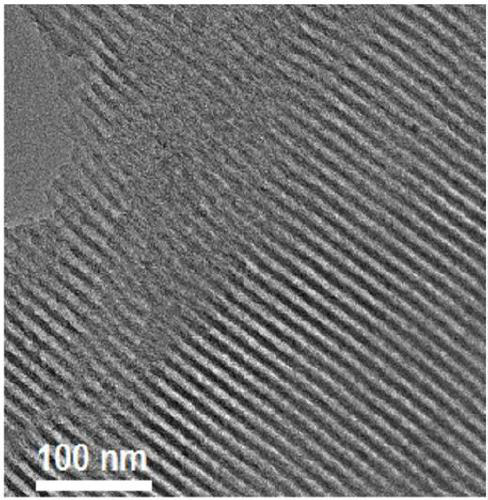

Mesoporous surface defect Mn-N-TiO2 microsphere photocatalytic material and preparation method thereof

InactiveCN107486229AGood dispersionLarge specific surface areaPhysical/chemical process catalystsMicrosphereNitrogen source

The invention relates to a mesoporous surface defect Mn-N-TiO2 microsphere photocatalytic material and a preparation method thereof. The preparation method specifically comprises preparing mesoporous surface defect Mn-TiO2 microspheres and carrying out nitriding treatment, wherein the nitrogen source used for the nitriding treatment is ammonia gas, a surfactant is added during the preparation of the mesoporous surface defect Mn-TiO2 microspheres, and the nitriding treatment is performed in ammonia gas so as to obtain the mesoporous surface defect Mn-N-TiO2 microsphere photocatalytic material. According to the present invention, the metal double-doped titanium dioxide photocatalytic material obtained through the experiment process has characteristics of mesoporous structure and uniform spherical structure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation and application of bifunctional ionic liquid loaded mesoporous polymer

ActiveCN109174181ALarge specific surface areaUniform poresOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium acetateIon exchange

The invention discloses a preparation and an application of a bifunctional ionic liquid loaded mesoporous polymer. The preparation is characterized by the following steps: taking an imidazole functional ordered mesopore polymer as a carrier, connecting 1,2-dibromoethane and triethylamine in the form of covalent bond, and using sodium acetate and bifunctional ionic liquid for performing ion exchange, thereby acquiring the bifunctional ionic liquid loaded mesoporous polymer. The bifunctional ionic liquid loaded mesoporous polymer is served as a catalyst in the reaction of CO2 and amino compoundfor compounding formamide through heterogeneous catalysis synthesis. Compared with the prior art, the bifunctional ionic liquid loaded mesoporous polymer has the characteristics of large specific surface area of mesoporous material, uniform duct, high heat stability, high chemical stability, and the like; the bifunctional ionic liquid loaded mesoporous polymer is capable of catalyzing the reactionof CO2 and amino compound under a mild condition, has high catalytic activity, can be easily separated and recycled and is reusable; the bifunctional ionic liquid loaded mesoporous polymer is a novelenvironment-friendly catalyst and has a huge development potential in the field of heterogeneous catalysis.

Owner:EAST CHINA NORMAL UNIV

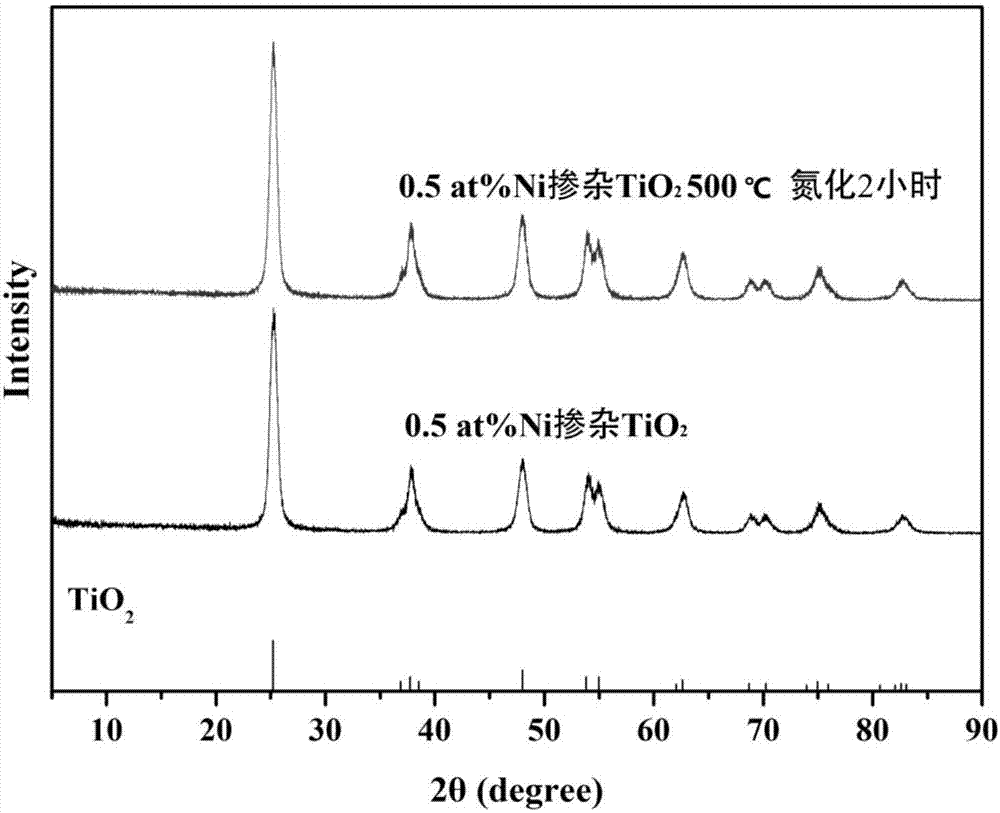

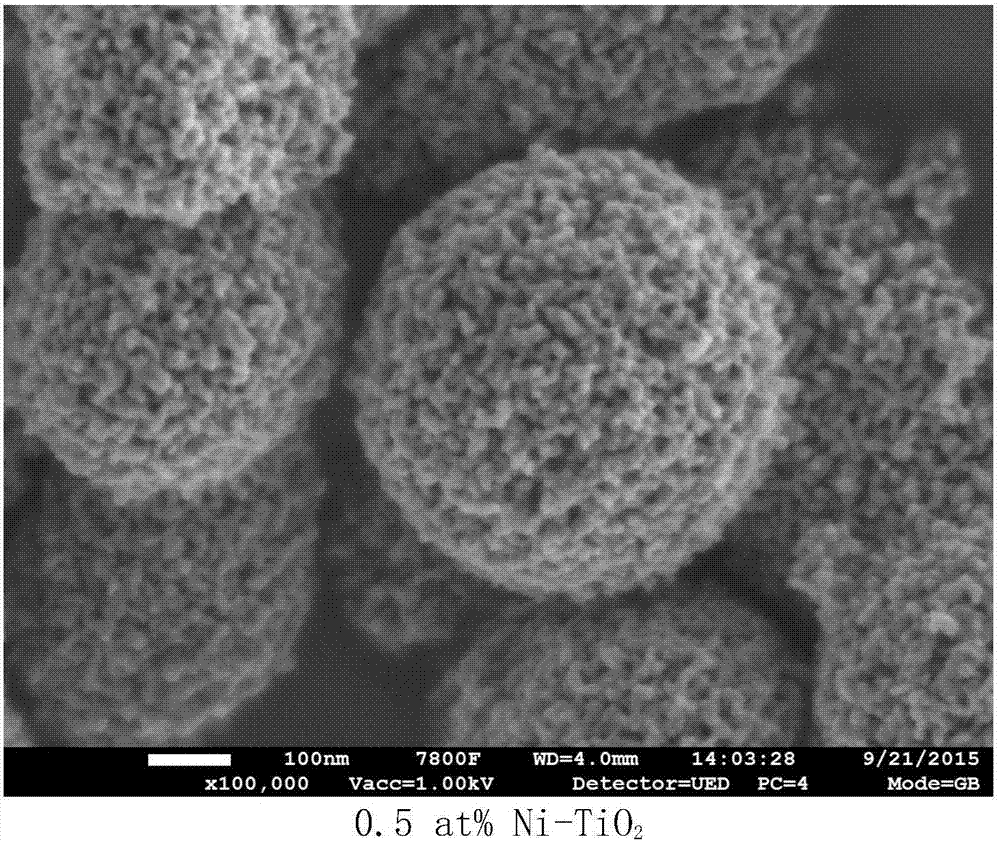

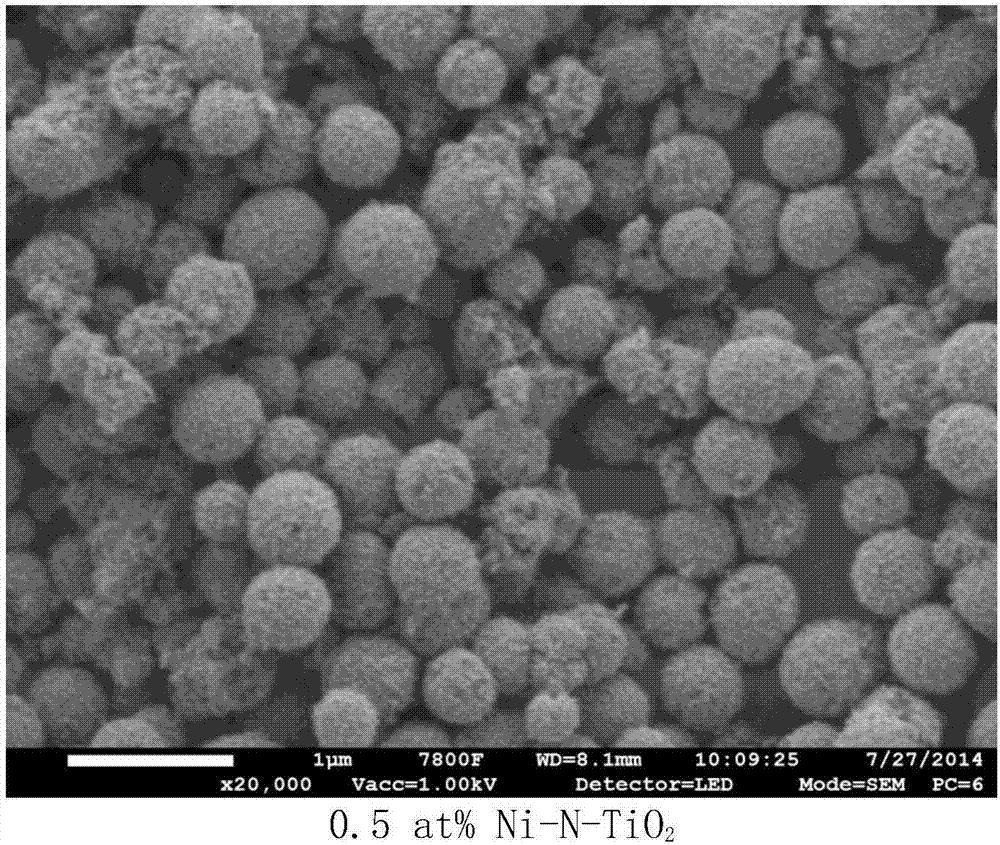

Mesoporous surface defect Ni-N-TiO2 microsphere photocatalytic material and preparation method thereof

InactiveCN107486227AGood dispersionLarge specific surface areaPhysical/chemical process catalystsMicrosphereNitrogen source

The invention relates to a mesoporous surface defect Ni-N-TiO2 microsphere photocatalytic material and a preparation method thereof. The preparation method specifically comprises: preparing mesoporous surface defect Ni-TiO2 microspheres, and carrying out nitriding treatment, wherein a surfactant is added during the preparation of the mesoporous surface defect Ni-TiO2 microspheres, the nitrogen source for the nitriding treatment is ammonia gas, and the nitriding treatment is performed in the ammonia gas to obtain the mesoporous surface defect Ni-N-TiO2 microsphere photocatalytic material. According to the present invention, the mesoporous surface defect Ni-N-TiO2 microsphere photocatalytic material obtained through the experiment process has the mesoporous structure and has the uniform spherical structure.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

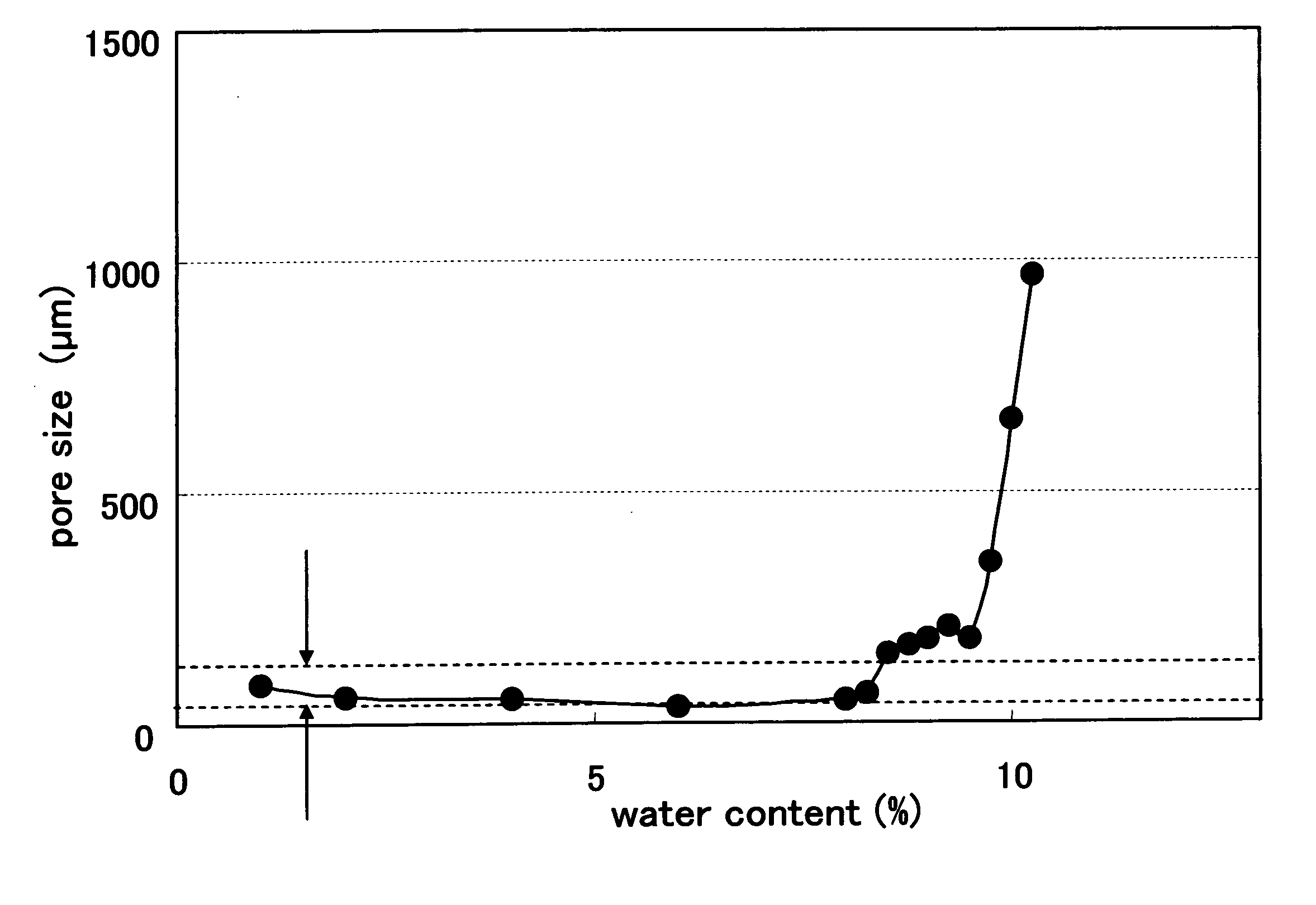

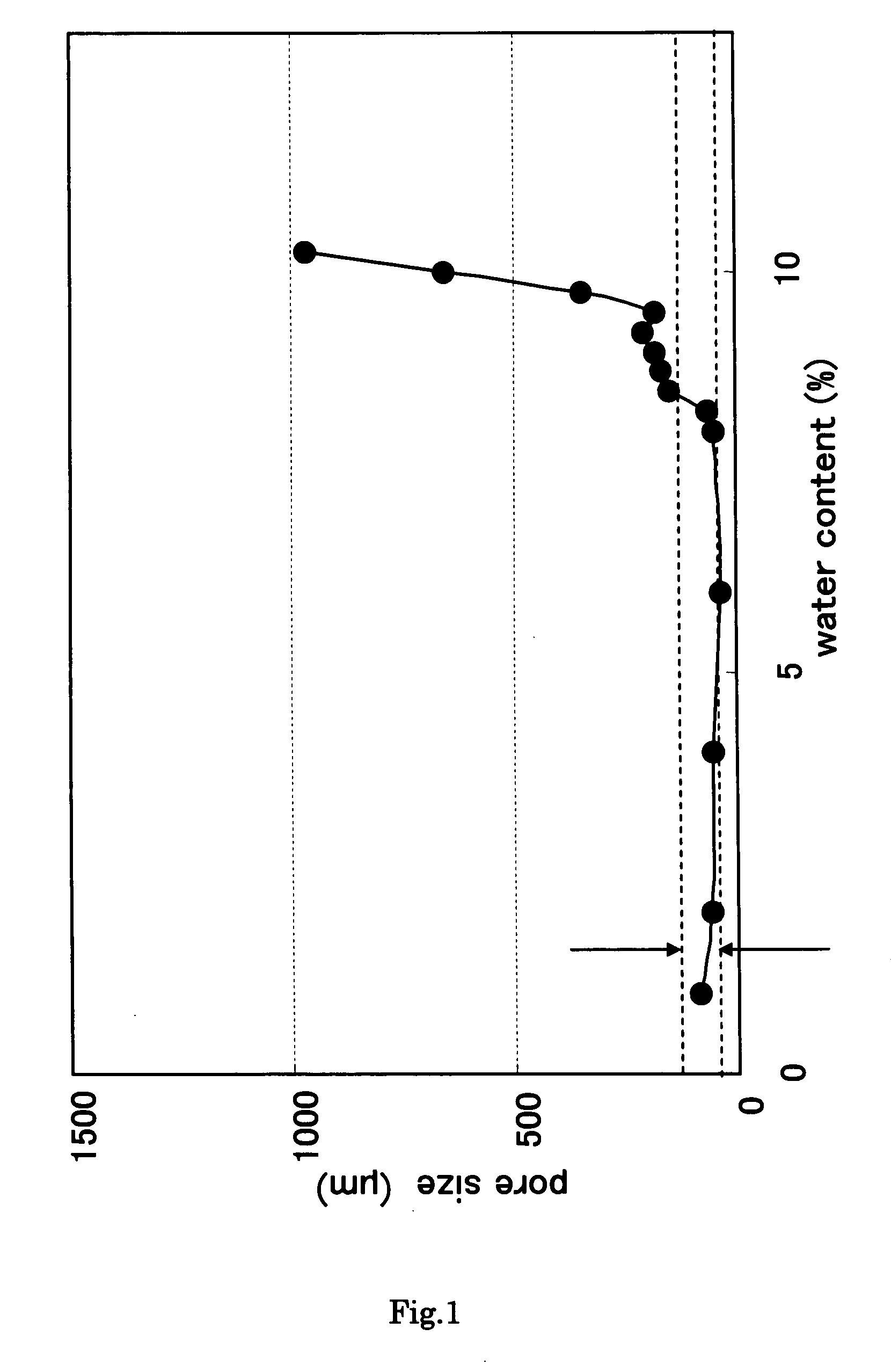

Process for Producing Porous Object and Porous Object Obtained By the Same

A process for producing a porous object is provided that makes it possible to control pore sizes, particularly not only smaller pore sizes but also larger pore sizes. The pore sizes are controlled by: preparing a mixed solution containing a polymer including a copolymer of lactide and caprolactone, a solvent in which the polymer has a relatively low solubility, and a solvent in which the polymer has a relatively high solubility and that is compatible with the solvent in which the polymer has a relatively low solubility; varying the content of the solvent in which the polymer has a relatively low solubility in the mixed solution, when the mixed solution is frozen and dried to produce the porous object; and cooling the mixed solution at a rate of 300° C. / hr or lower in freeze-treating. Thus a porous object with a pore size of 30 to 1800 μm can be obtained.

Owner:JMS CO LTD

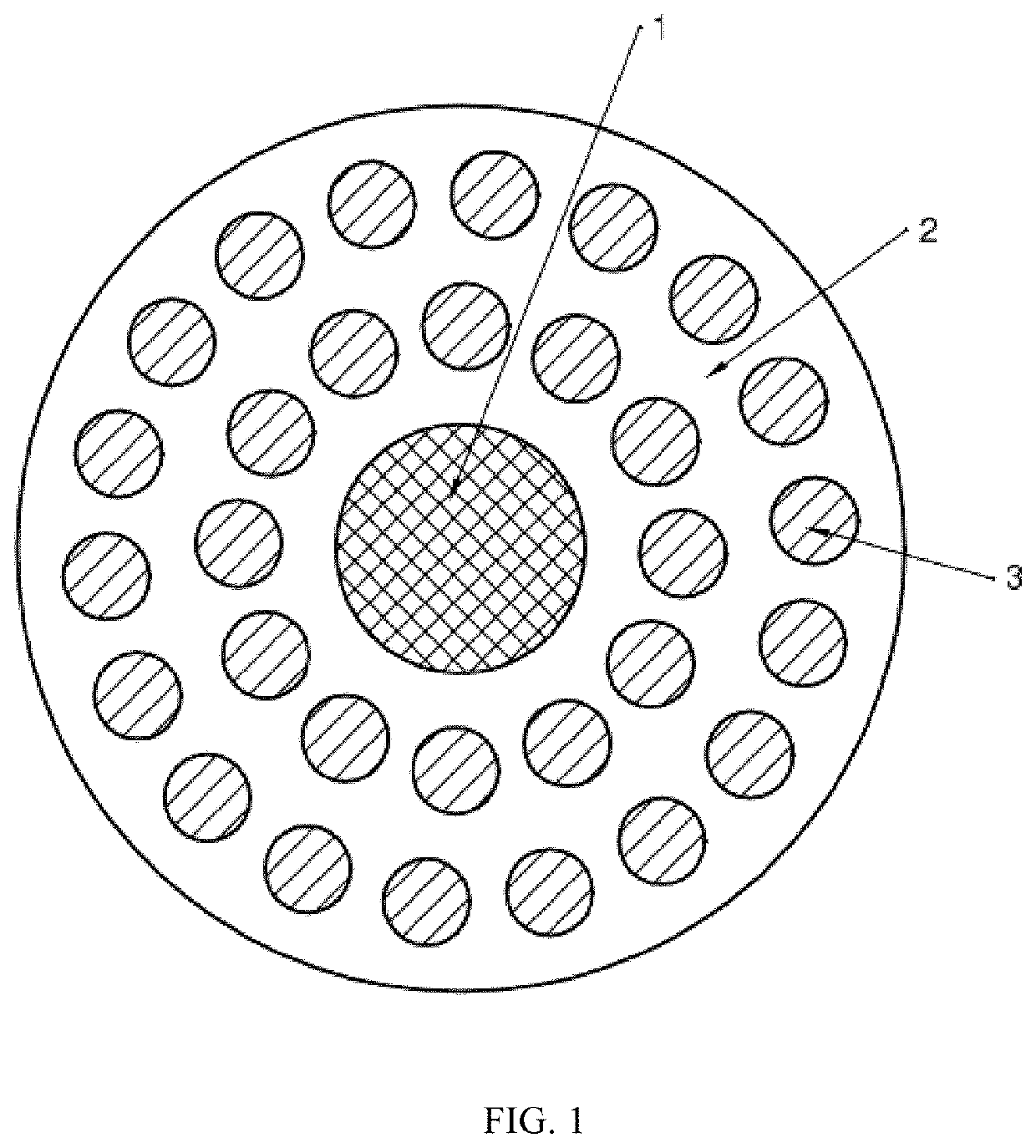

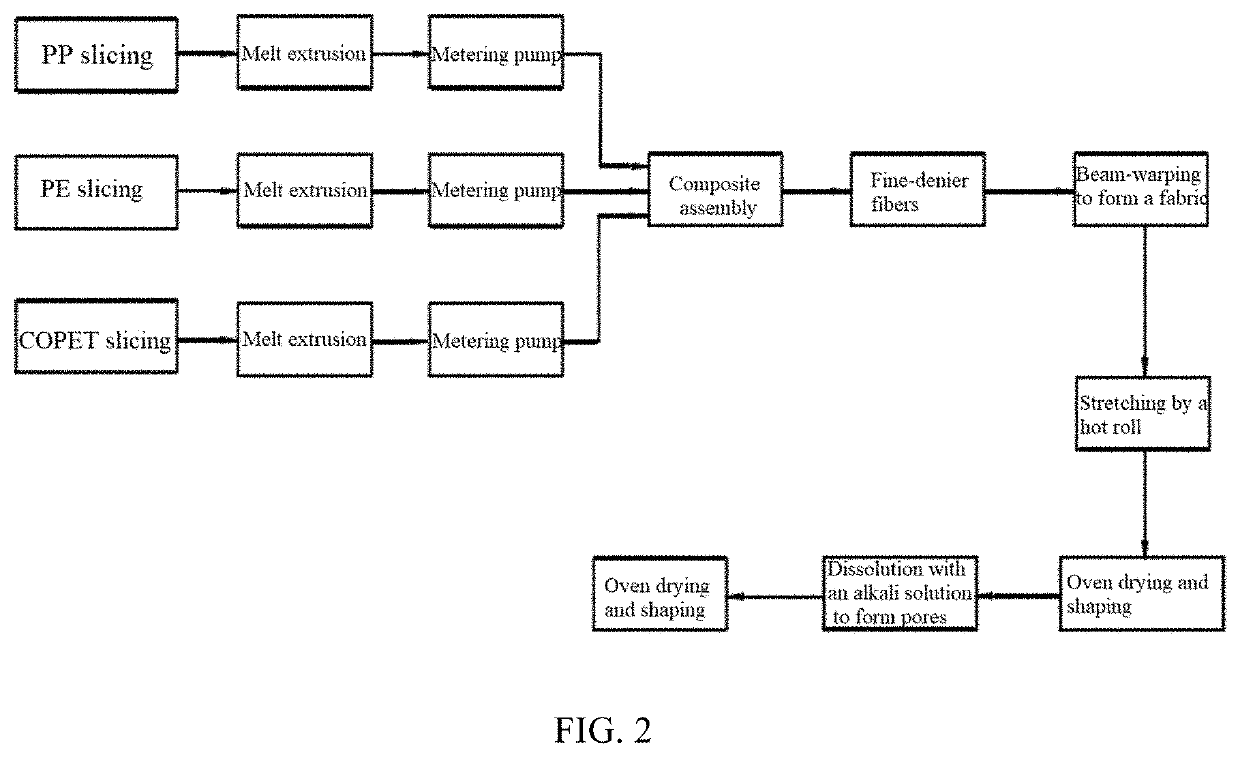

Lithium ion battery separator and manufacturing method therefor

ActiveUS20200035970A1High strengthUniform poreFilament/thread formingSecondary cellsPolypropylenePolyester

The present invention relates to a new lithium ion battery separator and a manufacturing method therefor, composite fine-denier POY fibers with polypropylene PP acting as a core and alkali-soluble polyester COPET and polyethylene PE acting as a skin are produced by means of a chemical fiber composite spinning technology, wherein the COPET and PE are distributed as an islands-in-the-sea form, then the POY fibers are arranged as a fabric with a certain breadth by means of beam-warping, the fabric is subjected to stretching and hot-pressing by a hot roll such that the PE component having a low melting point is melted and joined to form a film, and then the COPET is dissolved away by means of an alkali solution such that a place where the COPET is present in the film become pores and PP fibers become the skeleton of the film, thus forming a lithium ion battery separator.

Owner:GUANGDONG MODERN HIGH TECH FIBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com