An efficient catalyst for catalytic incineration of VOC waste gas and a preparing method thereof

A technology of catalytic incineration and catalyst, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, combustion method, etc., can solve the problems of easy blockage and poisoning, high catalyst cost, prevent loss from falling off, good catalytic effect, and difficult to block. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

[0031] The following method is used to prepare a high-efficiency catalyst for VOCs exhaust gas catalytic incineration:

[0032] Stir the active metal salt solution evenly according to a certain proportion to obtain a mixed solution, then add an appropriate amount of activated carbon and continue to stir for 2 to 6 hours, then add activated alumina and ceria powder as catalyst carriers and stir overnight, and finally stir and dry at a constant temperature to obtain a mixture Powder; the active metal is a mixture of copper, manganese, cobalt and antimony; active material mass ratio MnO:CuO:Co 3 o 4 :Sb 2 o 3 =(6~2):(1~5):(1~2):(2~1).

[0033] Mix the dry mixture powder, pore-forming agent starch, and polyethylene glycol into a ball mill and mill for 6 hours, then add adhesive silica sol and gum, mix evenly, and extrude into strips to obtain a catalyst precursor;

[0034] The catalyst precursor is calcined, the calcining temperature is 550°C, and the calcining time is 4h.

...

Embodiment 10

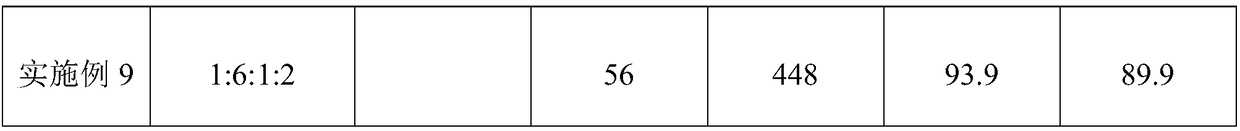

[0041] The catalysts prepared in Examples 1-9 were used for catalytic incineration experiments on incineration gas containing propylene and chloroform.

[0042] This catalytic combustion experiment condition is: light-off temperature 280 ℃-350 ℃ (embodiment 1,4,7 light-off temperature is 300 ℃, embodiment 2,5,8 light-off temperature is 280 ℃, embodiment 3,6, 9 The light-off temperature is 350°C), and the intake air concentration is 2000mg / m 3 , control the reaction space velocity to 8000h -1 , using Shimadzu 2014C gas chromatography to analyze the exhaust gas treatment ability of the catalyst on-line. The results are listed in Table 1.

[0043] As can be seen from Table 1, MnO:CuO:Co 3 o 4 :Sb 2 o 3 =4:3:1:2, ceria:activated alumina=1:1, the catalytic incineration effect is the best, the removal rate of propylene can reach more than 99%, and the removal rate of chloroform can reach more than 96%.

Embodiment 11

[0045] Using the same catalytic incineration experimental conditions as in Example 10, the active component mass ratio of the selected catalyst is MnO:CuO:Co 3 o 4 :Sb 2 o 3 =4:3:1:2; alumina: ceria = 1:1, treating methanol, benzene, toluene, xylene, aniline, acrolein, acrylonitrile and other organic pollutant gases, the treatment results are shown in Table 2.

[0046] As can be seen from Table 2, the catalyst produced by the present invention has a good removal rate for various volatile organic pollutants and has wide applicability.

[0047] Table 2 Catalytic combustion experiment results of various volatile organic pollutants

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com