Method for producing blowing up electrolyte and high specific surface area aluminum electrolytic capacitor electrode foil

An aluminum electrolytic capacitor, high specific surface area technology, applied in the direction of anodic oxidation, etc., can solve the problems of reduced mechanical strength, low area expansion rate, high data dispersion rate, etc., and achieve the effect of increasing specific capacitance value, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

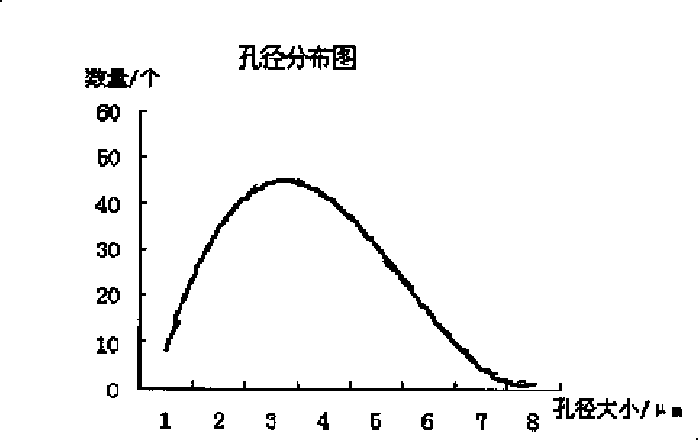

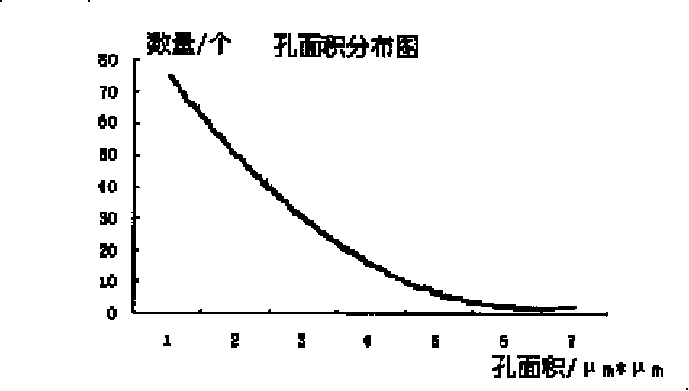

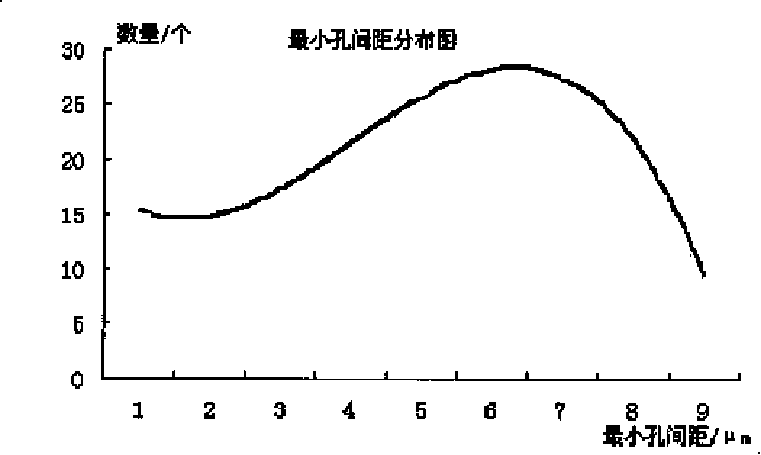

Image

Examples

Embodiment 1

[0038] Embodiment 1, the production method of the high specific surface area aluminum electrolytic capacitor electrode foil is carried out according to the following steps:

[0039] The first step of pretreatment: Alkali or pickling of aluminum foil for aluminum electrolytic capacitors that need to be corroded;

[0040] The second step of anodizing: Put the pre-treated aluminum foil into a phosphoric acid solution at a temperature of 5°C or 18°C or 30°C, and use 1mA / cm 2 or 5mA / cm 2 or 10mA / cm 2 After the DC constant current and the voltage rise from 0 volts to the set voltage of 40 volts or 75 volts or 110 volts, the current drops to 0.01mA / cm under the condition of uninterrupted power supply 2 or 0.05mA / cm 2 Dip or 0.1mA / cm 2 Finally, constant current oxidation until the oxidation voltage drops to 1 volt or 5 volts or 10 volts;

[0041] The third step of acid leaching treatment: on the basis of the second step, soak the aluminum foil in 10% or 30% or 50% nitric acid s...

Embodiment 2

[0045] Embodiment 2, the production method of the high specific surface area aluminum electrolytic capacitor electrode foil is carried out according to the following steps:

[0046] The first step of pretreatment: Alkali or pickling of aluminum foil for aluminum electrolytic capacitors that need to be corroded;

[0047] The second step of anodizing: put the pre-treated aluminum foil into a phosphoric acid solution at a temperature of 5°C or 30°C, and use 1mA / cm 2 to 10mA / cm 2 The DC constant current raises the voltage from 0 volts to 40 volts or 75 volts or 110 volts after setting the voltage, constant voltage for 400 seconds or 1000 seconds or 2000 seconds or 3000 seconds or 1 hour or 3 hours or 5 hours or 7 hours, at Under the condition of uninterrupted power supply, the current drops to 0.01mA / cm 2 or 0.1mA / cm 2 Finally, constant current oxidation until the oxidation voltage drops to 1 volt or 10 volts;

[0048] The third step of acid leaching treatment: on the basis of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com