Porous oxide and preparation method thereof

A technology of porous oxide and porous structure, applied in the field of porous materials, can solve the problems of complex post-processing, easy collapse, low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a method for preparing a porous oxide, comprising the following steps:

[0048] mixing the inorganic salt solution and the polymer solution to obtain a precursor solution;

[0049] The precursor solution is sequentially subjected to freezing treatment and drying treatment to obtain a porous structure precursor;

[0050] The porous structure precursor is calcined to obtain a porous oxide.

[0051] The invention mixes the inorganic salt solution and the polymer solution to obtain the precursor solution. In the present invention, the inorganic salt is preferably a soluble salt, more preferably one or more of bismuth nitrate, nickel nitrate, phosphotungstic heteropolyacid (HPW), zinc acetate and tin chloride; The mass concentration of the solution is preferably 1-10%, more preferably 2-9%, most preferably 4-6%. The present invention does not have any special requirements on the source of the inorganic salt, and commercially available products of th...

Embodiment 1

[0063] 2.5wt% PVA aqueous solution and 9wt% HPW aqueous solution were mixed according to a mass ratio of 0.25:1, and magnetically stirred at a speed of 800r / min for 12h to obtain a precursor solution.

[0064] Put the precursor solution in a centrifuge tube, insert it into liquid nitrogen quickly in an orientation, and quickly move it into a vacuum drying device, keep the vacuum degree below 20Pa, and dry it at -60°C for 48 hours to obtain HPW / PVA with a regular pore structure Precursor.

[0065] The above precursors were stabilized at 100 °C in air for 24 h.

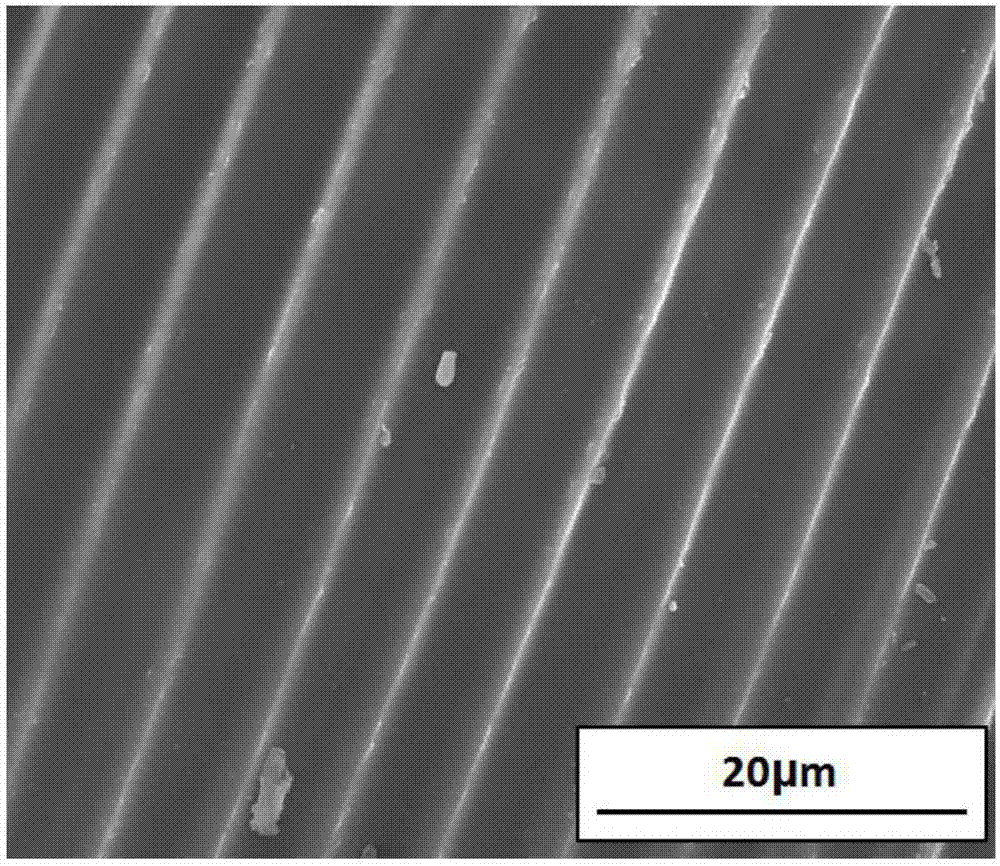

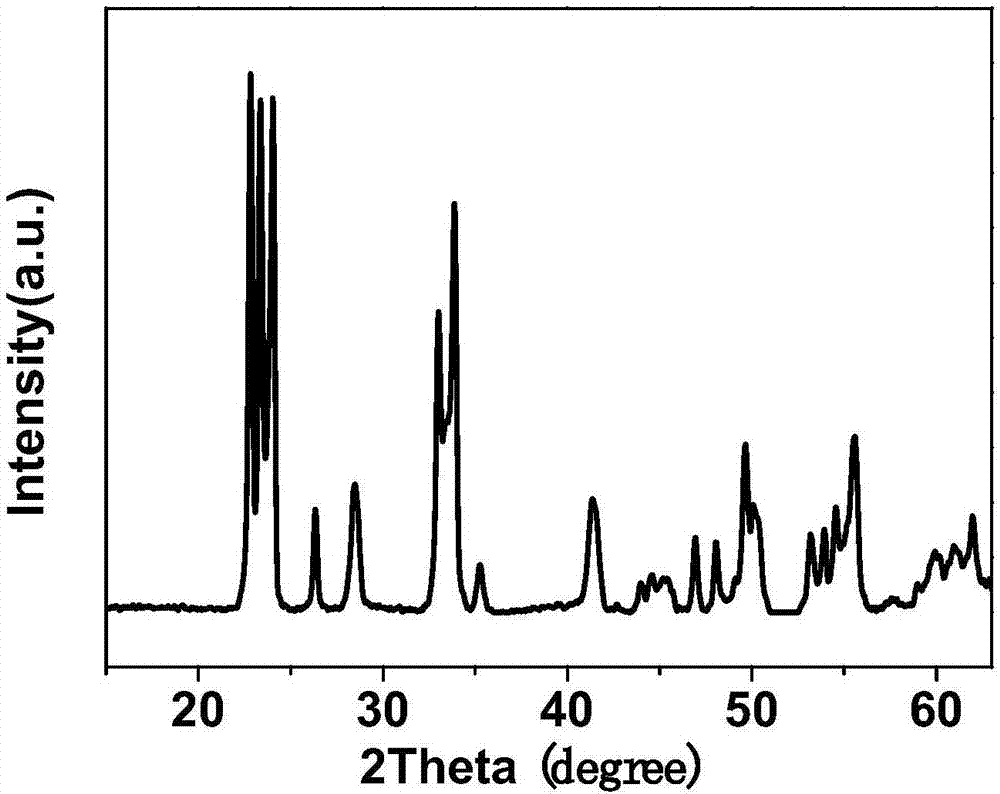

[0066] After stabilization treatment, the HPW / PVA precursor was placed in a muffle furnace, raised from room temperature to 300 °C, and kept for 1 h, and raised from 300 °C to 600 °C in an air environment, and kept for 2 h, and the temperature was naturally lowered. During the process, the heating rate was 2° C. / min, and macroporous tungsten trioxide with a pore diameter of about 4.3 microns was obtained.

[0067] The...

Embodiment 2

[0070] Mix 5wt% PVA aqueous solution and 9wt% HPW aqueous solution at a mass ratio of 1.8:1, and magnetically stir at 850r / min for 12h to obtain a precursor solution.

[0071] Put the precursor solution in a centrifuge tube, insert it into liquid nitrogen quickly in an orientation, and quickly move it into a vacuum drying device, keep the vacuum degree below 20Pa, and dry it at -55°C for 40 hours to obtain HPW / PVA with regular pore structure Precursor.

[0072] The above precursors were stabilized at 110 °C in air for 24 h.

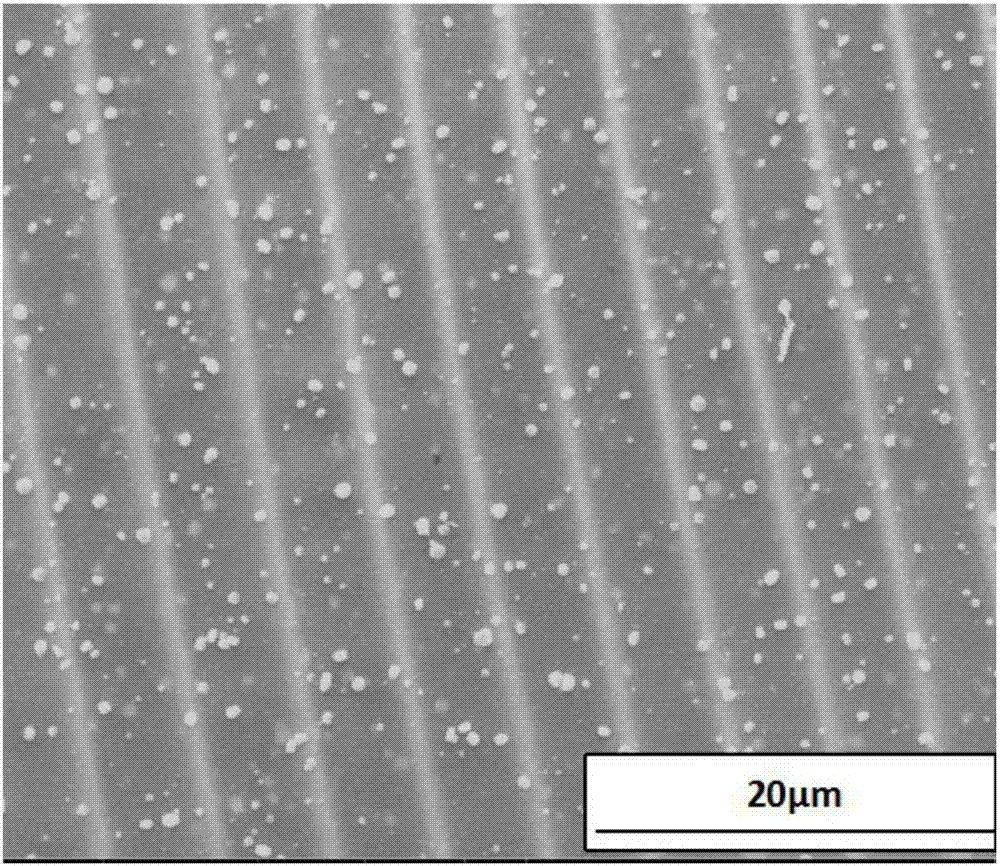

[0073] After stabilization treatment, the HPW / PVA precursor was placed in a muffle furnace, raised from room temperature to 300 °C, and kept for 1 h, and raised from 300 °C to 600 °C in an air environment, and kept for 2 h, and the temperature was naturally lowered. During the process, the heating rate is 2° C. / min, and the macroporous tungsten trioxide with a pore diameter of 3 to 10 μm and a fishbone three-dimensional structure is obtained.

[0074] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Channel diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com