Preparation method of mesoporous lithium vanadium phosphate cathode material

A mesoporous lithium vanadium phosphate, cathode material technology, applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., to achieve high specific capacity, shorten the electron transmission distance, increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

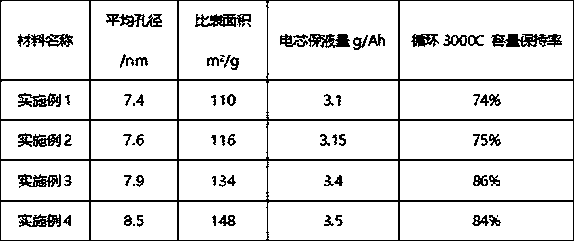

Examples

preparation example Construction

[0017] The invention provides a method for preparing a mesoporous lithium vanadium phosphate positive electrode material, comprising the following steps: (1) preparing a mixed solution in proportion with a vanadium source, a phosphorus source, a template agent, and oxalic acid, and drying to obtain a dry mixture; (2) mixing The dry mixture in step (1) is roasted in an inert atmosphere, and then an alkaline solution is added to remove the template, washed and dried to obtain mesoporous vanadium phosphate; (3) the mass ratio of mesoporous vanadium phosphate to lithium source in step (2) is 1: (0.1~5) mixed with deionized water to prepare a solution with a lithium ion concentration of 0.01mol / L~10mol / L. After drying and roasting in an inert atmosphere, remove unreacted lithium elements with deionized water. After drying, Prepared mesoporous lithium vanadium phosphate.

[0018] The method shown in the specific embodiment of the present invention includes: (1) V2O5, oxalic acid, te...

Embodiment 2

[0022] Example 2 V2O5: oxalic acid: template agent (KIT-6 is a kind of mesoporous silica): ammonium monohydrogen phosphate = 1: 2: 2: 4 Add V2O5, oxalic acid, template agent, monohydrogen phosphate ammonium, mixed and stirred for 3 hours, and dried with water at a temperature of 30°C and an air pressure of -95KPa to obtain a mixture. The obtained mixture was calcined at 300°C for 7 hours in a nitrogen atmosphere, and KIT-6 was removed from the obtained product with 30% sodium hydroxide solution at 40°C, washed and dried to obtain mesoporous vanadium phosphate. Add the obtained mesoporous vanadium phosphate and lithium hydroxide into deionized water at a mass ratio of 1:0.5. The concentration of lithium ions in the solution is 0.2mol / L. After mixing and stirring for 1 hour, the temperature is 30°C and the pressure is -95KPa. Dry to obtain the mixture. In an argon protective atmosphere, it was calcined at 400°C for 30 hours, and unreacted lithium elements were removed with deio...

Embodiment 3

[0023] Example 3 Add V2O5, oxalic acid, template agent, and ammonium dihydrogen phosphate at a molar ratio of V2O5: oxalic acid: template (mesoporous carbon): ammonium dihydrogen phosphate = 1: 4.5: 4: 3.2, mix and stir for 4 hours, and the passing temperature is Dry the water at 60°C with an air pressure of -75KPa to obtain a mixture. The obtained mixture was calcined at 500°C for 20 hours in a nitrogen atmosphere, and the mesoporous carbon was removed from the obtained product with 40% barium hydroxide solution at 45°C, washed and dried to obtain mesoporous vanadium phosphate. Add the obtained mesoporous vanadium phosphate and lithium carbonate into deionized water at a mass ratio of 1:0.8. The lithium ion concentration in the solution is 2mol / L. After mixing and stirring for 3 hours, the water is dried at a temperature of 50°C and an air pressure of -75KPa. to get the mixture. In an argon protective atmosphere, it was calcined at 500°C for 20 hours, and unreacted lithium e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com