Porous ceramic film and preparation method thereof

A technology of ceramic membrane and membrane layer, which is applied in the field of porous ceramic membrane, can solve the problems of temperature change sensitivity, uneven agglomeration and shrinkage, and increase of production cost, and achieve the effects of adjustable pore size, uniform pore channel, and good industrial applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

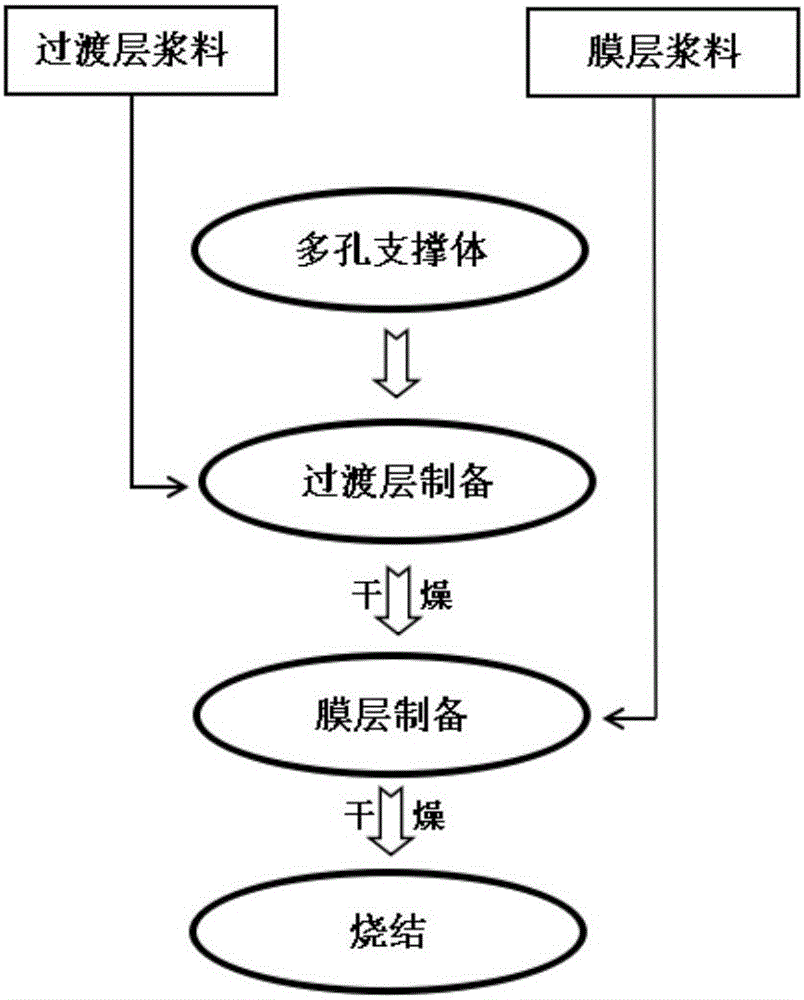

[0032] The preparation process of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] The flow chart of the preparation of porous ceramic membrane with uniform pore size is attached. figure 1 Shown:

[0034] (1) Preparation of slurry: the transition layer particles and the film layer particles are respectively dispersed in the PVA solution with a concentration of 2-8wt.%, and the transition layer slurry with a solid content of 10-50wt.% and 5-25wt.% is obtained material and film layer slurry;

[0035] (2) Preparation of the transition layer: using the transition layer slurry, the transition layer is deposited on the surface of the porous support by the dipping-pulling method, and dried at 40° C. to obtain the transition layer;

[0036] (3) Prepare the film layer: use the film layer slurry to deposit a film layer on the surface of the transition layer obtained in step (2) by dipping-pulling method, wherein the dipping ...

Embodiment 1

[0039] A certain amount of transition layer Al was added to the PVA solution with a concentration of 2wt.%. 2 o 3 Particles and layers of spherical nano-Al 2 o 3Granules, two sets of slurries with solid content of 10wt.% and 5wt.% were obtained. Prepare a transition layer on the surface of the porous support and dry it at 40°C; prepare a film layer on the surface of the transition layer by dipping and pulling, wherein the dipping time is 1min, the pulling rate is 1cm / min, and then the initial drying temperature is 30 °C for 10 hours, and finally dried thoroughly at 110 °C to obtain a ceramic membrane green body. The ceramic membrane green body was sintered at 1200°C for 0.5h to obtain a ceramic membrane with a multi-layer structure, wherein the temperature was raised at a rate of 0.5°C / min before 500°C. The obtained ceramic membrane had a porosity of 55%, an average pore diameter of 50 nm, and a membrane thickness of 5 μm.

Embodiment 2

[0041] A certain amount of transition layer Al was added to the PVA solution with a concentration of 4wt.%. 2 o 3 Particles and layers of spherical nano-TiO 2 Granules, two sets of slurries with solid contents of 20wt.% and 10wt.% were obtained. Prepare a transition layer on the surface of the porous support and dry it at 40°C; prepare a film layer on the surface of the transition layer by dipping and pulling, wherein the dipping time is 1min, the pulling rate is 1cm / min, and then the initial drying temperature is 30 °C for 10 hours, and finally dried thoroughly at 110 °C to obtain a ceramic membrane green body. The ceramic membrane green body was sintered at 1200°C for 0.5h to obtain a ceramic membrane with a multi-layer structure, wherein the temperature was raised at a rate of 0.5°C / min before 500°C. The obtained ceramic membrane had a porosity of 55%, an average pore diameter of 50 nm, and a membrane thickness of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com