Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99results about How to "The production process is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

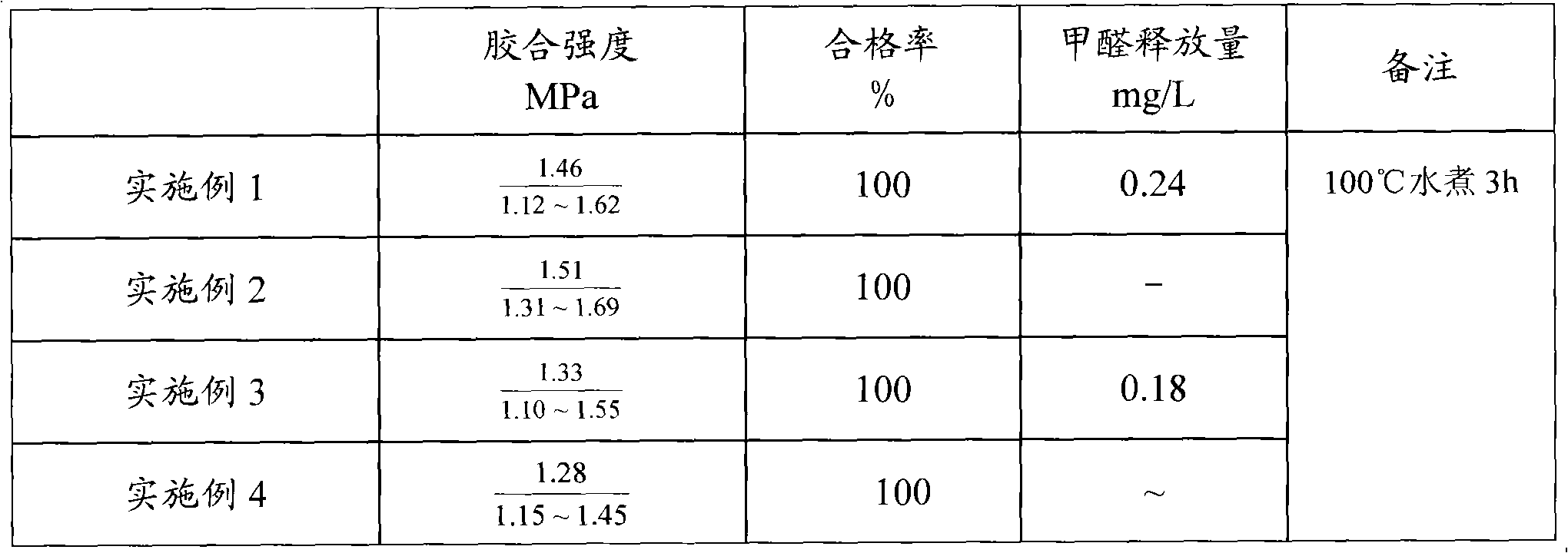

Method for preparing environmentally-friendly adhesive for lignin-based timber

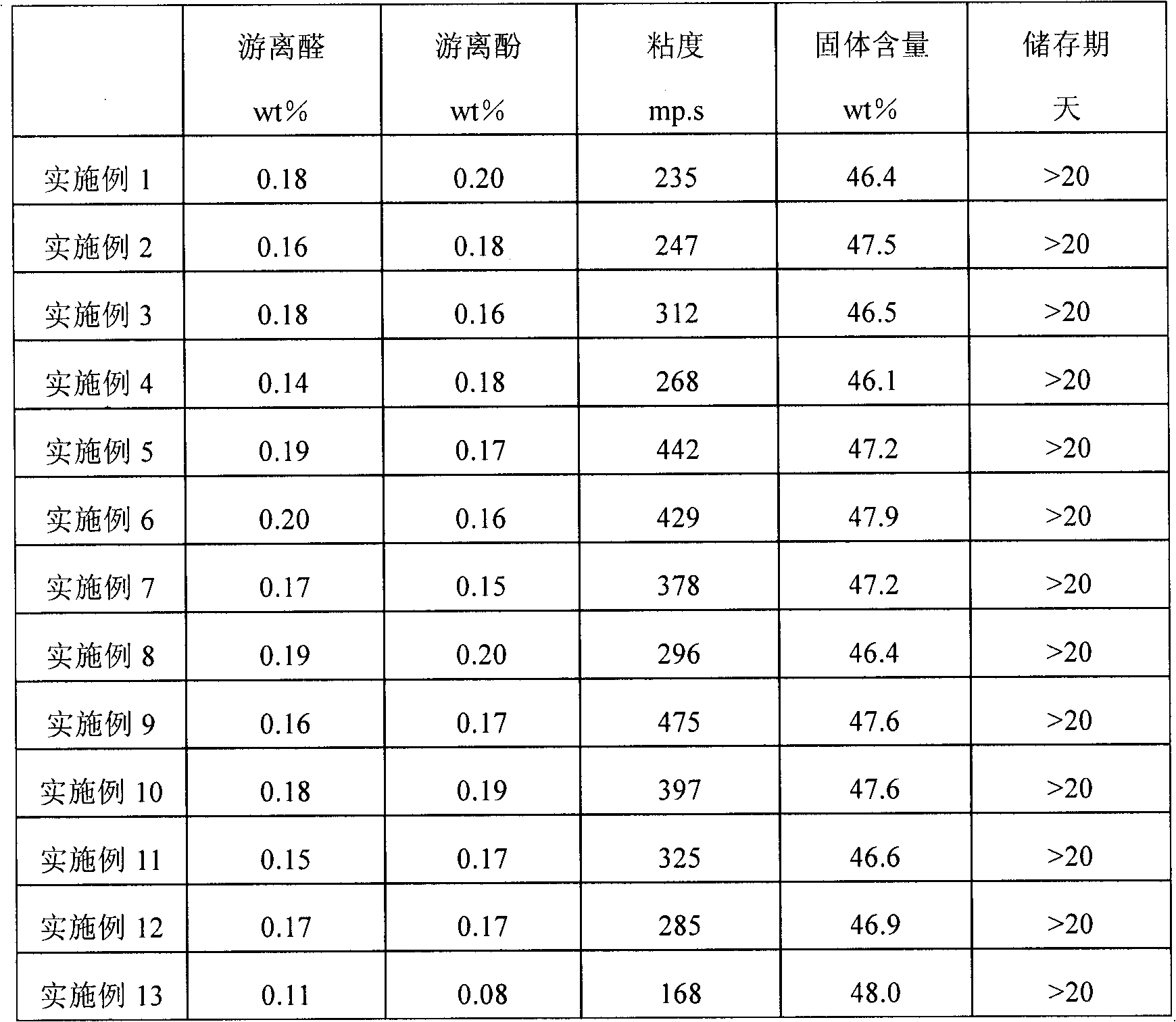

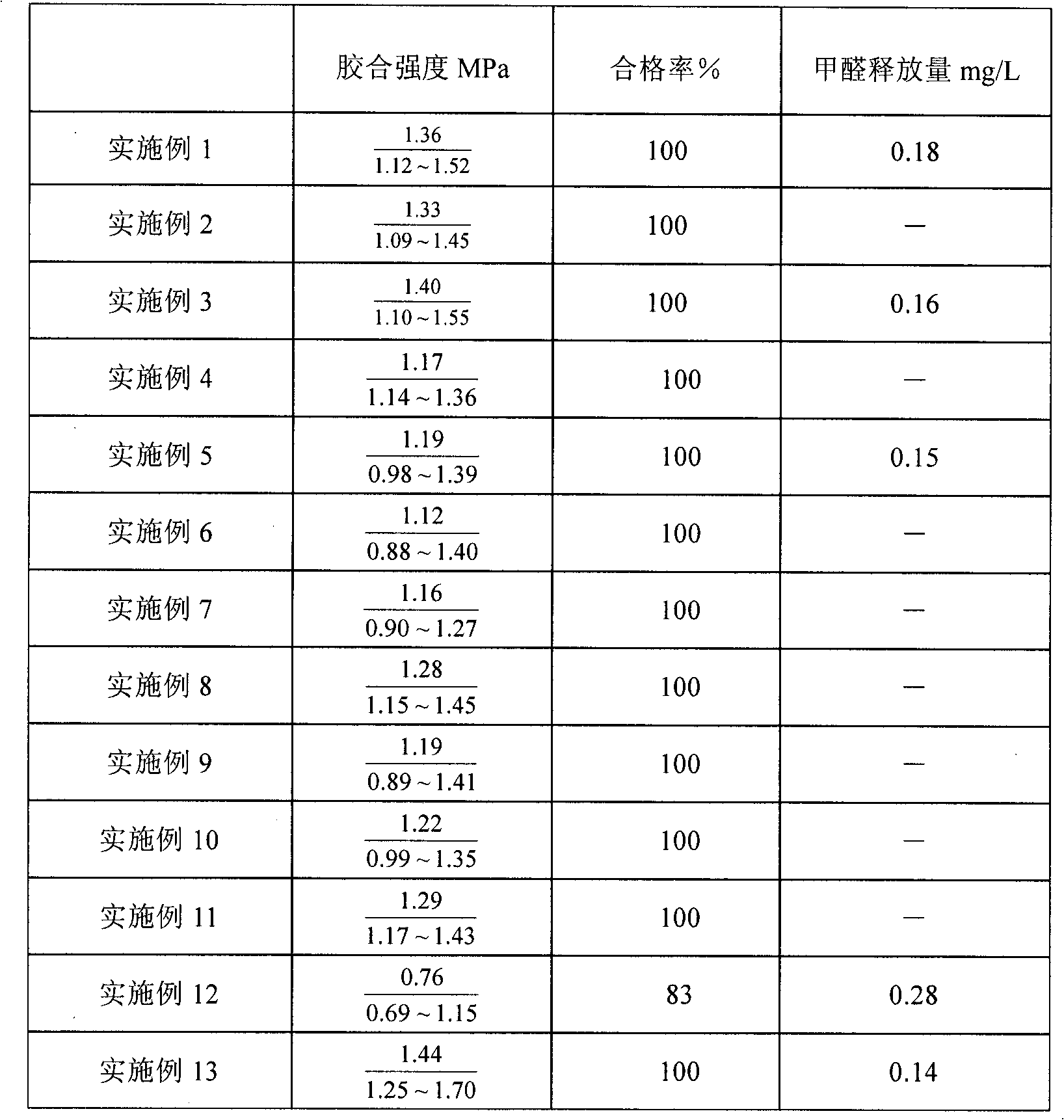

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Strontium containing hydroxyapatite biologically active film and preparation method thereof

InactiveCN1927410ANo side effectsHigh bonding strengthProsthesisElectrolytic agentPlasma electrolytic oxidation

The invention relates to the means of active biological film, especially the titanium radicel porous nanometer Strontium hydroxyapatite active biological film and the Process for the manufacture. The differential arc oxidation technology is used in the method, the film is generated in the surface of titanium and titanium alloy, a electrolyte solution with phosphate radical ion, calcium ion and Strontium ion is supplied; the titanium and titanium alloy is the anode and the rustless steel or the titanium is the cathode, the direct current power supply or the direct current impulsing power source is applied to differential arc oxygenize the titanium and titanium alloy; the oxidate time is 3-60min; the temperature of electrolyte is not above 50DEG C. There is no interface between the porous hydroxyapatite containing Strontium film produced by the invention and the basal body, the modulus of elasticity is approximate with the sclerotin, the porous hydroxyapatite containing Strontium film produced by the invention which has perfect bioactivity can be the alternate material of several parts with heavy load, such as femur, hip joint and teeth root.

Owner:SOUTH CHINA UNIV OF TECH

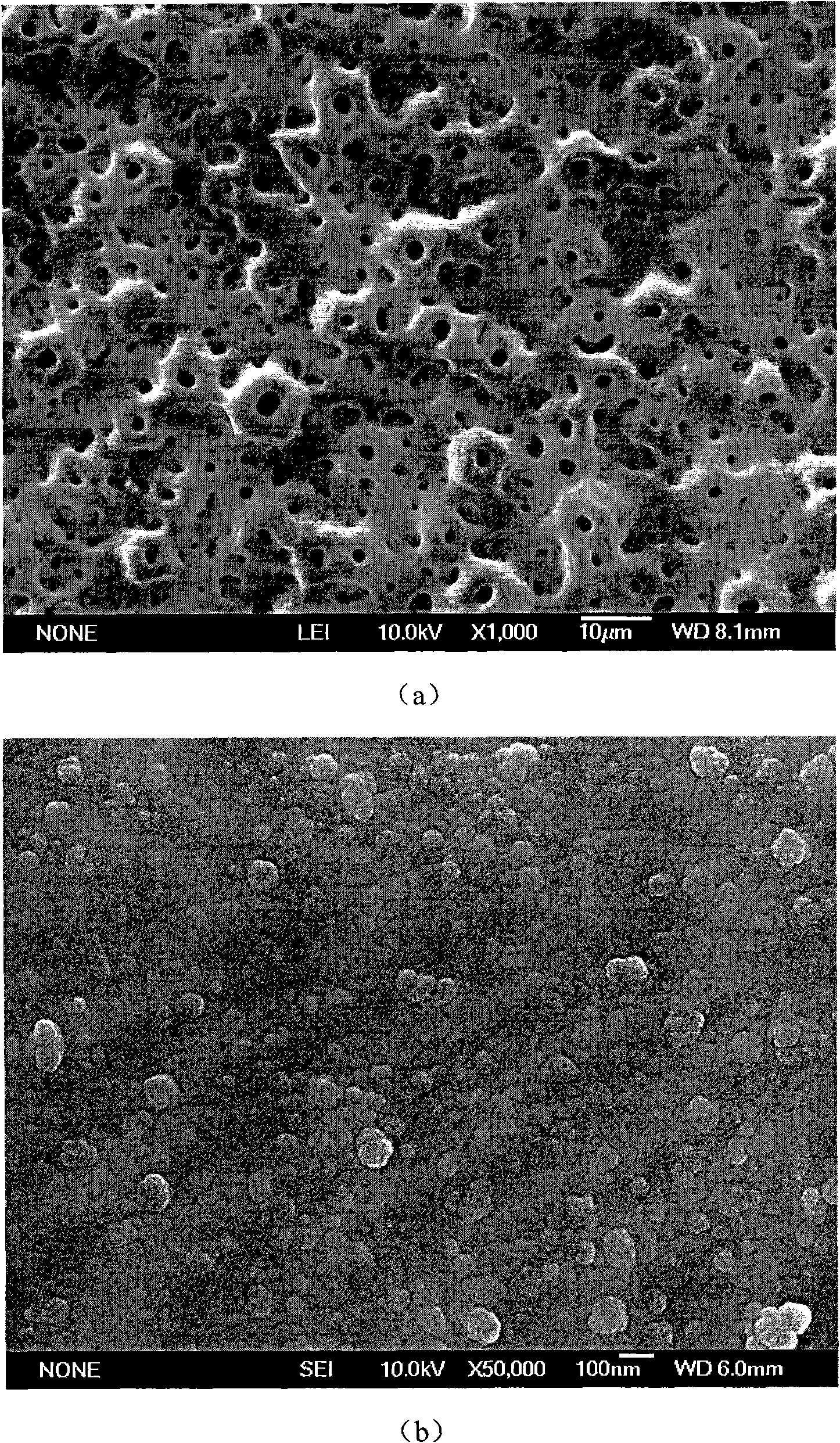

Bioactive film on titanium metal surface and its sand blasting-micro arc oxidizing compounding process

InactiveCN1974876ASolve for bond strengthAddressing Binding StabilitySurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The present invention relates to film on the surface of medical titanium-base metal material and its sand blasting-micro arc oxidizing compounding process. Through the first surface sand blasting treatment of titanium or titanium alloy material and the subsequent micro arc oxidizing in electrolyte solution containing phosphate radical ion and calcium ion and with the titanium or titanium alloy material as anode, stainless steel or titanium as cathode and DC power source or DC pulse power source, one bioactive film is in-situ formed on the surface of the titanium or titanium alloy material. The bioactive film of rough porous hydroxyapatite has surface roughness Ra of 2-4.5 micron, no interface with the substrate, elastic modulus reaching that of bone and excellent bioactivity, and may be used as the substitute for femur, hip joint, tooth root, etc. The bioactive film has optimized combination strength, stability and bioactivity.

Owner:SOUTH CHINA UNIV OF TECH

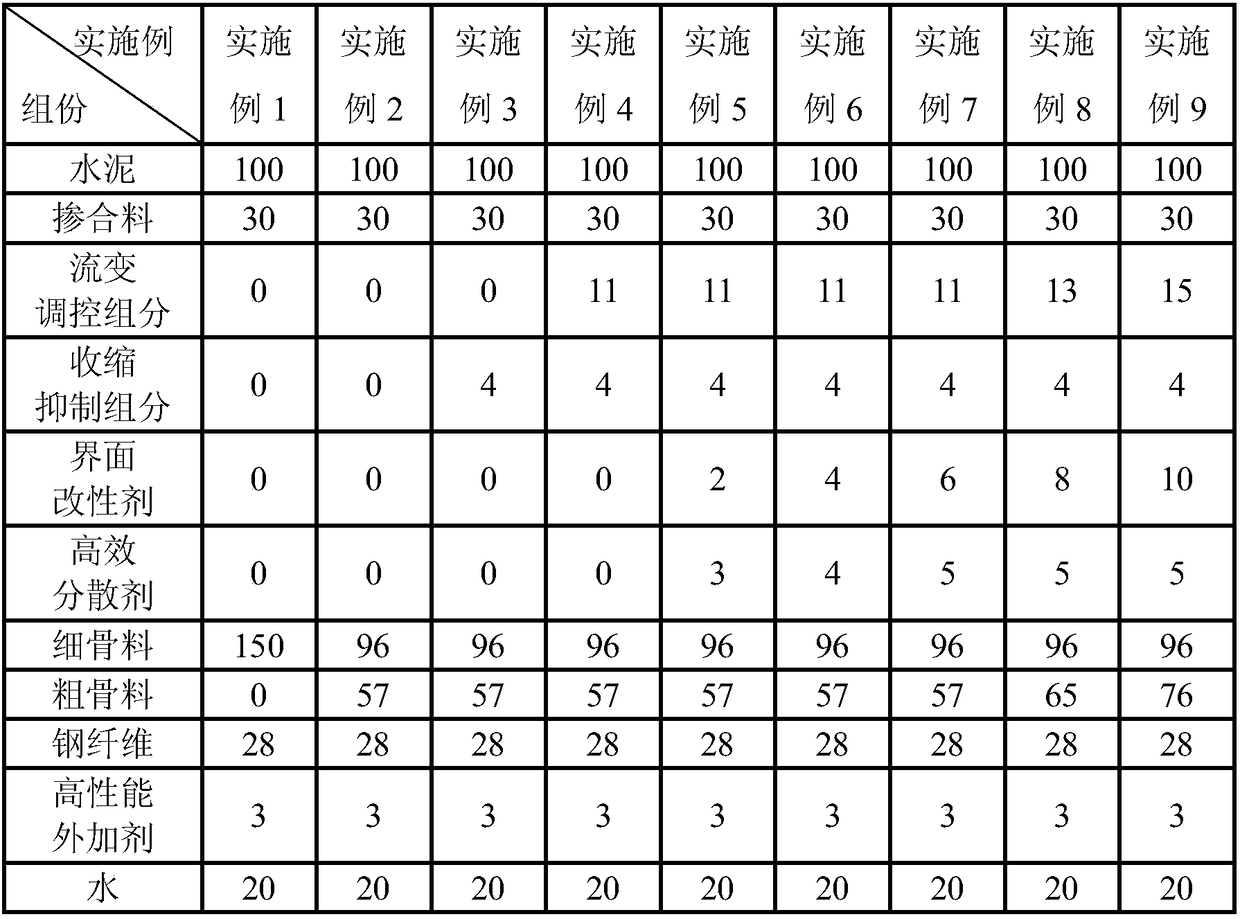

Bridge coarse aggregate active powder concrete and preparation method thereof

The invention discloses bridge coarse aggregate active powder concrete and a preparation method thereof. The coarse aggregate active powder concrete comprises, by weight, 100 parts of cement, 20-60 parts of blending materials, 2-10 parts of interface modifying agents, 60-120 parts of fine aggregates, 40-120 parts of coarse aggregates, 10-60 parts of fibers and 15-30 parts of water. Under conventional curing processes such as natural conditions, the coarse aggregate active powder concrete has super-high compressive strength, bending tensile strength and tensile strength and bonding strength andlow contraction performance and further has high elasticity modulus, anti-fatigue performance and durable performance and excellent construction performance, dead weight and shrinkage and creep influence of a bridge can be reduced, and the span, the structural stiffness and the bearing capacity of the bridge can be remarkably improved, and the service life of the bridge is prolonged.

Owner:南京市公共工程建设中心 +3

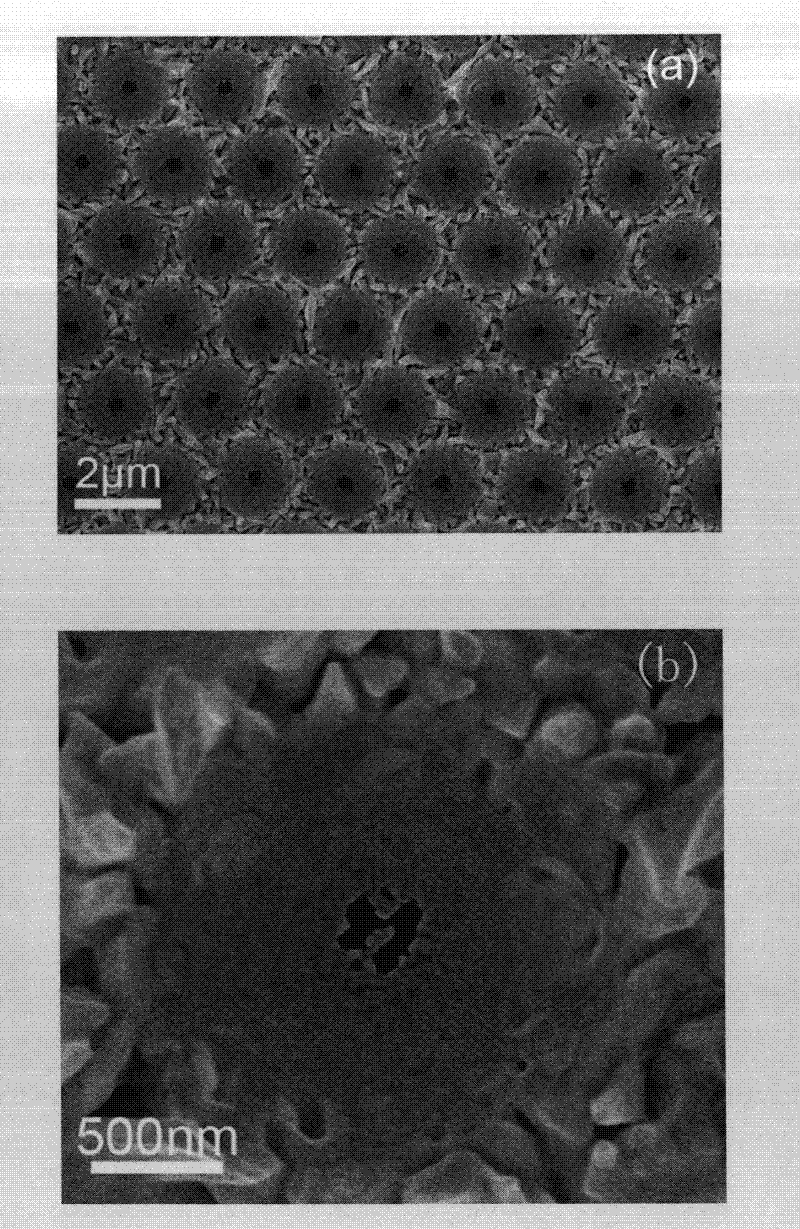

Gold micro-nano composite structure array and preparation method thereof

InactiveCN102674236AEliminate interfering peaksThe preparation process is simpleDecorative surface effectsCoupling light guidesGold filmMicrometer

The invention discloses a gold micro-nano composite structure array and a preparation method thereof. The array is a gold bowl array or a gold hollow sphere array disposed above a gold film covered on a substrate, wherein the diameter of a gold bow opening is from 500 nanometers to 10 micrometers, a bowl wall is composed of gold rods, the lengths of the gold rods are 100-1000 nanometers, the diameters of the gold rods are 50-400 nanometers, the inner diameter of a gold hollow sphere is from 500 nanometers to 10 micrometers, a sphere casing is composed of gold particles with diameters of 50-600 nanometers, and the thickness of the gold film is 5-25 nanometers. The preparation method includes sputtering a layer of the gold film on the substrate, placing a single layer colloidal crystal template which is composed of polystyrene colloidal spheres with diameters from 500 nanometers to 10 micrometers on the substrate which is covered with the gold film, then placing the substrate covered with the gold film and the colloidal crystal template into a chloroauric acid solution with concentration of 0.3-0.7g / L, using the solution with the substrate as a working electrode, subjecting the mixture to electro-deposition for 2-8 hours under the deposition electric current density of 0.03-0.05mA / cm<2> or 0.15-0.45mA / cm<2> to obtain a complex array, and placing the complex array in a dichloromethane solution for to removing the polystyrene colloidal spheres to obtain target products. The gold micro-nano composite structure array can be used as a surface enhanced raman scattering active substrate.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

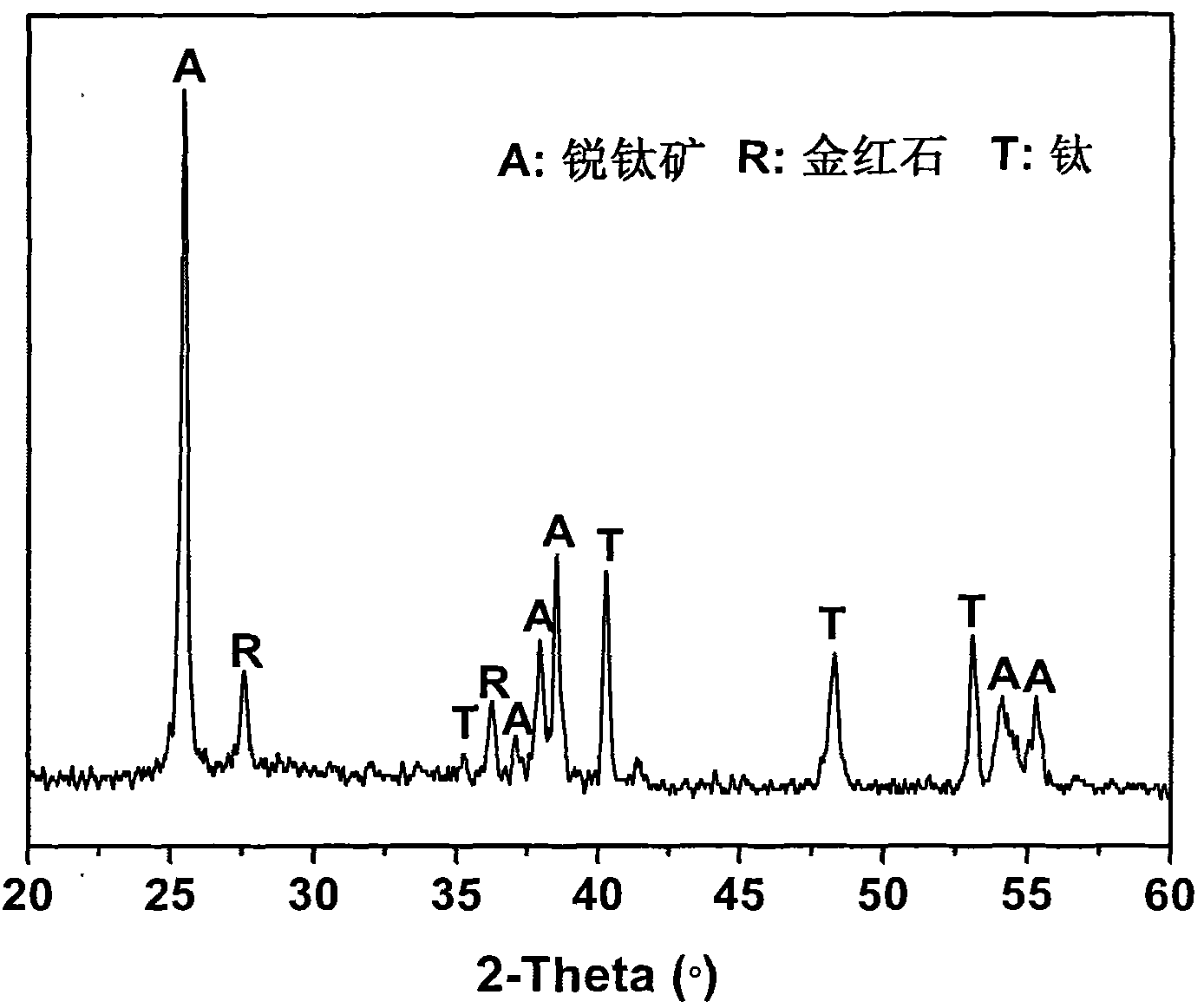

Method for preparing titanium dioxide layer with multi-level pore structure on surface of medicinal titanium

InactiveCN101871118AIncreased mechanical lockingImprove adhesionSurface reaction electrolytic coatingProsthesisSodium acetateTitanium metal

The invention relates to a method for preparing a titanium dioxide layer with a multi-level pore structure on the surface of medicinal titanium. The method provided by the invention comprises the following steps of: performing anode oxidation of a direct-current slow uniform-speed current raising mode on the medicinal titanium in acetic electrolyte, and performing secondary anode oxidation of a direct-current constant voltage mode in sulfuric acid or sodium acetate electrolyte to obtain the titanium dioxide layer with the multi-level pore structure, wherein the large-pore structure consists of staggered groove structures, the widths of grooves are 20 to 30 microns, the small-pore structure comprises submicron micropore structures densely distributed on the whole film, and the aperture is between dozens of and hundreds of microns. The method is simple and rapid, has simple and convenient operation, and is expected to become a surface modification method for medicinal titanium metal in the field of orthopedics, dentistry or plastic surgery.

Owner:SICHUAN UNIV

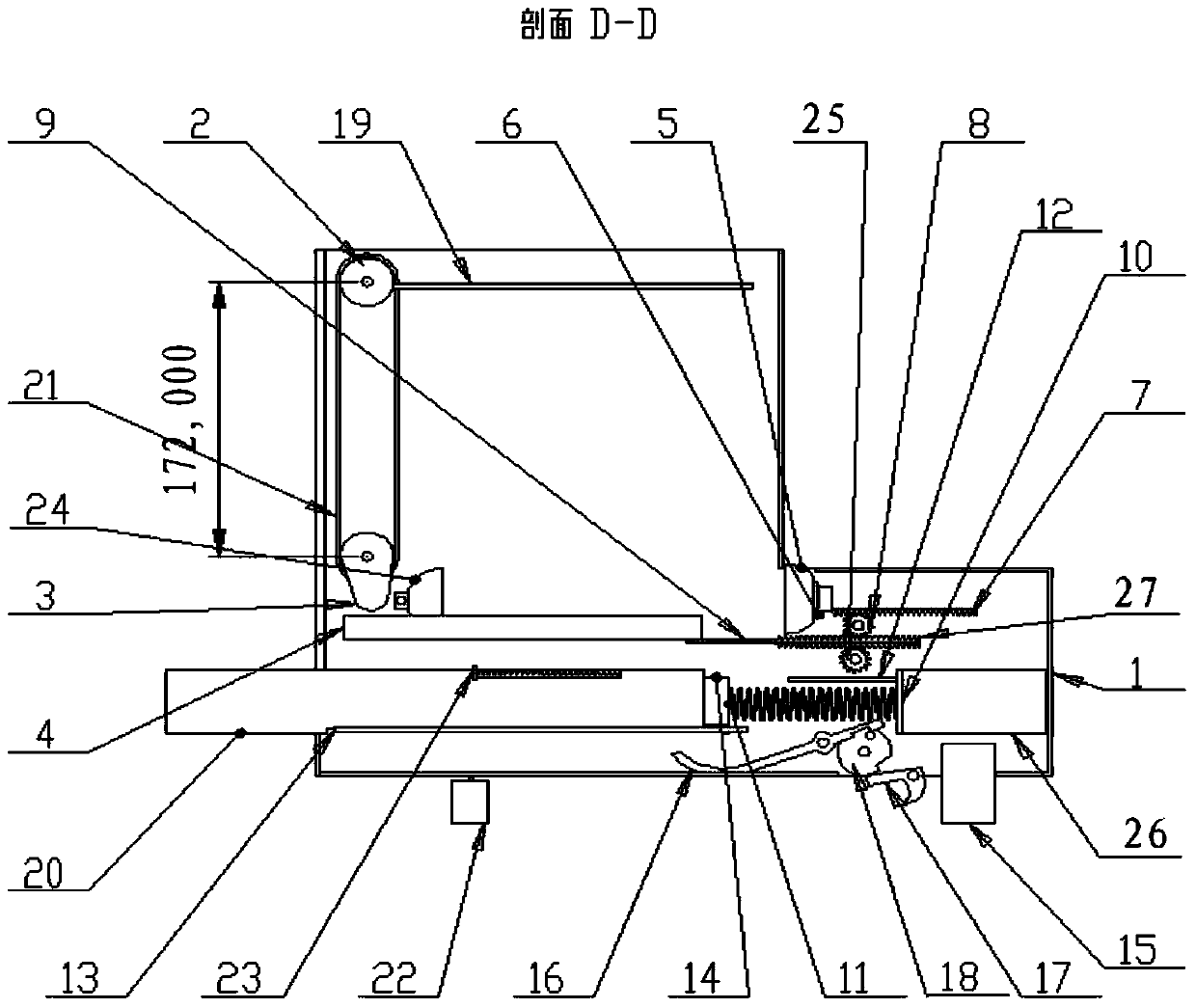

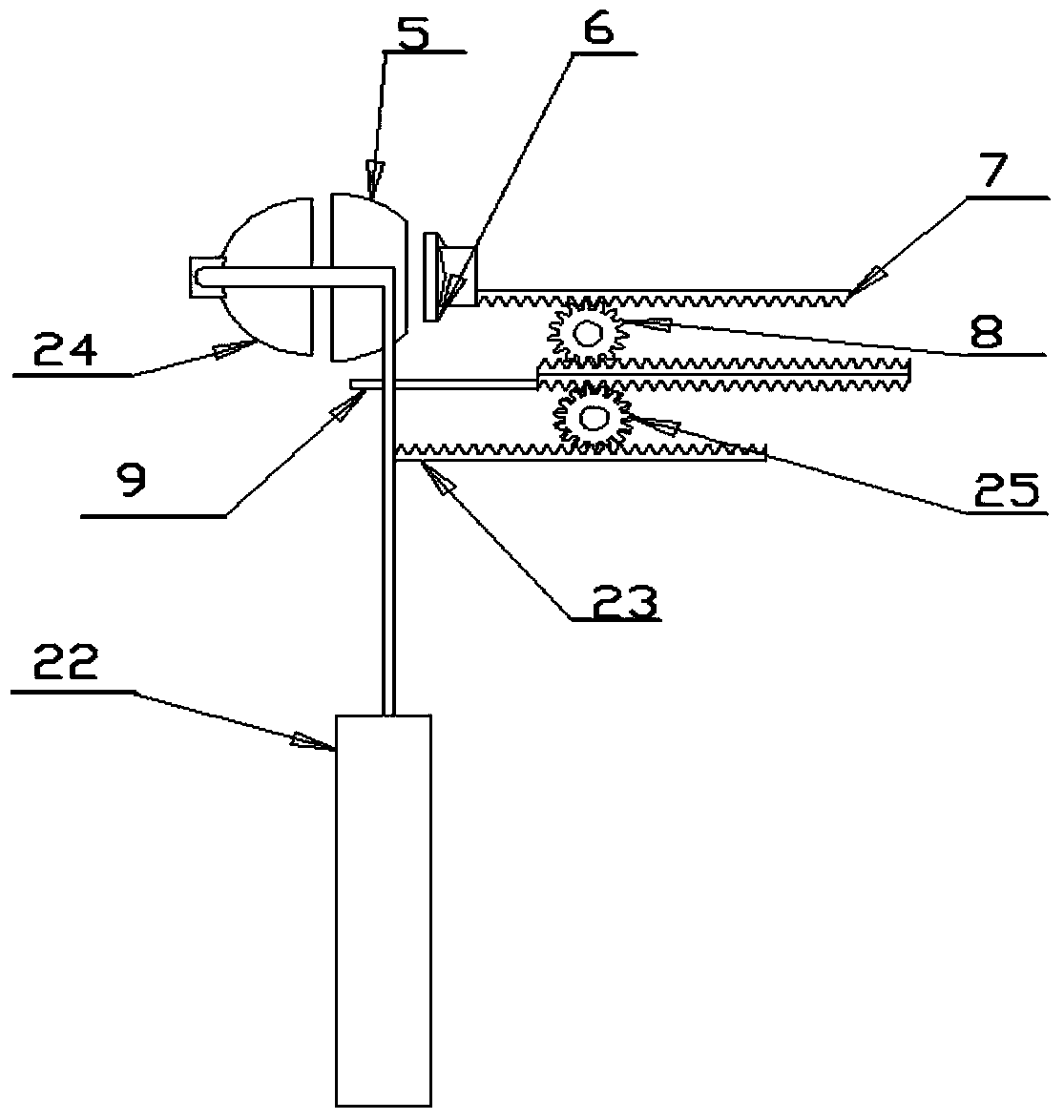

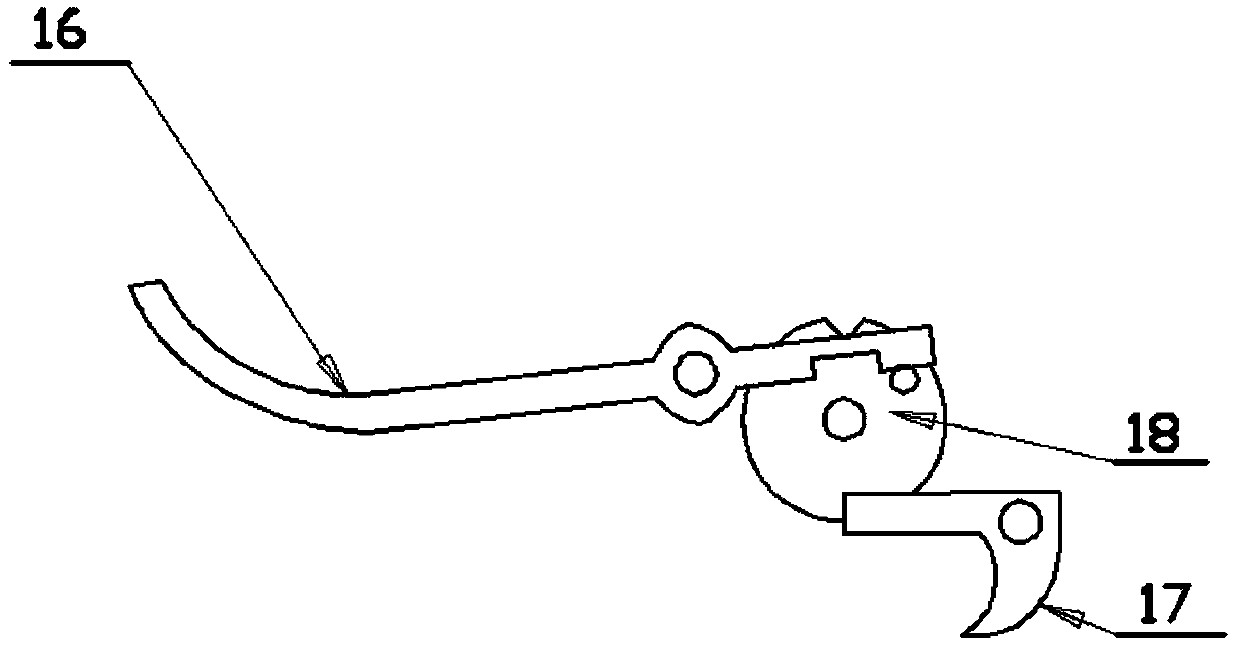

Equipment and process for industrially producing containers by using moso bamboo

InactiveCN102126238AImprove the utilization rate of rotary cuttingSmooth feedingPlywood pressesVeneer pressesThermal insulationAgricultural engineering

The invention discloses equipment and a process for industrially producing containers by using moso bamboo. The equipment comprises a moso bamboo cutter, a moso bamboo joint beating machine for beating internal joints of segment bamboo, a high-temperature segment bamboo softening container, a segment bamboo washing device, a segment bamboo thermal insulation device, a precision moso bamboo rotarycutter for rotationally cutting the segment bamboo, a bamboo sheet length control device, a bamboo sheet drying machine for drying bamboo sheets, a double-sided gluing machine for coating glue on thebamboo sheets, and a bamboo sheet hot-press section forming machine. The process comprises the following steps of: cutting the moso bamboo, beating the internal joints of the segment bamboo, softening the segment bamboo at high temperature, washing the segment bamboo, performing thermal insulation on the segment bamboo, rotationally cutting the segment bamboo into the bamboo sheets, drying the bamboo sheets, coating glue on the bamboo sheets, hot-pressing a plurality of bamboo sheets coated with the glue to obtain bamboo sheet sections meeting the requirements on thickness and dimension, and respectively moulding the bamboo sheet sections in a square container moulding mould, a bamboo sheet cylindrical container moudling mould and a once-setting mould for moulding containers to obtain square containers, cylindrical containers, round or square discs and the like without abutted seams.

Owner:三明市柏毅竹业技术开发有限公司

Technique of extracting acitve ingredient from roots, stems and leaves from artichoke and application

InactiveCN1562204ANon-toxic side effectsImprove gastrointestinal functionMetabolism disorderDigestive systemAdditive ingredientExcipient

A process for extracting the active component from the root, stem and leaf of arthicoke includes such steps as crushing, decocting in water or thermal reflux in alcohol 3 times, collected liquid, depositing, and concentrating its supernatant. It can be mixed with sweetening agent, excipient, filler and coloring agent to prepare medicines or health-care food for lossing weight, protecting liver and galladder, regulating gastrointestinal function, and relaxing cardiovascular disease.

Owner:李嫦梅 +2

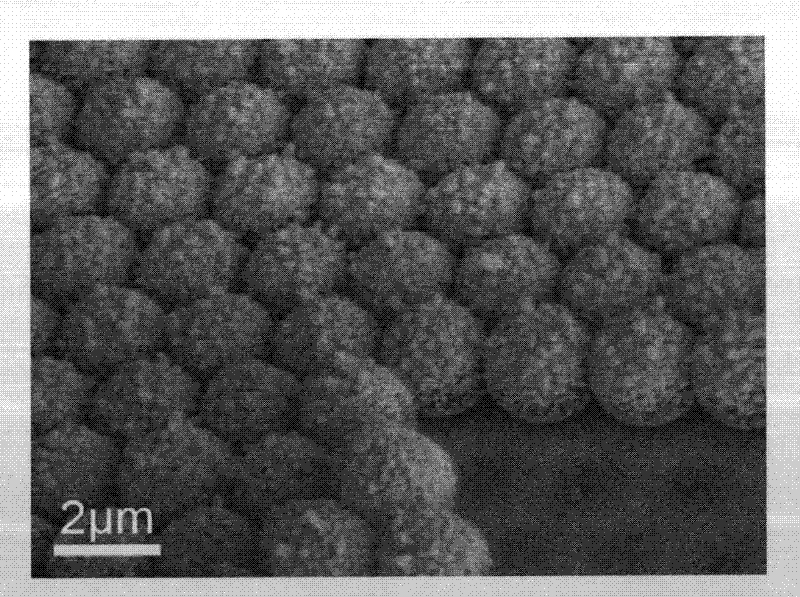

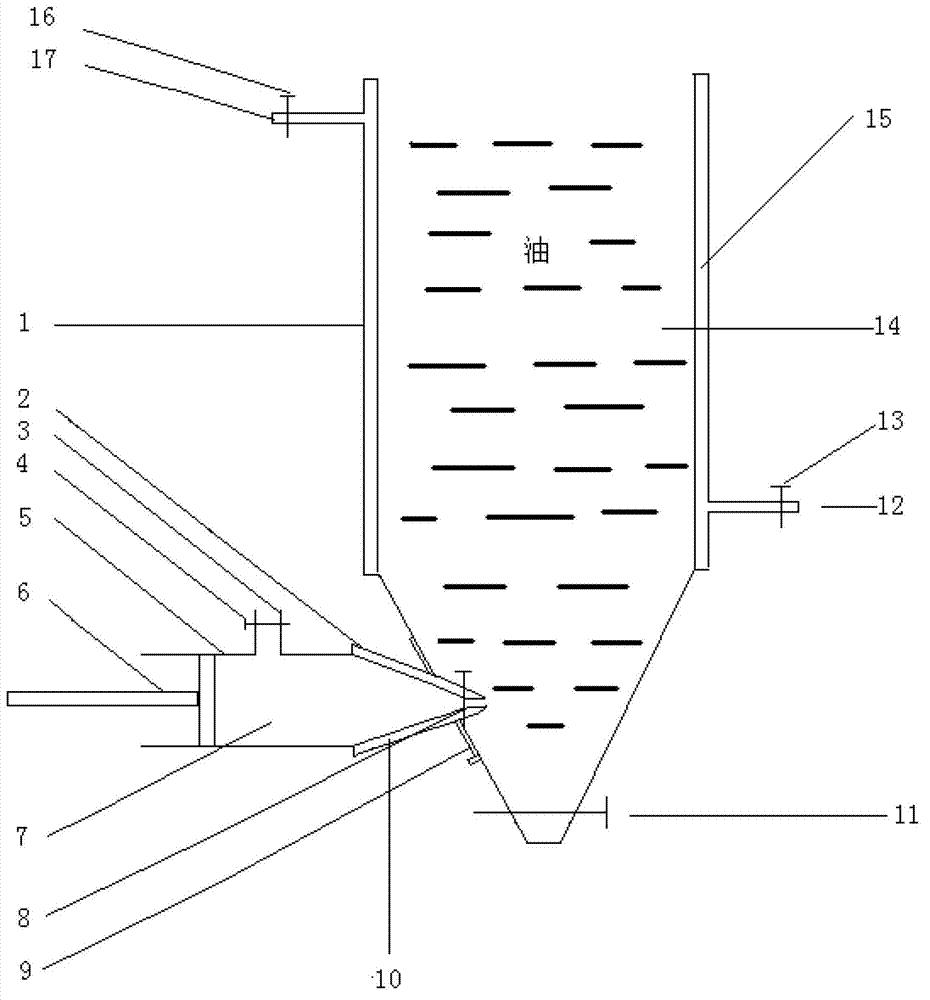

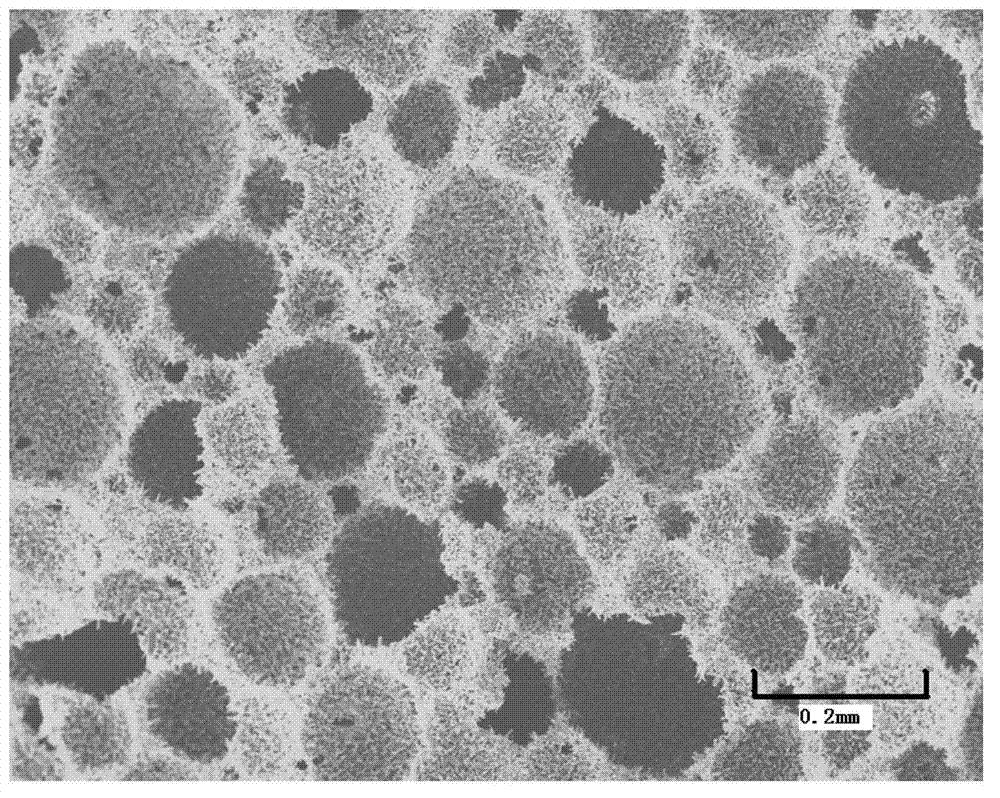

Method and device for preparing porous ceramic micro beads

The invention discloses a method and a device for preparing porous ceramic micro beads. The method comprises the following steps of: mixing an organic monomer and a crosslinking agent with water according to a certain proportion for dissolving, adding ceramic powder and a dispersing agent into a solution, and performing ball milling to obtain a ceramic suspension with high solid phase content and low viscosity; adding a foaming agent, an initiator and a catalyst into the suspension for stirring to obtain water-based stable foam ceramic slurry; and continuously injecting the water-base slurry into an oily medium of a certain temperature by using the device for preparing the porous ceramic micro beads to form foam slurry spheres, floating and curing into porous ceramic micro bead blanks in the oily medium, collecting, cleaning, drying and sintering to obtain a porous ceramic micro bead product. The invention further discloses a device for preparing the porous ceramic micro beads. The device comprises a micro bead forming tower and an injection gun, and can be used for realizing continuous automatic injection and generation of spheres. The device has universality, and can be used for realizing large-scale continuous production of porous ceramic micro beads which are of different systems and are 0.3-4.0 millimeters in diameter.

Owner:TSINGHUA UNIV

Snowball making machine gun

The invention discloses a snowball making machine gun. The machine gun comprises a snow storage device, a snowball making device and a snowball ejecting device, wherein the snow storage device comprises a snow storage bin, a fixed pulley is mounted above one side of the snow storage bin, a cam is mounted on the lower side of the same side where the fixed pulley is mounted, the fixed pulley and the cam are connected through a belt, a press plate is fixed on the belt, and the cam is contacted with a first casing of the snowball making device. By the aid of the snowball making machine gun, ejection of snowballs can be realized, all that is required is to slightly pull a trigger, and the snowballs can be ejected far. Thus, the strength is saved, and the farther snowball range can be realized.

Owner:QINGDAO UNIV

Titanium oxide composite coating and preparation method thereof

ActiveCN103834945APromote growthPromote recoveryVacuum evaporation coatingSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a titanium oxide composite coating and a preparation method thereof. The titanium oxide composite coating comprises a porous titanium oxide coating formed in situ on the surface of a titanium-based metal base material by virtue of a micro-arc oxidation technique, and ferric oxide nanoparticles mixed with the porous titanium oxide coating by virtue of a plasma-immersion ion implantation technique, wherein the content of the iron element in the titanium oxide composite coating ranges from 1% to 15%. The invention also provides a method for preparing the titanium oxide composite coating, and the method comprises the steps of (1) forming the porous titanium oxide coating in situ on the surface of the titanium-based metal base material by virtue of the micro-arc oxidation technique, and (2) implanting iron ions into the titanium oxide coating by virtue of the plasma-immersion ion implantation technique to form the ferric oxide nanoparticle modified titanium oxide composite coating.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

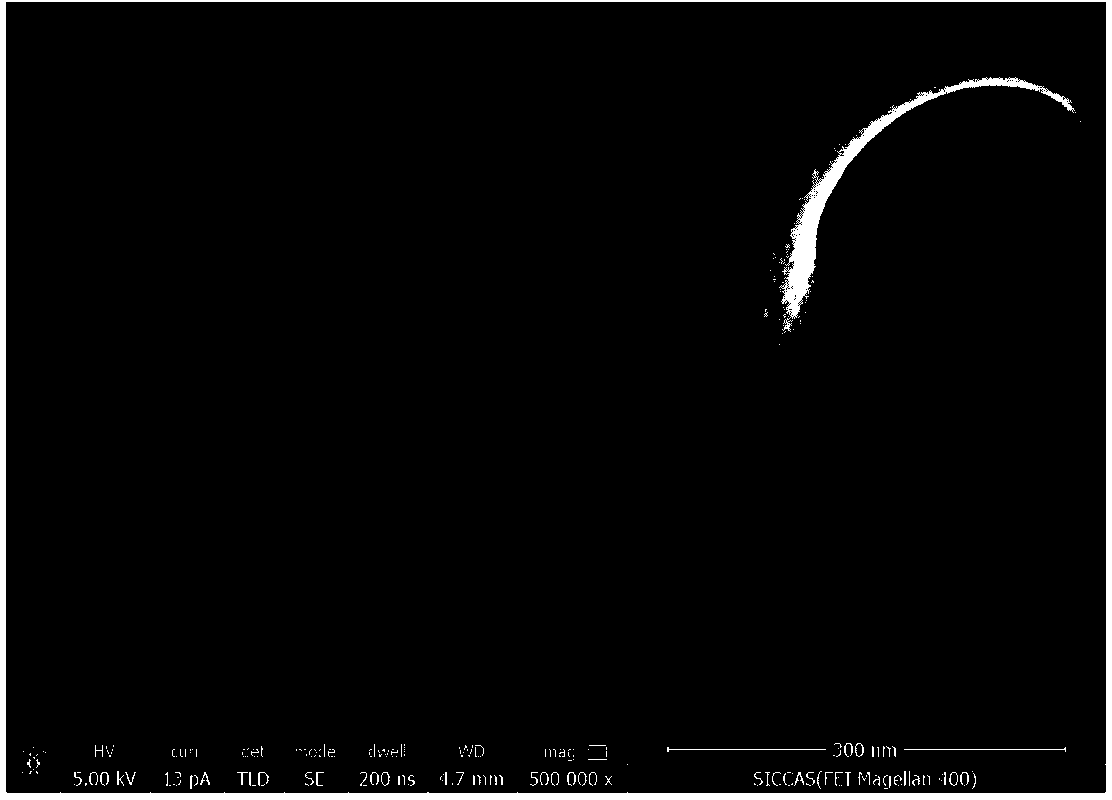

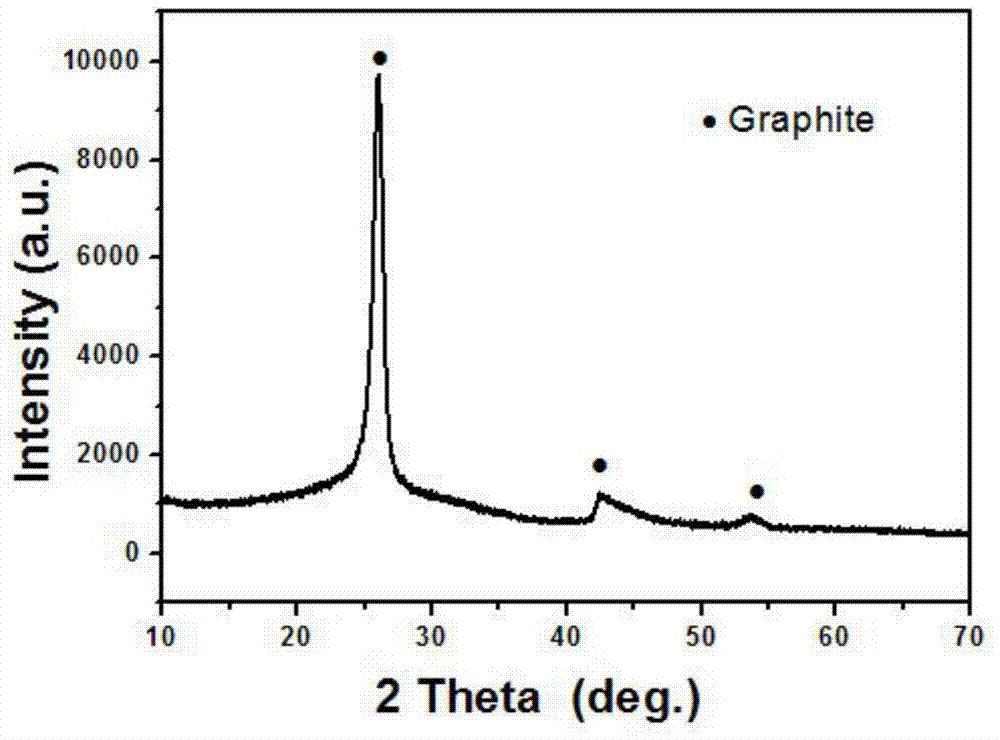

Method for preparing porous nanometer graphite

ActiveCN104495825ALow priceLow conversion temperatureMaterial nanotechnologyWater solubleCarbon source

The invention discloses a method for preparing porous nanometer graphite and belongs to the field of research on nanometer carbon materials. The method comprises the following main steps: preparing a water-soluble carbon source as a raw material, an auxiliary agent and iron salts according to an appropriate ratio into a solution and heating; evaporating, concentrating and reacting the solution to obtain carbon-containing precursor powder, reacting the precursor for 0.5-5 hours at 600-1300 DEG C under a certain atmosphere to obtain a reaction product, and washing the reaction product with acid to obtain porous nanometer graphite. The method is simple in operation and low in cost and is conductive to industrial production; the obtained product is high in degree of graphitization, has a porous structure and can be widely applied in such fields as lithium ion cells, field emission materials and super capacitors.

Owner:UNIV OF SCI & TECH BEIJING

Red-core dragon fruit all-fruit powder and preparation method thereof

InactiveCN103549315AIncrease powder yieldSimple preparation processMulti-step food processesFood shapingBiotechnologyDietary fiber

The invention relates to the technical field of food processing, and mainly relates to red-core dragon fruit all-fruit powder and a preparation method thereof. The red-core dragon fruit all-fruit powder is prepared by adopting the step of carrying out freeze-drying or spray-drying after red-core dragon fruit pulp and beta-cyclodextrin are mixed, wherein the red-core dragon fruit pulp is prepared by peeling and pulping fresh or freezing red-core dragon fruits, the adding amount of the beta-cyclodextrin is 0.2-1.0 percent of the dry weight of the red-core dragon fruit pulp, and the red-core dragon fruit all-fruit powder has the characteristics that the content of betanin is not less than 3.4mg / g, the water content is not more than 4.5 percent, the rehydration ratio is 8.0-10, the content of dietary fibers is not less than 11.0 percent, and the fatty acid content is not less than 7 percent. The red-core dragon fruit all-fruit powder provided by the invention is pure-natural all-nutrition fruit powder, ensures the instant effect and the mouth feel and the special flavor of the red-core dragon fruit, brings convenience for storage, transportation and carrying, and is wider in market prospect.

Owner:ZHEJIANG NORMAL UNIVERSITY

Infrared photoelectric detector and preparation method thereof

ActiveCN103681897AImprove detection abilityRealize the detection functionFinal product manufactureSemiconductor devicesPhotovoltaic detectorsInterconnection

The invention discloses an infrared photoelectric detector and a preparation method thereof. The detector comprises a substrate. An optical micro-cavity lower reflecting mirror, a lower optical path difference compensation layer, an upper optical path difference compensation layer and an optical micro-cavity upper reflecting mirror which are arranged on the substrate in turn. A semiconductor carbon nano-material photoelectric device used as a light absorption material and a conductive channel is arranged in an optical micro-cavity. The position of the optical micro-cavity with the maximum cavity state density is overlapped with a working area of the semiconductor carbon nano-material photoelectric device. As for infrared light with the same wavelength, an optical path through the lower optical path difference compensation layer is the same with the optical path through the upper optical path difference compensation layer, or difference of the two optical paths is integral times of half wavelength. Capability of detecting weak infrared light is enhanced, and the micro-cavity is simple and rapid in processing technology. The detector can be applied to interconnection of carbon tube circuit photoelectric devices or interconnection of carbon tubes and silicon integrated circuit sheets so that detection and response of communication wave band infrared light are executed.

Owner:PEKING UNIV

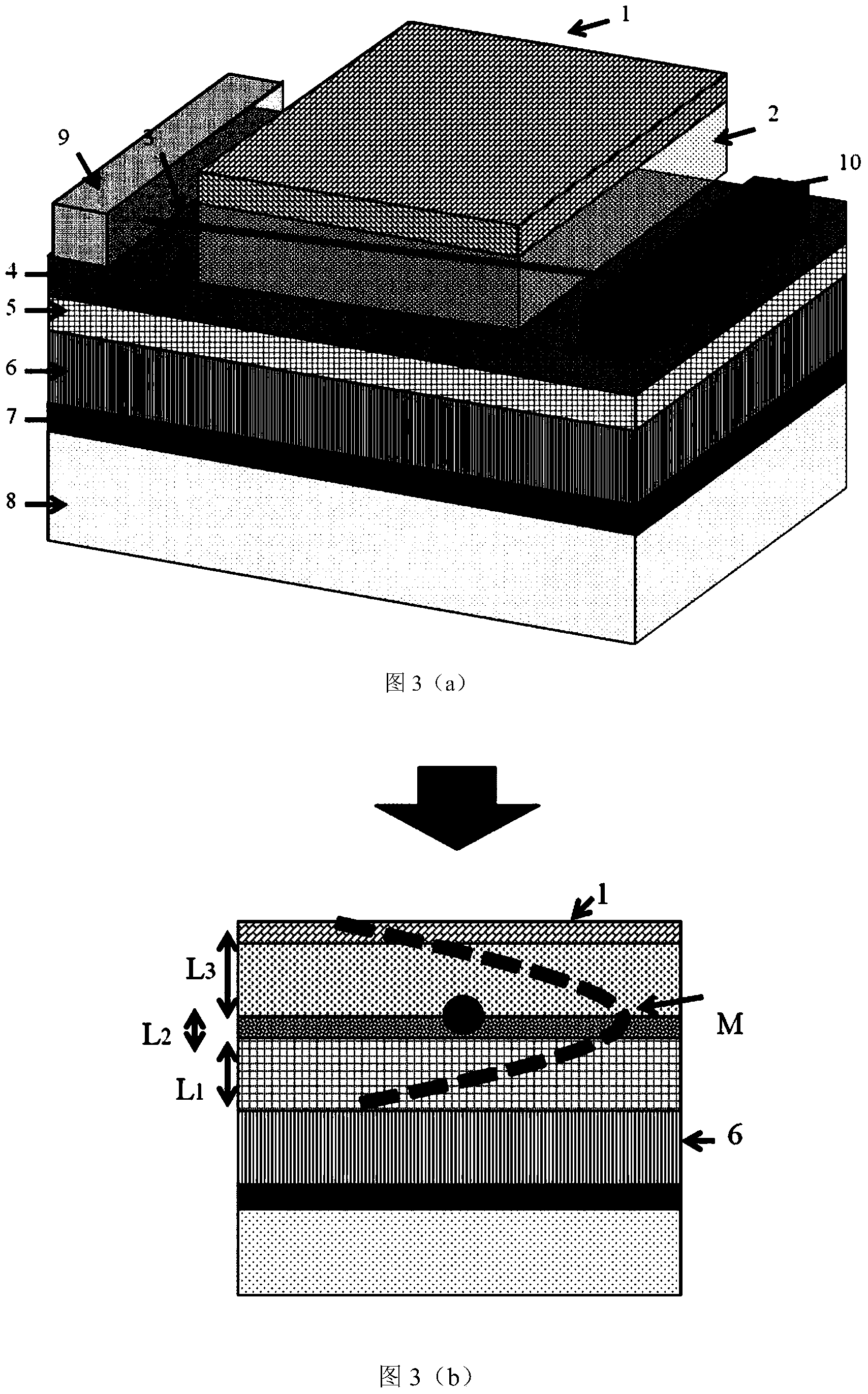

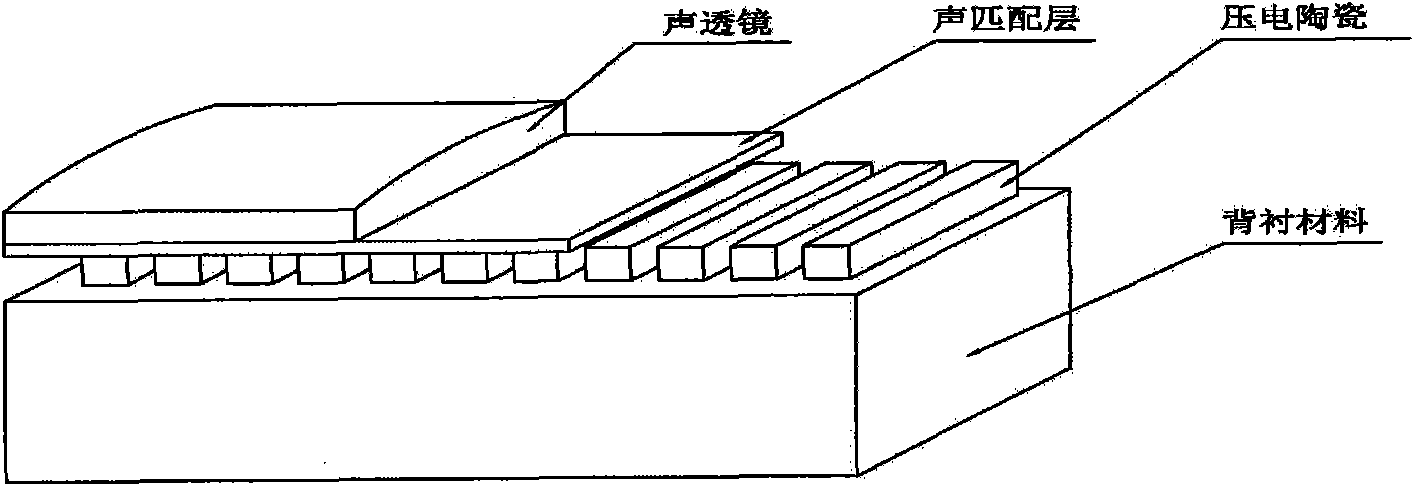

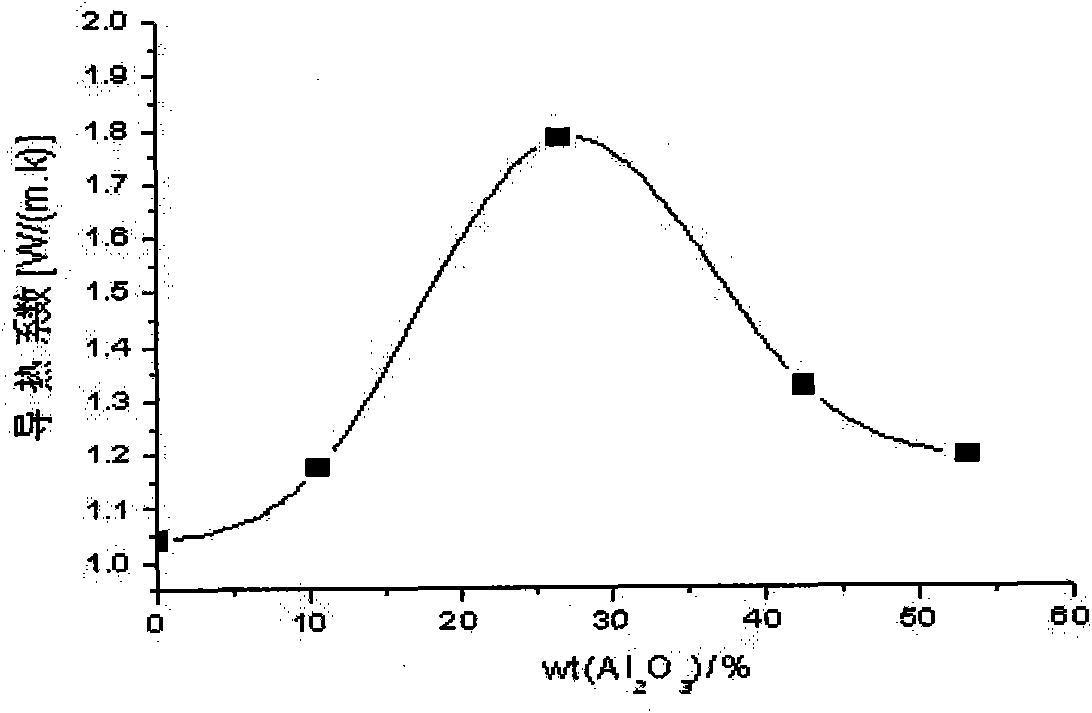

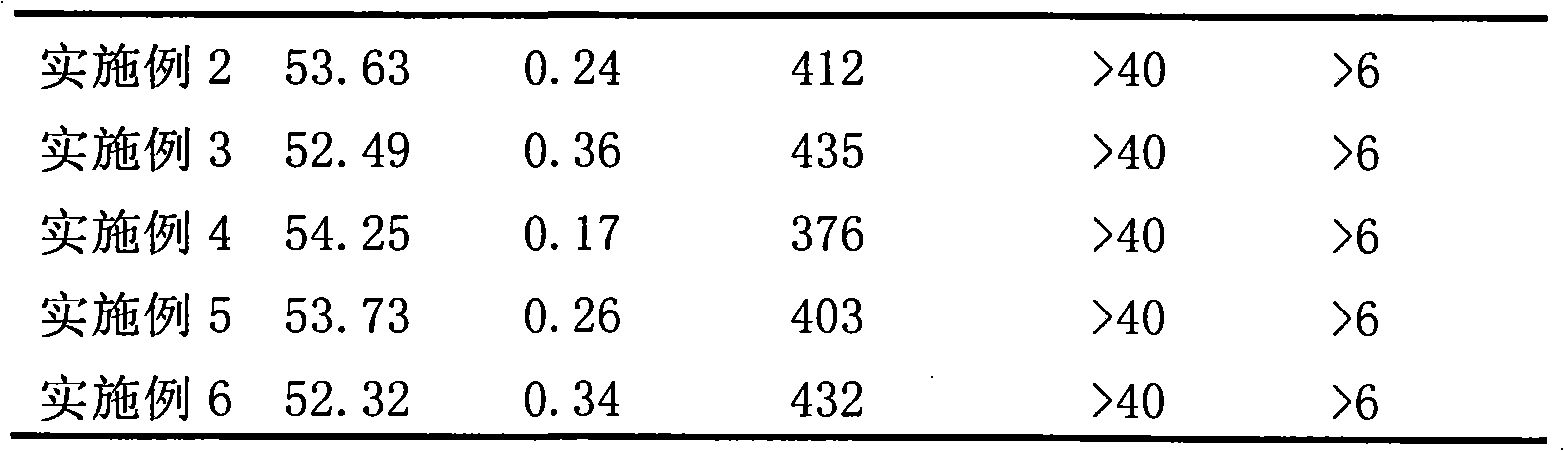

High heat conduction and high attenuation backing material for ultrasonic phased array probe and manufacturing method thereof

InactiveCN102338777AConvenient source of raw materialsLow priceMaterial analysis using sonic/ultrasonic/infrasonic wavesHeat-exchange elementsThermal conductivityImage resolution

A high heat conduction and high attenuation backing material for ultrasonic phased array probe is made from lutecium oxide, alumina, a tungsten compound material and an epoxy adhesive and is characterized in that the epoxy adhesive is prepared by mixing epoxy resin E-54 and triethanolamine; the tungsten compound material is prepared by mixing rubber and a tungsten powder; and the alumina accounts for 10.48-53.04wt% of the backing material. A manufacturing method of the backing material comprises the following steps of: (a) mixing the epoxy resin E-54, lutecium oxide, alumina and the tungsten compound material with stirring, wherein the epoxy resin E-54 accounts for 6.22% the total weight of the backing material and alumina accounts for 10.48-53.04wt% of the backing material; (b) adding triethanolamine which accounts for 0.95% the total weight of the backing material into the above composite particles with stirring; (c) putting the composite particles into a die, and extruding the composite particles into the required backing material by the use of a powder pressing machine; and (d) putting the pressed backing material into an air-blasting heating oven of 65 DEG C for heating-curing. The thermal conductivity of the backing material is 1.782W / (m.k), its specific acoustic impedance is 8.42*106Pa.s / m and its acoustic attenuation coefficient at 5MHz is 294.4dB / cm. The backing material has high thermal conductivity and high attenuation. In addition, the sensitivity and resolution of the phased array probe produced by the use of the backing material can satisfy the requirement for application.

Owner:广州多浦乐电子科技股份有限公司

Preparation method of bio oil-phenol-methanal copolycondensation resin wood adhesive

ActiveCN101974301AHigh mechanical strengthImprove waterproof performanceAldehyde/ketone condensation polymer adhesivesHydrocarbon oils treatmentAdhesiveAging resistance

The invention relates to a preparation method of a bio oil-phenol-methanal copolycondensation resin wood adhesive, belonging to the technical field of fine chemistry and high polymer materials, which comprises the following steps of filtering and refining bio oil to prepare the refined bio oil; adding sulfur and sodium hydroxide solution to the refined bio oil; stirring, heating and reacting to prepare the modified bio oil; and adding phenol and a catalyst to the modified bio oil to prepare the adhesive after reacting. In the method of the invention, the bio oil is taken as a substrate to synthesize the adhesive for wood, and the content of the bio oil is 50 to 60% of the total content of the adhesive. The prepared adhesive has the advantages of high mechanical strength, good waterproof performance and aging resistance, and can be used for preparing the products in high accessories of outdoor stage plywood, particle boards, fiberboards, layer base materials and the like. Moreover, thepreparation technology for pyrolyzing the bio oil wood adhesive is simple and fast, and the resins have the advantages of strong adhesion performance and long storage life.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method and application of magnesium-doped porous nano titanium oxide coating

InactiveCN101928974AHigh bonding strengthChemically stableSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

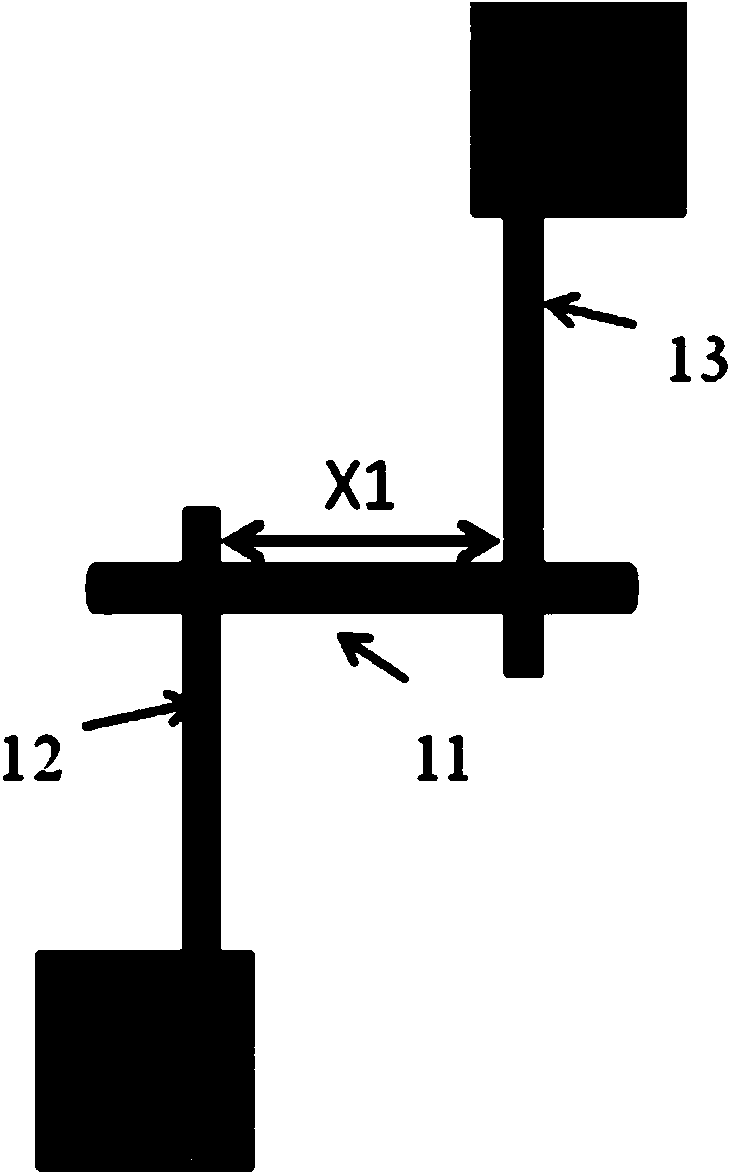

Flexible texture coating and preparation method thereof

InactiveCN101633812ASimple processGood value for moneyMulticolor effect coatingsSolventAluminium silicate

The invention discloses a flexible texture coating which comprises the following components according to percentage by mass: 5-10% of water, 0.1-0.3% of anti-mildew anti-algae agent, 0.05-0.15% of preservative, 0.1-0.3% of dispersing agent, 0.05-0.15 of wetting agent, 0.02-0.07% of defoaming agent A, 7.5-11.5% of 600-mesh heavy calcium carbonate power, 10-15% of titanium dioxide, 1.5-3.0% of ultra-fine aluminium silicate, 10-15% of emulsion A, 15-20% of emulsion B, 10-12% of X1-X2-mesh heavy calcium stone tablet, 10-12% of X3-X4-mesh heavy calcium stone tablet, 13-15% of X5-X6-mesh heavy calcium stone tablet, 0.05-0.1% of defoaming agent B, 0.5-0.15% of solvent HA, 1-3% of solvent HB, 0.2-0.3% of cellulose A, 0.1-0.2% of cellulose B, 0.5-0.7% of thickening agent and 0.05-0.15% of PH value adjusting reagent. The flexible texture coating of the invention has the advantages of bridging slight crack, rich forms and colors and environmental protection; the preparation method of the invention has simple, easy and fast process.

Owner:广东自然涂化工有限公司

Efficient environment-friendly low-temperature composite phase change cold accumulating agent, as well as preparation method and application thereof

ActiveCN104726072ASimple preparation processThe production process is fastFood preservationHeat-exchange elementsPotassiumPhase change

The invention discloses an efficient environment-friendly low-temperature composite phase change cold accumulating agent. The cold accumulating agent is prepared from the following components in percentage by mass: 5-11 percent of potassium chloride, 10-15 percent of sodium chloride, 0.1-0.6 percent of citric acid, 1-1.5 percent of sodium tetraborate, 0.5-2 percent of guar gum and 70-83.4 percent of water. The invention further discloses a method for preparing the efficient environment-friendly low-temperature composite phase change cold accumulating agent, and application of the efficient environment-friendly low-temperature composite phase change cold accumulating agent in the field of storage and fresh preservation. Compared with a traditional cold accumulating agent preparation process, the process has the characteristics of convenience and rapidness, the prepared cold accumulating agent is transparent or translucent gel, and has the characteristics of safety, no pollution, efficiency, large latent heat of phase change and small condensate depression. Experiments prove that the phase-change temperature is between minus 21 and minus 24 DEG C, and the latent heat of phase change is 280-320kJ / kg.

Owner:南京久鼎环境科技股份有限公司

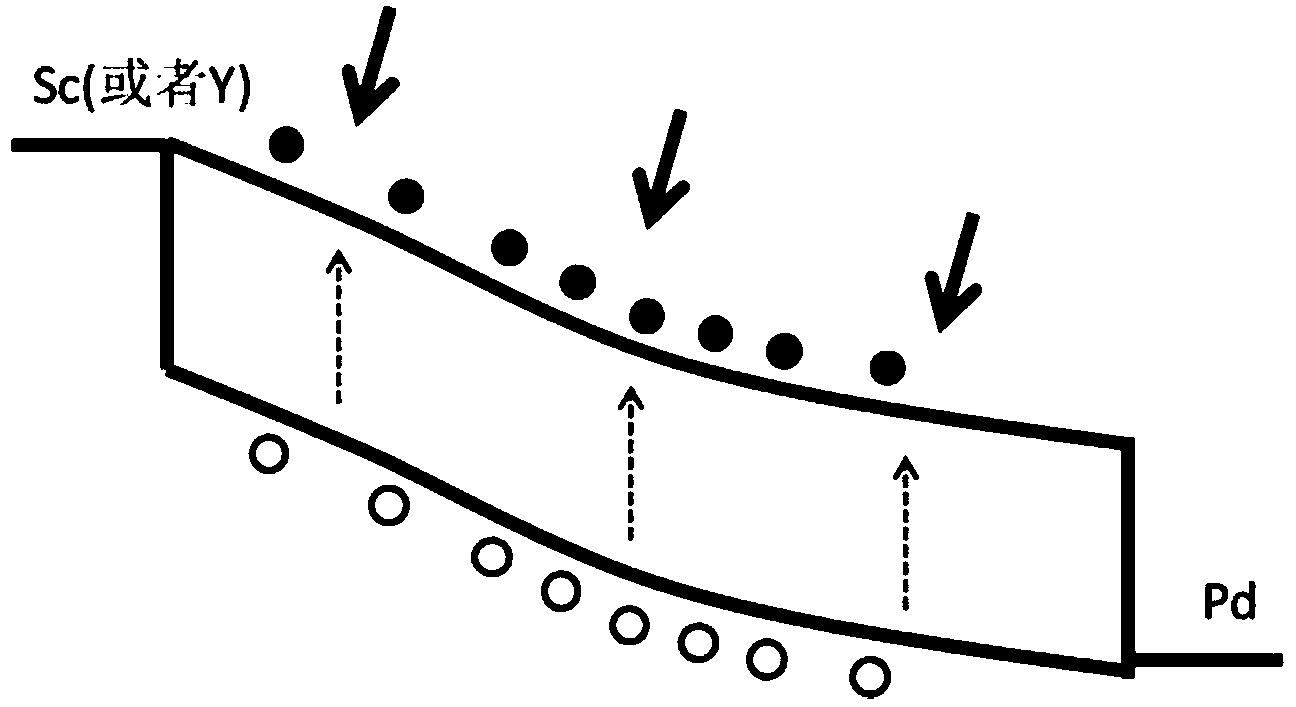

Rare earth-hydroxyapatite composite biologically active film and preparation method thereof

InactiveCN1927411ANo side effectsHigh bonding strengthProsthesisElectrolytic agentPlasma electrolytic oxidation

The invention relates to the means of active biological film on the surface of metal materials, especially the titanium radicel rare earth hydroxyapatite complex active biological film and the process for the manufacture. The differential arc oxidation technology is used in the method, the complex active biological film is generated in the surface of titanium and titanium alloy, a electrolyte solution with phosphate radical ion, calcium ion and rare earth ion is supplied; the titanium and titanium alloy is the anode and the rustless steel or the titanium is the cathode, the direct current power supply or the direct current impulsing power source is applied to differential arc oxygenize the titanium and titanium alloy; the oxidate deposit time is 3-60min; the temperature of electrolyte is not above 50DEG C. The film produced by the method which has perfect bioactivity, high conjugation, and stable chemical property can be the alternate material of several parts with heavy load to accelerate the postoperative healing, such as femur, hip joint and teeth root.

Owner:SOUTH CHINA UNIV OF TECH

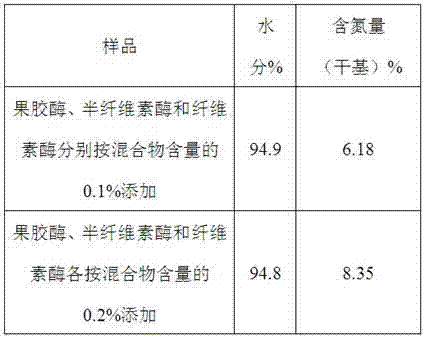

Method for reducing protein content in soybean dietary fiber

InactiveCN104256660ASimple preparation processHigh fiber purityFood preparationProtein contentPectinase

The invention relates to a method for reducing the protein content in soybean dietary fiber. The method comprises the following steps: feeding water into dried bean dregs, adjusting the pH, then feeding neutral protease into the dried bean dregs, carrying out heat preservation at the temperature of 60 DEG C, and oscillating; centrifuging the oscillated composition for 10 minutes at the rotating speed of 3000 revolutions / minute; removing supernatant to obtain lower sediment, washing the sediment by water, adjusting the pH, then feeding pectinase, hemicellulase and cellulase, carrying out heat preservation at the temperature of 60 DEG C, and oscillating; and separating fiber from supernatant by centrifugation, washing and then purifying to obtain the soybean dietary fiber. The preparation technology is simple and fast; the soybean dietary fiber prepared by the method is high in fiber purity, and does not easily have the phenomena of moisture absorption and color change; and the storage life of the soybean dietary fiber can be prolonged. After the soybean dietary fiber is treated by the method, the protein content in the soybean dietary fiber is reduced to about 6% from about 20%.

Owner:SHANDONG GAOTANG LANSHAN GRP CORP

Method for preparing graphene modified polyformaldehyde composite material

The invention belongs to the technical field of high polymer materials and in particular relates to a method for preparing a graphene modified polyformaldehyde composite material. The method specifically comprises the following steps: adding the modified graphene and polyformaldehyde into a reactor according to a weight ratio of (0.0001-1.0): 1, stirring and reacting at the temperature of 140-200 DEG C for 0.1-96 hours, discharging, drying at room temperature, and forming to obtain the material. According to the method, the graphene is uniformly dispersed in a polyformaldehyde matrix, and the interface bonding force between the graphene and the polyformaldehyde is improved, so that the performances, such as tensile strength, notch impact strength and breaking elongation, of the polyformaldehyde composite material are improved, and the polyformaldehyde composite material can be applied to the fields of automobiles, electric products, machinery, precise instruments and building materials.

Owner:HENAN UNIVERSITY

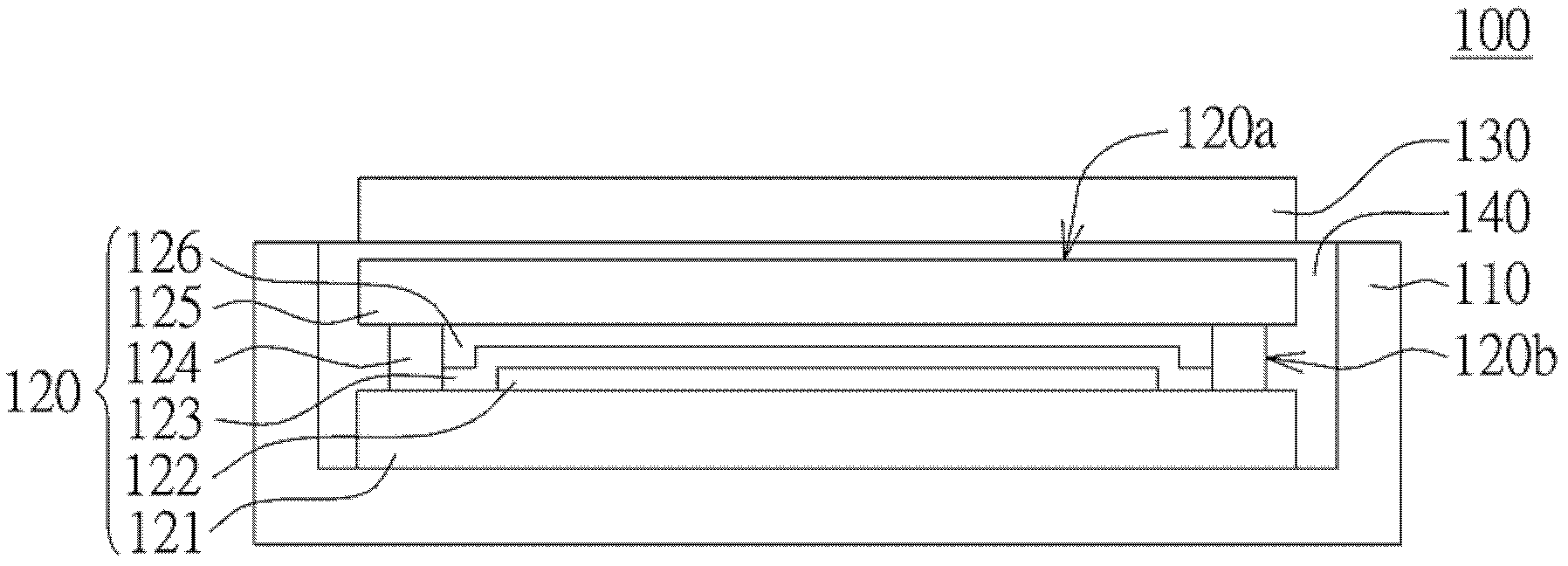

Display device and manufacturing method thereof

ActiveCN103325808AImprove water resistanceImprove oxygen barrier performanceSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention discloses a display device and a manufacturing method of the display device. The display device comprises a frame, an organic light-emitting diode panel, a light-transmitting element and a glue material. The organic light-emitting diode panel is arranged in the frame. The light-transmitting element is arranged on the organic light-emitting diode panel. The glue material is arranged between the organic light-emitting diode panel and the light-transmitting element and between the organic light-emitting diode panel and the frame in a filling mode.

Owner:INNOCOM TECH SHENZHEN +1

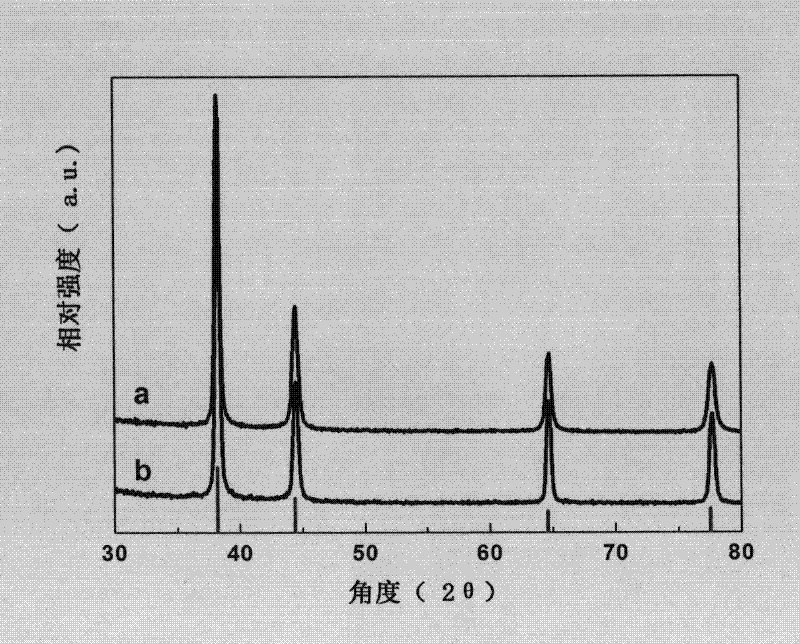

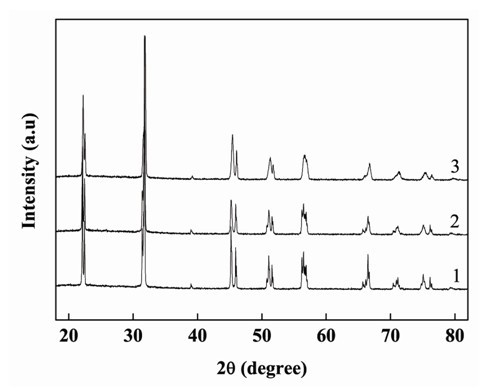

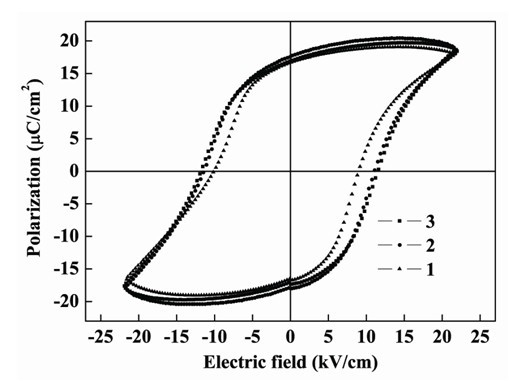

Preparation method of potassium-sodium niobate leadless piezo-electric ferroelectric ceramic

The invention discloses a method for preparing a potassium-sodium niobate leadless piezo-electric ferroelectric ceramic by a low-temperature normal-pressure complete liquid-state process, belonging to the field of a functional ceramic environment-friendly material. The method comprises the following steps: mixing raw materials in accordance with Na(1-x)KxNbO3, synthesizing precursor powder by using citric acid as a complexing agent and using a soluble salt as a raw material, tabletting at the pressure intensity of 20-40 MPa, and sintering at a temperature of 800-1000 DEG C to obtain a high-density pure-phase ceramic, wherein the ferroelectricity, the piezoelectricity and the dielectric property of the ceramic are excellent, and the process relates to processing steps of raw material mixing, molding, sintering, silver baking, polarizing and the like. The complete liquid-phase process effectively reduces the sintering temperature of the potassium-sodium niobate leadless piezo-electric ferroelectric ceramic, and the high-density ceramic can be molded by pressure under the pressure intensity of a conventional grinding tool; and ceramic particles grow uniformly and well, and the electric performance of the ceramic is excellent. Besides, the preparation process has the characteristics of simplicity, convenience, energy conservation, no poison, no environmental pollution and the like, thereby having wide application prospects.

Owner:HUAZHONG UNIV OF SCI & TECH

Ceramic material and preparation method thereof

InactiveCN106747385AMaintain biological activityControllable degradation rateCalcium silicateBioceramic

The invention belongs to the field of biological materials, and discloses a preparation method of a ceramic material. The method comprises the following steps of preparing a ZnO-CaO-SiO2 sol-gel powder material; putting a powder sample prepared in the first step into a muffle furnace for heating and heat preservation; and after sintering, stopping heating and carrying out furnace cooling to obtain an in-situ generated calcium silicate / hardystonite-based composite bioceramic material. The ceramic material is the calcium silicate / hardystonite-based composite biodegradable material. The ceramic material has the beneficial effects that the ceramic powder with uniformity and different zinc contents is accurately prepared through a sol-gel method, and thermal treatment is carried out by using the muffle furnace and the calcium silicate / hardystonite-based composite bioceramic material is generated in situ. The degradation rate can be regulated and controlled through adjusting the content of hardystonite in the material on the premise of ensuring the biological activity of the material. The ceramic material is simple and fast in preparation technology, simple and controllable in operation, and easy to popularize and apply.

Owner:LIAOCHENG UNIV

Method of preparing alkali lignin modified phenolic resin

InactiveCN101492522BAdequate responseTo achieve the purpose of modifying phenolic resinAldehyde/ketone condensation polymer adhesivesResource utilizationAdhesive

A method for preparing alkali lignin modified phenol-formaldehyde resin comprises the following steps: phenol, a first batch of formaldehyde solution, alkali lignin, metal oxide and dilution water are added into a reactor; a second batch of formaldehyde solution is added into the reactor; and a third batch of formaldehyde solution and a first batch of alkaline solution are added, formaldehyde trapping agent and a second batch of alkaline solution are added, and then material is discharged after cooling. The invention adopts the copolymerization technique to prepare an alkali lignin phenol formaldehyde adhesive, lignin and the phenol are added simultaneously, obtained hydroxymethylated lignin is reacted with hydroxymethyl phenol, a small part of the obtained hydroxymethylated lignin participates in the polycondensation of the hydroxymethyl phenol to form a main chain, and a large part of the obtained hydroxymethylated lignin forms branch chains through graft copolymerization, therefore, the lignin is introduced into a molecular chain and the aim of modifying phenol-formaldehyde resin is achieved. The invention can replace the use of 30-50 percent of the phenol, realizes stable and easy reaction control and easy industrial production; the bonding strength satisfies the requirements of national I-level plates; formaldehyde release reaches E0 level; therefore, the invention provides a new approach to the development of environment-friendly biomass-based wood adhesive and resource utilization of waste materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Biodegradable material with antibacterial effect and high strength, and preparation and application thereof

The invention discloses a preparation and an application of a biodegradable material with an antibacterial effect and a high strength. Biological resin and polylactic acid are added and blended to improve the mechanical properties and the thermal stability of polylactic acid, and the biological resin is grafted with antibacterial groups and is uniformly distributed in the polylactic acid matrix, so that the polylactic acid biodegradable material is endowed with an excellent antibacterial performance, and the influence of the decomposition effect of microorganisms in the environment on the storage, the service life and the safety of the material is prevented. The barrier property and the antibacterial property of polylactic acid can be further improved by performing functional modificationon a filler, so the safety of foods or medicines in the packaging material is guaranteed, and the high standard for the performance of the polylactic acid material in the industry is met. The method has the advantages of simplicity, high efficiency and low cost, and can be applied to the wide fields of material packaging and the like.

Owner:湖南绿斯达生物科技有限公司

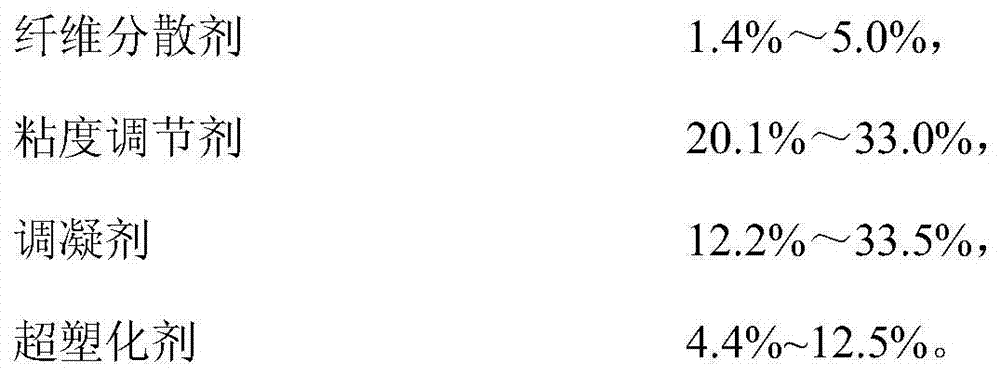

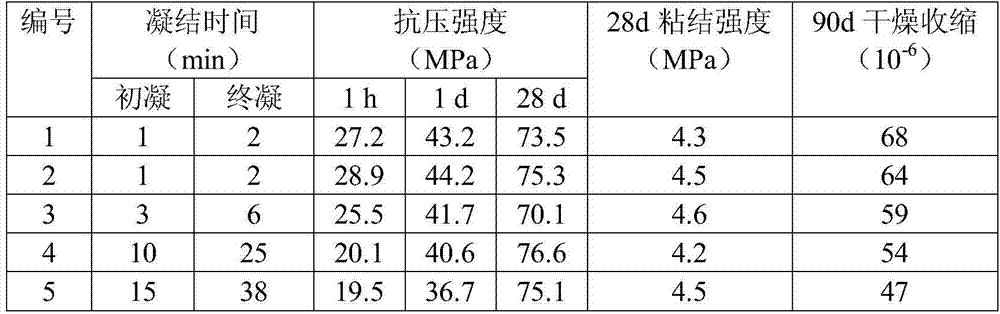

A performance-adjusting admixture of magnesium phosphate cement-based composite material

Owner:JIANGSU SOBUTE NEW MATERIALS

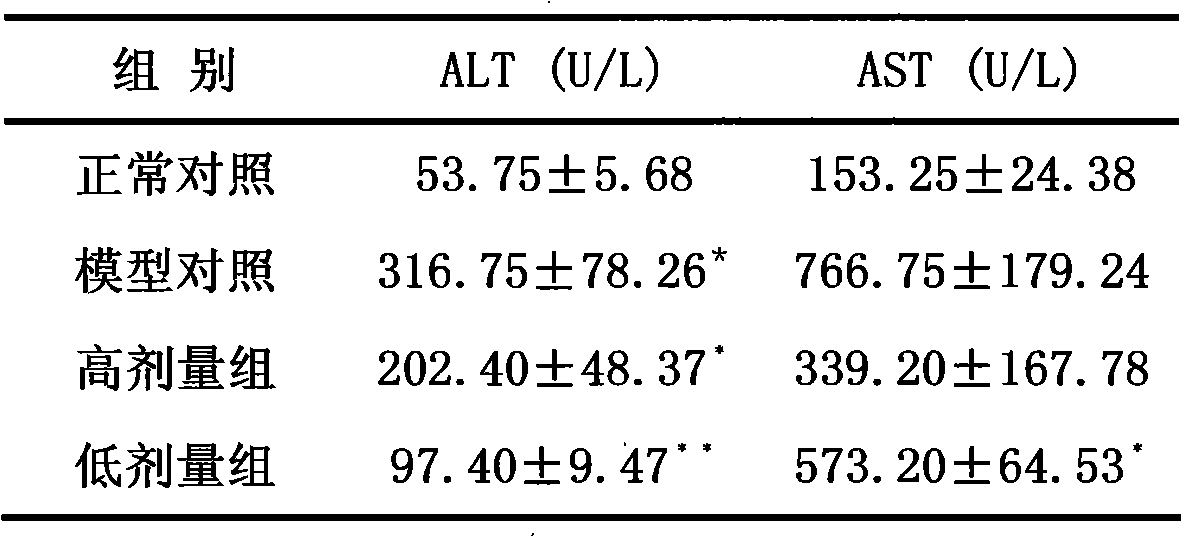

Method for preparing non-alkaloids part of subprostrate sophora root

InactiveCN101278969ASimple preparation processThe production process is fastDigestive systemPlant ingredientsChromatographic separationPolystyrene

The invention discloses a preparation method for the non-alkaloid part of sophorae tonkinensis, which belongs to the technical field of Chinese medicine. The preparation method is as follows: ethanol is added into water regurgitation extract of the sophorae tonkinensis; insoluble substance is precipitated and filtered; filtrate is condensed and carries out column chromatograph separation by the strong acid cationic resin of crosslinked polystyrene series; the filtrate is eluted by water; eluted water is collected and condensed to ointment; and the ointment is decompressed and dried to obtain the non-alkaloid part. The non-alkaloid part contains carbohydrate, organic acid, phenols and saponin and son on. The preparation process of the invention is easy and quick and the cost of preparation is low. In addition, the quality of various substances of the obtained product is stable and controllable. The non-alkaloid part is applied for reducing enzyme and protecting liver, and offers substance base for seeking more efficient non-alkaloid active components.

Owner:SHANGHAI JIAO TONG UNIV

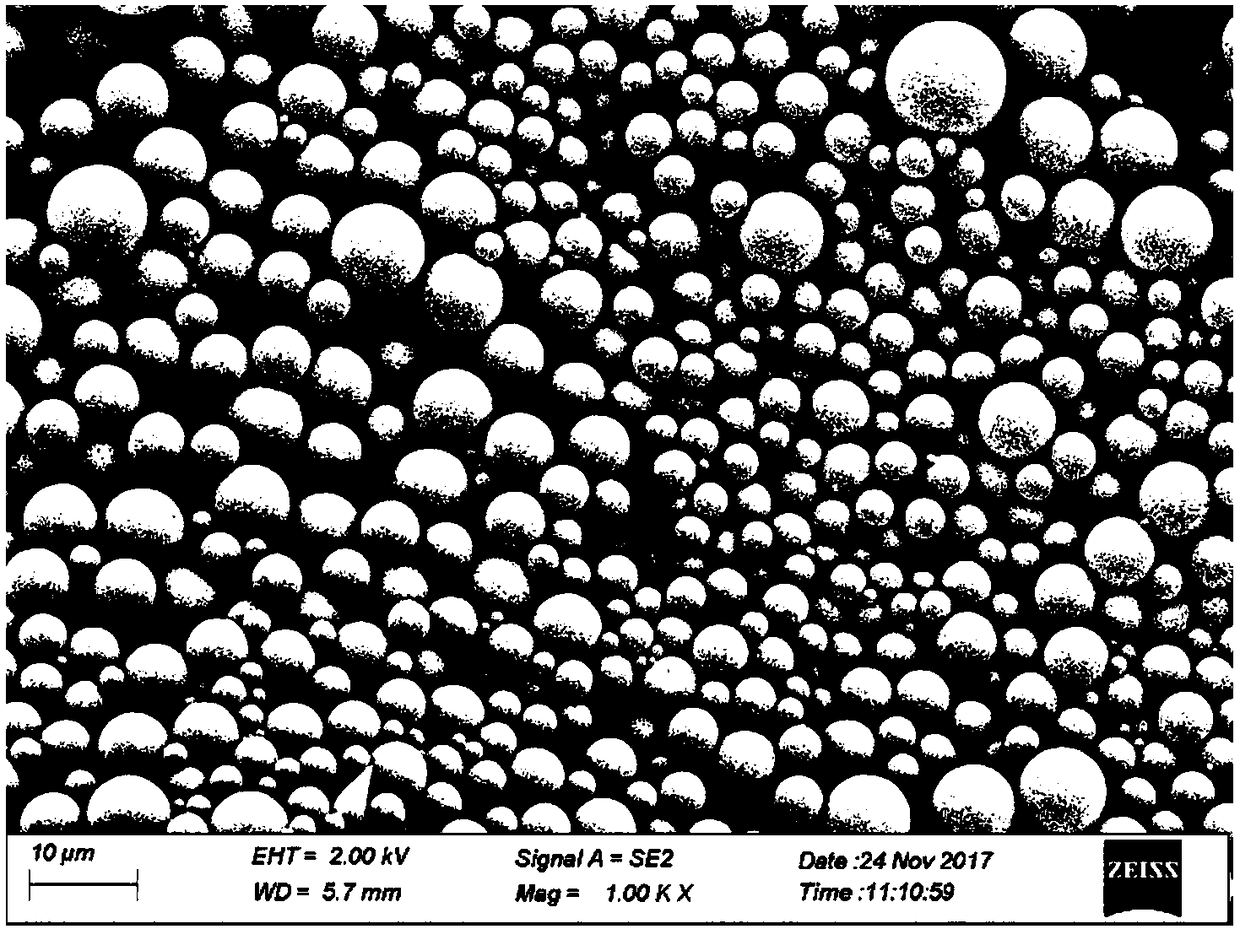

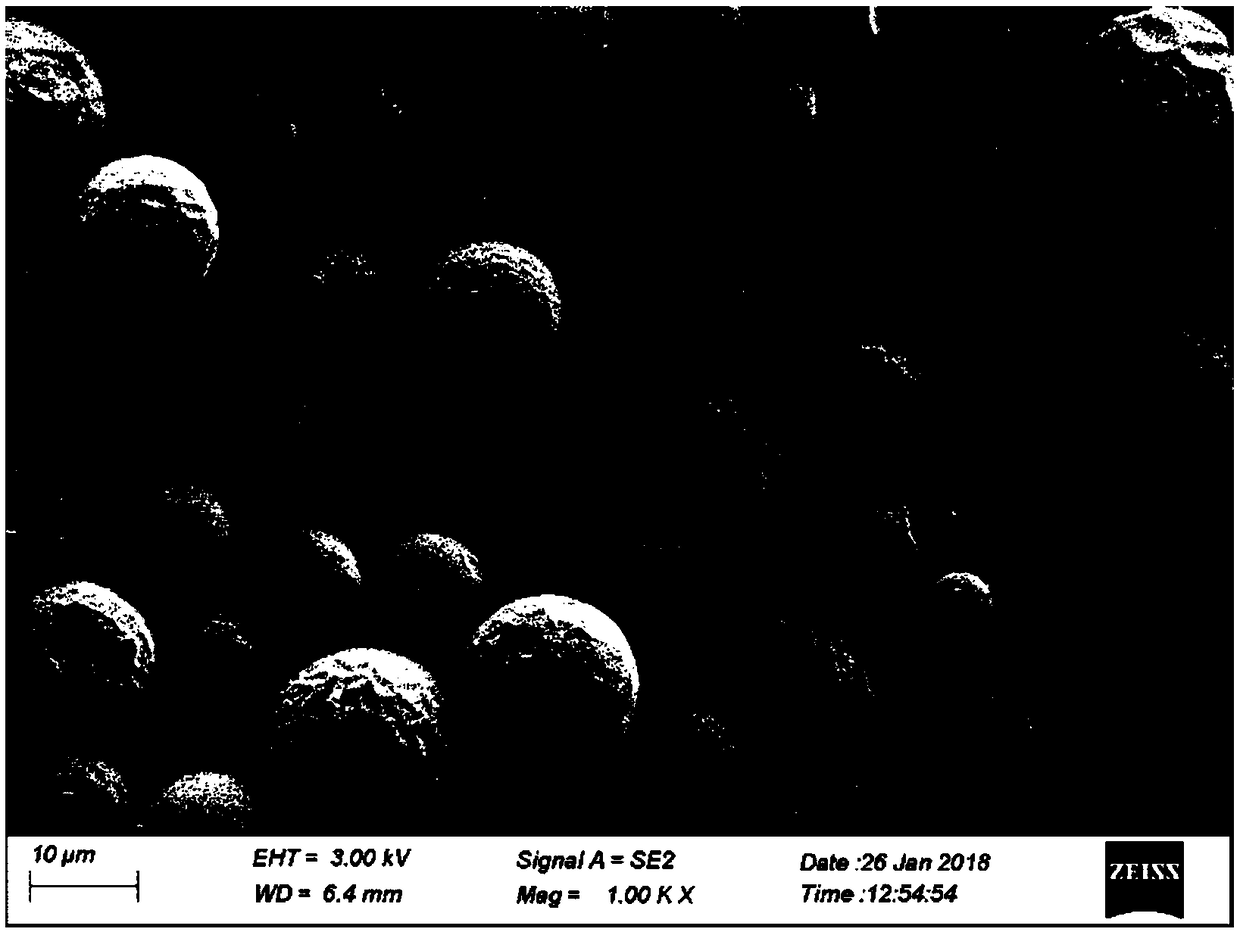

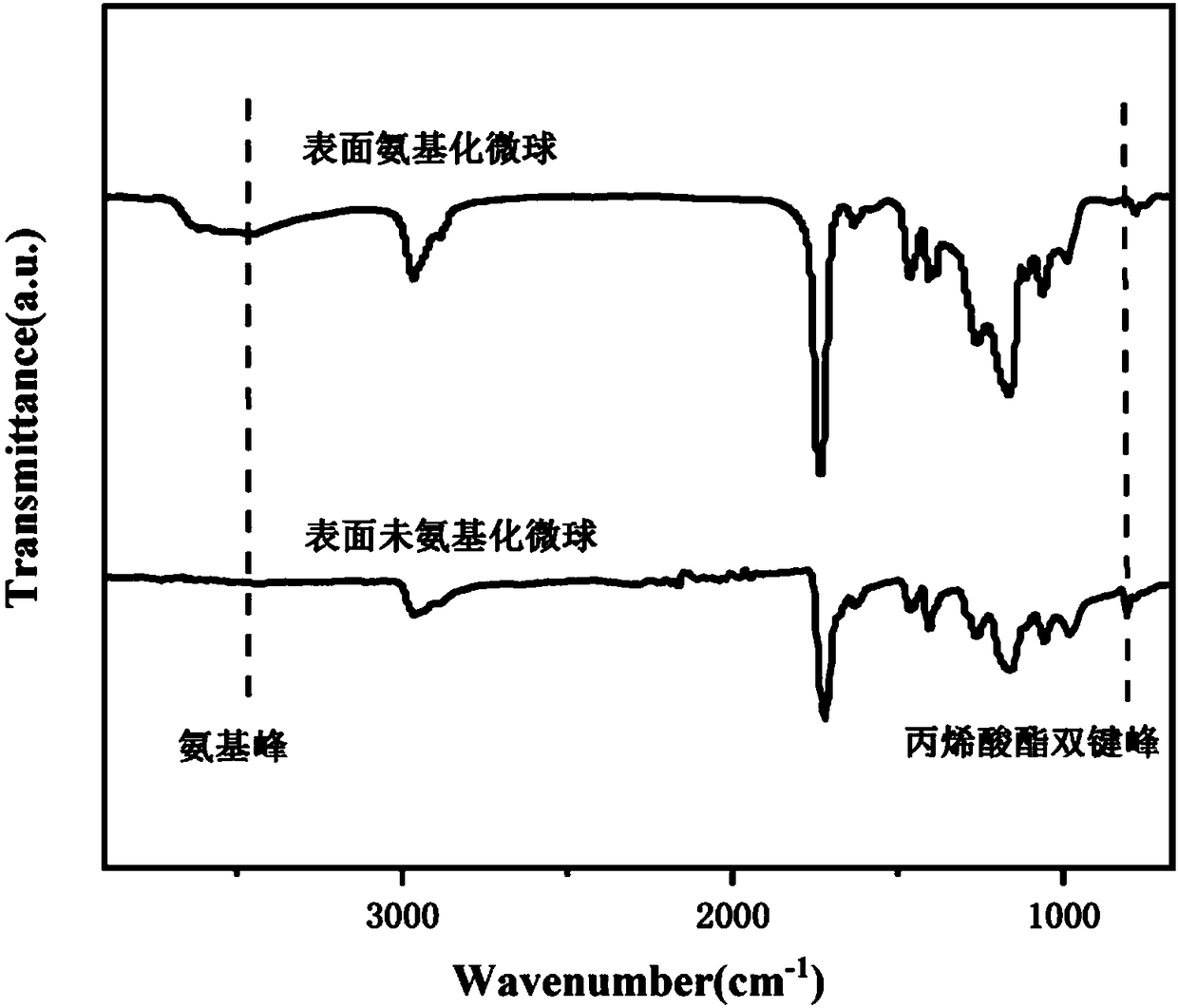

Preparation method of functionalized polymer microspheres

ActiveCN108341966AEnergy saving in preparation processHigh product purityWater contaminantsWater/sewage treatment by sorptionSolventPhotoinitiator

The invention relates to a preparation method of functionalized polymer microspheres, belonging to the technical field of preparation of functional polymers. According to the preparation method, an oil-soluble polyfunctionality acrylate monomer, polyethyleneimine and a photoinitiator are used as raw materials, wherein the weight ratio of the polyfunctionality acrylate monomer to the photoinitiatorto the polyethyleneimine to a water solvent is equal to 100 to (1-5) to (5-20) to (500-2000). After the system is uniformly mixed, emulsification is firstly carried out under the action of a high-speed disperser, and ultraviolet light irradiation is performed after the emulsification is finished, so that polymer microspheres of polyfunctionality acrylate are obtained; after that, the polymer microspheres and polyethyleneimine are subjected to a Michael addition reaction, so that the functional polymer microspheres having surfaces modified by active primary amino groups and secondary amino groups. The functional macromolecular microspheres, which are prepared by the method and have aminated surfaces, are low in reaction energy consumption, and the reaction rate and the reaction yield can be adjusted by means of time. The particle sizes of the polymer microspheres can be adjusted within a range of 2-100mu m. The polyethyleneimine not only serves as a stabilizer in a formation process ofthe microspheres, but also can be used as a modifier in a microsphere modification process.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com