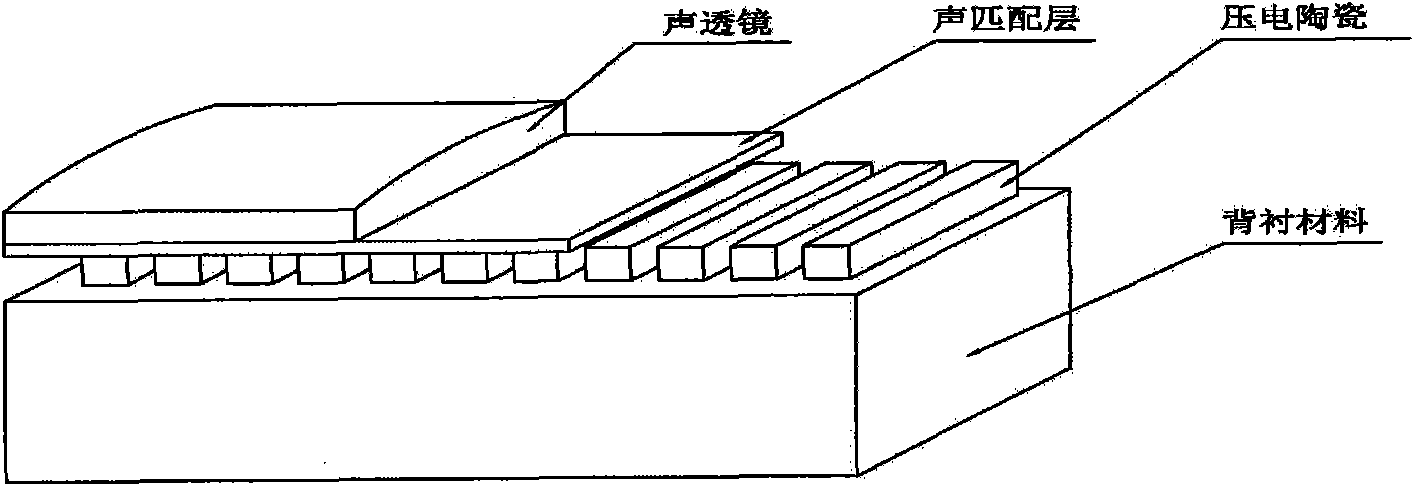

High heat conduction and high attenuation backing material for ultrasonic phased array probe and manufacturing method thereof

An ultrasonic phased array, high thermal conductivity technology, applied in the direction of material analysis, heat exchange materials, and analysis materials using sonic/ultrasonic/infrasonic waves. It can improve the mass percentage, the source of raw materials is easy, and the price is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

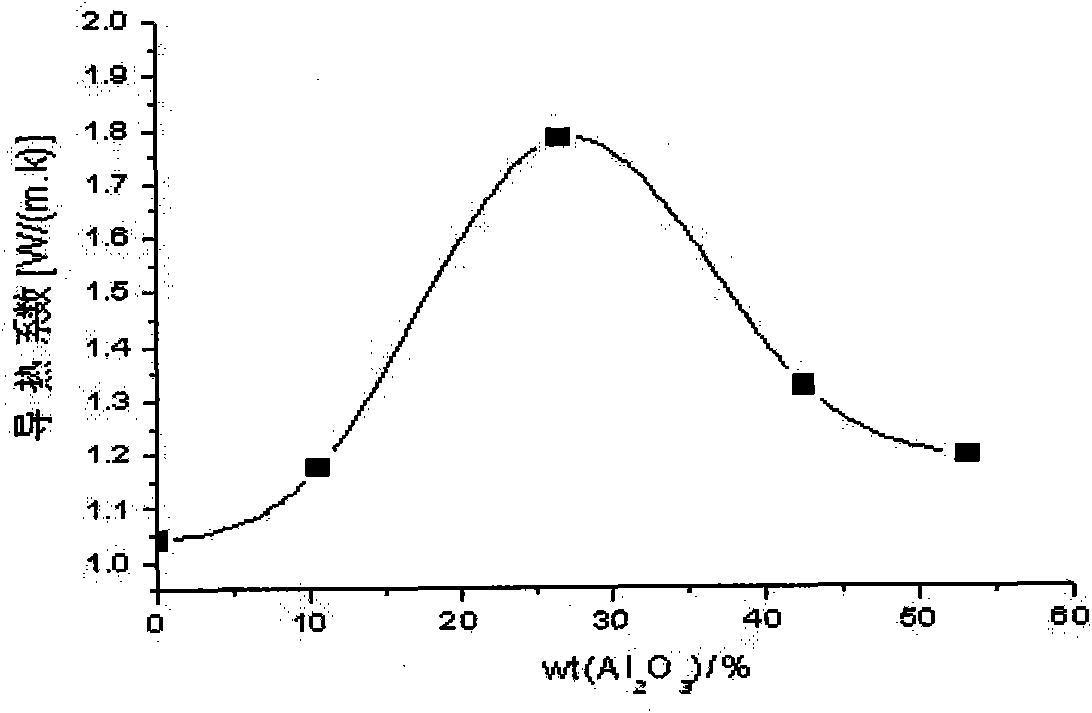

[0030] The high thermal conductivity and high attenuation backing material suitable for ultrasonic phased array probes of the present invention is composed of lutetium trioxide, alumina, composite tungsten powder and epoxy adhesive, wherein alumina accounts for the mass fraction of the backing material 26.52% of the aluminum oxide is produced by Shanghai Gona Powder Technology Co., Ltd. The particle size is 1500 mesh and the density is 4.0g / cm 3 , Lutetium trioxide accounts for 26.52% of the mass fraction of the backing material. Lutetium trioxide is produced by Guangzhou Weber Chemical Co., Ltd. The particle size is 400 mesh and the density is 9.4g / cm. 3 ; Composite tungsten powder accounts for 39.79% of the mass fraction of the backing material. It is made by mixing rubber and tungsten powder with a particle size of 0.5mm.

[0031] Epoxy adhesive is made by stirring and mixing epoxy resin E-54 and triethanolamine, among which epoxy resin E-54 and triethanolamine are made by Guang...

Embodiment 2

[0041] The high thermal conductivity and high attenuation backing material suitable for ultrasonic phased array probes of the present invention is composed of lutetium trioxide, alumina, composite tungsten powder and epoxy adhesive, wherein alumina accounts for the mass fraction of the backing material 10.48% of the alumina, the particle size is 1500 mesh produced by Shanghai Gona Powder Technology Co., Ltd., and the density is 4.0g / cm 3 , Lutetium trioxide accounts for 42.56% of the mass fraction of the backing material. Lutetium trioxide is produced by Guangzhou Weber Chemical Co., Ltd. The particle size is 400 mesh and the density is 9.4g / cm. 3 ; Composite tungsten powder accounts for 39.79% of the mass fraction of the backing material. It is made by mixing rubber and tungsten powder with a particle size of 0.5mm.

[0042] Epoxy adhesive is made by stirring and mixing epoxy resin E-54 and triethanolamine, among which epoxy resin E-54 and triethanolamine are made by Guangzhou Che...

Embodiment 3

[0050] The high thermal conductivity and high attenuation backing material suitable for ultrasonic phased array probes of the present invention is composed of lutetium trioxide, alumina, composite tungsten powder and epoxy adhesive, wherein alumina accounts for the mass fraction of the backing material 42.56% of the aluminum oxide is produced by Shanghai Gona Powder Technology Co., Ltd. The particle size is 1500 mesh and the density is 4.0g / cm 3 , Lutetium trioxide accounts for 10.48% of the mass fraction of the backing material. Lutetium trioxide is produced by Guangzhou Weber Chemical Co., Ltd. The particle size is 400 mesh and the density is 9.4g / cm. 3 ; Composite tungsten powder accounts for 39.79% of the mass fraction of the backing material. It is made by mixing rubber and tungsten powder with a particle size of 0.5mm.

[0051] Epoxy adhesive is made by stirring and mixing epoxy resin E-54 and triethanolamine, among which epoxy resin E-54 and triethanolamine are made by Guang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com