Slump retention agent and preparation method thereof

A technology of retaining agent and slump, which is applied in the field of slump retaining agent and its preparation, can solve the problems of uneven slump retaining performance of concrete, limited source of slump retaining agent raw materials, and affecting concrete construction performance, etc., to achieve the expansion of raw materials Source, excellent effect of slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

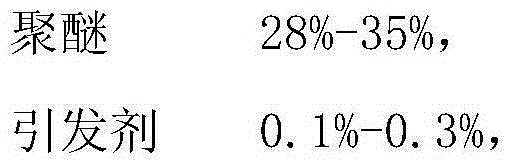

Method used

Image

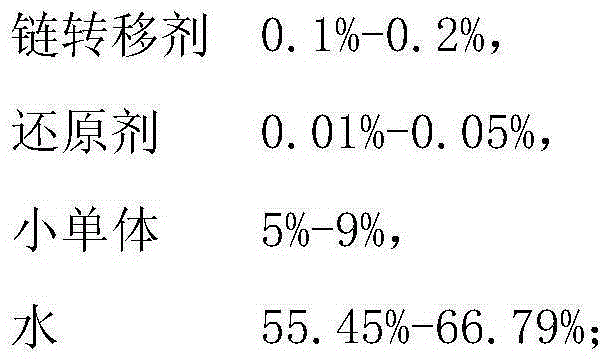

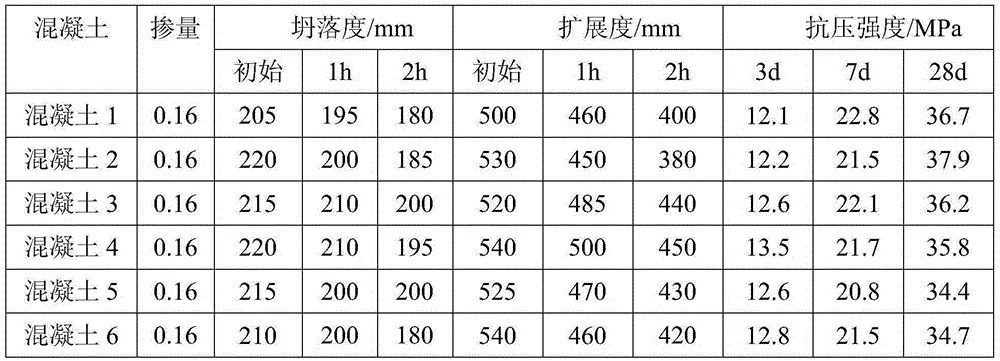

Examples

Embodiment 1

[0024] The raw material components are as follows in parts by mass: 123 parts of methallyl glycol polyoxyethylene ether, 1109 parts of methallyl polyoxyethylene ether, 4.4 parts of ammonium persulfate, 4.4 parts of thioglycolic acid, 0.44 parts Ascorbic acid, 40 parts of acrylic acid, 170 parts of hydroxyethyl acrylate, 10 parts of hydroxybutyl acrylate, 2938.76 parts of water;

[0025] Put the above-mentioned 123 parts of methallyl glycol polyoxyethylene ether, the above-mentioned 1109 parts of methallyl polyoxyethylene ether and 968 parts of water into the reaction device, start stirring the ingredients, and obtain the mass percentage after fully dissolving A polyether solution with a concentration of 56%, the temperature of the polyether solution is 20°C, mix the above-mentioned 4.4 parts of thioglycolic acid, the above-mentioned 0.44 parts of ascorbic acid and 91.96 parts of water, and stir evenly to obtain a mixture solution with a concentration of 5% by mass , mixing the...

Embodiment 2

[0029] The raw material components are as follows in parts by mass: 308 parts of methallyl glycol polyoxyethylene ether, 1232 parts of methylbutenyl polyoxyethylene ether, 13.2 parts of sodium persulfate, 8.8 parts of mercaptopropionic acid, 2.2 parts Parts of sodium sulfite, 300 parts of acrylic acid, 96 parts of hydroxyethyl methacrylate, 2439.8 parts of water;

[0030] Put the above-mentioned 308 parts of methallyl glycol polyoxyethylene ether, the above-mentioned 1232 parts of methyl butenyl polyoxyethylene ether and 660 parts of water into the reaction device, start stirring the ingredients, and obtain the mass percentage after fully dissolving A polyether solution with a concentration of 70%, the temperature of the polyether solution is 22°C, mix the above-mentioned 8.8 parts of mercaptopropionic acid, the above-mentioned 2.2 parts of sodium sulfite and 99 parts of water, and stir evenly to obtain a mixture with a concentration of 10% by mass solution, mixing the above 3...

Embodiment 3

[0034] The raw material components are as follows in parts by mass: 693 parts of methallyl glycol polyoxyethylene ether, 350 parts of methallyl polyoxyethylene ether, 342 parts of methylbutenyl polyoxyethylene ether, 8.8 Parts of hydrogen peroxide, 9.68 parts of mercaptopropionic acid, 2.2 parts of ascorbic acid, 80 parts of acrylic acid, 180 parts of hydroxyethyl acrylate, 101 parts of hydroxypropyl acrylate, 14 parts of hydroxybutyl acrylate, 2620.32 parts of water;

[0035] Put the above 693 parts of methallyl glycol polyoxyethylene ether, 350 parts of methallyl polyoxyethylene ether, 342 parts of methylbutenyl polyoxyethylene ether and 924 parts of water into the reaction device, open Stir the chemical material, and obtain a polyether solution with a mass percentage concentration of 60% after fully dissolving. The temperature of the polyether solution is 25°C. Mix the above-mentioned 9.68 parts of mercaptopropionic acid, the above-mentioned 2.2 parts of ascorbic acid and 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com