Gold micro-nano composite structure array and preparation method thereof

A composite structure and array technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of Raman signal inhomogeneity, uncertainty, inconsistency, etc., to eliminate interference peaks and improve the preparation process easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concrete steps of preparation are:

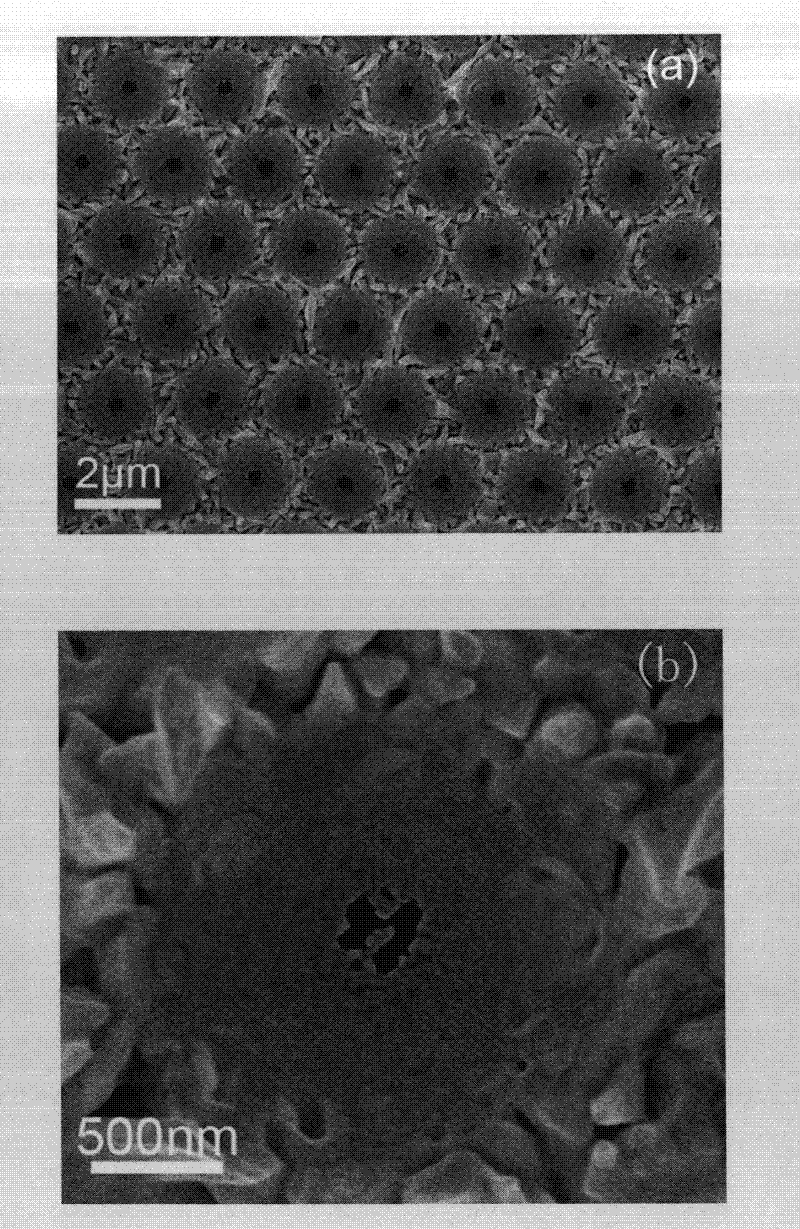

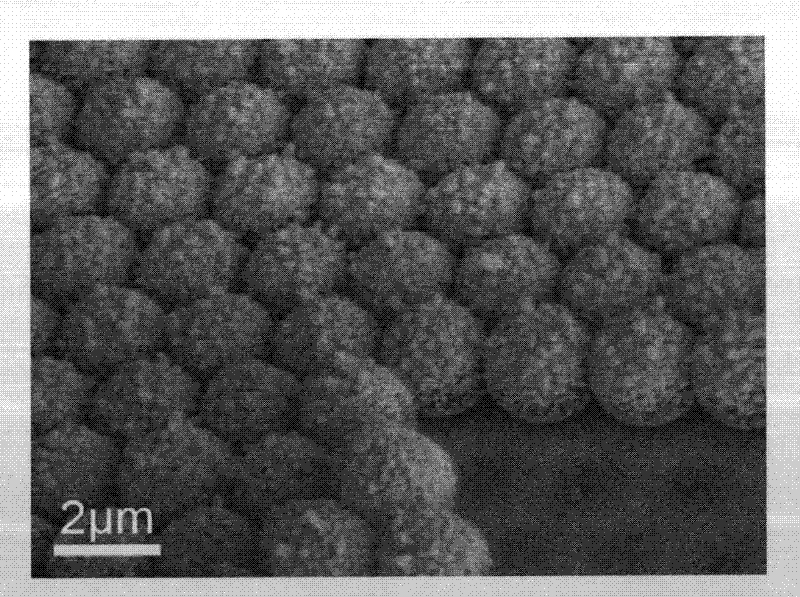

[0026] In step 1, a layer of gold film is deposited on the substrate by ion sputtering or vacuum evaporation; wherein, the substrate is conductive glass in a conductor substrate. Then, a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2000 nm was placed on the substrate covered with gold film.

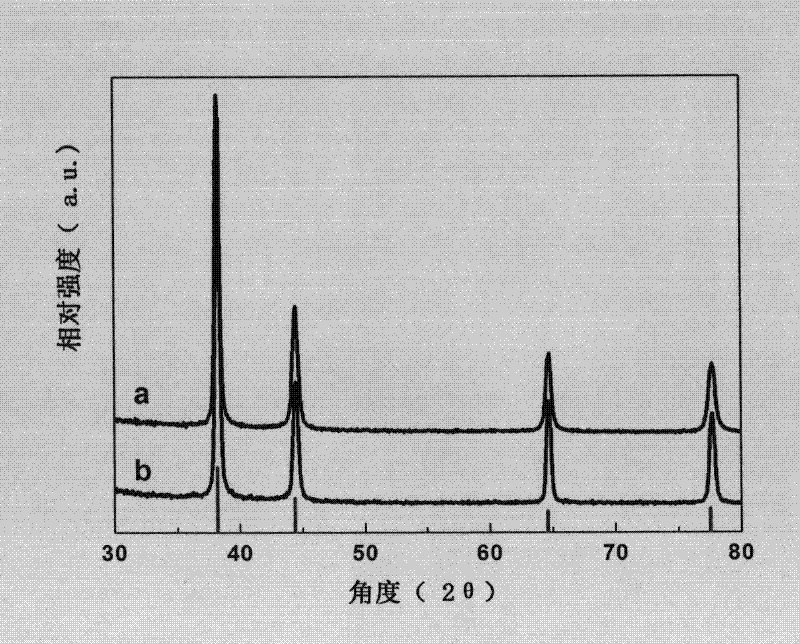

[0027] In step 2, the substrate covered with the gold film and the single-layer colloidal crystal template is heated at 100° C. for 10 minutes. Then it is placed in a chloroauric acid solution with a concentration of 0.3g / L, and it is used as a working electrode, and the deposition current density is 0.03mA / cm 2 (or 0.15mA / cm 2 ) under electrodeposition for 8 hours; wherein, the temperature during electrodeposition was 13° C., and the counter electrode during electrodeposition was a graphite electrode to obtain a complex array. Then the composite array was placed in dichloromethane s...

Embodiment 2

[0029] The concrete steps of preparation are:

[0030] In step 1, a layer of gold film is deposited on the substrate by ion sputtering or vacuum evaporation; wherein, the substrate is conductive glass in a conductor substrate. Then, a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2000 nm was placed on the substrate covered with gold film.

[0031] In step 2, the substrate covered with the gold film and the single-layer colloidal crystal template is heated at 105° C. for 7.5 minutes. Then it is placed in a chloroauric acid solution with a concentration of 0.4g / L, and it is used as a working electrode, and the deposition current density is 0.035mA / cm 2 (or 0.23mA / cm 2 ) under electrodeposition for 6.5 h; wherein, the temperature during electrodeposition was 15° C., and the counter electrode during electrodeposition was a graphite electrode to obtain a complex array. Then the composite array was placed in dichloromethane s...

Embodiment 3

[0033] The concrete steps of preparation are:

[0034] In step 1, a layer of gold film is deposited on the substrate by ion sputtering or vacuum evaporation; wherein, the substrate is conductive glass in a conductor substrate. Then, a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 2000 nm was placed on the substrate covered with gold film.

[0035]In step 2, the substrate covered with the gold film and the single-layer colloidal crystal template is heated at 110° C. for 5 minutes. Then it is placed in a chloroauric acid solution with a concentration of 0.5g / L, and it is used as a working electrode, and the deposition current density is 0.04mA / cm 2 (or 0.3mA / cm 2 ) under electrodeposition for 5 h; wherein, the temperature during electrodeposition was 18° C., and the counter electrode during electrodeposition was a graphite electrode to obtain a complex array. Then the composite array was placed in dichloromethane solvent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com