Method for preparing porous nanometer graphite

A technology of nano-graphite and iron salt, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult operation, expensive raw materials, high production cost, etc., to reduce energy consumption and production cost , Lower conversion temperature, lower equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

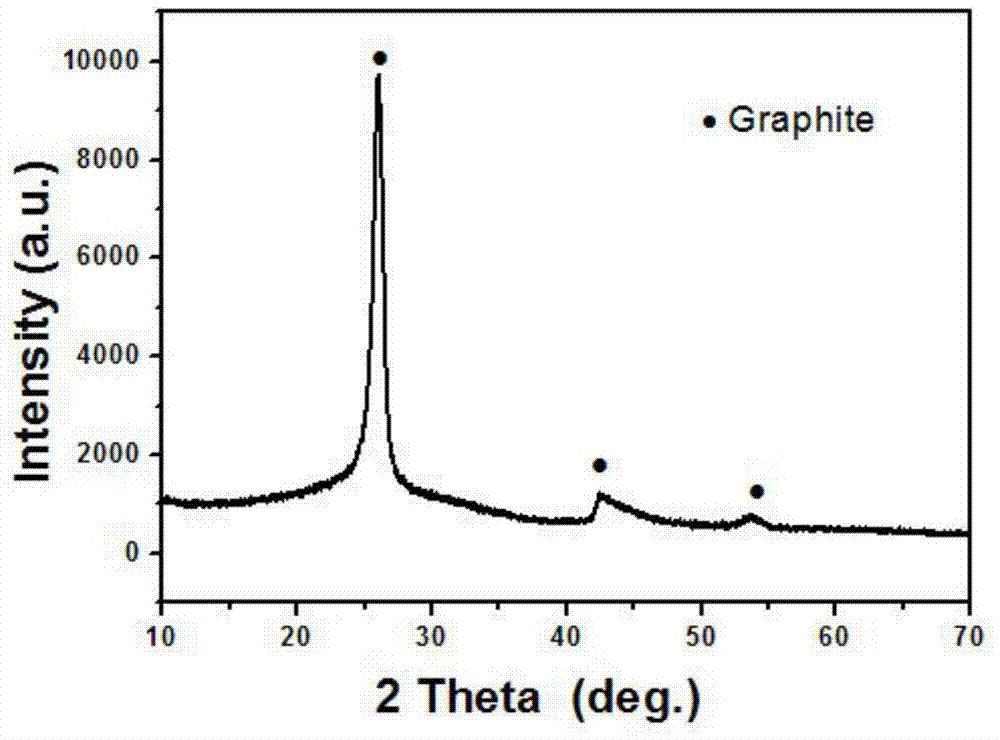

Image

Examples

Embodiment 1

[0020] Weigh 0.025 moles of ferric nitrate, 0.075 moles of glycine, and 0.075 moles of carbon source, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. The solution reacts after volatilization and concentration to obtain a precursor powder. The precursor powder is reacted at 700°C under a nitrogen atmosphere for 4 hours, and then the powder is washed with hydrochloric acid and ethanol and dried to obtain porous nano-graphite.

Embodiment 2

[0022] Weigh 0.025 moles of ferric nitrate, 0.025 moles of urea, and 0.05 moles of carbon source, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. The solution reacts after volatilization and concentration to obtain a precursor powder. The precursor powder is reacted at 900°C and an argon atmosphere for 3 hours, and then the powder is washed with hydrochloric acid and water and dried to obtain porous nano-graphite .

Embodiment 3

[0024] Weigh 0.025 moles of ferric chloride, 0.075 moles of ammonium nitrate, 0.075 moles of glycine, and 0.1 moles of carbon source, dissolve various raw materials in distilled water to prepare a solution, and place the solution on a temperature-controllable electric furnace for heating. The solution undergoes a reaction after volatilization and concentration to obtain a precursor powder. The precursor powder is reacted at 1000°C in a vacuum atmosphere for 2 hours, and then the powder is washed with nitric acid and ethanol and dried to obtain porous nano-graphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com