Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Energy saving in preparation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film-forming solution, and preparation method and application thereof

InactiveCN103666254AImprove EdibilityImprove securityMeat/fish preservation by coatingFruits/vegetable preservation by coatingAqueous ethanolMoisture resistance

The invention provides a film-forming solution. The film-forming solution is characterized by comprising the following components: 5-30wt% of alcohol-soluble protein, 1-5wt% of nano TiO2 particles, 0.1-3wt% of gelatinizing agent, 0.05-3wt% of coagulant aid, 0.1-3wt% of plasticizer, and the balance of ethanol water of which the volume ratio is 45-65%. The invention also provides a method for preparing the film-forming solution. Furthermore, the invention also provides application of the film-forming solution as a food preservation film. According to the film-forming solution provided by the invention, not only are the edibility, the safety and the stability of the preservation film improved due to the alcohol-soluble protein, but also the preservation film is degradable and free of pollution to the environment. The nano TiO2 particles are contained, so that the film-forming solution has unique barrier property and mechanical property after a film is formed, and has an antibacterial effect. In addition, the preparation method of the film-forming solution provided by the invention is simple in process, and low in cost. The preservation film not only is good in moisture resistance, but also does not become tacky after being moistened, is degradable, green and environment-friendly, can well keep the quality of the food, and prolongs the shelf life after being formed on the food surface.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

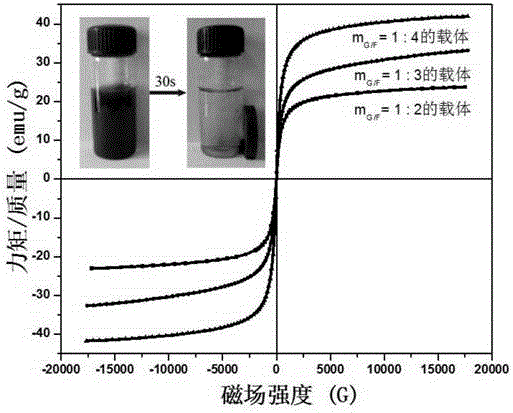

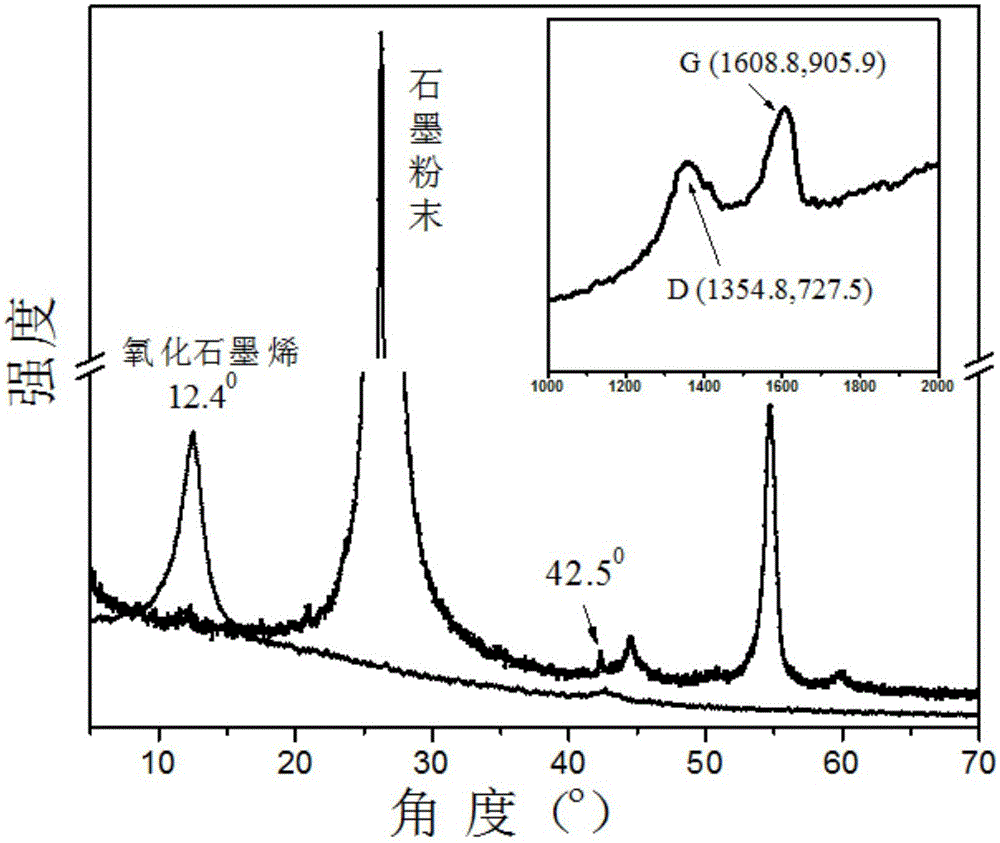

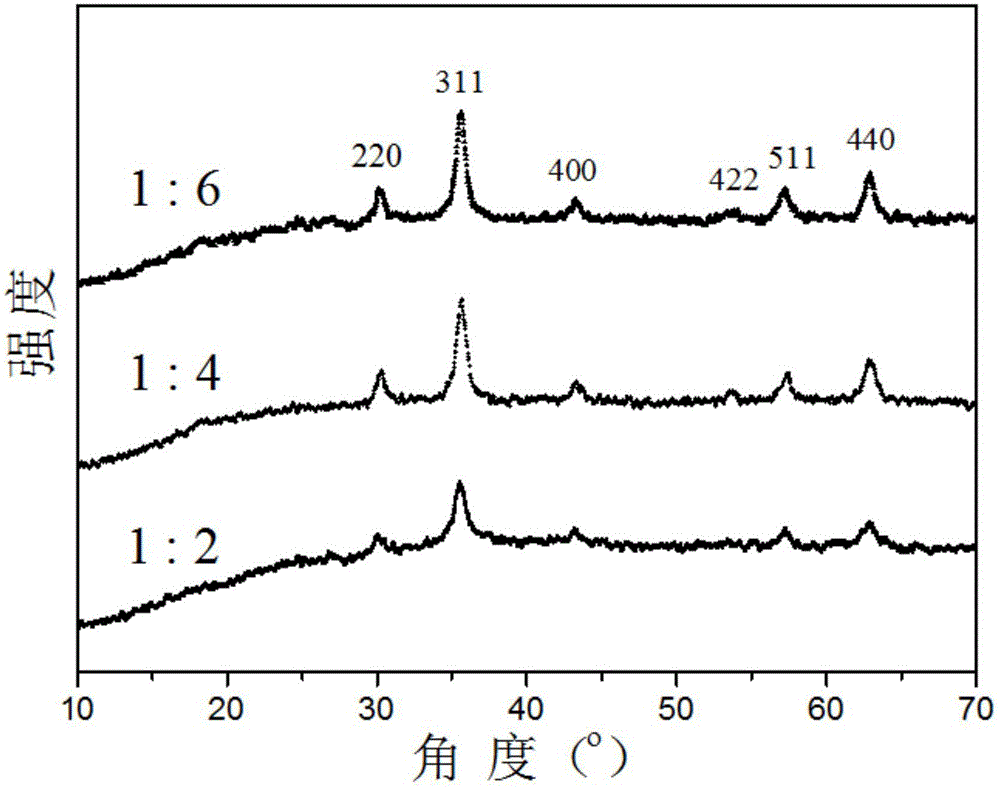

Preparation and application of magnetic graphene oxide compound

ActiveCN104998266ASave raw materialsRaw materials are easy to getOrganic active ingredientsEnergy modified materialsCvd grapheneIon

The invention relates to preparation and application of a reusable drug carrier with magnetic targeting drug delivery, namely a magnetic graphene oxide compound. The preparation of the magnetic graphene oxide compound comprises the following steps: (1) taking a graphite powder, adding a concentrated H2SO4 solution with NaNO3 dissolved therein, stirring, adding KMnO4, reacting, adding distilled water for dilution, keeping warm, cooling to room temperature, adding H2O2 to react, conducting suction filtration, washing respectively with diluted hydrochloric acid and distilled water, carrying out vacuum drying to obtain graphite oxide; dispersing graphite oxide in deionized water, and carrying out ultrasonic exfoliation at room temperature to obtain a GO suspension; (2) respectively weighing ferrous salt and ferric salt and dissolving in deionized water to obtain a solution A; and (3) taking a GO suspension, adding distilled water for dilution, adjusting to acid, dropwise adding the solution A obtained in the step (2) so as to obtain a mixed solution B, carrying out constant temperature curing on the mixed solution B, adjusting to alkaline, ageing for several hours, carrying out magnetic separation to obtain a solid crude product, washing the solid crude product to neutral, and carrying out vacuum drying to obtain the product.

Owner:ZHEJIANG NORMAL UNIVERSITY

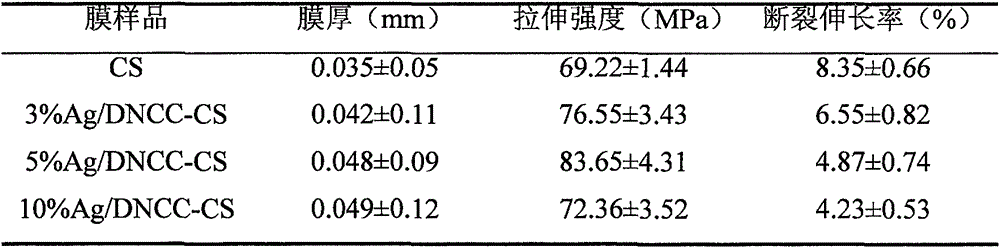

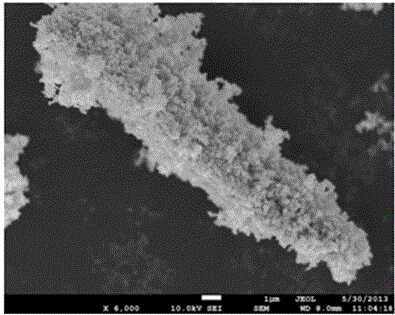

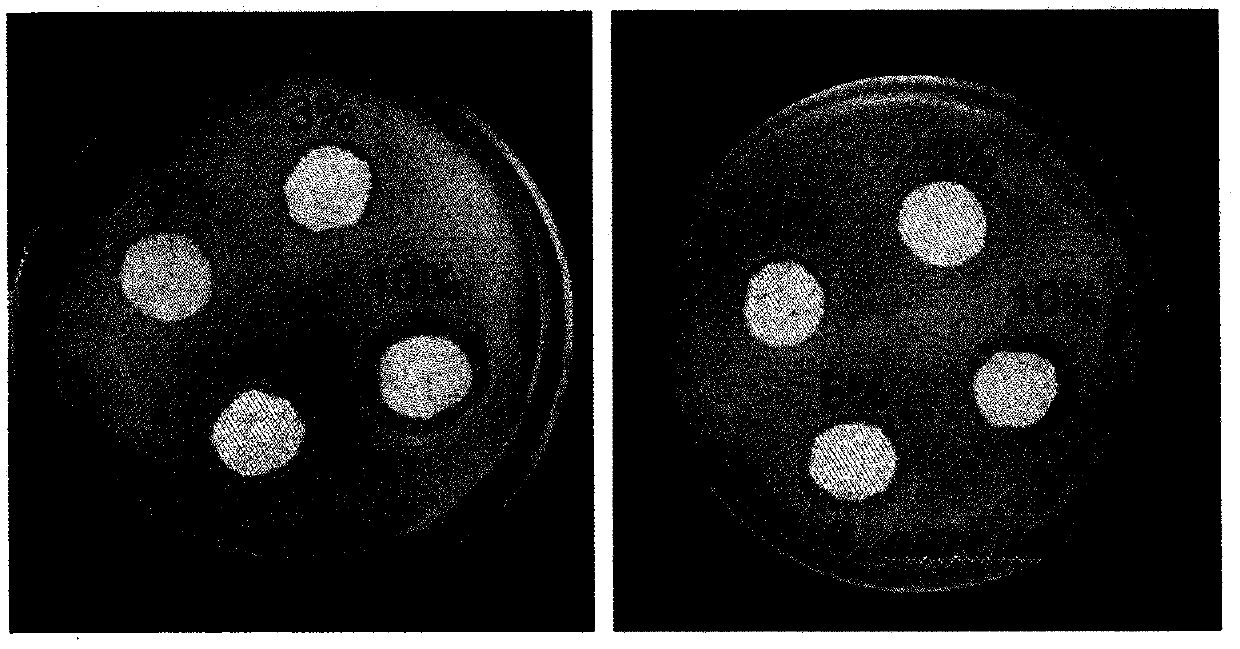

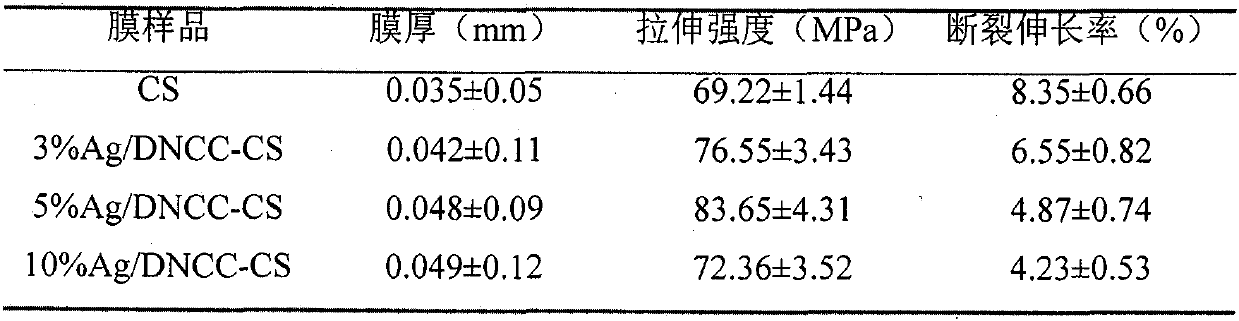

Preparation method of silver-loaded nano cellulose-chitosan composite film

InactiveCN106832437APreparation Process GreenThe preparation process is simple and environmentally friendlyComposite filmWound dressing

The invention discloses a preparation method of a silver-loaded nano cellulose-chitosan composite film, the preparation method of the silver-loaded nano cellulose-chitosan composite film comprises the following steps: adding sodium periodate into a nano cellulose solution, stirring in a dark place, centrifuging for separation, and washing to obtain dialdehydo nano cellulose; adding a newly-prepared saturated silver ammonia solution for preparation of silver-loaded nano cellulose; mixing the silver-loaded nano cellulose with a chitosan solution to obtain a silver-loaded nano cellulose-chitosan antibacterial film. Nano silver particles prepared in the method are evenly distributed in dialdehydo nano cellulose network structures, the easy agglomeration problem of the nano silver particles can be well solved, the preparation process does not require the use of special instruments, also does not need a chemical reducing agent, and the production cost is reduced. Through use of good mechanical properties of the nano cellulose, the low mechanical strength problem of the chitosan film is improved, and the antibacterial property of the chitosan film is improved by silver loading operation. The silver-loaded nano cellulose-chitosan composite film has broad application prospects in antibacterial wound dressings and food packaging and other industries.

Owner:QIQIHAR UNIVERSITY +1

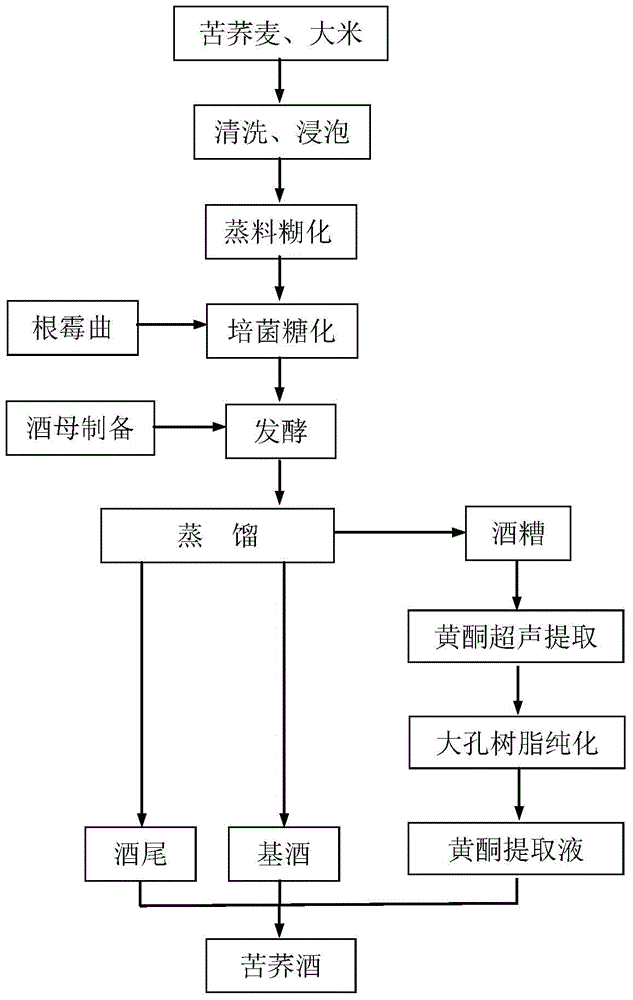

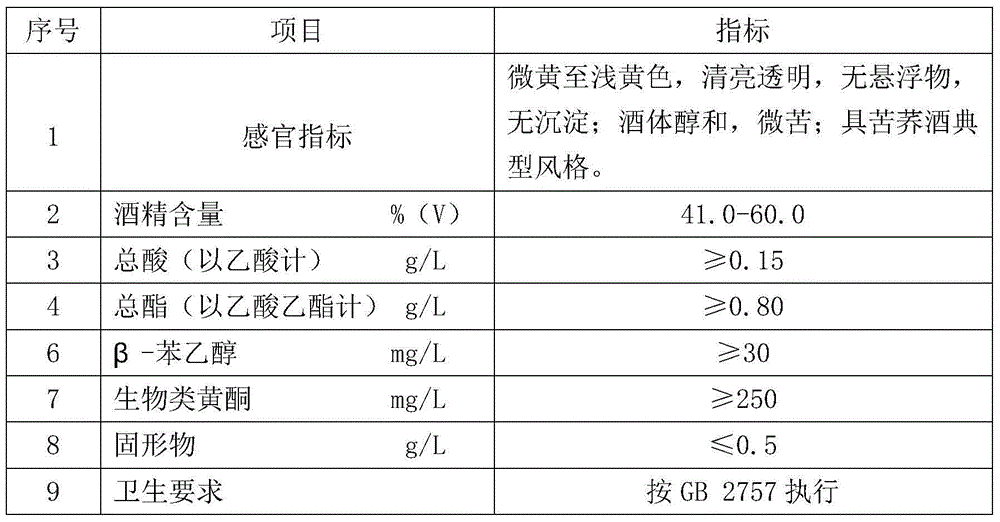

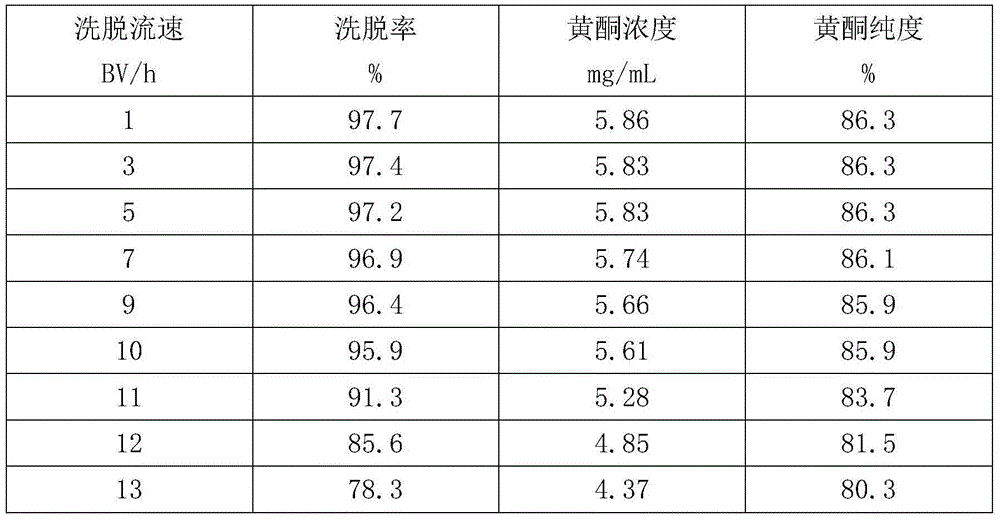

Preparation method for distilled bitter buckwheat wine

InactiveCN104403905AGood health effectIncrease profitAlcoholic beverage preparationPolygonum fagopyrumAlcohol content

The invention relates to distilled bitter buckwheat wine and a preparation method of the distilled bitter buckwheat wine, and belongs to the technical field of wine brewing. The preparation method comprises the following steps: (1) preparing raw materials of bitter buckwheat and rice; (2) washing and soaking; (3) gelatinizing steamed materials; (4) performing culture saccharification; (5) preparing yeasts; (6) fermenting; (7) distilling until the alcohol content of mixed wine liquid is 55-65% (V) to obtain base liquor and end liquor in sequence, separately receiving the base liquor and the end liquor, and after the distilling process is finished, recovering distilled grains; (8) ultrasonically extracting distilled grain flavones to obtain distilled grain crude extract liquid; (9) performing macroporous resin purification on distilled grain flavones to obtain flavone extract liquid; (10) mixing the flavone extract liquid, the base liquor and the end liquor, and checking until the quality standards are met to obtain the distilled bitter buckwheat wine. According to the preparation method, flavone substances remained in the bitter buckwheat distilled grains are fully utilized while unique flavor of the bitter buckwheat wine is retained, and the distilled end liquor is recycled, so that the healthcare effect of the bitter buckwheat wine is improved and the utilization rate of the bitter buckwheat is greatly increased.

Owner:TIANJIN UNIV OF SCI & TECH

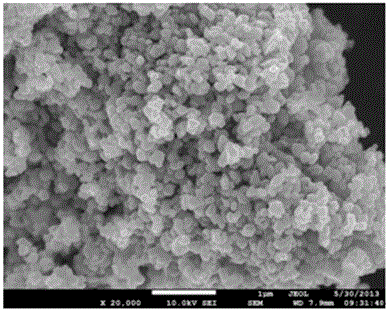

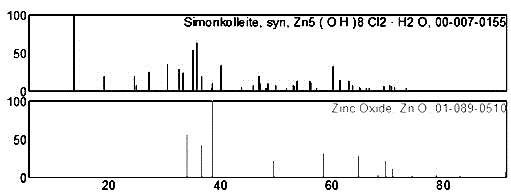

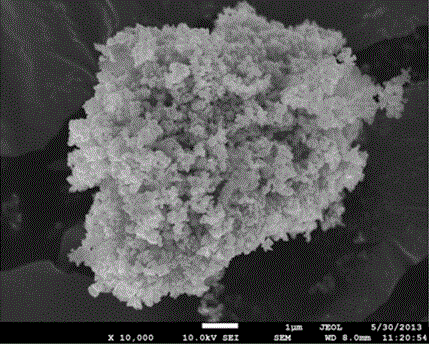

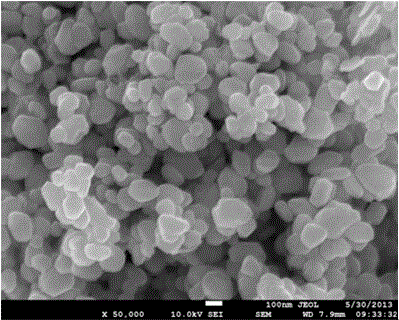

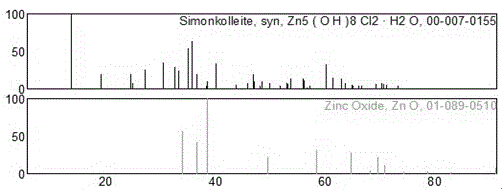

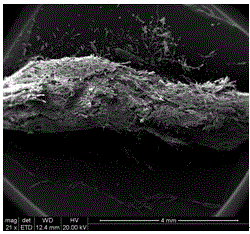

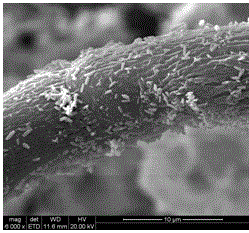

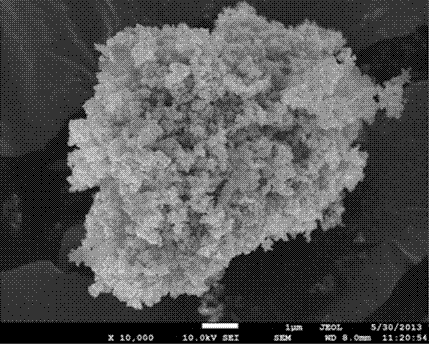

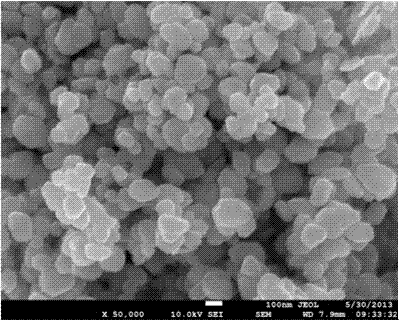

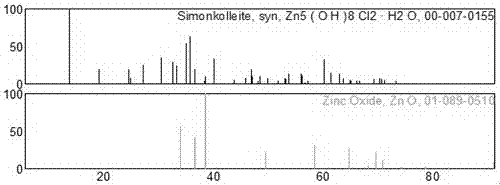

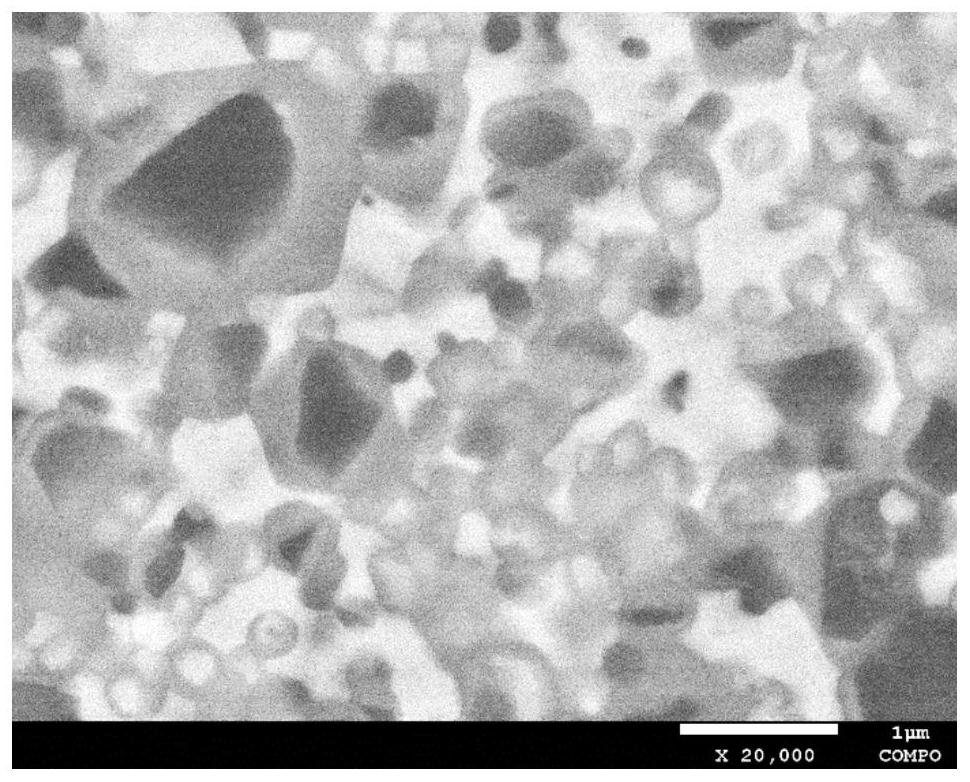

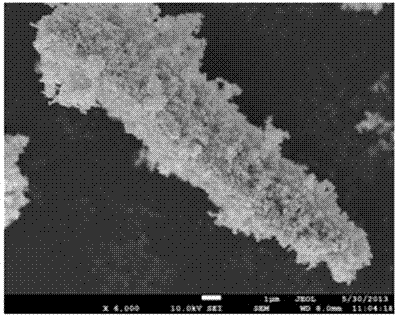

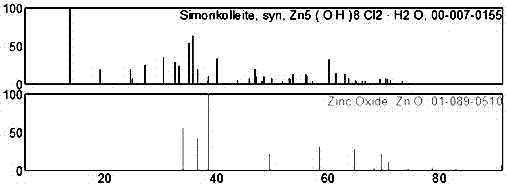

Preparation method for strip-type nano ZnO/cellulose gel material

ActiveCN104941537AThe preparation process is clean and environmentally friendlyPromote generationMaterial nanotechnologyColloidal chemistry detailsSolventIon

The invention discloses a preparation method for a strip-type nano ZnO / cellulose gel material. A ZnCl2 aqueous solution is used as a solvent for cellulose and a zinc source for nano ZnO; dissolving pulp cellulose fibers are cellulose raw materials; the strip-type nano ZnO / cellulose gel material is prepared by dissolving, co-separation, hydrothermal synthesis and freeze drying. As the ZnCl2 aqueous solution is ingeniously used as the solvent for the cellulose and the zinc source for nano ZnO, other cellulosesolvents are not needed to be added, and the preparation technology is clean and environment-friendly; furthermore, after cellulose is dissolved, hydroxyl on the molecules of the cellulose is combined with zinc ions, so that generation of nano ZnO is promoted, and the hydrothermal synthesis temperature is correspondingly obviously reduced; therefore, the preparation technology has the advantage of energy conservation.

Owner:NANJING FORESTRY UNIV

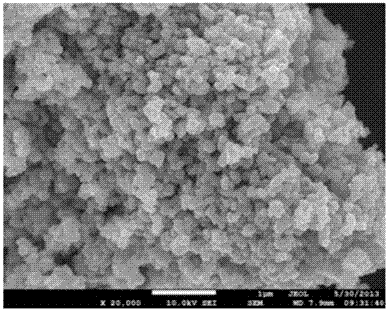

Nano ZnO/cellulose gel particles and preparation method thereof

ActiveCN104941540AThe preparation method hasThe preparation process is clean and environmentally friendlyMicroballoon preparationMicrocapsule preparationFreeze-dryingCellulose fiber

The invention discloses nano ZnO / cellulose gel particles and a preparation method thereof. According to the nano ZnO / cellulose gel particles, cellulose gel is used as a core, and the outer layer is loaded with nano ZnO. According to the preparation method, a ZnCl2 aqueous solution is used as a solvent for cellulose and a zinc source for nano ZnO; dissolving pulp cellulose fibers are cellulose raw materials; the nano ZnO / cellulose gel particles are prepared by dissolving, co-separation, hydrothermal synthesis and freeze drying. As the ZnCl2 aqueous solution is ingeniously used as the solvent for the cellulose and the zinc source for nano ZnO, other cellulosesolvents are not needed to be added, and the preparation technology is clean and environment-friendly; furthermore, after cellulose is dissolved, hydroxyl on the molecules of the cellulose is combined with zinc ions, so that generation of nano ZnO is greatly promoted, and the hydrothermal synthesis temperature is correspondingly obviously reduced; therefore, the preparation technology has the advantage of energy conservation.

Owner:NANJING FORESTRY UNIV

A kind of nano-micro ZnO/composite cellulose strip material and preparation method thereof

ActiveCN104941683BThe preparation process is clean and environmentally friendlyPromote generationMaterial nanotechnologyOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceFreeze-drying

The invention discloses a method for preparing nano-micro ZnO / composite cellulose strip materials. ZnCl2 aqueous solution is used as the swelling agent and solvent of cellulose and the zinc source of nano-ZnO, and the cellulose fiber of the dissolved pulp is used as the cellulose raw material. Swelling and partial dissolution, injection co-precipitation, hydrothermal synthesis and freeze-drying prepared nano-micro ZnO / cellulose strips supported by raw cellulose fibers and regenerated cellulose fibers. Since the present invention uses the ZnCl2 aqueous solution as the swelling agent and solvent of the cellulose and the zinc source of the nano-ZnO, there is no need to add other cellulose solvents, and the preparation process is clean and environment-friendly. In addition, after the cellulose is swelled and partially dissolved, the hydroxyl groups on its molecules combine with zinc ions, which promotes the formation of nano-ZnO, and the hydrothermal synthesis temperature is also significantly reduced accordingly. Therefore, the preparation process has the advantage of energy saving.

Owner:NANJING FORESTRY UNIV

A kind of nano-zno/cellulose gel particle and preparation method thereof

ActiveCN104941540BThe preparation method hasThe preparation process is clean and environmentally friendlyMicroballoon preparationMicrocapsule preparationFreeze-dryingCellulose fiber

The invention discloses a nanometer ZnO / cellulose gel particle and a preparation method thereof. The nanometer ZnO / cellulose gel particle uses cellulose gel as a core, and the outer layer is loaded with nanometer ZnO. In the preparation method, ZnCl2 aqueous solution is used as the solvent of cellulose and the zinc source of nano-ZnO, and the pulp cellulose fiber is used as the cellulose raw material, and the nano-ZnO / cellulose gel is prepared by dissolution, co-precipitation, hydrothermal synthesis and freeze-drying particles. Since the present invention skillfully uses the ZnCl2 aqueous solution as the solvent of the cellulose and the zinc source of the nano-ZnO, there is no need to add other cellulose solvents, and the preparation process is clean and environment-friendly. In addition, after the cellulose is dissolved, the hydroxyl groups on its molecules combine with zinc ions, which effectively promotes the formation of nano-ZnO, and the hydrothermal synthesis temperature is correspondingly significantly reduced. Therefore, the preparation process has the advantage of energy saving.

Owner:NANJING FORESTRY UNIV

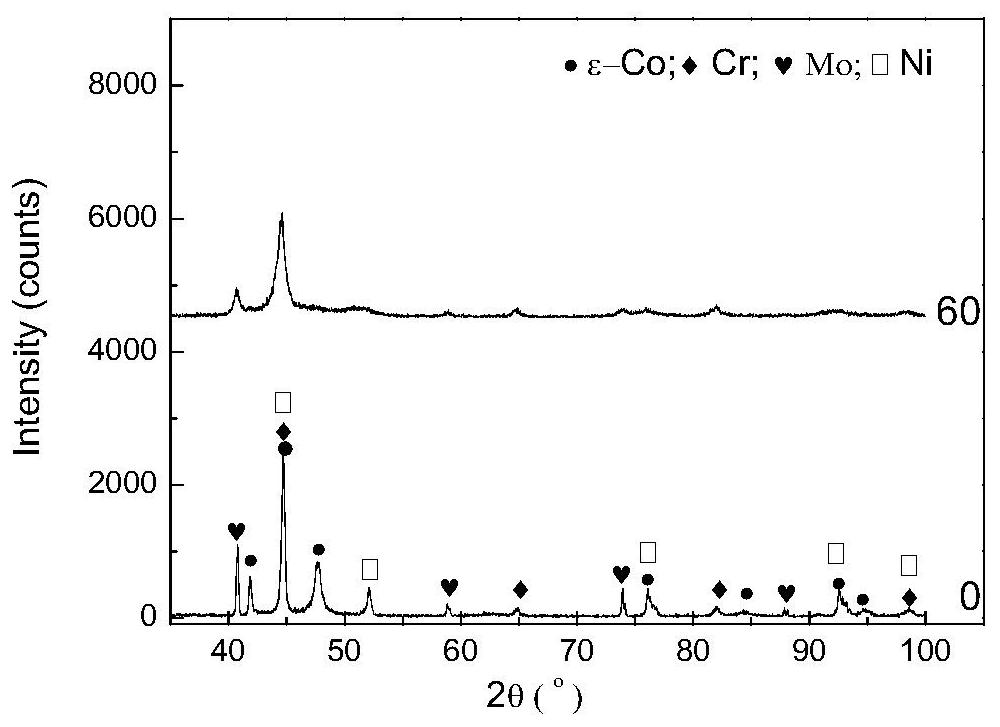

Method for preparing TiC-based metal ceramic with high-entropy alloy binding phase

The invention relates to the field of powder metallurgy and multi-principal-element high-entropy alloy materials, in particular to a method for preparing a metal ceramic composite material with a high-entropy alloy binding phase. The TiC-based metal ceramic material with the high-entropy alloy binding phase prepared by the method is characterized in that the binding phase is high-entropy alloy NiCoCrMoWTi, the molar fraction of Ni is 30.0%-35%, the molar fraction of Co is 10.0%-35%, the molar fraction of Cr is 5.0%-20.0%, the molar fraction of Mo is 5.0%-20.0%, the molar fraction of W is 5.0%-15%, the molar fraction of Ti is 5.0%-35%, and the sum of the molar fractions of all the components is 100%. The prepared TiC-based metal ceramic with the high-entropy alloy binding phase prepared by the method has higher strength, hardness, wear resistance and oxidation resistance, in-situ precipitation of a TiC ceramic phase is achieved in the preparation process, and therefore the grain size of a sintered body is refined, and an interface between the binding phase and a hard phase of the sintered body have a coherency relationship.

Owner:CHINA THREE GORGES UNIV

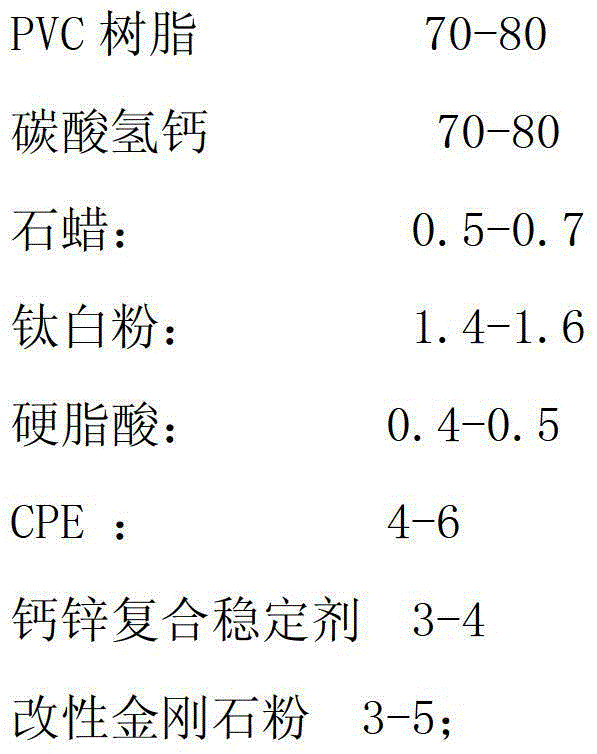

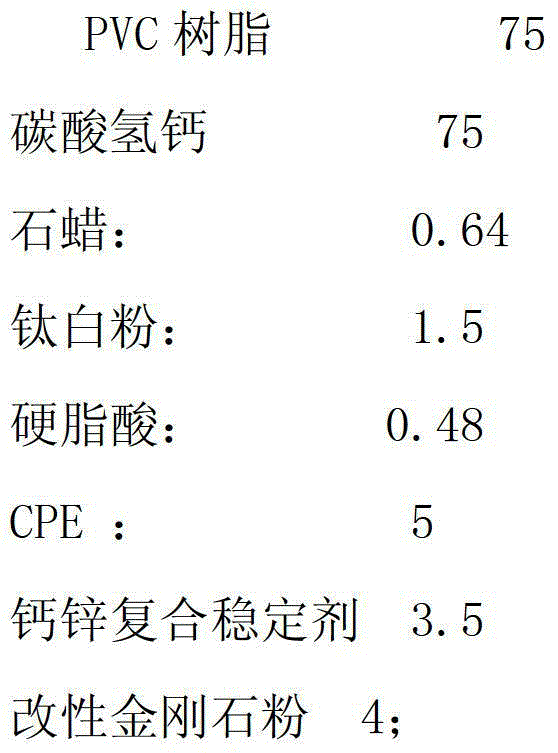

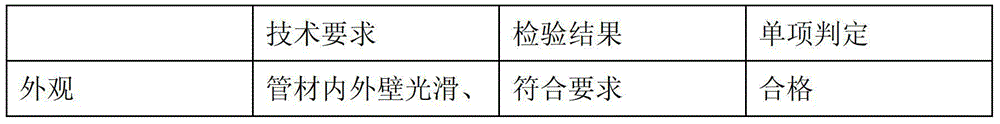

Preparation method for energy-saving polyvinyl chloride tubular product

The invention discloses a preparation method for an energy-saving polyvinyl chloride tubular product. The preparation method comprises the steps of pouring all raw materials except for titanium dioxide and CPE into a stirring kettle, mixing the raw materials at the rotating speed of 55-70r / m for 1 hour, then putting the raw materials into a double-screw extruder, kneading the raw materials under the temperature of 140-150 DEG C for 8-10 minutes, adding the rest of the raw materials according to the weight parts, performing mixing and granulation, controlling the temperature at 150-160 DEG C, and performing a forming technology to obtain a finished product. The tubular product prepared by the preparation method disclosed by the invention is stable in quality and high in strength and has a smooth surface. The preparation technology is energy-saving, economical and environment-friendly.

Owner:安徽玉发塑业有限公司

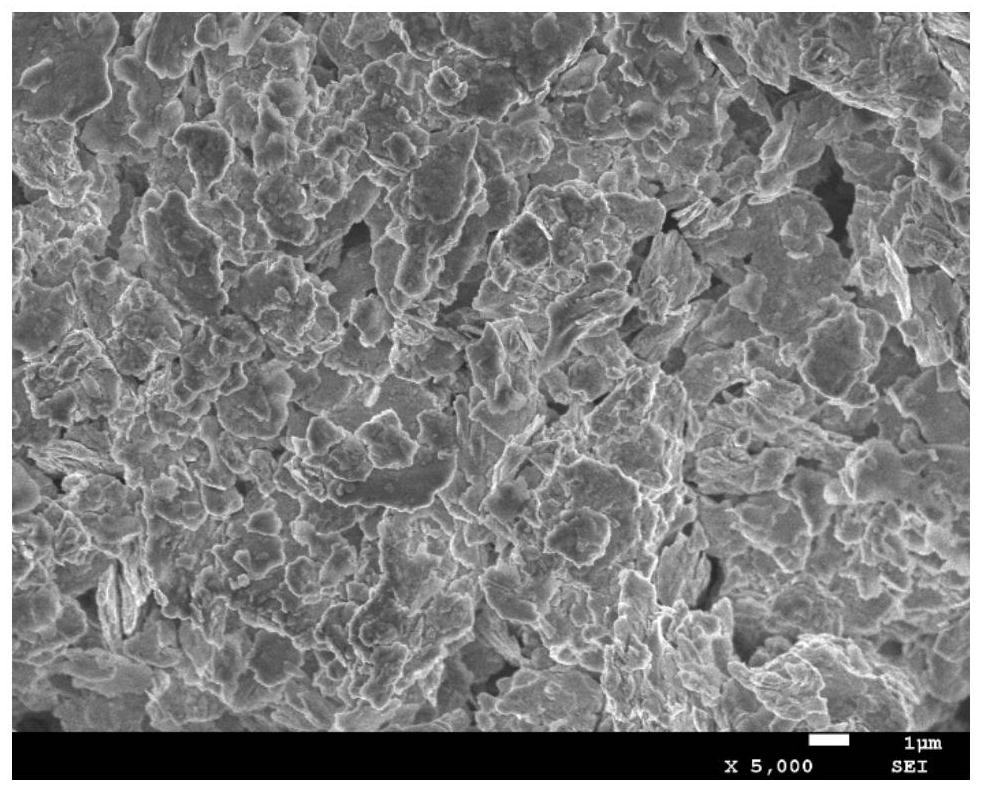

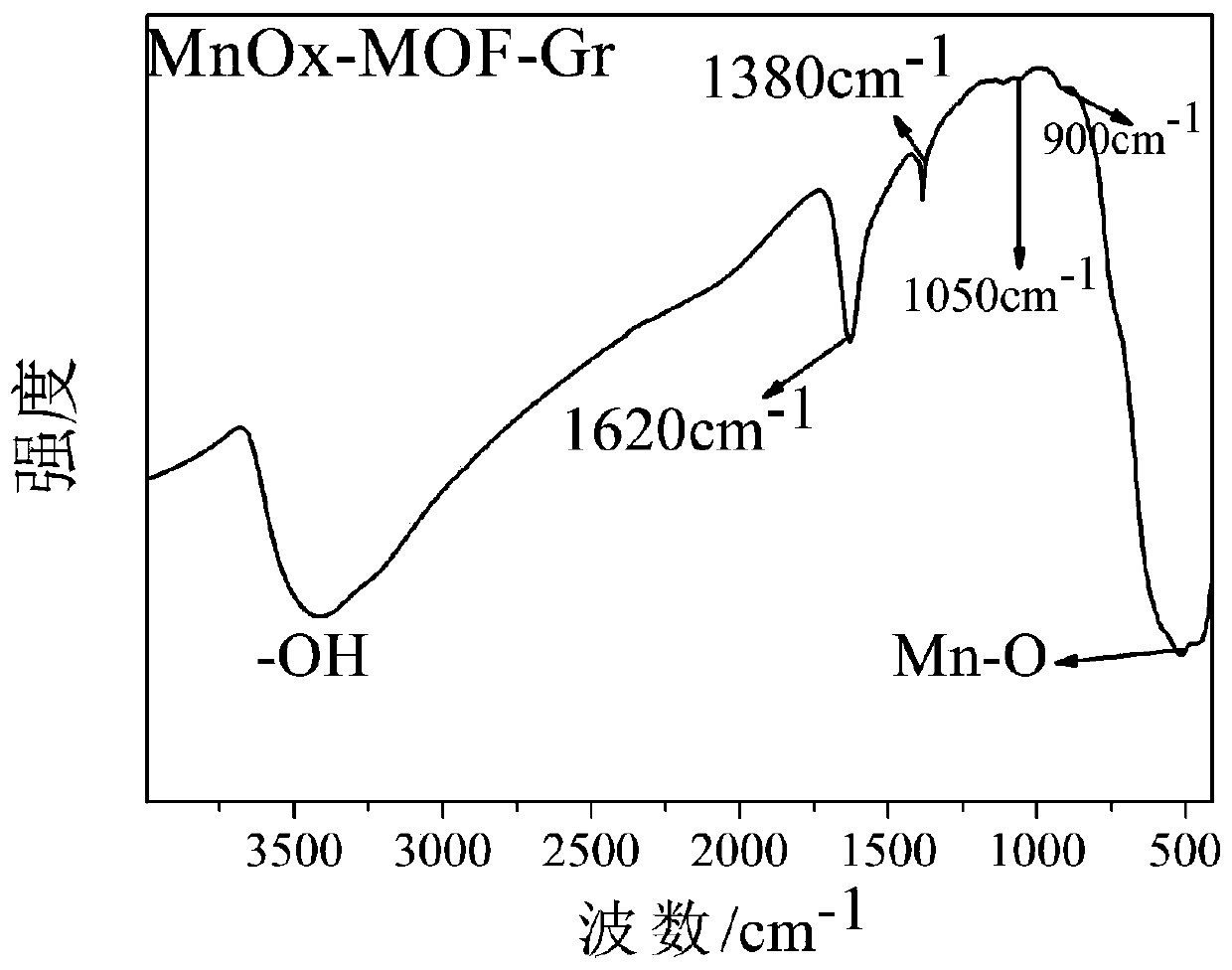

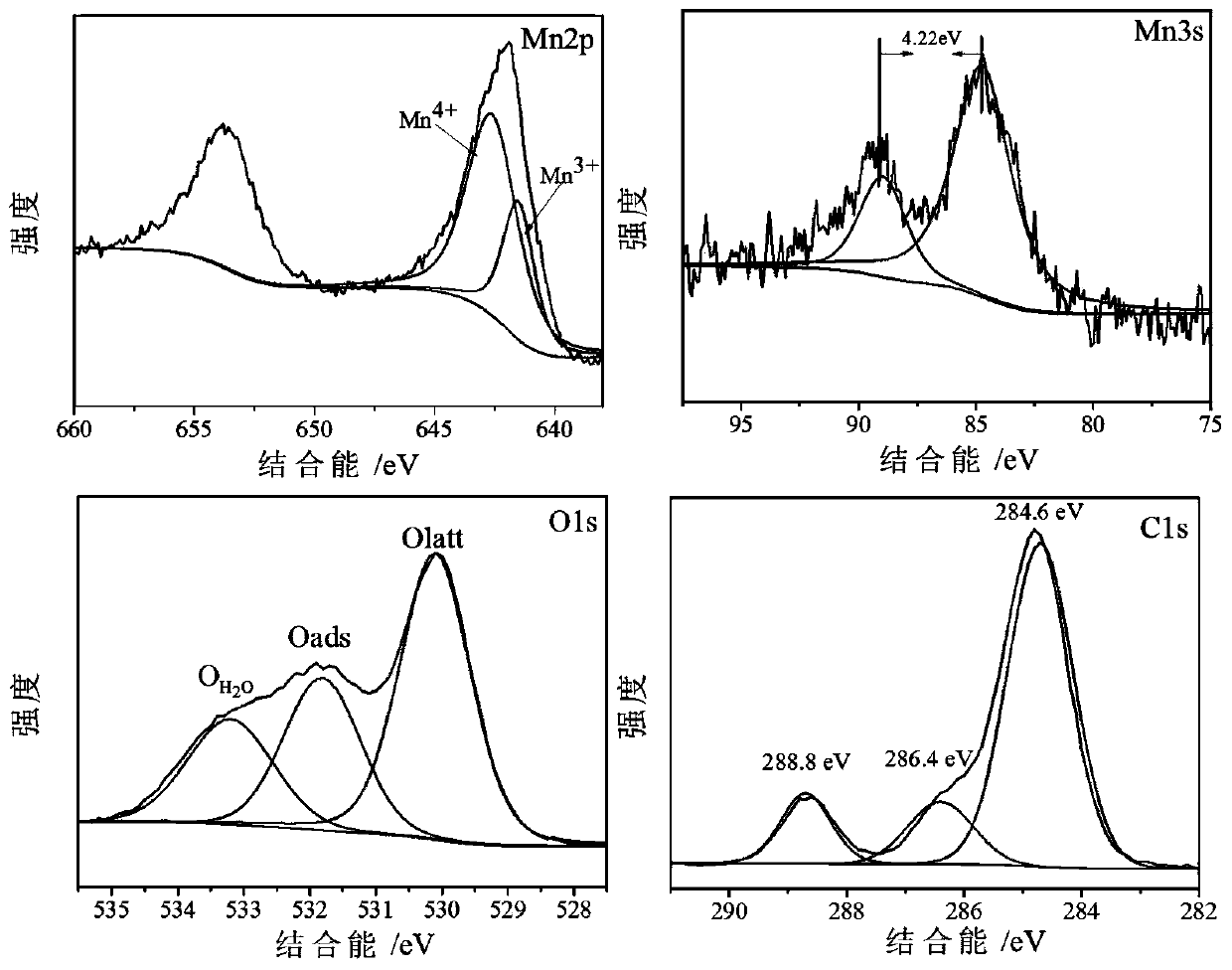

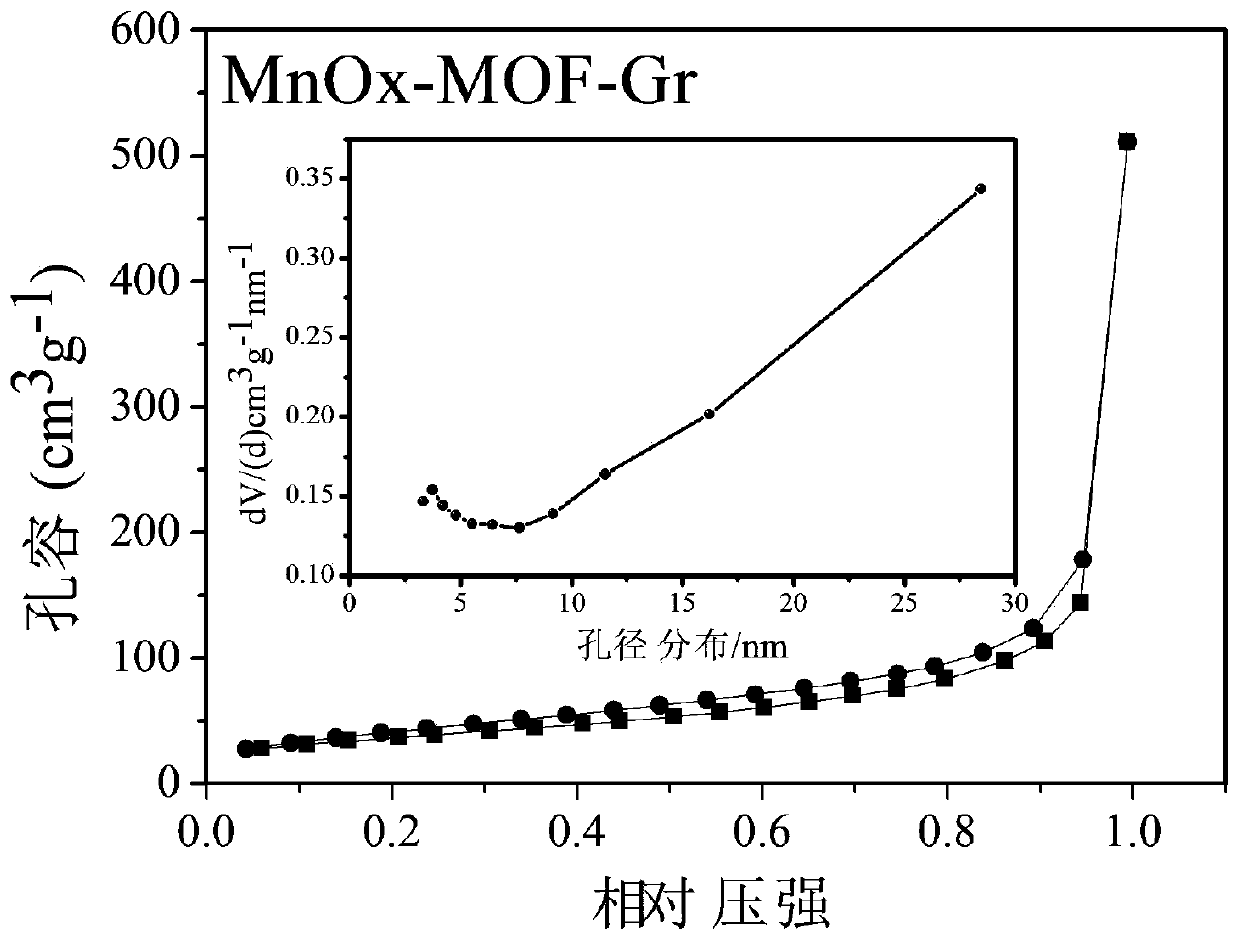

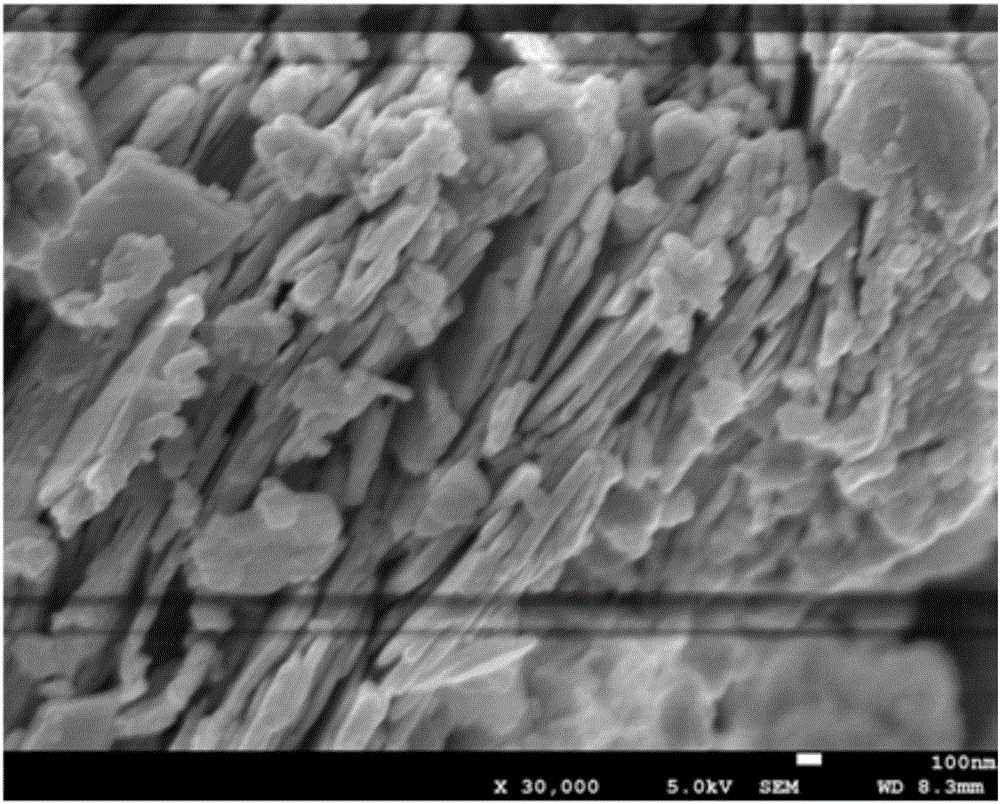

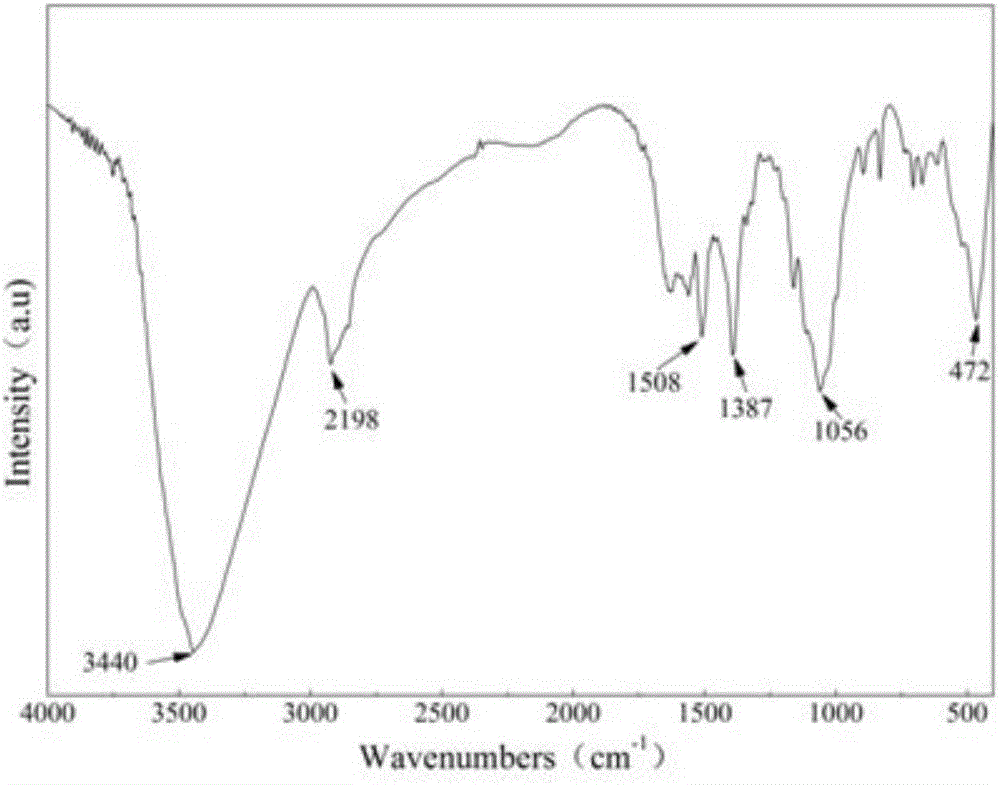

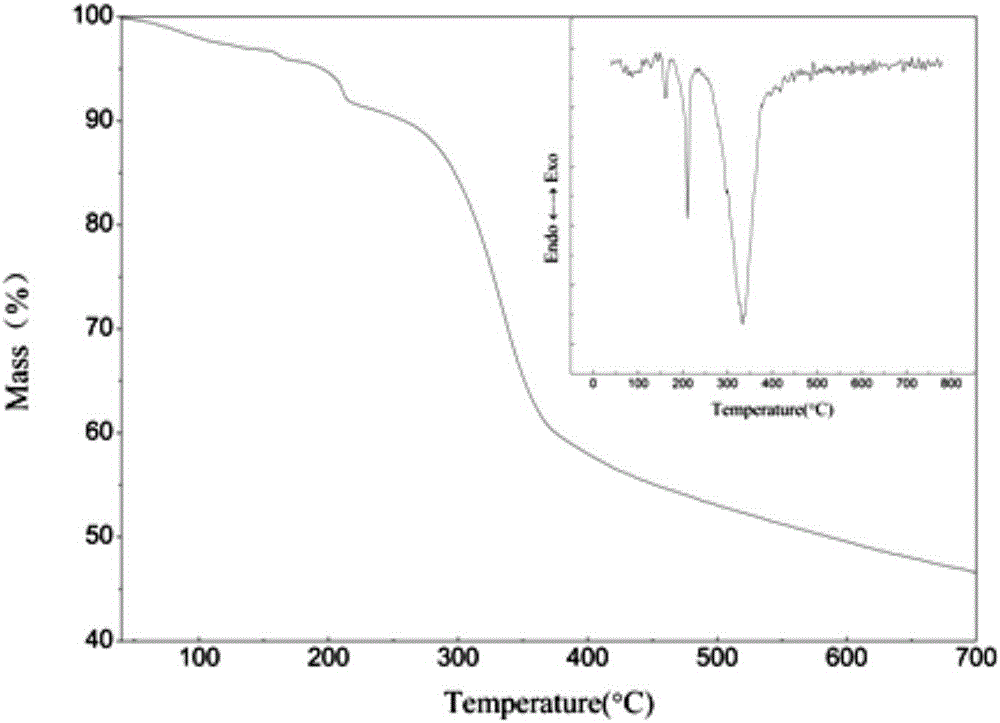

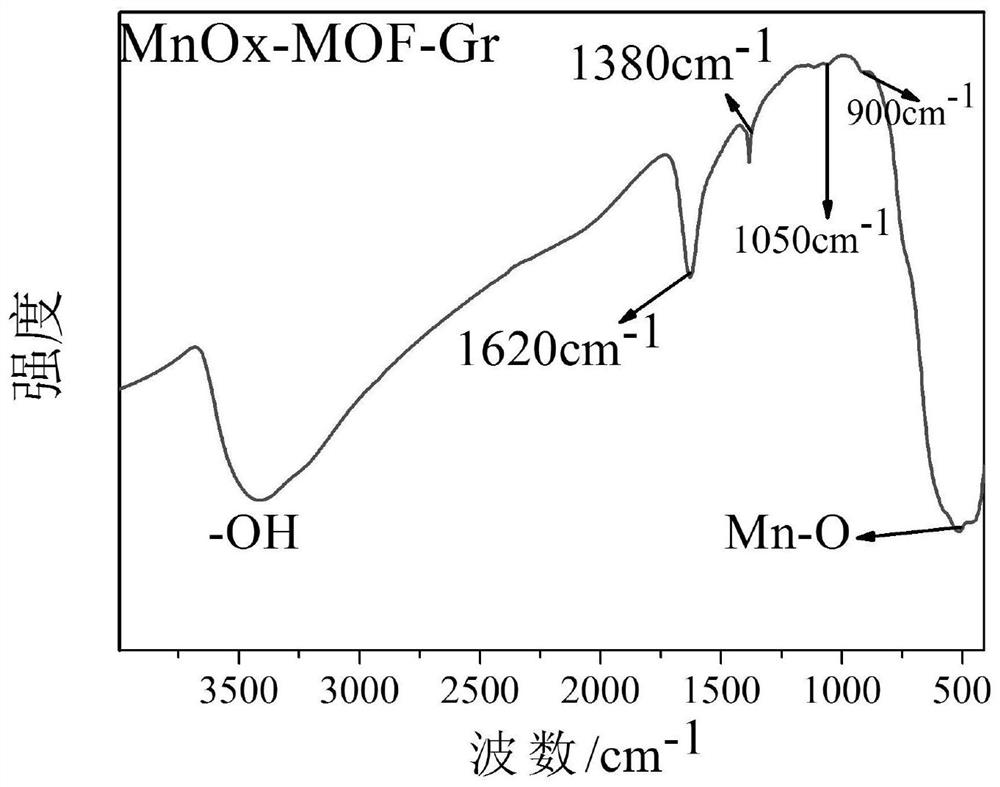

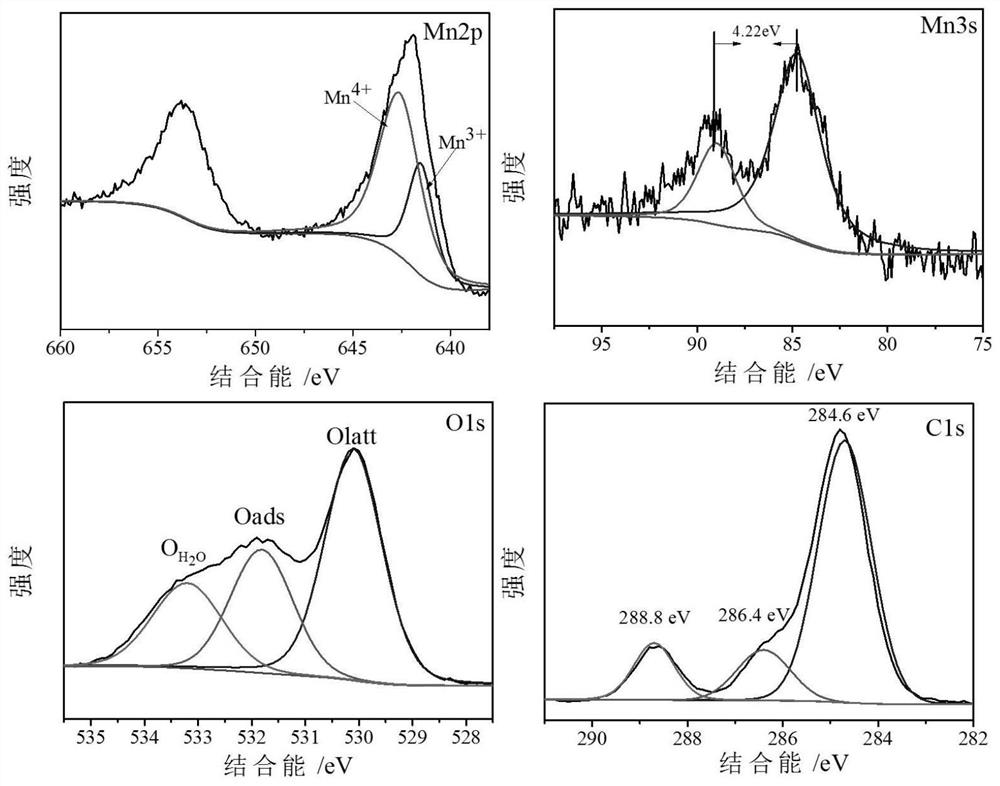

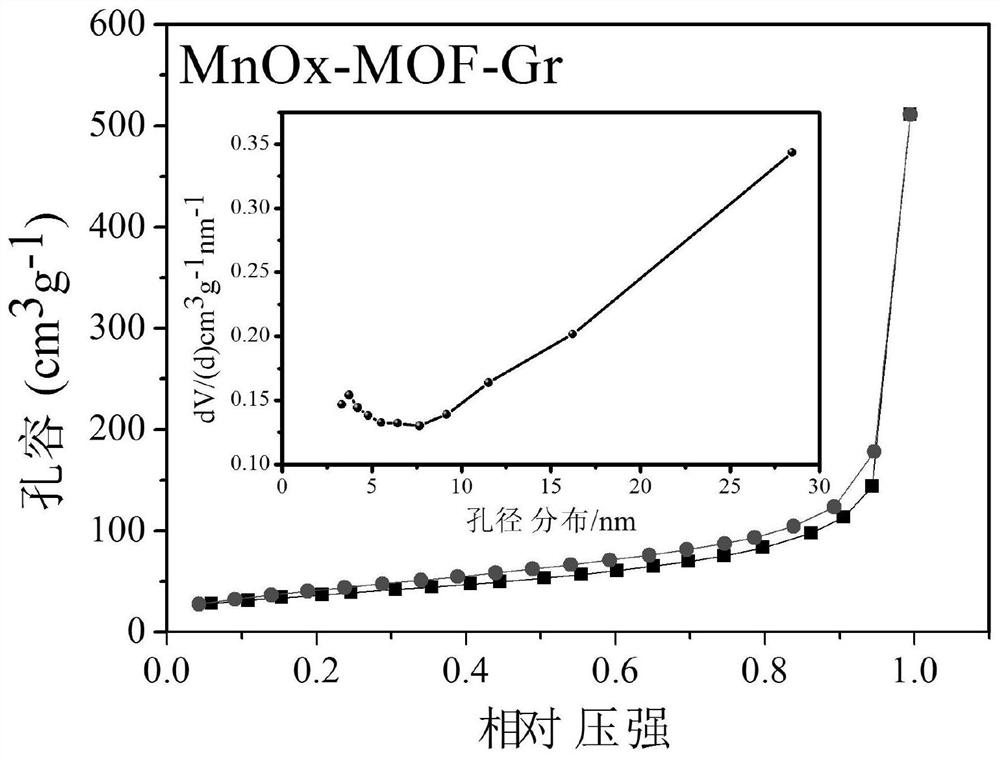

MnOx-MOF-Gr composite material and preparation method and application thereof

ActiveCN110270379ASolve the problem of poor formaldehyde removal effectLow costOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationN dimethylformamideOxygen

The invention discloses a MnOx-MOF-Gr composite material and a preparation method and application thereof. The method comprises the steps that 1, manganese chloride and para toluic acid are dissolved in a mixed solution of water and N,N-dimethylformamide, a hydrothermal reaction is conducted at 100-160 DEG C, and after the reaction is completed, treatment is conducted to obtain a Mn-MOFs crystal material; 2, the Mn-MOFs crystal material is added to a graphene dispersion solution, and dispersion is even; 3, the mixed solution obtained in step 2 and an oxidant aqueous solution are mixed at 20-60 DEG C and react to obtain the MnOx-MOF-Gr composite material. The prepared composite material has a high specific surface area, contains rich surface adsorbed oxygen species and can quickly and effectively degrade low-concentration formaldehyde at the room temperature, the preparation technology is simple and saves energy, any precious metal does not need to be added, the material cost is low, and large-scale production can be achieved.

Owner:SICHUAN UNIV

Hydrothermal preparation method of nano-ZnO cellulose composite material on basis of NaOH-urea solution and application

ActiveCN106279763APromote generationImprove removal efficiencyWater/sewage treatment by irradiationWater treatment compoundsCelluloseWastewater

The invention discloses a hydrothermal preparation method of a nano-ZnO cellulose composite material on the basis of a NaOH-urea solution and application. The method comprises the step that in the NaOH-urea cellulose solution, the nano-ZnO cellulose composite material is prepared through in-situ compounding by adopting the hydrothermal method. According to the hydrothermal preparation method of the nano-ZnO cellulose composite material on the basis of the NaOH-urea solution, after cellulose is dissolved, hydroxyl groups on molecules of the cellulose are combined with zinc ions, and the defect that a zinc source does not easily penetrate into a carrier is overcome; in addition, the adopted NaOH-urea solvent is cheap and easy to obtain, and the hydrothermal synthesis temperature is obviously reduced. The nano-ZnO cellulose composite material contains 47.5% of ZnO and has the high removal efficiency on phenol in photodegradation wastewater. The ZnO cellulose composite material prepared through the method is cheap and environmentally friendly and has the very good practicability on phenolic wastewater treatment by serving as a photodegradation catalyst.

Owner:NANJING FORESTRY UNIV

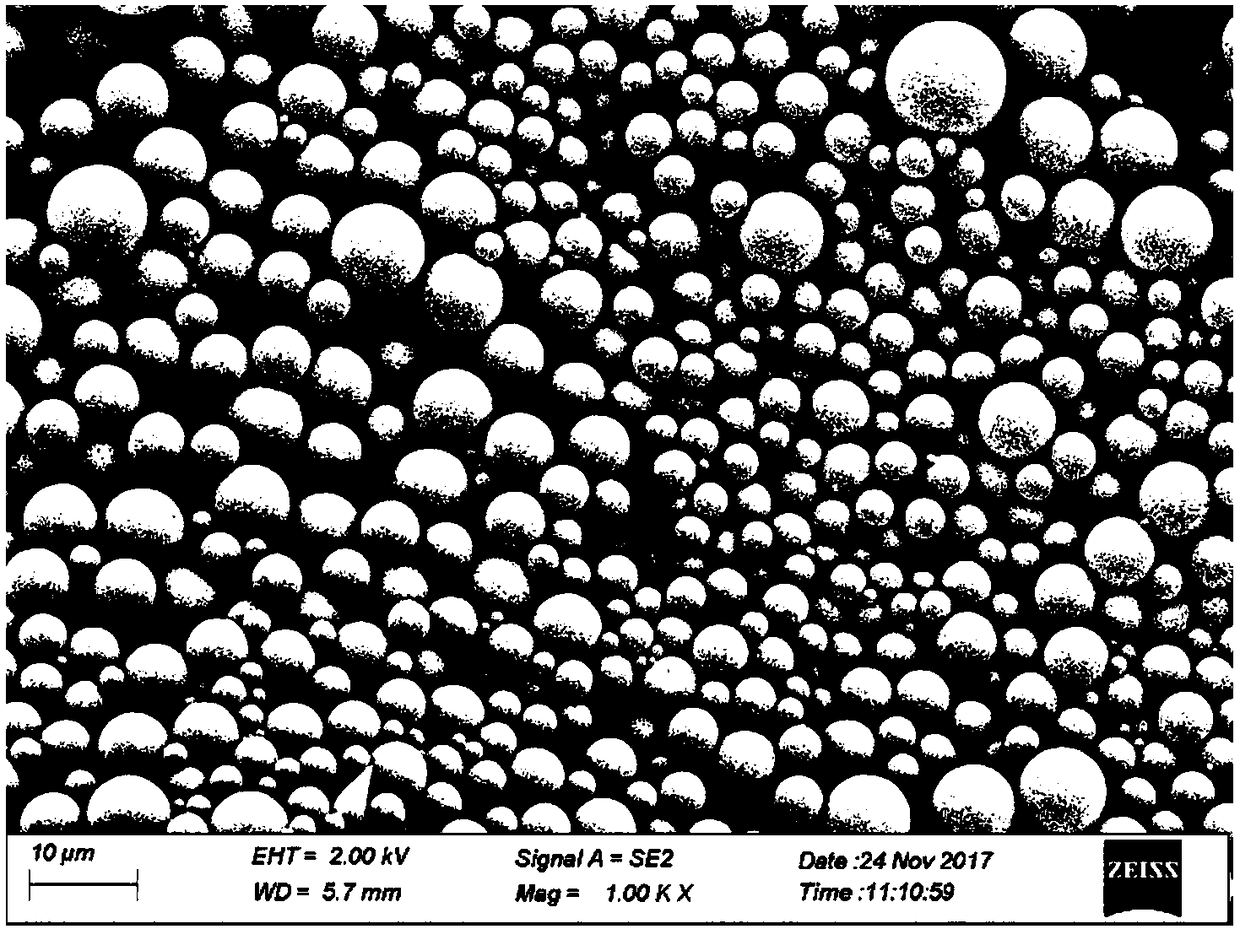

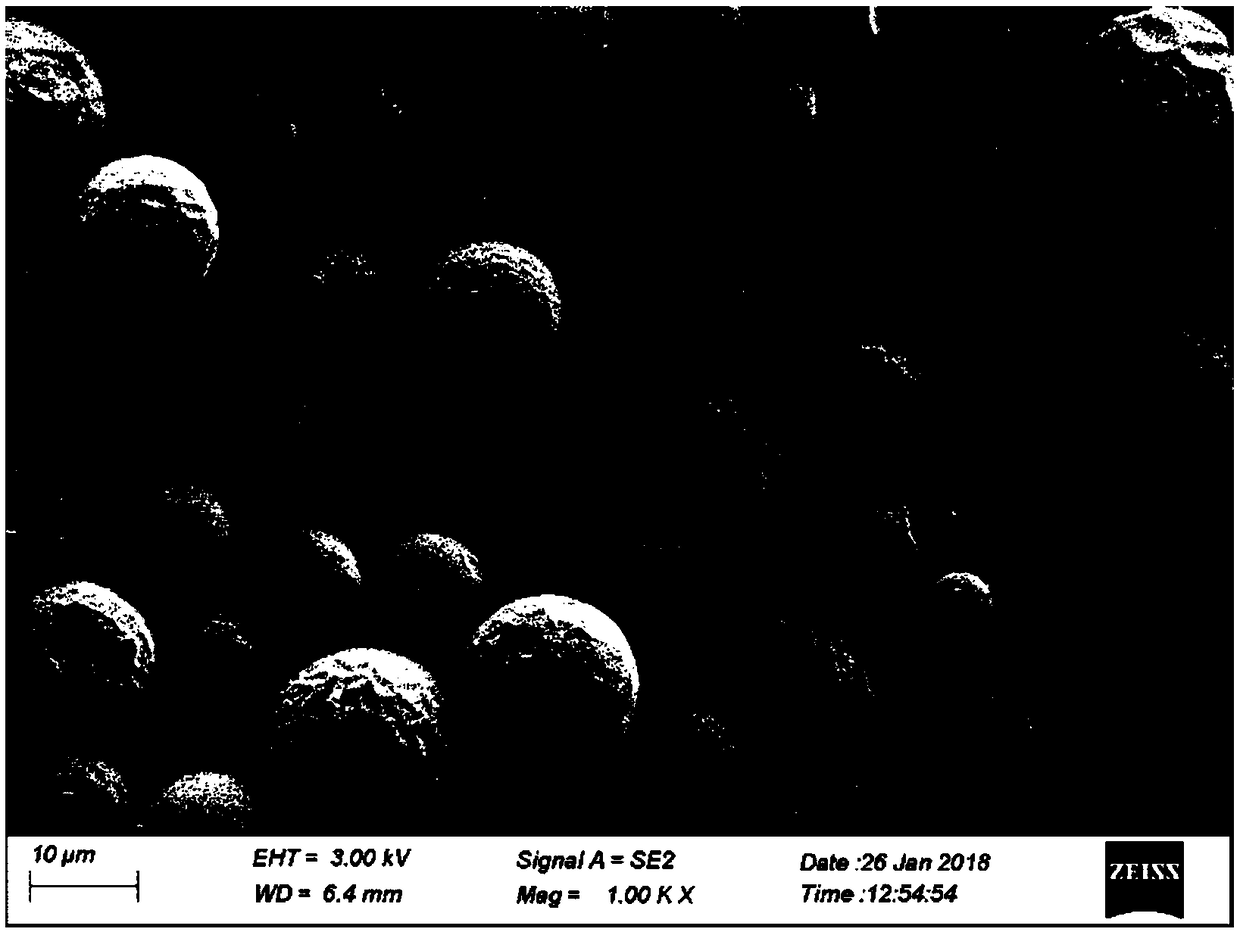

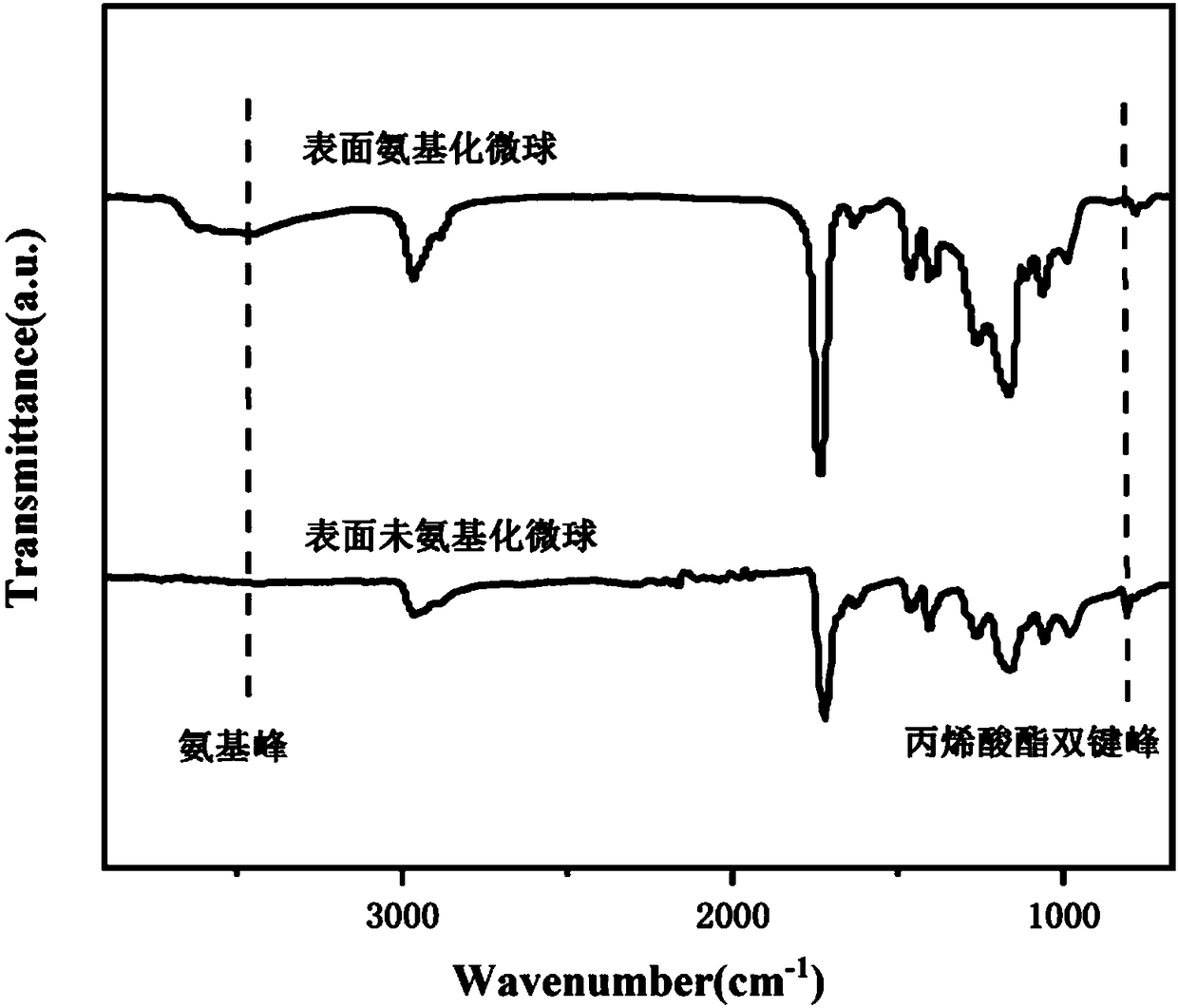

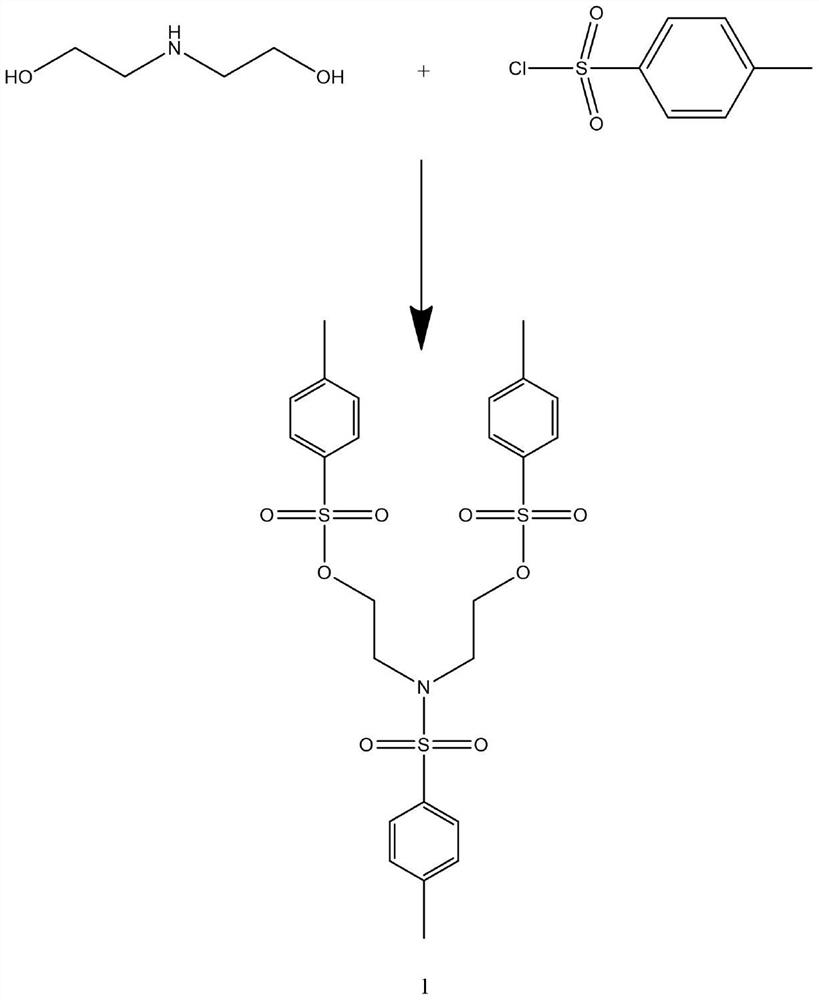

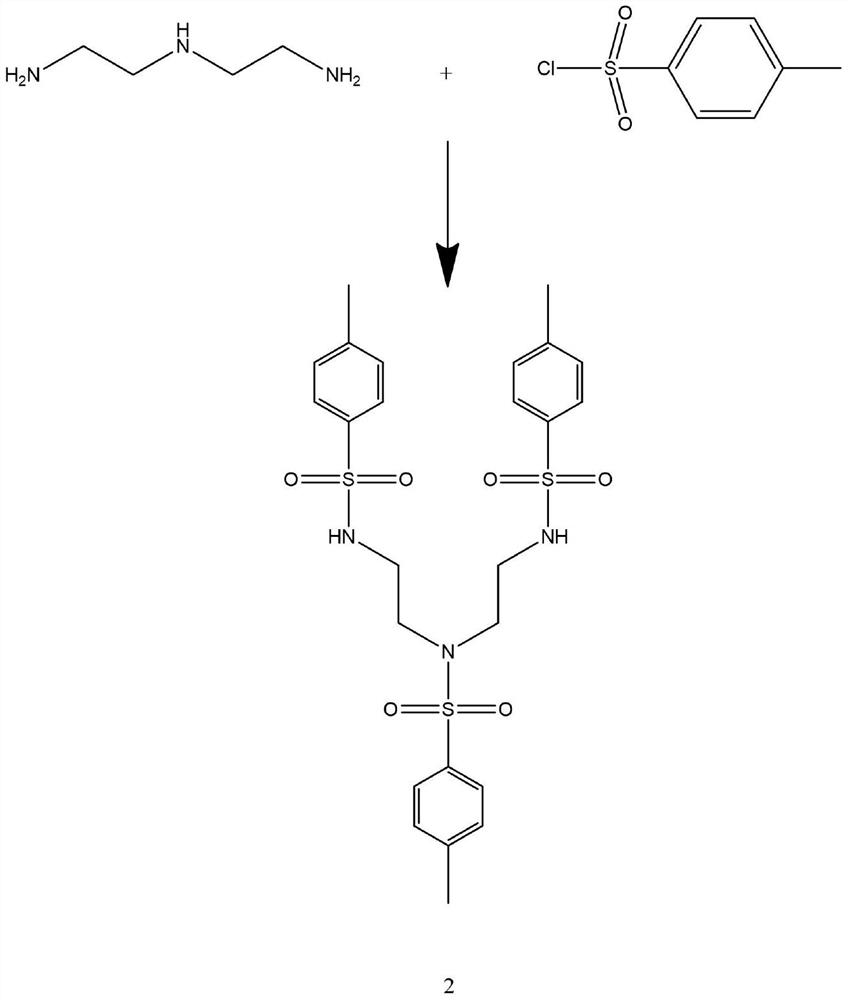

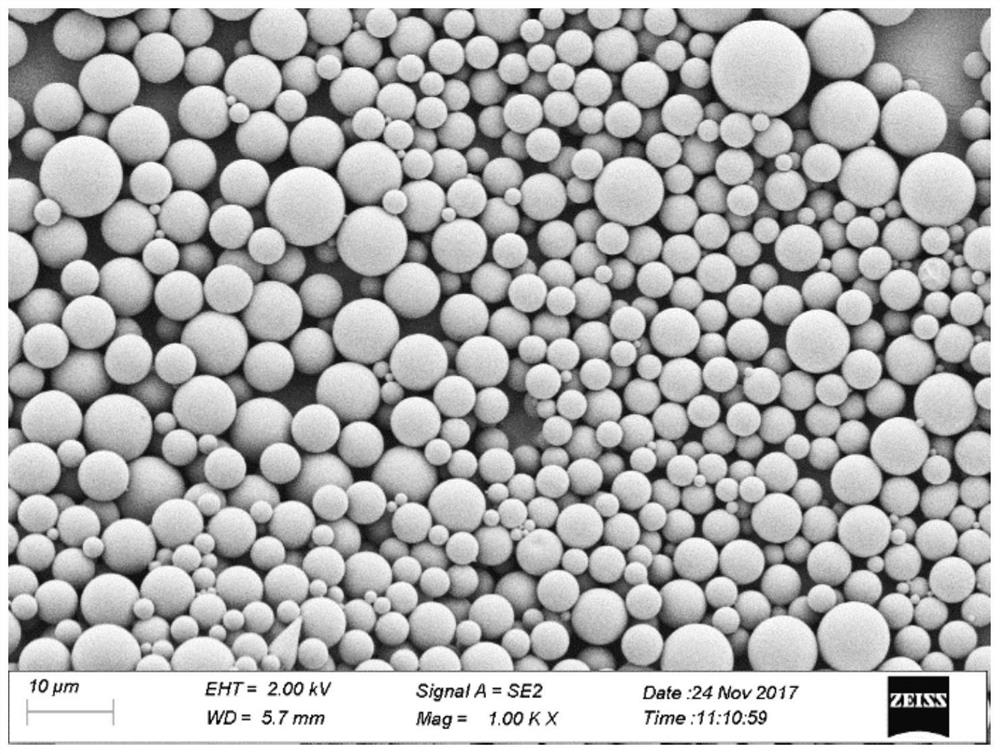

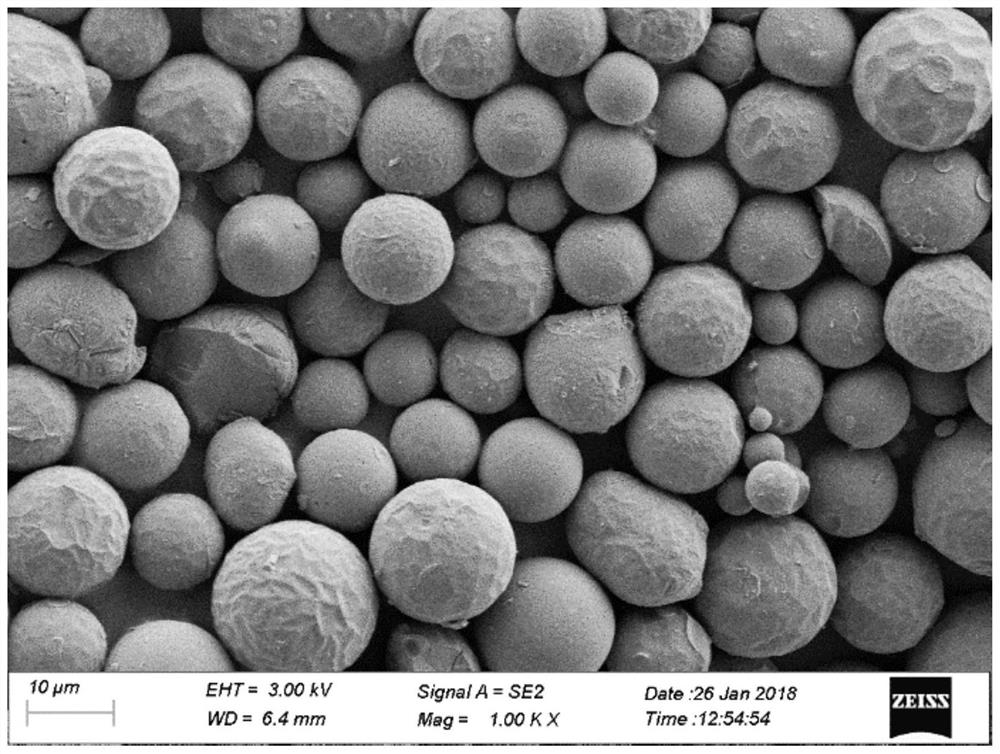

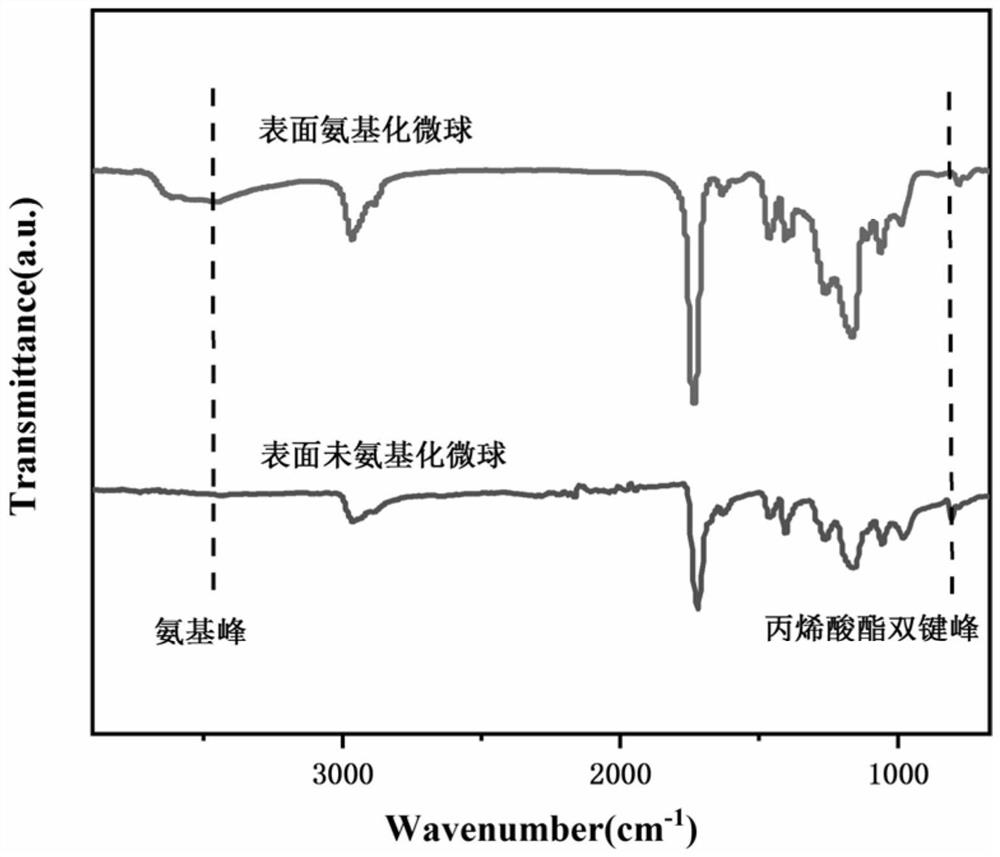

Preparation method of functionalized polymer microspheres

ActiveCN108341966AEnergy saving in preparation processHigh product purityWater contaminantsWater/sewage treatment by sorptionSolventPhotoinitiator

The invention relates to a preparation method of functionalized polymer microspheres, belonging to the technical field of preparation of functional polymers. According to the preparation method, an oil-soluble polyfunctionality acrylate monomer, polyethyleneimine and a photoinitiator are used as raw materials, wherein the weight ratio of the polyfunctionality acrylate monomer to the photoinitiatorto the polyethyleneimine to a water solvent is equal to 100 to (1-5) to (5-20) to (500-2000). After the system is uniformly mixed, emulsification is firstly carried out under the action of a high-speed disperser, and ultraviolet light irradiation is performed after the emulsification is finished, so that polymer microspheres of polyfunctionality acrylate are obtained; after that, the polymer microspheres and polyethyleneimine are subjected to a Michael addition reaction, so that the functional polymer microspheres having surfaces modified by active primary amino groups and secondary amino groups. The functional macromolecular microspheres, which are prepared by the method and have aminated surfaces, are low in reaction energy consumption, and the reaction rate and the reaction yield can be adjusted by means of time. The particle sizes of the polymer microspheres can be adjusted within a range of 2-100mu m. The polyethyleneimine not only serves as a stabilizer in a formation process ofthe microspheres, but also can be used as a modifier in a microsphere modification process.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of solid honey and chrysanthemum particle

The invention specifically relates to a preparation method of a solid honey and chrysanthemum particle. The preparation method comprises the following steps: adding dry chrysanthemum and water into a distillation still, boiling the chrysanthemum and water so as to obtain chrysanthemum extract; adding honey and erythritol into the chrysanthemum extract, then adding seed crystals into the chrysanthemum extract to grow crystals, and finally cooling to crystallize so as to obtain the solid honey and chrysanthemum particle. The solid honey and chrysanthemum particle product prepared by the method mentioned above has the advantages of good dispersibility, uniformity, instant capacity, and fluidity, is convenient to bring with, use and drink, furthermore, and does not contain any cane sugar, so that modern people who are afraid of chronic metabolism diseases caused by intakes of too much cane sugar, such as sub-health, obesity, cardiovascular and cerebrovascular diseases, and the like, can safely enjoy the product. The preparation method does not contain a drying process; besides, the operation temperature of the preparation method is 100 DEG C lower than that of an erythritol melting and co-crystallizing technology, so that the preparation technology is simpler, more economic, and more energy-saving.

Owner:WUHAN UNIV OF SCI & TECH

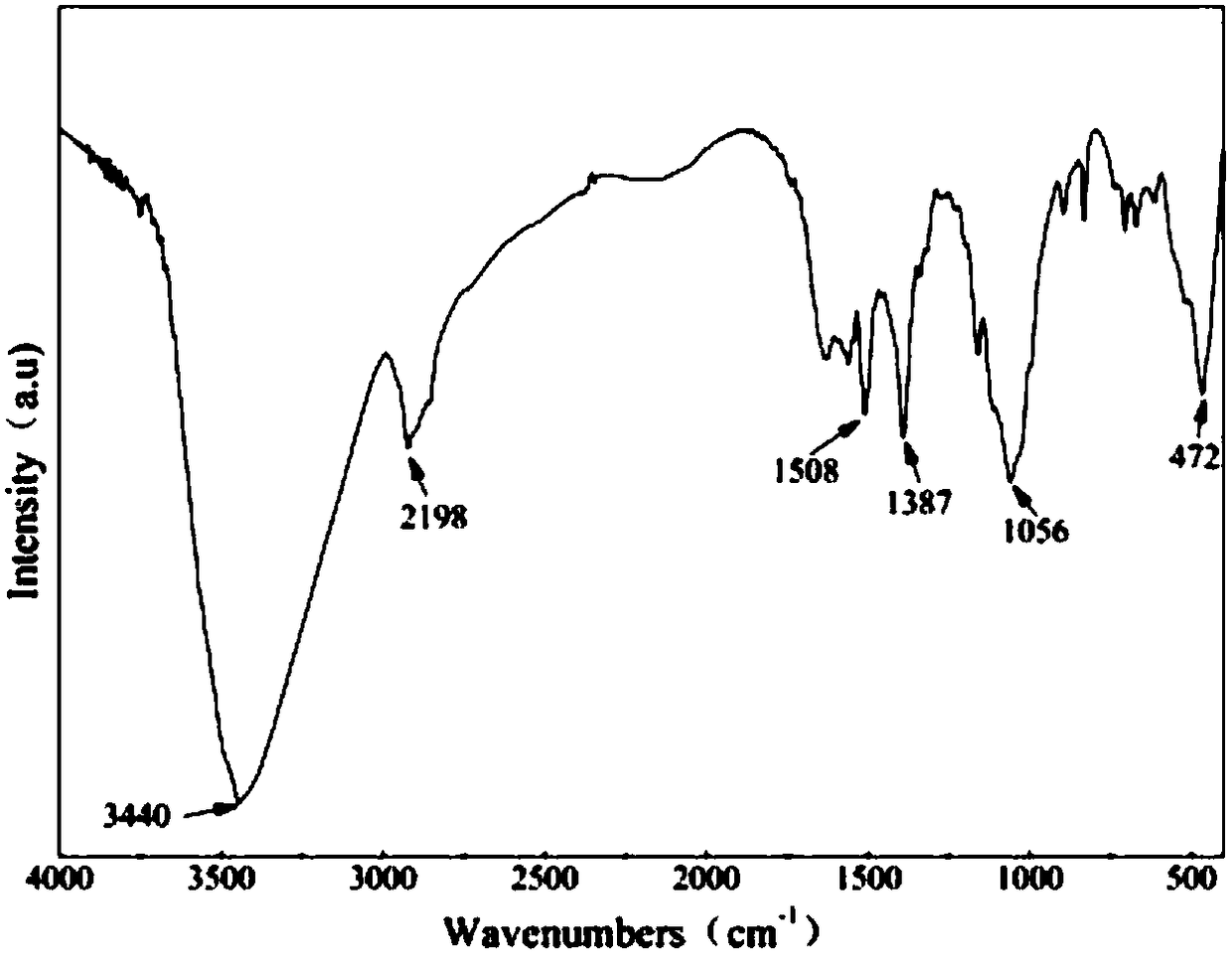

Preparation method for thiamine modified bentonite

The invention relates to preparation methods of bentonite, in particular to a preparation method for thiamine modified bentonite. The method includes: preparing original soil into soil suspension of 5%, stirring for 20min, standing for 5min, using the siphon method to take upper serous liquid, standing for 1 day, taking the upper serous liquid for centrifugation, drying bottom pasty soil, grinding, and going through a sieve of 0.074mm for standby; preparing modifier solution, namely, using hydrochloric acid of 0.1mol / L and analytically pure thiamine to prepare thiamine solution with a mass concentration of 3.5g / L; and finally preparing the thiamine modified bentonite, namely, taking 100mL of the thiamine solution with the mass concentration of 3.5g / L to be uniformly mixed with refined soil, stirring for 60min, leaching, washing, freeze-drying at 0 DEG C, grinding, and going through the 0.074mm sieve to obtain the thiamine modified bentonite. The prepared modified bentonite has no toxic effect on human, animals and plants, and the modified bentonite after use can be recycled as feed and fertilizer, so that secondary pollution is avoided.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Lead oxide preparation process based on waste lead-acid storage battery lead plaster

ActiveCN113621812AAvoid emissionsEfficient preparation processLead monoxideWaste accumulators reclaimingLead dioxidePhysical chemistry

The invention discloses a lead oxide preparation process based on waste lead-acid storage battery lead plaster, and relates to the technical field of waste storage battery treatment. The waste lead-acid storage battery lead plaster and alkali liquor are fed into a ball mill for ball milling to obtain pre-desulfurized paste, lead sulfate is formed to generate lead oxide, the pre-desulfurized paste, hydrogen peroxide, a lead catching agent and water are stirred to react, the hydrogen peroxide enables lead and lead dioxide to react to generate lead oxide, then the newly generated active lead oxide and the lead catching agent generate a complexation dissolution reaction to obtain lead complex ions, a mixed solution is obtained, finally a precipitating agent is introduced into the mixed solution, roasting is carried out a precipitation product, and lead oxide is obtained; and the lead oxide preparation process is low in energy consumption, reduces secondary pollution caused by lead dust and sulfur dioxide, is short in process flow, high in recovery rate and high in recovery purity, and is an efficient, environment-friendly and energy-saving lead oxide preparation process, and the lead catching agent and a precipitating agent are recycled.

Owner:太和县大华能源科技有限公司

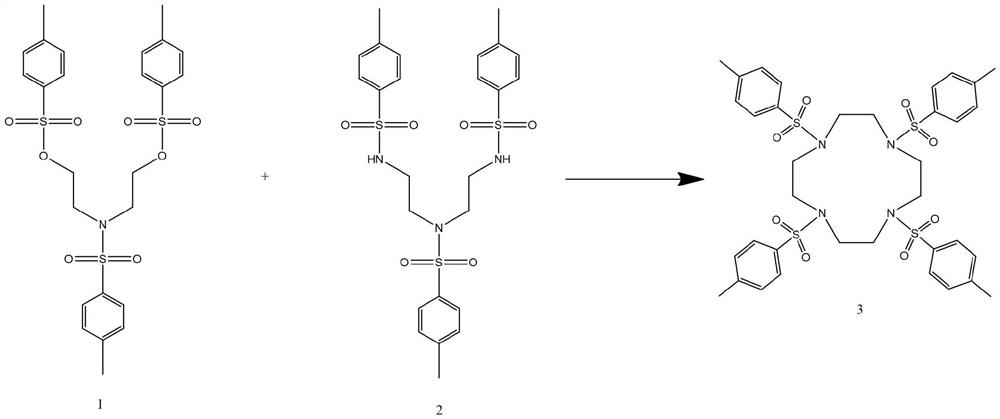

Low-phosphorus and low-sulfur high-strength heat-resistant Cr35Ni45 nichrome welding wire and preparation technology thereof

InactiveCN107138873AEfficient processHigh strengthWelding/cutting media/materialsSoldering mediaChromium nickelNichrome

The invention relates to a low-phosphorus and low-sulfur high-strength heat-resistant Cr35Ni45 nichrome welding wire and a preparation technology of the welding wire. The welding wire comprises, by mass, 0.35-0.45% of C, 1.20-1.60% of Si, 33.00-36.00% of Cr, 0.50-0.80% of Mn, 42.00-45.00% of Ni, 0.30-0.60% of Nb, 0.30-0.60% of Ti, 0.012%-0.014% of P, 0.007-0.009% of S, 0.25-0.30% of Al, 15.63-22.08% of Fe, and other unavoidable impurity elements. The preparation technology of the welding wire comprises the processes of vacuum smelting, homogenizing annealing, hot-forging cogging, multi-pass hot rolling, multi-pass cold drawing and finished product annealing. The welding wire has the good comprehensive mechanical property and well thermostable performance, the room temperature tensile strength of the welding wire is 1150-1250 MPa, and the room temperature percentage of elongation of the welding wire is 10-15%; and when the welding wire is tested at 1000 DEG C, the tensile strength is 600-700 MPa, and the elongation is greater than 25%.

Owner:JIANGSU YULI NEW MATERIAL TECH

Method for preparing aluminum oxide whiskers

The invention relates to a method for preparing aluminum oxide whiskers. The method comprises the steps of preparing a 0.4-0.5mol / L aluminum sulfate solution, and adding ammonia water to adjust the pH value of the solution to be 6.5; pouring hydrochloric acid into a reaction kettle accommodating calcium carbonate, quickly closing the reaction kettle, and stirring till the reaction in the reaction kettle is complete and a pressure is formed; slowly introducing the obtained carbon dioxide into the prepared aluminum sulfate solution, and stirring for 20-24 hours till the reaction is complete; putting the slurry after reacting into a closed container, introducing carbon dioxide of which the pressure is 0.1-0.6MPa, and performing filter pressing; then drying at 100 DEG C, and calcining at 1000-1200 DEG C to obtain nano aluminum oxide whiskers; finally, drying the calcium chloride solution obtained by the reaction to obtain a calcium chloride drying agent. The technical scheme provided by the invention has the advantages that the morphology of the aluminum oxide whiskers can be controlled, the cost is low, the pollution is avoided, the industry is simplified, the application is wide, the calcium chloride drying agent serving as a byproduct can be obtained, and the like.

Owner:LUOYANG WIDSOM LIFE MATERIAL SCI & TECH

A kind of preparation method of silver-loaded nanocellulose-chitosan composite film

InactiveCN106832437BPreparation Process GreenThe preparation process is simple and environmentally friendlyWound dressingMechanical property

The invention discloses a preparation method of a silver-loaded nano cellulose-chitosan composite film, the preparation method of the silver-loaded nano cellulose-chitosan composite film comprises the following steps: adding sodium periodate into a nano cellulose solution, stirring in a dark place, centrifuging for separation, and washing to obtain dialdehydo nano cellulose; adding a newly-prepared saturated silver ammonia solution for preparation of silver-loaded nano cellulose; mixing the silver-loaded nano cellulose with a chitosan solution to obtain a silver-loaded nano cellulose-chitosan antibacterial film. Nano silver particles prepared in the method are evenly distributed in dialdehydo nano cellulose network structures, the easy agglomeration problem of the nano silver particles can be well solved, the preparation process does not require the use of special instruments, also does not need a chemical reducing agent, and the production cost is reduced. Through use of good mechanical properties of the nano cellulose, the low mechanical strength problem of the chitosan film is improved, and the antibacterial property of the chitosan film is improved by silver loading operation. The silver-loaded nano cellulose-chitosan composite film has broad application prospects in antibacterial wound dressings and food packaging and other industries.

Owner:QIQIHAR UNIVERSITY +1

Alumina whisker preparation method

InactiveCN106319627ALow costNo pollution in the processPolycrystalline material growthFrom normal temperature solutionsNano al2o3Slurry

The invention relates to a low-cost energy-saving effluent-free recycling method for preparation of an alumina plate with uniform morphology, and the method is as follows: preparing an aluminum sulfate solution with the concentration of 0.4-0.5mol / L; adding a hydrochloric acid solution into a reaction kettle with calcium carbonate, quickly closing the reaction kettle, stirring until the reaction in the reaction kettle is completed and a pressure is formed; slowly introducing obtained carbon dioxide and ammonia into the prepared aluminum sulfate solution, stirring for 20 to 24 hours until the reaction is completed; putting reacted slurry into a sealed container, introducing the carbon dioxide with the pressure of 0.1-0.6MPa for press-filteration; and drying at 100 DEG C, and calcining at the temperature of 1000-1200 DEG C to obtain nano alumina whiskers. A calcium chloride solution obtained by the above reaction is reacted with ammonium sulfate waste liquor to obtain calcium sulfate, waste liquor ammonium chloride is reacted with the calcium carbonate for recycling, and the method has the advantages of control the morphology of alumina, small concentration changes in feeding process, uniform morphology, low cost, no pollution, recycling, simplification of industry, wide use, acquisition of by-product calcium sulfate whiskers, and the like.

Owner:北京交泰科技有限公司

a mno x -mof-gr composite material and its preparation method and application

ActiveCN110270379BLow costLarge specific surface areaOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationBenzoic acidN dimethylformamide

The invention discloses a MnO x ‑MOF‑Gr composite material and its preparation method and application, the method comprises: (1) dissolving manganese chloride tetrahydrate and p-benzoic acid in a mixed solution of water and N,N dimethylformamide, at 100~ Hydrothermal reaction at 160°C, post-treatment after the reaction, to obtain Mn-MOFs crystal material; (2) adding the Mn-MOFs crystal material to the graphene dispersion liquid, and dispersing evenly; (3) adding the Mn-MOFs crystal material obtained in step (2) The mixed liquid and the aqueous oxidant solution are mixed and reacted at 20-60°C to obtain MnO x ‑MOF‑Gr composites. The composite material prepared by the invention has a high specific surface area, is rich in surface adsorbed oxygen species, can quickly and effectively degrade low-concentration formaldehyde at room temperature, and its preparation process is simple, energy-saving, does not add any precious metals, and the material cost is low. capable of mass production.

Owner:SICHUAN UNIV

A kind of preparation method of functionalized polymer microsphere

ActiveCN108341966BThe production process is fastHigh purityWater contaminantsWater/sewage treatment by sorptionPolymer scienceMicrosphere

A method for preparing functional polymer microspheres belongs to the technical field of functional polymer preparation. The present invention takes oil-soluble multifunctionality acrylate monomer, polyethyleneimine and photoinitiator as raw materials, and the weight ratio of multifunctionality acrylate monomer, photoinitiator, polyethyleneimine and water solvent is 100:( 1~5): (5~20): (500~2000). After the system is evenly mixed, it is first emulsified under the action of a high-speed disperser, and then subjected to ultraviolet light irradiation to obtain multifunctional acrylate polymer microspheres. Then Michael addition reaction occurs with polyethyleneimine to obtain functional polymer microspheres with active primary and secondary amino groups on the surface. The invention obtains surface aminated functional polymer microspheres, the reaction energy consumption is low, and the reaction rate and reaction yield can be adjusted through time. The particle size of polymer microspheres can be adjusted within the range of 2μm-100μm. Polyethyleneimine is used not only as a stabilizer during the formation of microsphere polymerization, but also as a modifier during the modification of microspheres.

Owner:BEIJING UNIV OF CHEM TECH

A kind of hydrothermal preparation method and application of nano zno cellulose composite material based on naoh/urea solution

ActiveCN106279763BPromote generationImprove removal efficiencyWater/sewage treatment by irradiationWater treatment compoundsCelluloseWastewater

The invention discloses a hydrothermal preparation method of a nano-ZnO cellulose composite material on the basis of a NaOH-urea solution and application. The method comprises the step that in the NaOH-urea cellulose solution, the nano-ZnO cellulose composite material is prepared through in-situ compounding by adopting the hydrothermal method. According to the hydrothermal preparation method of the nano-ZnO cellulose composite material on the basis of the NaOH-urea solution, after cellulose is dissolved, hydroxyl groups on molecules of the cellulose are combined with zinc ions, and the defect that a zinc source does not easily penetrate into a carrier is overcome; in addition, the adopted NaOH-urea solvent is cheap and easy to obtain, and the hydrothermal synthesis temperature is obviously reduced. The nano-ZnO cellulose composite material contains 47.5% of ZnO and has the high removal efficiency on phenol in photodegradation wastewater. The ZnO cellulose composite material prepared through the method is cheap and environmentally friendly and has the very good practicability on phenolic wastewater treatment by serving as a photodegradation catalyst.

Owner:NANJING FORESTRY UNIV

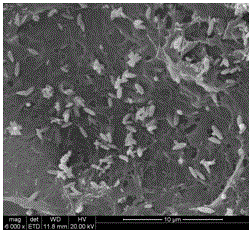

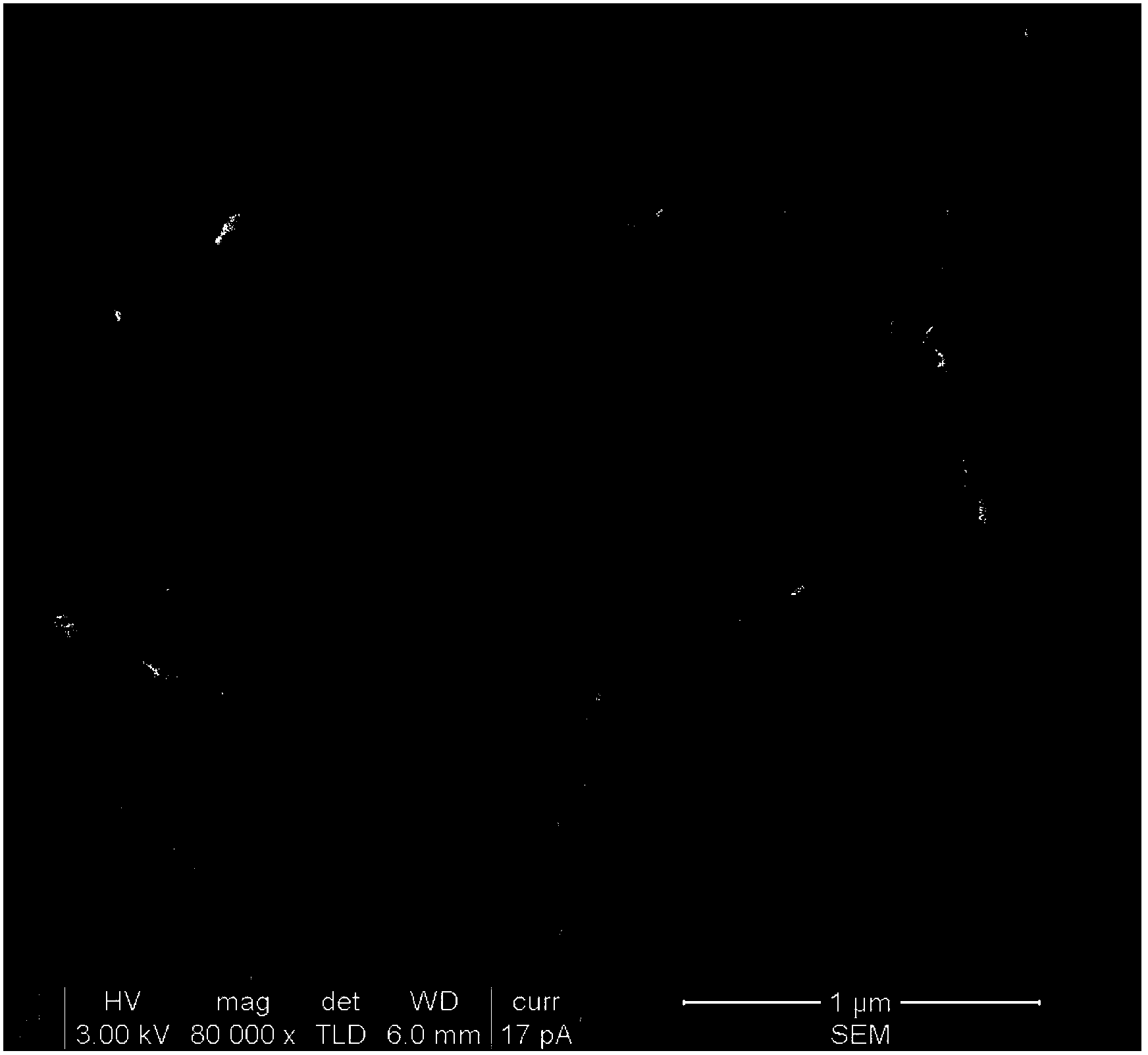

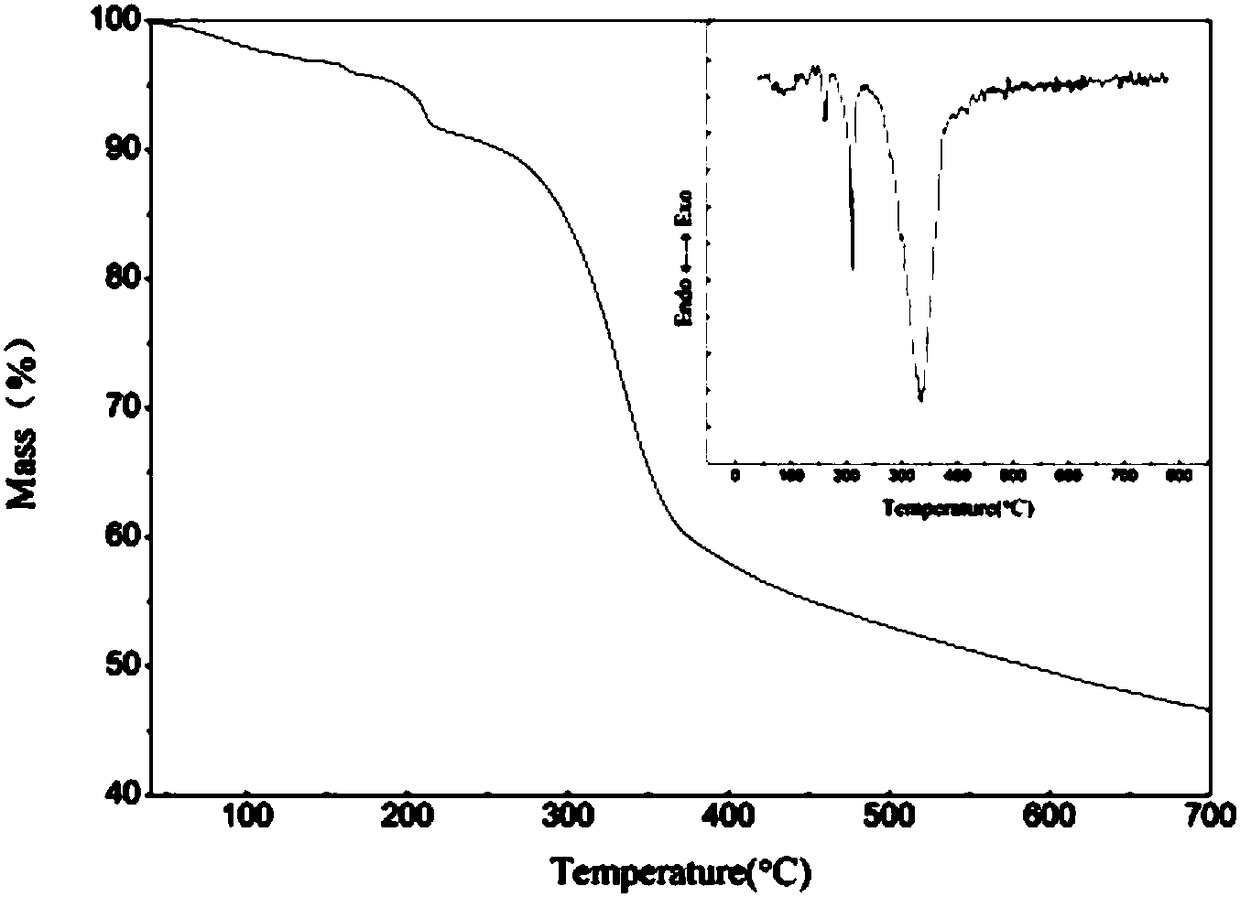

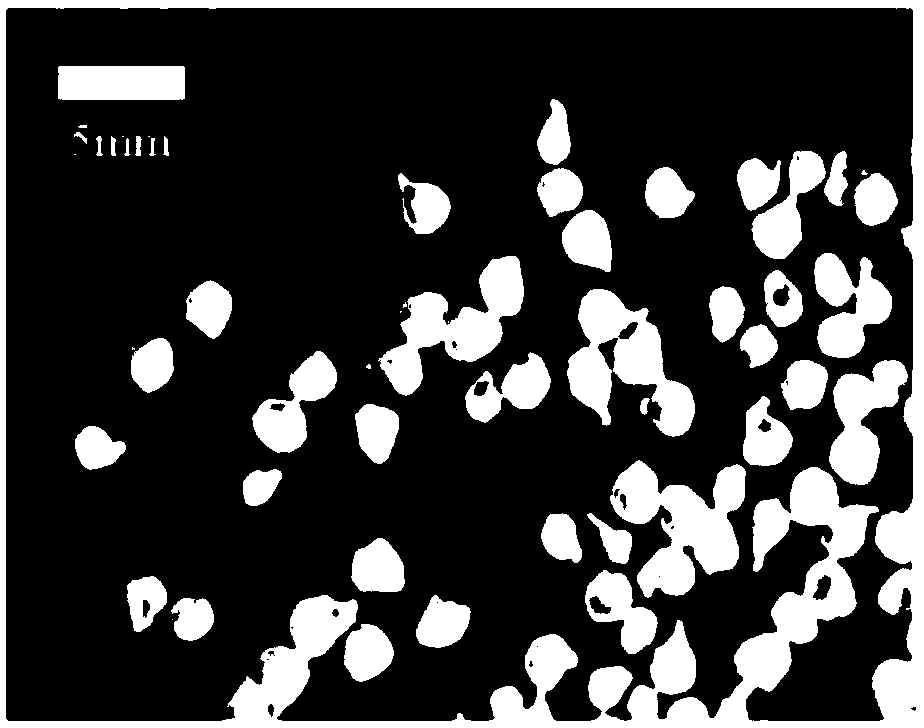

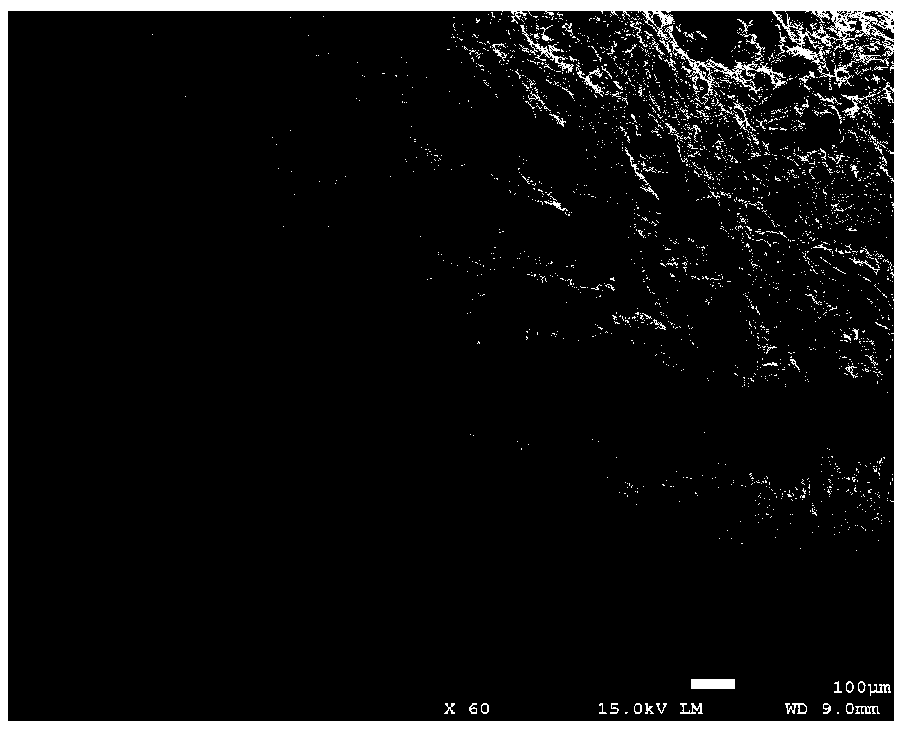

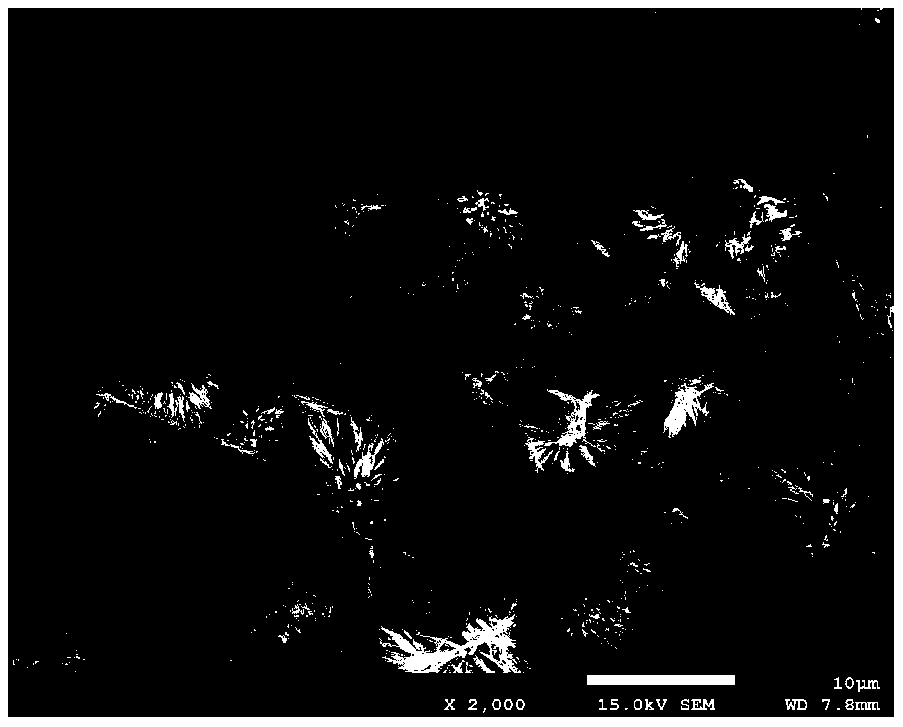

Regenerated cellulose microsphere containing flower-like nanometer ZnO and preparation method thereof

ActiveCN108889339AImprove the shortcomings of difficult recyclingPromote high-value utilizationWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic reactionMicrosphere

The invention discloses a regenerated cellulose microsphere containing flower-like nanometer ZnO and a preparation method thereof. According to the novel regenerated cellulose microsphere, the thickness of petaline nanometer ZnO is 100-200 nm, and the diameter of the regenerated cellulose microsphere is 2-4 mm. According to the preparation method, a ZnCl2 water solution is adopted as a solvent forcellulose and a zinc source of nanometer ZnO, and dissolving pulp cellulose fibers are adopted as the raw materials of cellulose and subjected to low-temperature pretreatment, dissolution, injectioninto a ball shape, in-situ synthesis and freeze drying to prepare the regenerated cellulose microsphere containing flower-like nanometer ZnO. A preparation process is clean, environmentally friendly and capable of saving energy; through in-situ synthesis, the regenerated cellulose microsphere containing flower-like nanometer ZnO is prepared without a hydrothermal reaction or heating, flower-like nanometer ZnO is mainly distributed in the regenerated cellulose microsphere and cannot shed, and the regenerated cellulose microsphere has wide application in light-catalyzed reactions.

Owner:NANJING FORESTRY UNIV

A kind of preparation method of polyvinyl chloride pipe

The invention discloses a preparation method for an energy-saving polyvinyl chloride tubular product. The preparation method comprises the steps of pouring all raw materials except for titanium dioxide and CPE into a stirring kettle, mixing the raw materials at the rotating speed of 55-70r / m for 1 hour, then putting the raw materials into a double-screw extruder, kneading the raw materials under the temperature of 140-150 DEG C for 8-10 minutes, adding the rest of the raw materials according to the weight parts, performing mixing and granulation, controlling the temperature at 150-160 DEG C, and performing a forming technology to obtain a finished product. The tubular product prepared by the preparation method disclosed by the invention is stable in quality and high in strength and has a smooth surface. The preparation technology is energy-saving, economical and environment-friendly.

Owner:安徽玉发塑业有限公司

Preparation method of porous effervescent sodium percarbonate particles used as sanitizer

PendingCN114794096ASimple manufacturing processEnergy saving in preparation processBiocidePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMother liquorAqueous solution

The invention provides a preparation method of porous effervescent sodium percarbonate serving as a sanitizer, which comprises the following steps: (S1) preparing alkali liquor which comprises mother liquor, sodium carbonate, sodium chloride and a stabilizer; (S2) preparation of a hydrogen peroxide aqueous solution: adding disodium ethylene diamine tetraacetate and magnesium sulfate into the hydrogen peroxide mother solution; (S3) introducing the prepared alkali liquor and hydrogen peroxide aqueous solution into a reaction kettle for reaction, wherein the introduction flow rate of the alkali liquor is 1600-2500 kg / h, the introduction flow rate of the hydrogen peroxide aqueous solution is 600-1000 kg / h, the reaction temperature is 15-30 DEG C, and the reaction time is 30-50 minutes; and (S4) after the reaction is finished, separating a crystallization product from the reaction liquid through a centrifugal machine, and drying to obtain a finished product, wherein the water content of the crystallization product is 16-22%. According to the method, the sodium percarbonate intermediate with the water content of 16%-22% is prepared by controlling the flow of the alkali liquor and the hydrogen peroxide and rapidly reacting, the sodium percarbonate finished product with the loose porous structure can be obtained by drying, and the method is free of a tabletting process, low in equipment investment and lower in energy consumption.

Owner:ZHEJIANG JINKE CHEM

A kind of film-forming liquid, preparation method and application thereof

InactiveCN103666254BImprove EdibilityImprove securityMeat/fish preservation by coatingFruits/vegetable preservation by coatingMoisture resistanceMechanical property

The invention provides a film-forming solution. The film-forming solution is characterized by comprising the following components: 5-30wt% of alcohol-soluble protein, 1-5wt% of nano TiO2 particles, 0.1-3wt% of gelatinizing agent, 0.05-3wt% of coagulant aid, 0.1-3wt% of plasticizer, and the balance of ethanol water of which the volume ratio is 45-65%. The invention also provides a method for preparing the film-forming solution. Furthermore, the invention also provides application of the film-forming solution as a food preservation film. According to the film-forming solution provided by the invention, not only are the edibility, the safety and the stability of the preservation film improved due to the alcohol-soluble protein, but also the preservation film is degradable and free of pollution to the environment. The nano TiO2 particles are contained, so that the film-forming solution has unique barrier property and mechanical property after a film is formed, and has an antibacterial effect. In addition, the preparation method of the film-forming solution provided by the invention is simple in process, and low in cost. The preservation film not only is good in moisture resistance, but also does not become tacky after being moistened, is degradable, green and environment-friendly, can well keep the quality of the food, and prolongs the shelf life after being formed on the food surface.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

New multi-wild fruit refining beverage process

The invention relates to a new multi-wild fruit refining beverage process, which mainly comprises: weighing washed rhodomyrtus tomentosa, washed wild grape, j washed injinguo, washed phyllanthus emblica l and washed peppermint according to a ratio of 5-6:3-2:0.3-0.1:0.2-0.1:0.1-0.2 by adopting 10 as a base rate, simultaneously pouring into a crusher, crushing and thinning to obtain a slurry, carrying out filtration juice and residue separation treatment by using a filter, respectively weighing the main ingredient filtration juice, mineral water and a preservative according to a ratio of 8-6:4-3:0.02-0.01 by adopting 100 as a base rate, uniformly stirring with a stirrer or artificially and uniformly stirring, filling into a special health bottle by using a filling machine, pouring the bottle into a heating sterilization apparatus, carrying out heating sterilization treatment for 20-30 min, carrying out sealed storage and natural quality increasing for 5-7 days, and unsealing so as to obtain the natural and delicious multi-wild fruit refining beverage.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

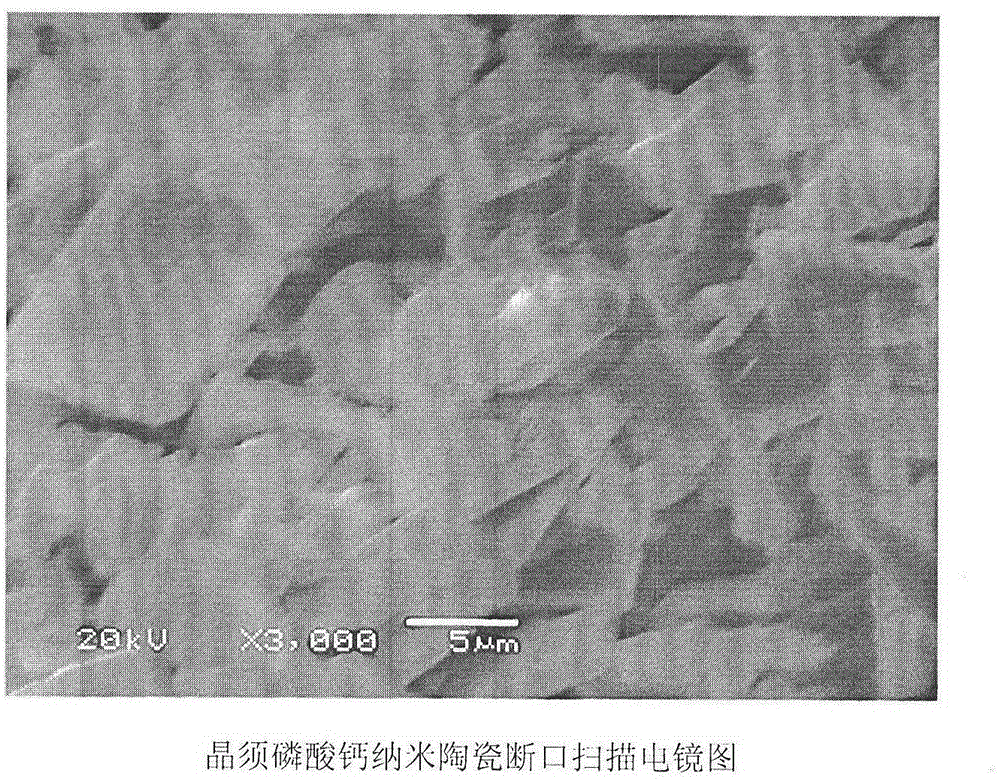

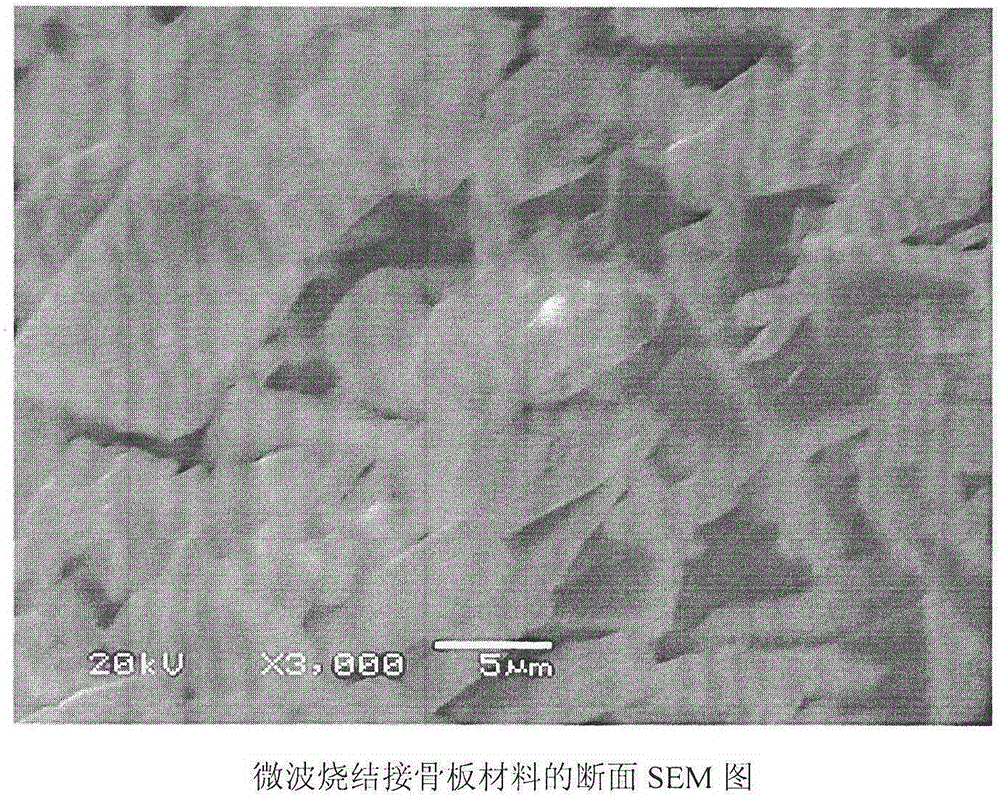

Method for low-cost industrialized preparation of recoverable degradable calcium phosphate bone fracture plate

InactiveCN106310387ALow costNo pollution in the processSurgeryPhosphoric acidCalcium phosphate ceramics

The invention relates to a method for low-cost recycling reuse industrialized preparation of a novel degradable bone fracture plate material, wherein the method comprises the steps: carrying out a heating reaction of ammonium chloride and calcium carbonate, to generate CO2, ammonia gas and calcium chloride; adding phosphoric acid into a calcium chloride solution with the calcium-to-phosphorus ratio of 3 to 2, introducing the CO2 and the ammonia gas, stirring for 3 hours to generate a nano powder, filtering, then drying at the temperature of 100 DEG C, calcining at the temperature of 900 DEG C for standby application, and recycling filtrate ammonium chloride; repeating the above steps, adding CTAB with the weight ratio of 1-3 mol% before introducing gas, carrying out a reaction with a calcium mixed solution for 10-24 hours, and filtering to obtain crystal whiskers after obtaining a crystal whisker precipitate; carrying out ball milling of the calcium phosphate and the crystal whiskers with the ratio of 5 to 1 for 1 hour, mixing evenly, carrying out dry-pressing molding at the pressure of 25-30 MPa into a bone fracture plate shape; and sintering for 10 minutes at the temperature of 1100 DEG C with a microwave oven to prepare nano calcium phosphate ceramics, drilling to form a thread, to obtain a bone fracture plate, and finally, cleaning the bone fracture plate after use, soaking in a 0.1 M dilute hydrochloric acid for 24 hours, and recycling, wherein an obtained solution is used for raw material preparation.

Owner:北京交泰科技有限公司

A kind of preparation method of strip nano zno/cellulose gel material

ActiveCN104941537BPromote generationThe preparation process is clean and environmentally friendlyMaterial nanotechnologyColloidal chemistry detailsFreeze-dryingZinc ion

The invention discloses a preparation method of a strip nano-ZnO / cellulose gel material. ZnCl2 aqueous solution is used as a solvent for cellulose and a zinc source of nano-ZnO, and the cellulose fiber of a dissolved pulp is used as a cellulose raw material. Precipitation, hydrothermal synthesis and freeze-drying, a new strip-shaped nano-ZnO / cellulose gel material was prepared. The invention skillfully uses ZnCl2 aqueous solution as the solvent of cellulose and the zinc source of nanometer ZnO, therefore, no need to add other cellulose solvents, and the preparation process is clean and environment-friendly. In addition, after the cellulose is dissolved, the hydroxyl groups on its molecules combine with zinc ions to promote the formation of nano-ZnO, and the hydrothermal synthesis temperature is also significantly reduced accordingly. Therefore, the preparation process has the advantage of energy saving.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com