Preparation and application of magnetic graphene oxide compound

An oxide stone and composite technology, which is applied in the directions of alkali metal compounds, alkali metal oxides/hydroxides, chemical instruments and methods, etc., can solve the problems of insufficient capacity and insufficient guidance, and achieves easy availability of raw materials and low cost of raw materials. , the effect of mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

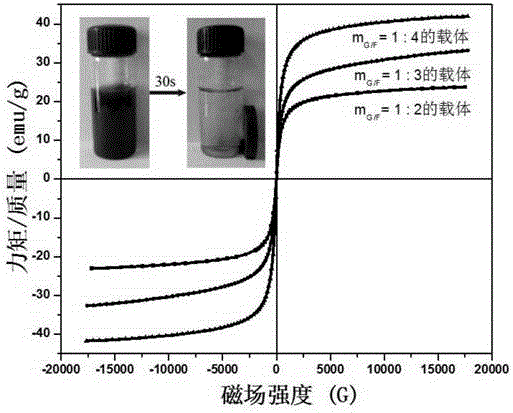

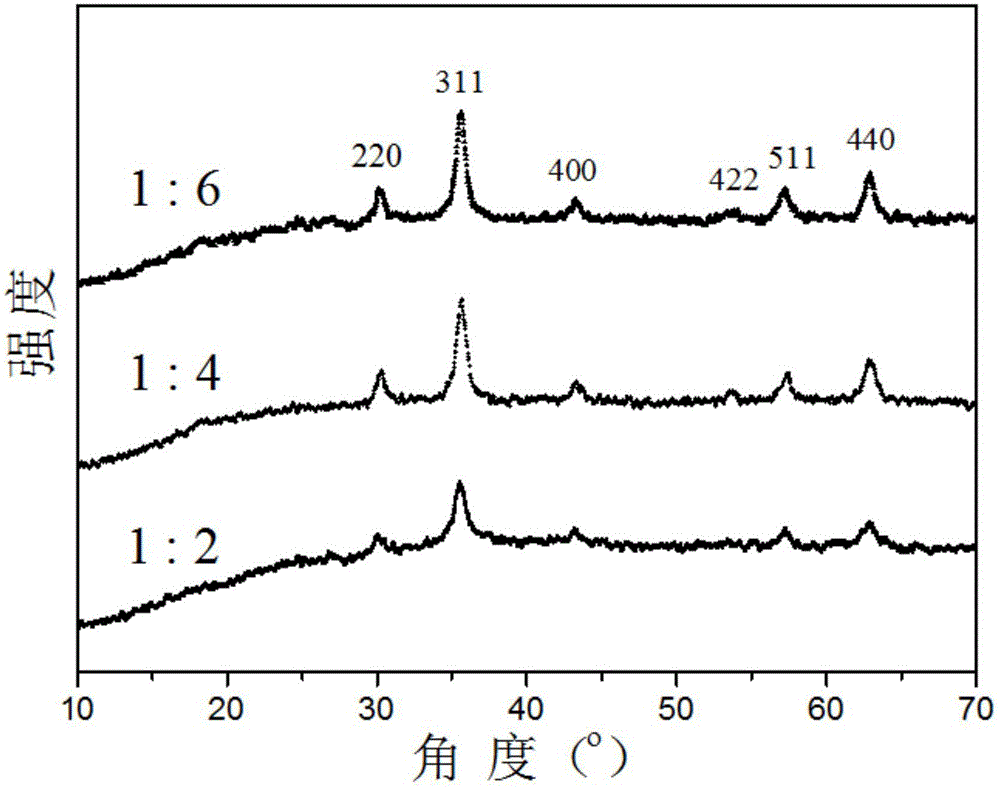

[0040] Example 1: m G / F =1:2 preparation and application of magnetic graphene oxide composite

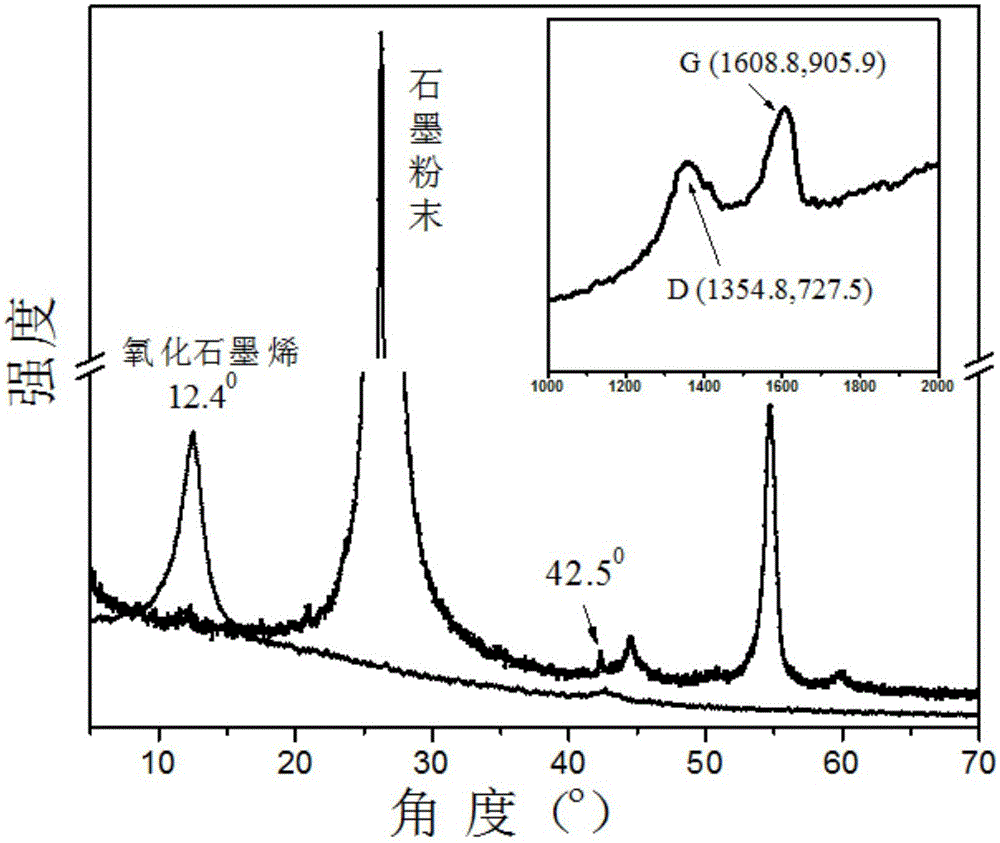

[0041] 1.m G / F =1:2 Preparation of Magnetic Graphene Oxide Composite

[0042] ⑴Weigh 0.23g graphite powder, add 50mL dissolved in 0.25g NaNO 3 Concentrated H 2 SO 4 solution, after stirring for 20min, slowly add 6g KMnO 4 After reacting at 35°C for 2 hours, raise the temperature to 80°C, keep warm for 15min, add 200mL distilled water to dilute, heat to boiling and keep warm for 15min, then cool down to room temperature, add 10mL H 2 o 2 After reacting for 6 hours, the solid crude product obtained by suction filtration was centrifuged and washed with dilute hydrochloric acid and distilled water until there was no SO in the centrifuged liquid. 4 2- ; The washed solid was vacuum-dried at 60°C for 12 hours to obtain graphite oxide; 0.2 g of graphite oxide powder was dispersed in 400 mL of deionized water, and ultrasonically stripped at room temperature for 4 hours to obtain a GO...

Embodiment 2

[0047] Example 2: m G / F =1:4 preparation and application of magnetic graphene oxide composite

[0048] 1.m G / F =1:4 Preparation of Magnetic Graphene Oxide Composite

[0049] ⑴Weigh 0.23g graphite powder, add 50mL dissolved in 0.25g NaNO 3 Concentrated H 2 SO 4 solution, after stirring for 20min, slowly add 6g KMnO 4 After reacting at 35°C for 2 hours, raise the temperature to 80°C, keep warm for 15min, add 200mL distilled water to dilute, heat to boiling and keep warm for 15min, then cool down to room temperature, add 10mL H 2 o 2 After reacting for 6 hours, the solid crude product obtained by suction filtration was centrifuged and washed with dilute hydrochloric acid and distilled water until there was no SO in the centrifuged liquid. 4 2- ;The washed solid was vacuum-dried at 60°C for 12h to obtain graphite oxide; 0.2g of graphite oxide powder was dispersed in 400mL of deionized water, and ultrasonically peeled at room temperature for 4h to obtain a GO suspension wit...

Embodiment 3

[0054] Example 3: m G / F =1:6 preparation and application of magnetic graphene oxide composite

[0055] 1.m G / F =1:6 Preparation of Magnetic Graphene Oxide Composite

[0056] ⑴Weigh 0.23g graphite powder, add 50mL dissolved in 0.25g NaNO 3 Concentrated H 2 SO 4 solution, after stirring for 20min, slowly add 6g KMnO 4 After reacting at 35°C for 2 hours, raise the temperature to 80°C, keep warm for 15min, add 200mL distilled water to dilute, heat to boiling and keep warm for 15min, then cool down to room temperature, add 10mL H 2 o 2 After reacting for 6 hours, the solid crude product obtained by suction filtration was centrifuged and washed with dilute hydrochloric acid and distilled water until there was no SO in the centrifuged liquid.4 2- ;The washed solid was vacuum-dried at 60°C for 12h to obtain graphite oxide; 0.2g of graphite oxide powder was dispersed in 400mL of deionized water, and ultrasonically peeled at room temperature for 4h to obtain a GO suspension with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com