Bridge coarse aggregate active powder concrete and preparation method thereof

A technology of active powder and coarse aggregate, which is applied in the field of building materials, can solve the problems of difficulty in improving the elastic modulus of active powder concrete, the difficulty in improving the elastic modulus, and the complicated maintenance process, so as to reduce the risk of shrinkage cracking, reduce the preparation cost, Effect of improving fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

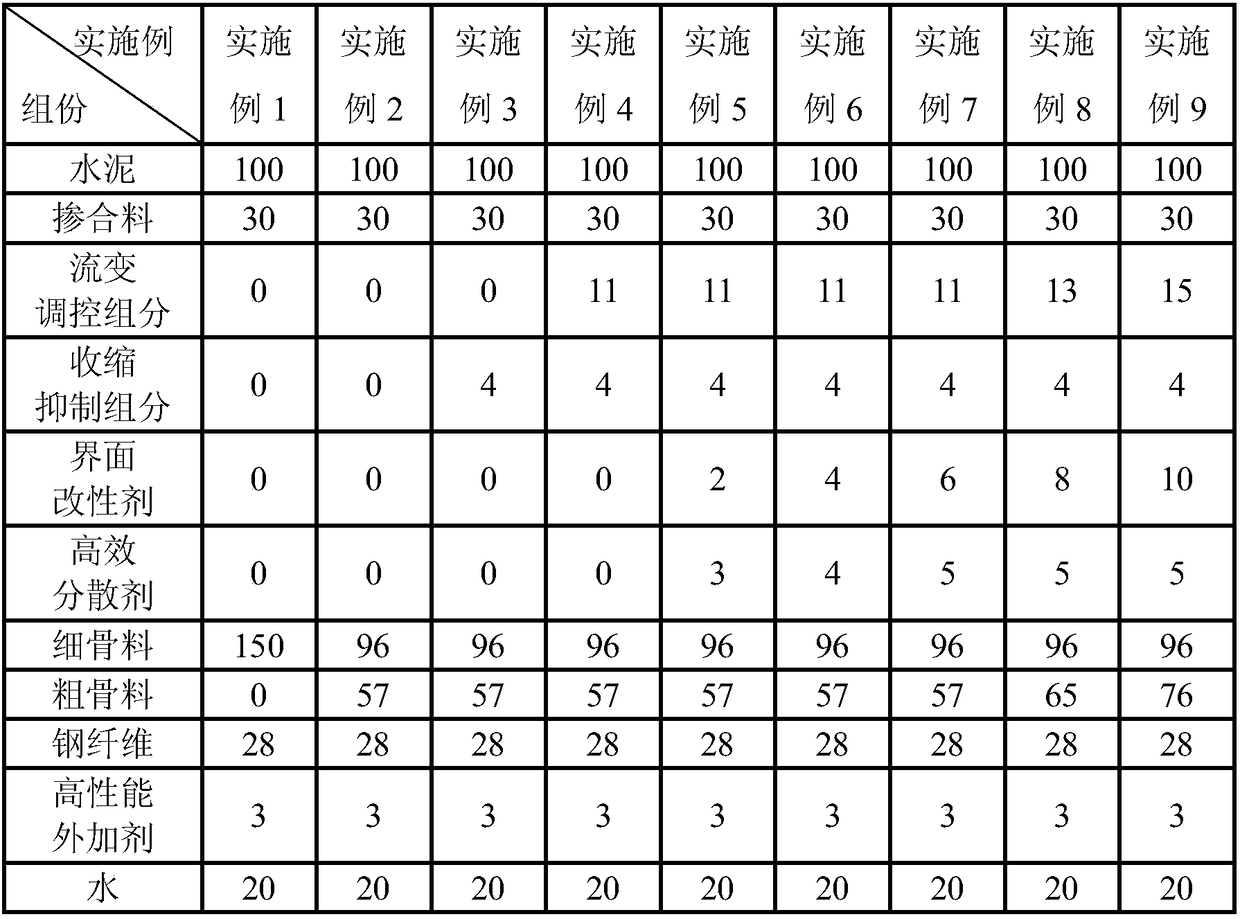

Embodiment 1

[0054] Example 1 is a basic concrete without rheology control components, shrinkage inhibition components, interface modifiers, high-efficiency dispersants and coarse aggregates.

Embodiment 2

[0055] Coarse aggregate is mixed in Example 2, and rheology control components, shrinkage inhibition components, interface modifiers, and high-efficiency dispersants are not mixed.

Embodiment 3

[0056] In Example 3, the coarse aggregate and the shrinkage inhibiting component were mixed, but no rheology control component interface modifier and high-efficiency dispersant were added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com