Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Relief of residual stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

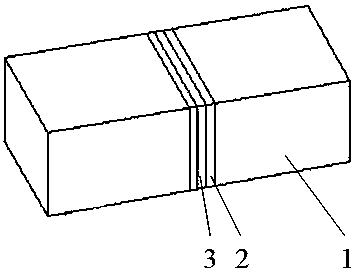

Manufacturing method for novel nickel base solder brazing monolayer diamond grinding wheel

A manufacturing method for a brazing monolayer diamond grinding wheel comprises a first step of adopting a machining method to prepare a base body of the diamond grinding wheel and removing oil and rust of the base body; a second step of preparing Ni-Cr solder, adding Al powder into the Ni-Cr solder, mechanically evenly mixing mixture of the Ni-Cr solder and the Al powder to form solder alloy; a third step of manufacturing tool forming blank according to the sequence of the base body of the diamond grinding wheel, the solder alloy and diamond abrasive grains; a fourth step of adopting a vacuum rapid heating mode to heat the Al powder to enable the Al powder to melt, releasing massive heat due to a reaction of the melted Al and Ni to enable Ni-Cr solder to melt and undergo interface reaction with the diamond abrasive grains, and forming the monolayer diamond grinding wheel. By adding the fine Al powder into the Ni-Cr solder, brazing temperature can be reduced; under the condition that the holding force of the solder to the diamond abrasive grains is not changed, heat injury to diamond is reduced, deformation of the base body is reduced, and accordingly performance of a diamond abrasive tool can be fully performed.

Owner:ZHONGYUAN ENGINEERING COLLEGE

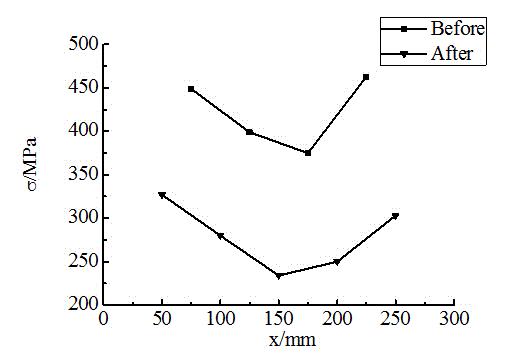

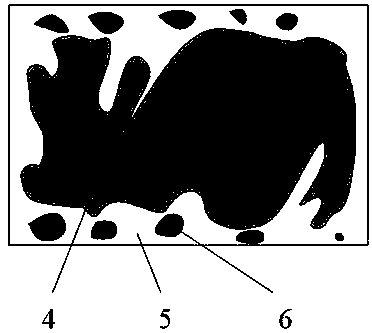

Railway vehicle axle repair process

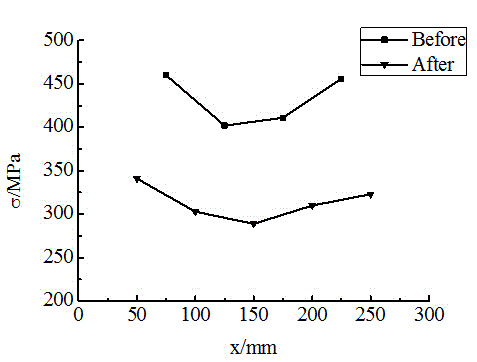

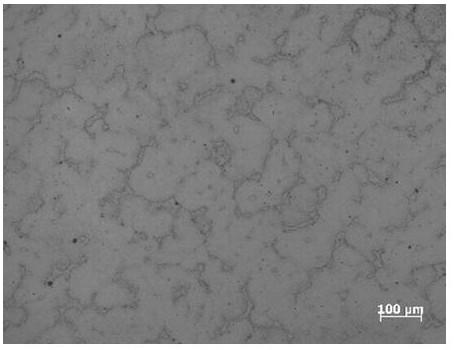

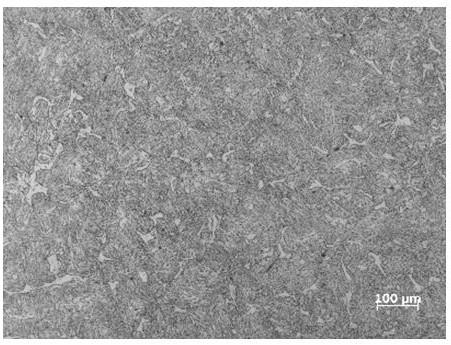

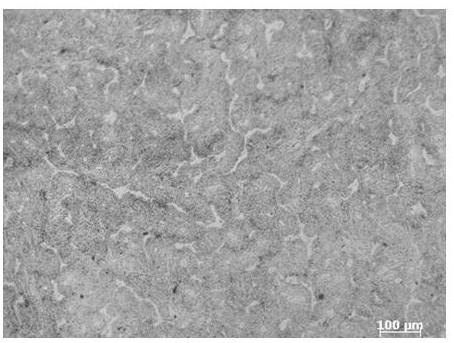

InactiveCN104480466AGood metallurgical bondRelief of residual stressMetallic material coating processesSlagAutomotive engineering

The invention discloses a railway vehicle axle repair process. The process comprises the steps of pretreatment, laser cladding, residual stress relaxation and machining, wherein in the laser cladding step, the adopted metal powder comprises, by mass, 0.1-0.25% of carbon, 17.5-28% of chromium, 10.5-16% of nickel, 0-0.65% of boron, 0.12-1.0% silicon, 0-4.5% of molybdenum, 0-0.8% of manganese and the balance being iron. A vehicle axle repaired through the process is small in microstructure, free of the defects such as air holes, slag inclusion and cracks and capable of meeting the requirement for use performance; the service life of the repaired vehicle axle reaches or exceeds that of a new axle. The railway vehicle axle repair process has the advantages that operation is easy, the controllability is good, the damaged vehicle axle can be repaired quickly in a short time, the cost for replacement of the damaged axle with the new axle is lowered, the use cost of the vehicle axle is lowered, harm of the discarded vehicle axle to the environment is reduced, and environmental friendliness is achieved.

Owner:SOUTHWEST JIAOTONG UNIV

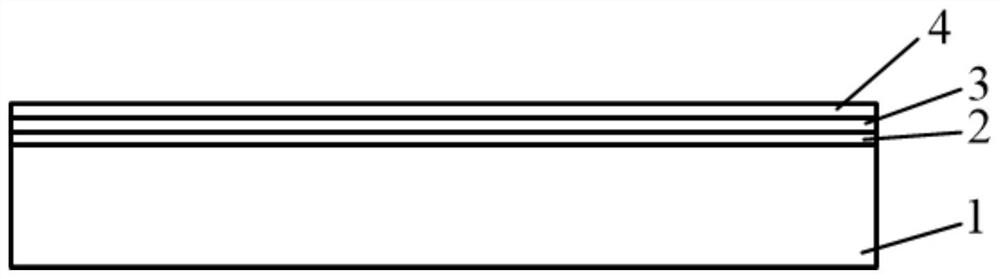

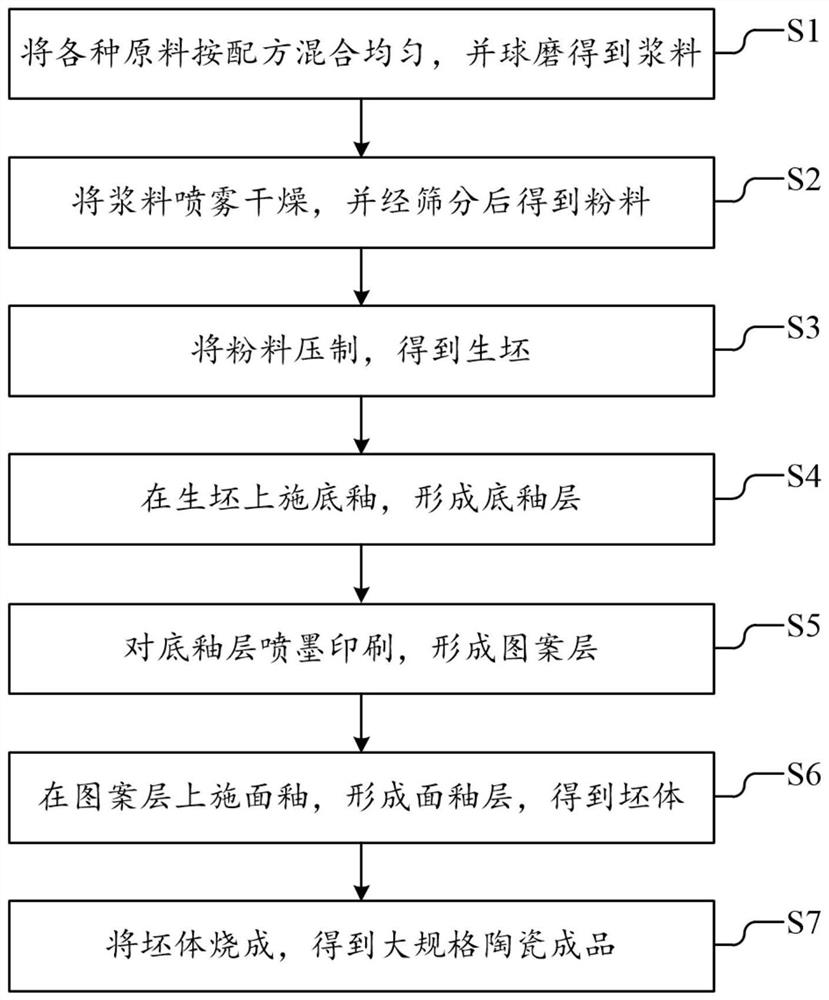

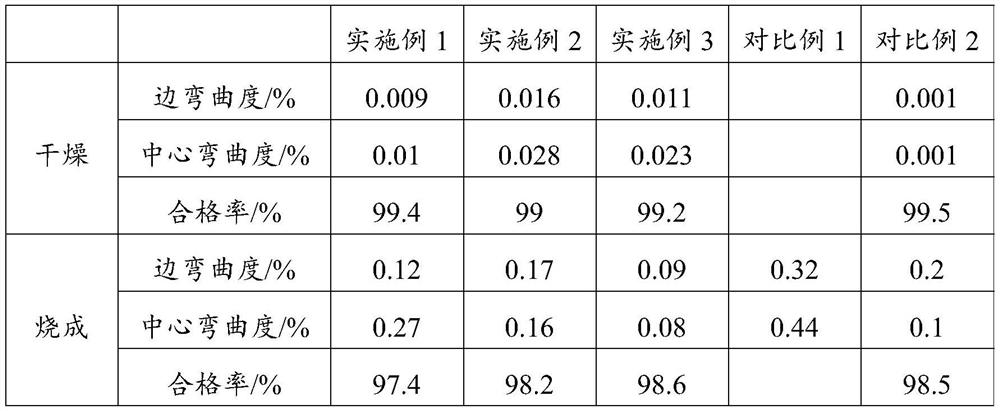

Large-size ceramic rock plate and preparation method thereof

ActiveCN111646788ALess stress buildupRelief of residual stressCovering/liningsPotassium feldsparKaolin clay

The invention discloses a large-size ceramic rock plate which has a surface area of 3-12m<2> and a thickness of 12-30mm. The large-size ceramic rock plate comprises a green body layer, a ground coat layer, a pattern layer and a cover coat layer; wherein the thickness of the green body layer is 11.5-29.5mm; the green body layer is mainly prepared from the following raw materials by weight: 15-20 parts of potassium feldspar, 8-15 parts of albite, 15-20 parts of calcined kaolin, 12-20 parts of black mud, 8-15 parts of white mud, 15-20 parts of pyrophyllite and 1-10 parts of a toughening agent; wherein the sum of the weight parts of the raw materials is 100 parts. The ceramic rock plate can well adapt to a later deep processing technology, can be widely applied to the fields of floors, curtainwalls and veneers, and has the advantages of high strength, high hardness, acid and alkali resistance, high temperature resistance and the like.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

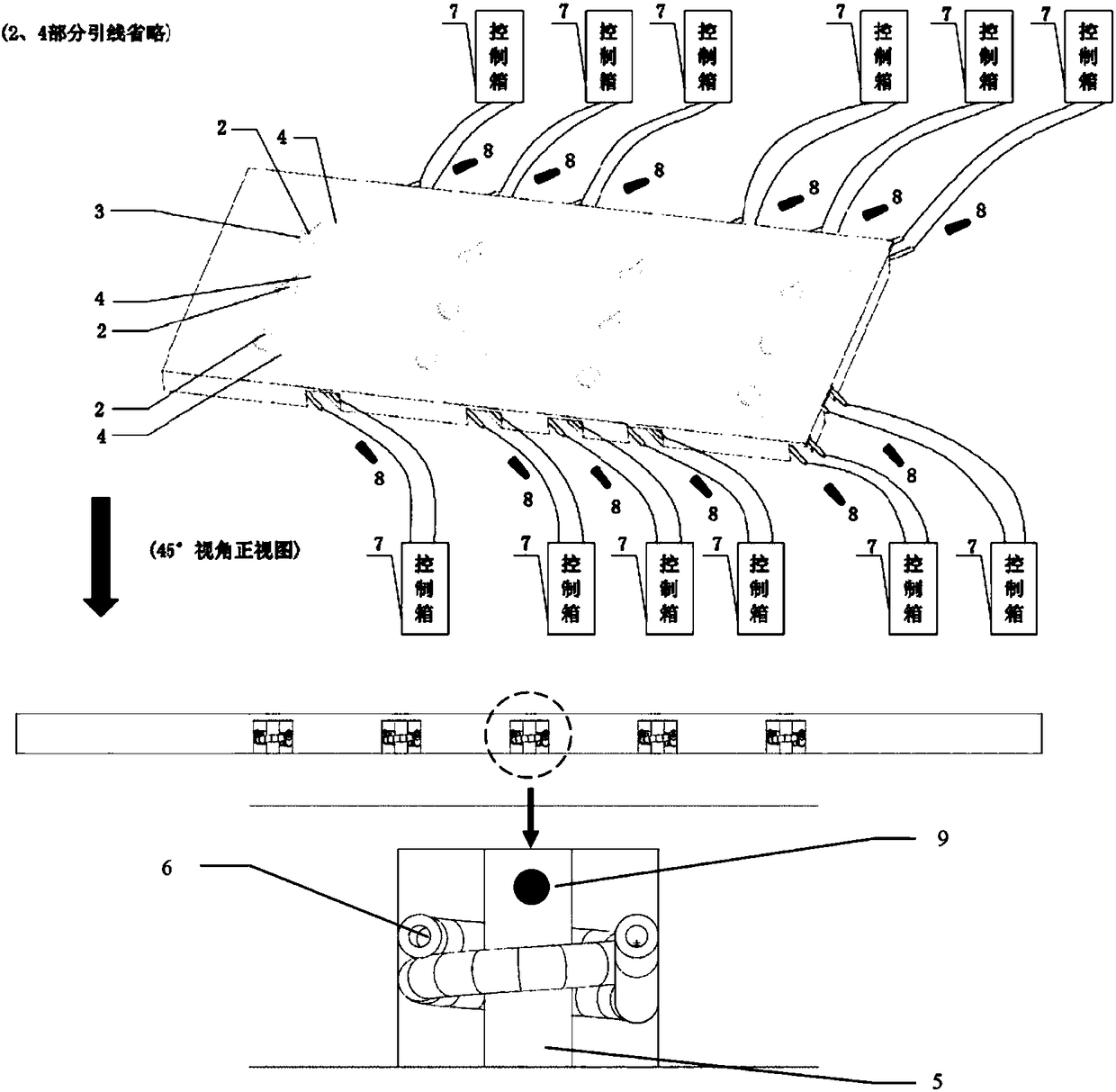

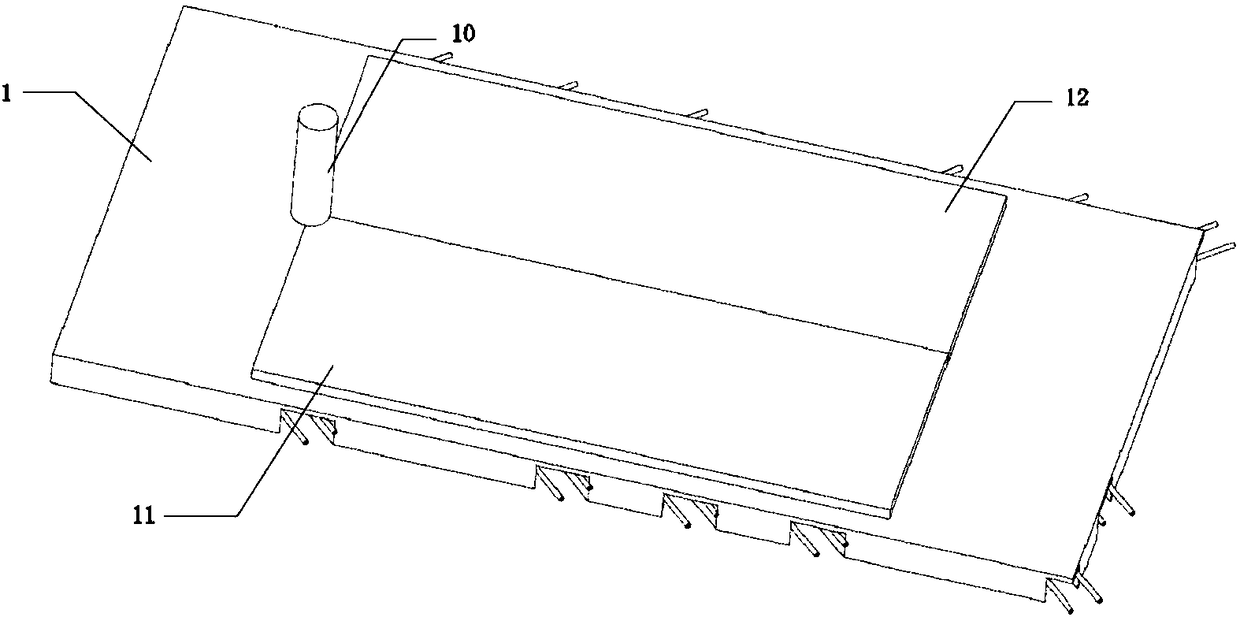

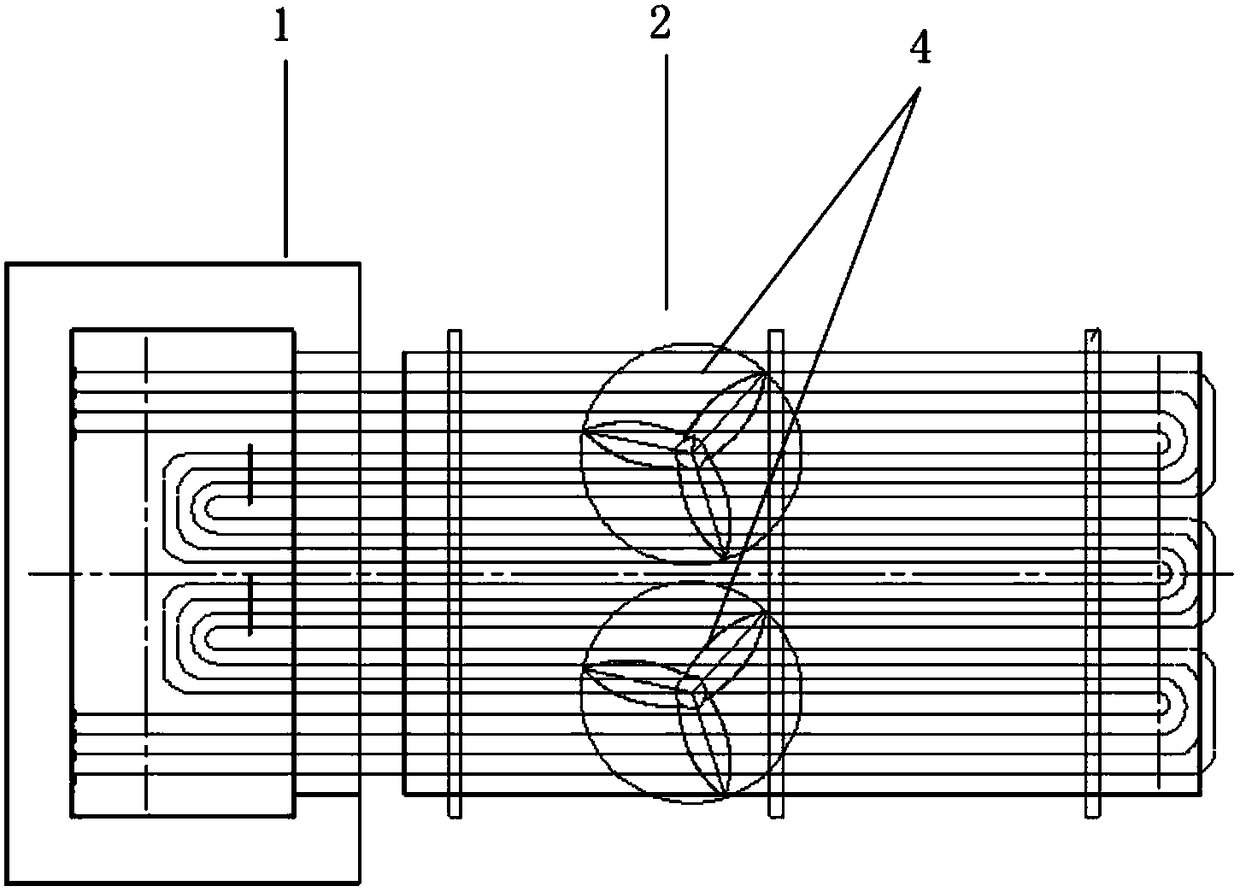

Method and device for effectively reducing or eliminating residual stress of friction stir welding plate

InactiveCN108237323ARelief of residual stressImprove performanceFurnace typesProcess efficiency improvementEngineeringFriction stir welding

The invention discloses a method and a device for effectively reducing or eliminating a residual stress of a friction stir welding plate. The method and the device is characterized in that a pluralityof heat source points are arranged at two sides at the position, opposite to a weld joint, of a base plate for stirring friction welding, an array type arrangement is formed, and each heat source point is heated by utilizing a high-frequency induction coil to generate heat; and the heat source generated by the heat source point is matched with the heat generated in the friction stir welding process, the array type point-shaped heat source can generate different residual stress for different plates due to different temperature conduction rates, and then temperature control is carried out. In the welding process, the temperature distribution is generated by stirring heads in the welding process by controlling the point-shaped heat source of the array type arrangement in a simulation FSW process, so that the temperature distribution of the welded plate is uniform, the temperature gradient in the welded plate is reduced, and the residual stress generated due to thermal gradient is reduced. After the welding is completed, the heat of the heat source of the control point is controlled, so that the temperature of the welded plate is kept, and mechanical residual stress in the joint is eliminated.

Owner:JIANGXI UNIV OF SCI & TECH

Aluminum alloy 3D printing heat treatment method

ActiveCN111922347AImprove density and strengthRelief of residual stressAdditive manufacturing apparatusHot isostatic pressingMetallic materials

The invention provides an aluminum alloy 3D printing heat treatment method. The method includes the following steps that an aluminum alloy 3D printing sample is subjected to hot isostatic pressing treatment, and then furnace cooling is conducted; the treated sample is subjected to solution treatment and then water cooling is performed; and afterwards, the sample is subjected to aging treatment, and heat-treated 3D printing aluminum alloy is obtained after air cooling. According to the aluminum alloy 3D printing heat treatment method provided in the invention, the combined heat treatment technology of hot isostatic pressing, solid solution and aging is adopted to be assisted with a proper cooling mode to improve the density and strength of a 3D printing aluminum alloy material, the inner residual stress of the material can be removed particularly, the plastic properties like yield strength and ductility are improved, the comprehensive mechanical properties of the aluminum alloy materialare also improved, and the applied field of 3D printing metal materials is widened; and the combined heat treatment technology is selected according to the defects of the 3D printing metal materials, and the reference function on improvement of the properties of various types of metal materials can be achieved.

Owner:飞而康快速制造科技有限责任公司

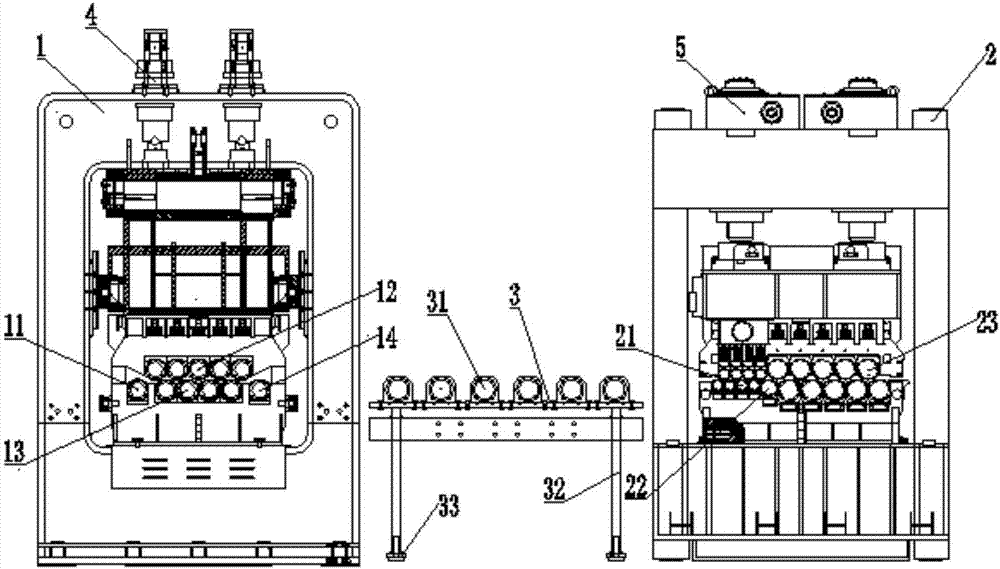

Straightening equipment for eliminating unevenness of tungsten-molybdenum composite board after shearing separation

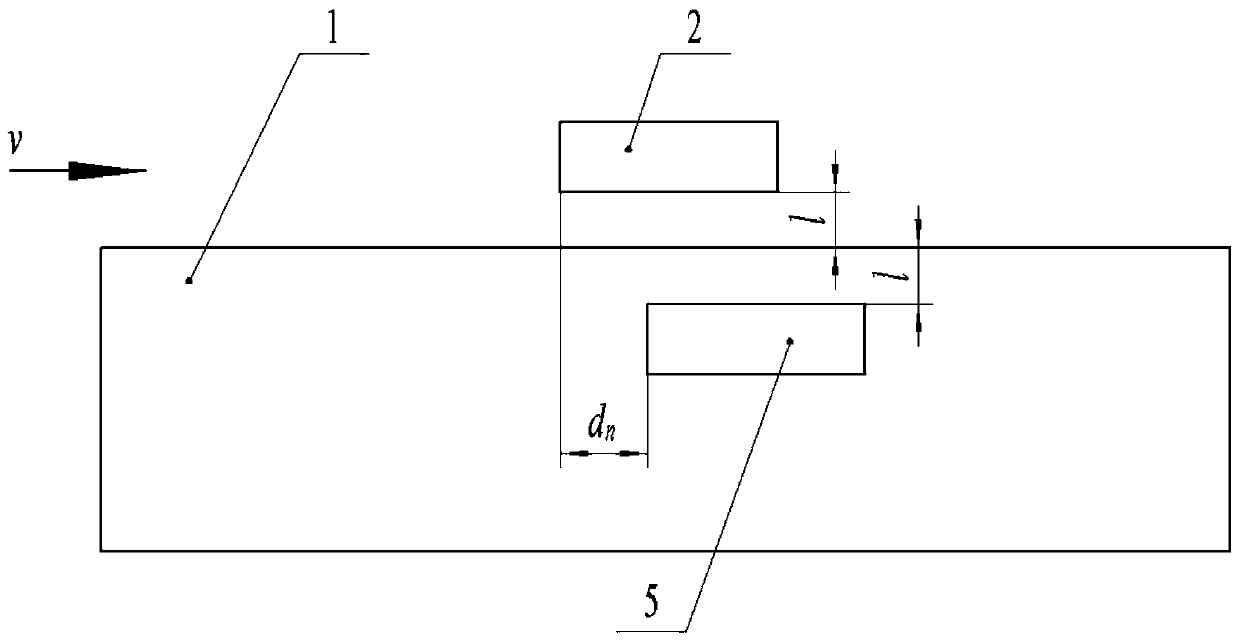

The invention discloses straightening equipment for eliminating the unevenness of a tungsten-molybdenum composite board after shearing separation. The straightening equipment comprises an inlet straightening machine provided with straightening reverse-bending rolls A, an outlet straightening machine provided with straightening reverse-bending rolls B, and a rail located between the inlet straightening machine and the outlet straightening machine. Compared with the prior art, the straightening equipment disclosed by the invention is capable of effectively eliminating residual stress in the tungsten-molybdenum composite board during a straightening process, a foundation bolt is arranged, and the same height of the rail, the inlet straightening machine and the outlet straightening machine can be kept through adjusting the foundation bolt; and lower-row straightening reverse-bending rolls with two-section structures are arranged, and automatic adjustment can be carried out according to the widths of different tungsten-molybdenum composite boards.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Processing method for eliminating residual stress of light alloy material

The invention relates to a processing method for eliminating the residual stress of the light alloy material, and is suitable for eliminating the quenching residual stress of various shapes and size light alloy materials. The method comprises the following steps of after quenching treatment, carrying out cryogenic treatment on the light alloy material; after subzero treatment, rapidly transferringthe light alloy material into a steam box for quenching heat treatment; and then carrying out air cooling to room temperature. The method disclosed is not limited by the size and shape of the material, the residual stress of the light alloy material is greatly reduced, and the strength and toughness of the light alloy material are synchronously improved.

Owner:青岛四通八达商贸有限公司

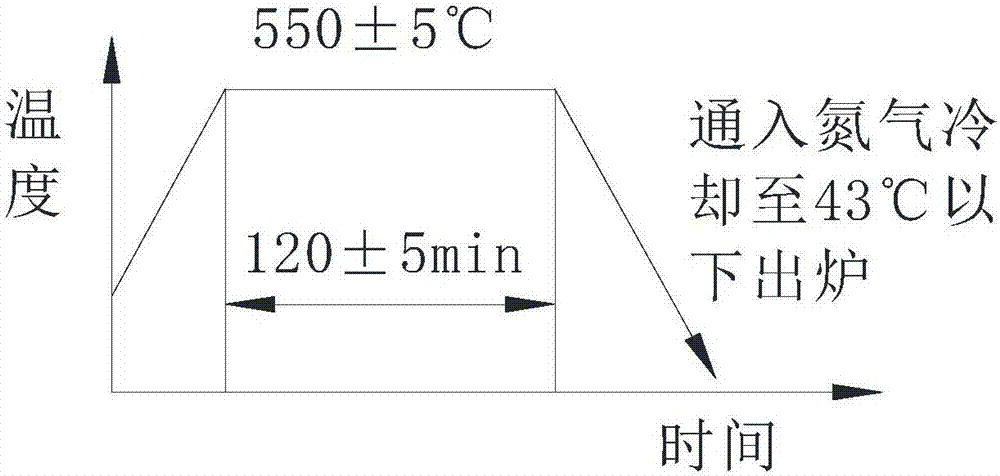

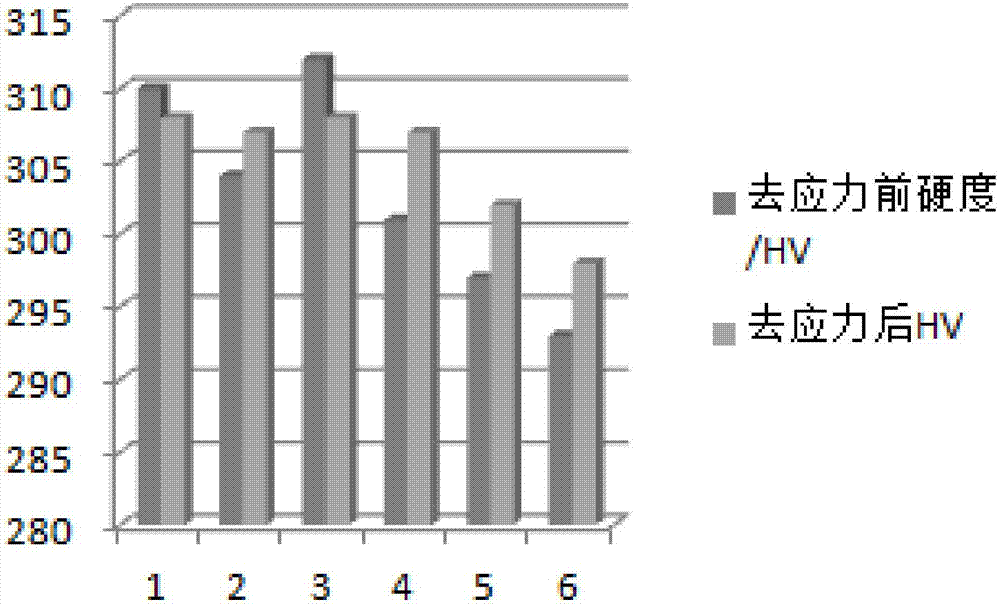

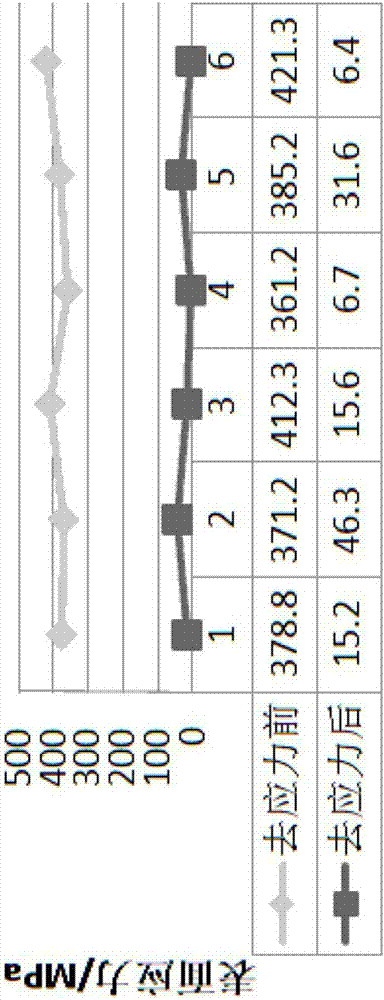

Stress-relief annealing technology for steel bearing retainer

InactiveCN107034344ARelief of residual stressImprove plastic toughnessFurnace typesHeat treatment furnacesTemperature treatmentWarming rate

The invention discloses a stress-relief annealing technology for a steel bearing retainer, and relates to a heat treatment machining method. The stress-relief annealing technology solves the problems that due to the fact that surface stress generated in the machining process of an existing 40CrNiMoA steel bearing retainer is high, the plasticity and toughness of the retainer are poor, the overall strength of the retainer is low and machining precision is also poor. The technology includes the specific steps that (1) ethyl alcohol is used for cleaning the retainer, surface cutting fluid is removed and then the retainer is rubbed clean; and (2) the retainer rubbed clean is put into a vacuum gas hardening furnace, and the vacuum stress-relief annealing technology is set; and the step specifically comprises the contents that warming begins after the vacuum degree reaches 3x10<-4>mbar, the warming rate is 8-20 DEG C / min, constant temperature treatment is conducted when the retainer temperature reaches 550+ / -5 DEG C, the constant temperature time is 120+ / -5min, and then nitrogen is connected in so that the retainer can be discharged out of a furnace after being cooled. The stress-relief annealing technology for the steel bearing retainer is used for stress-relief annealing of the bearing retainer.

Owner:AVIC HARBIN BEARING

Tube sheet component and bottom head component circumferential weld local heat treatment technology

PendingCN107723454ARelief of residual stressStable local heat treatmentFurnace typesHeat treatment furnacesElectrical and Electronics engineeringHeat treating

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

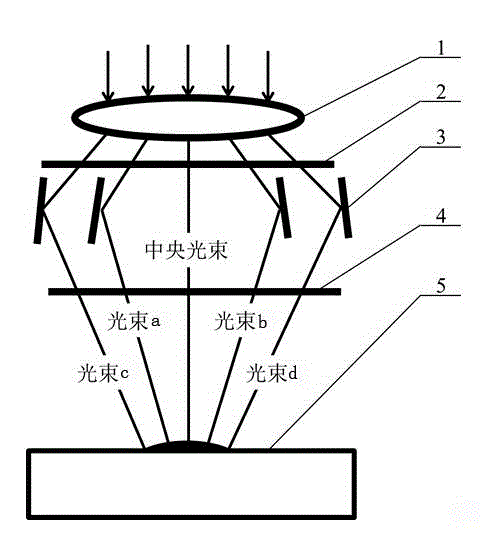

Laser-pulsed magnetism-based welded-pipe welding residual stress relieving method

ActiveCN104131154ARelief of residual stressEliminate welding residual stressProcess efficiency improvementPulsed magnetParticle physics

The invention provides a laser-pulsed magnetism-based welded-pipe welding residual stress relieving method. The laser-pulsed magnetism-based welded-pipe welding residual stress relieving method comprises laser splitting treatment and pulsed magnetism treatment and concretely comprises the following steps of 1, laser treatment: by a spectroscope, carrying out splitting on an original laser beam emitted by a laser, treating the laser beams by a first grating to obtain a central beam, a beam a, b and a beam c, d, and controlling spot sizes and positions of the three beams by a reflector and a second grating, and 2, pulsed magnetism treatment: carrying out pulsed discharging by different types of magnetizers of a pulsed discharging device to obtain a strong pulsed magnet field, and carrying out pulsed magnetism treatment on a welded-pipe welding line by outputting pulsed magnetism having pulsed magnetism treatment parameters by a magnetic read to carry out scanning treatment on the welding line. The method provided by the invention utilizes combination of laser treatment and pulsed magnetism treatment. The laser treatment aims at thermal stress and the pulsed magnetism treatment aims at structural stress and thus surface treatment can be realized by the laser treatment and the inner treatment can be realized by the pulsed magnetism treatment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

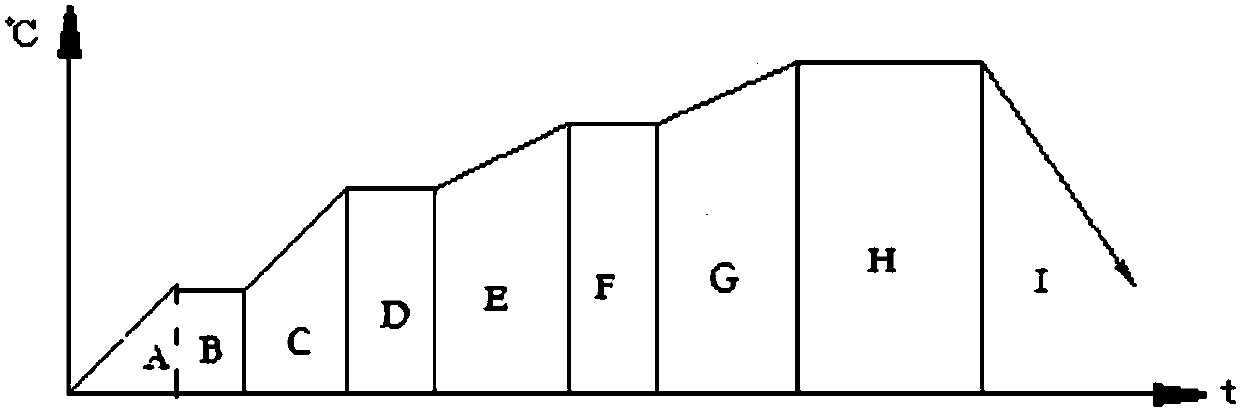

Improvement and heat treatment process of stainless steel 1.4740 material

The invention relates to the technical field of heat treatment, in particular to an improvement and heat treatment process of a stainless steel 1.4740 material. Chemical components of the 1.4740 material are optimized through the process, the residual stress is eliminated, a crushing condition generated when a shell is vibrated is reduced, the structure is uniform, the hardness is controllable, the machining is facilitated, the annealing efficiency is improved, and the cost is reduced; and the stainless steel 1.4740 material comprises the following element contents of, in percentage, 0.3%-0.4%of C, 1%-1.5% of Si, less than or equal to 0.5% of Mn, less than or equal to 0.04% of P, less than or equal to 0.03% of S, 16%-17% of Cr, less than or equal to 0.5% of Ni and less than or equal to 0.5% of Mo. According to the improvement and heat treatment process of the stainless steel 1.4740 material, the to-be-treated stainless steel is subjected to normalizing treatment, the temperature is 850 DEG C-900 DEG C, heat preservation is carried out for 4.5-5.5 hours, the carbon potential in a furnace is 0.18, and when air cooling is directly carried out to 200 DEG C in the furnace, the stainless steel is discharged out of the furnace.

Owner:鹰普(中国)有限公司

Method for brazed connection of DD98M single-crystal high-temperature alloy by Pd-Si composite solder

ActiveCN108188520ARelief of residual stressLess destructiveWelding/cutting media/materialsSoldering mediaActual useSingle crystal

The invention relates to a method for brazed connection of DD98M single-crystal high-temperature alloy by Pd-Si composite solder. The method includes the steps that foil-type Pd and powdered Si with the fixed mass ratio are selected as the Pd-Si composite solder, DD98M, the foil-type Pd and the powdered Si are assembled according to the sequence of DD98M-Pd-Si-Pd-DD98M, and then a product is placed into a vacuum brazing furnace to be heated and brazed; and cooling is carried out after brazing is finished, Pd4Si, a Ni-based solid solution, Al2Pd5 and other structures are formed in soldering seams in the cooling stage, and thus connection of the DD98M single-crystal high-temperature alloy is achieved. By means of the soldering technology, the room-temperature shearing strength of an obtainedjoint is 338 Mpa, the shear strength is 328 Mpa after heat treatment at the high temperature of 700 DEG C for 240h, and actual using requirements are met. By means of the brazing technology, high-quality connection of aero-engine turbine single-crystal blades is achieved, and the method has the advantages that damage to mother materials is small, the joint strength is high, and the joint can be stably used at the high temperature of 700 DEG C; and the aero-engine manufacturing level is improved to a certain extent.

Owner:ZHEJIANG UNIV OF TECH

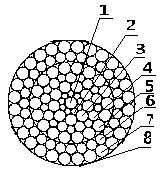

Fatigue resistant steel wire rope and manufacturing method thereof

PendingCN107905007AImprove high corrosion resistanceRelief of residual stressRope making machinesWire ropeAluminium alloy

Owner:GUIZHOU WIRE ROPE

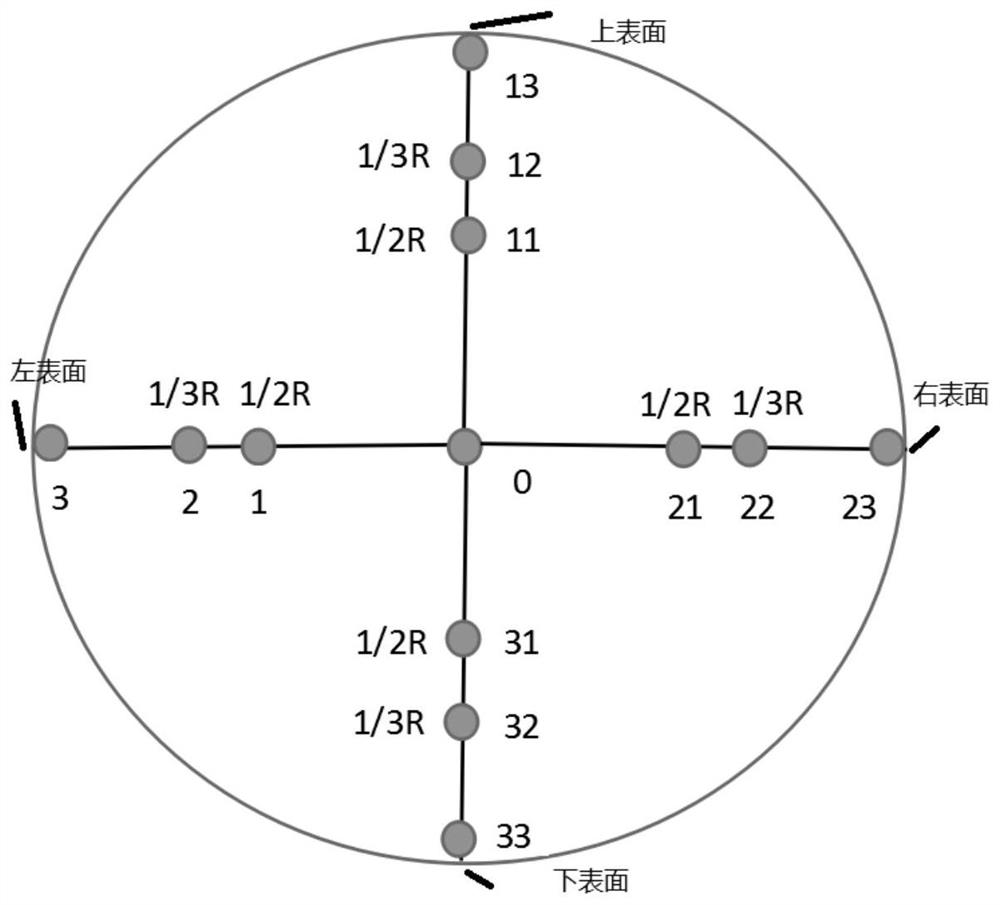

Welding pipe medium-frequency induction heating heat source optimization method

ActiveCN111187884AReduce residual stressRelief of residual stressIncreasing energy efficiencyFurnace typesPhysicsHeating efficiency

The invention relates to a welding pipe medium-frequency induction heating heat source optimization method. A heating method comprises the steps that the axial distance between an inner coil and an outer coil and the motion speed of a pipe blank are obtained; the total heating time is determined according to the axial distance and the motion speed; the outer axial path and the inner axial path areobtained; an outer array of the outer axial path and an inner array of the inner axial path are extracted; the width of a heat source coincidence line is determined according to the inner temperatureand the outer temperature; the width of a welding line fusion line is obtained; and when the heating temperature is too high, the smallest heating area in the moving process is determined according to the width of the welding line fusion line and the width of the heat source coincidence line; and according to the smallest heating area, the pipe blank is heated through corresponding technology parameters, and a welding pipe is prepared. By adoption of a heating device and method, the welding residual stress of the welding pipe welding line area can be reduced, the overburning area in the welding pipe heat treatment process is reduced, and the heating efficiency is improved.

Owner:武汉事达同泰汽车零部件有限公司

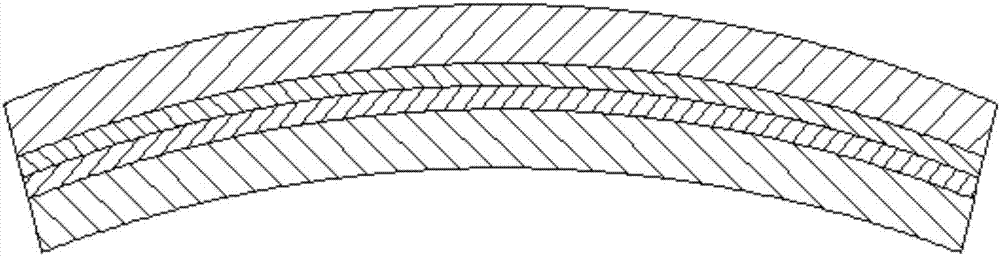

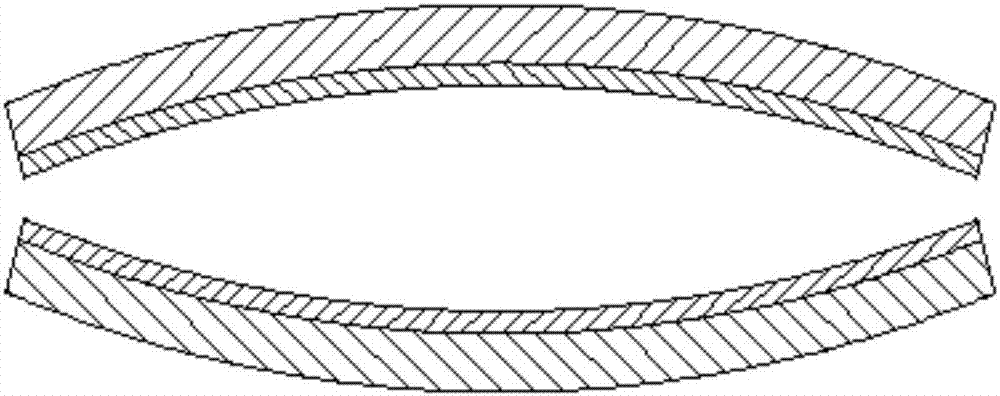

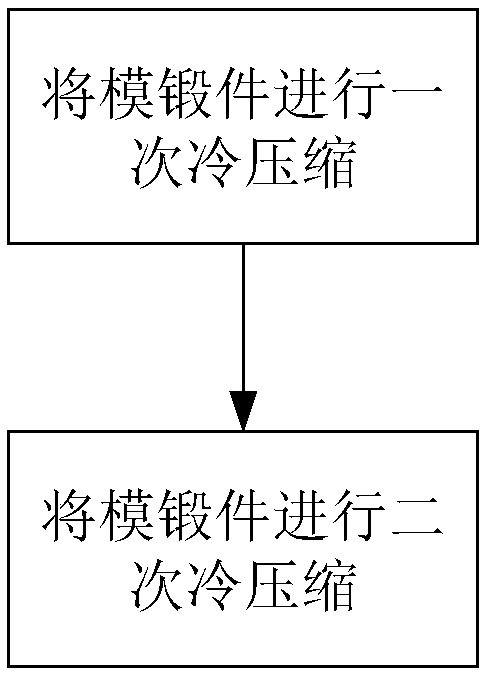

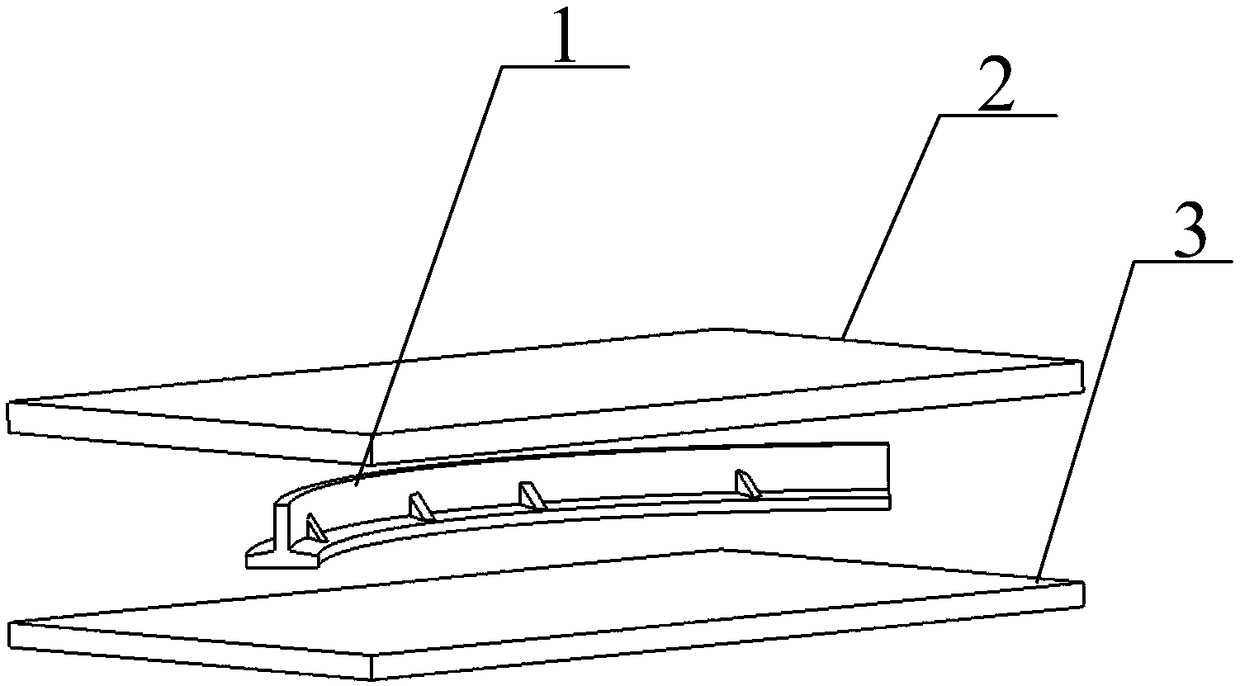

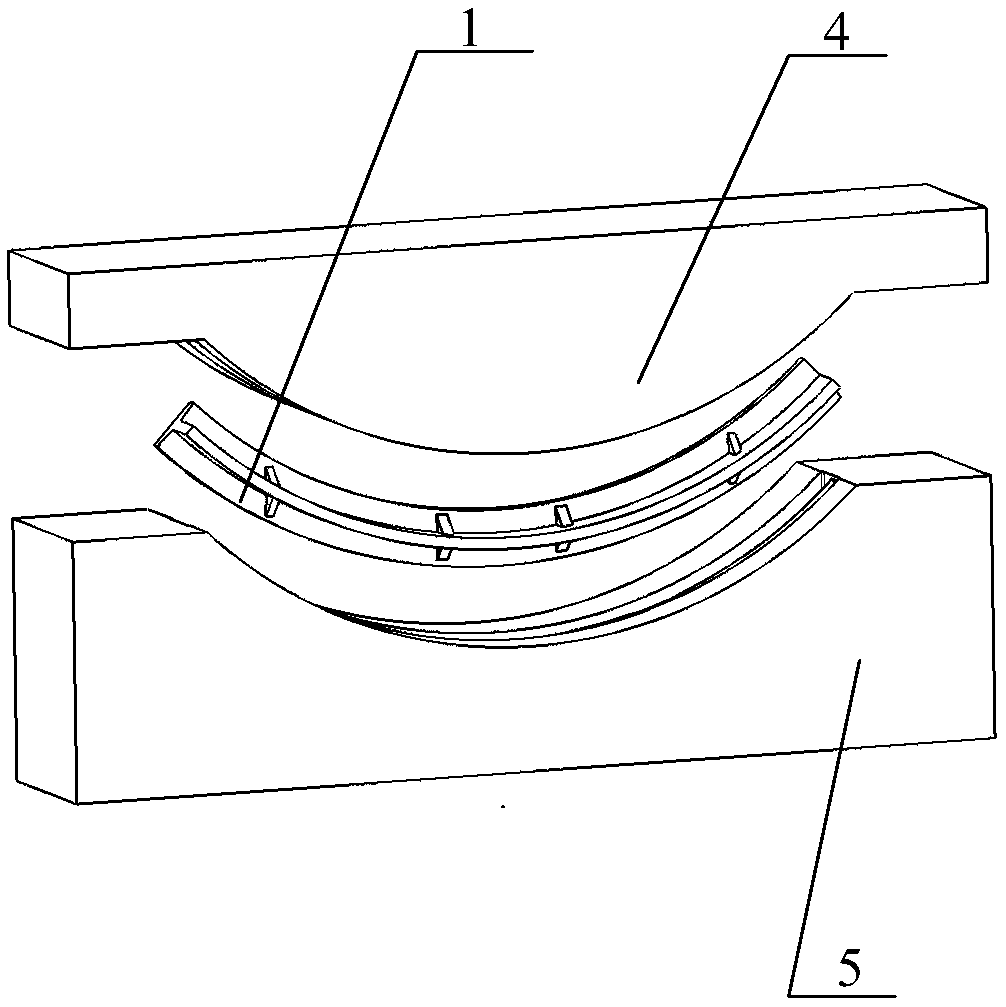

Technological method for removing residual stress of arc-shaped forging

ActiveCN109440033ARelief of residual stressReduce the difficulty of operationForgingMaterials science

The invention discloses a technological method for removing residual stress of an arc-shaped forging. The technological method comprises the step (1) of performing primary cold compression for a die forging; and the step (2) of performing secondary cold compression for the die forging. Through the above technological method, not only can the residual stress of the arc-shaped forging be removed, but also the operation difficulty is low; and the cost is low.

Owner:SOUTHWEST ALUMINUM GRP

Manufacturing method of thin-walled large-diameter pipe with high-pressure copper-nickel alloy for marine engineering

The invention relates to a manufacturing method of a thin-walled large-diameter pipe with high-pressure copper-nickel alloy for marine engineering. The manufacturing method comprises the following steps: (1), performing semi-continuous casting on copper and nickle as raw materials to obtain a copper-nickel alloy solid round billet; (2), performing boring: boring in the center of the copper-nickelalloy solid round billet to obtain an inner hole which can penetrate through the center of the copper-nickel alloy solid round billet in the axial direction; (3), performing reaming: heating a billetmaterial, controlling the outside diameter to be invariable, and reaming the inner hole by 3.5 times to 7 times; (4), performing hot extrusion: carrying out water sealing and extrusion on the billet material into hot extrusion pipe in a way of matching with an extrusion module and extruding a steel pipe in the radial direction and in the axial direction, enabling a discharging end of the extrusionmodule to be directly in abutting joint with a water sealing tank, and directly immersing a pipe billet subjected to hot extrusion molding into water to ensure that the pipe billet is isolated from the air so as to prevent oxidation, removing a surface layer of the pipe billet subjected to hot extrusion, and eliminating surface defects; (5), performing straightening: straightening the pipe billetsubjected to hot extrusion; (6), stretching or cold-rolling the pipe billet in several times until a final specification of the pipe billet is obtained, and carrying out annealing after stretching orcold rolling is performed every time; (7) shaping; and (8) performing formation and thermal treatment.

Owner:江阴和宏精工科技有限公司

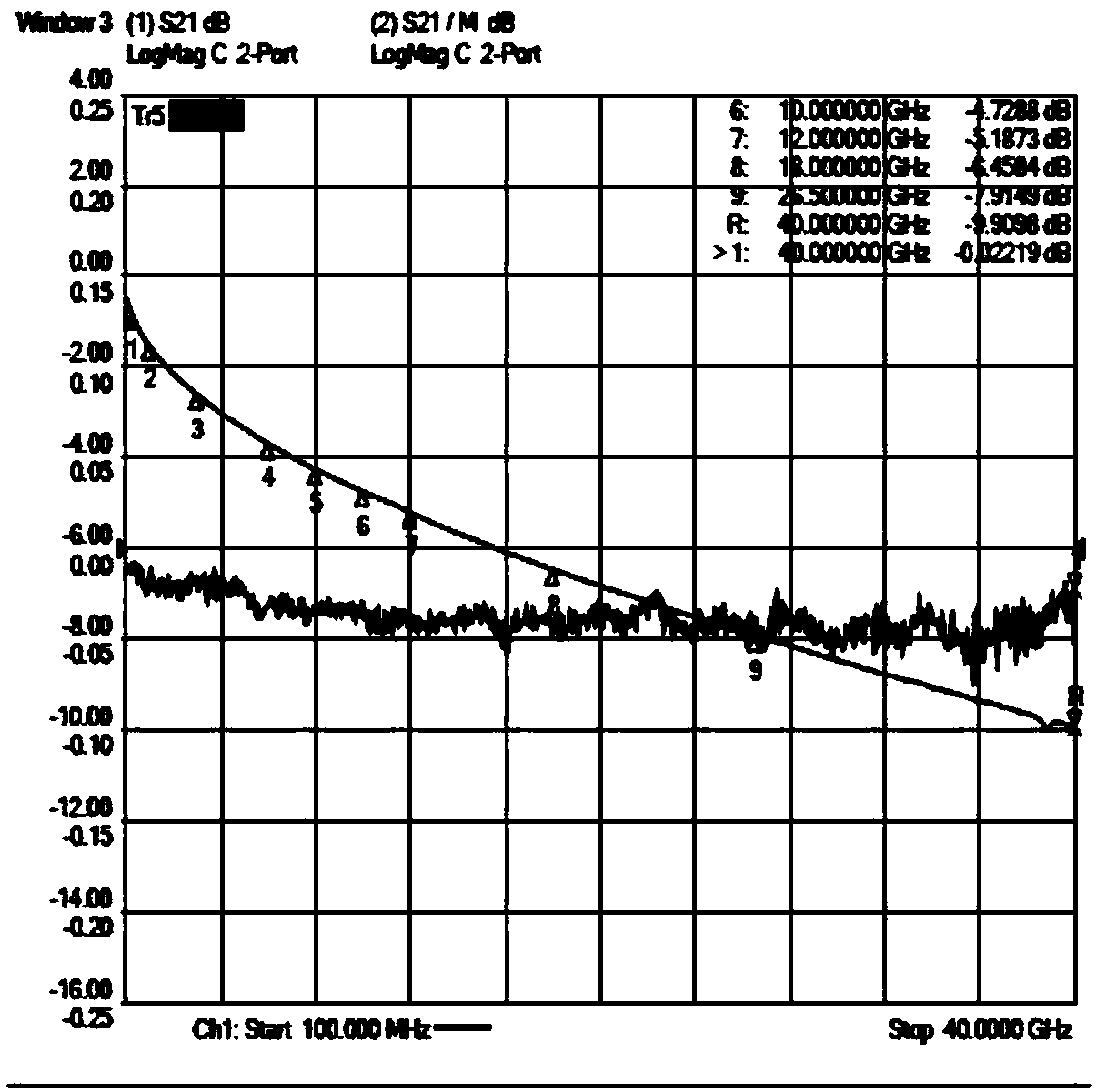

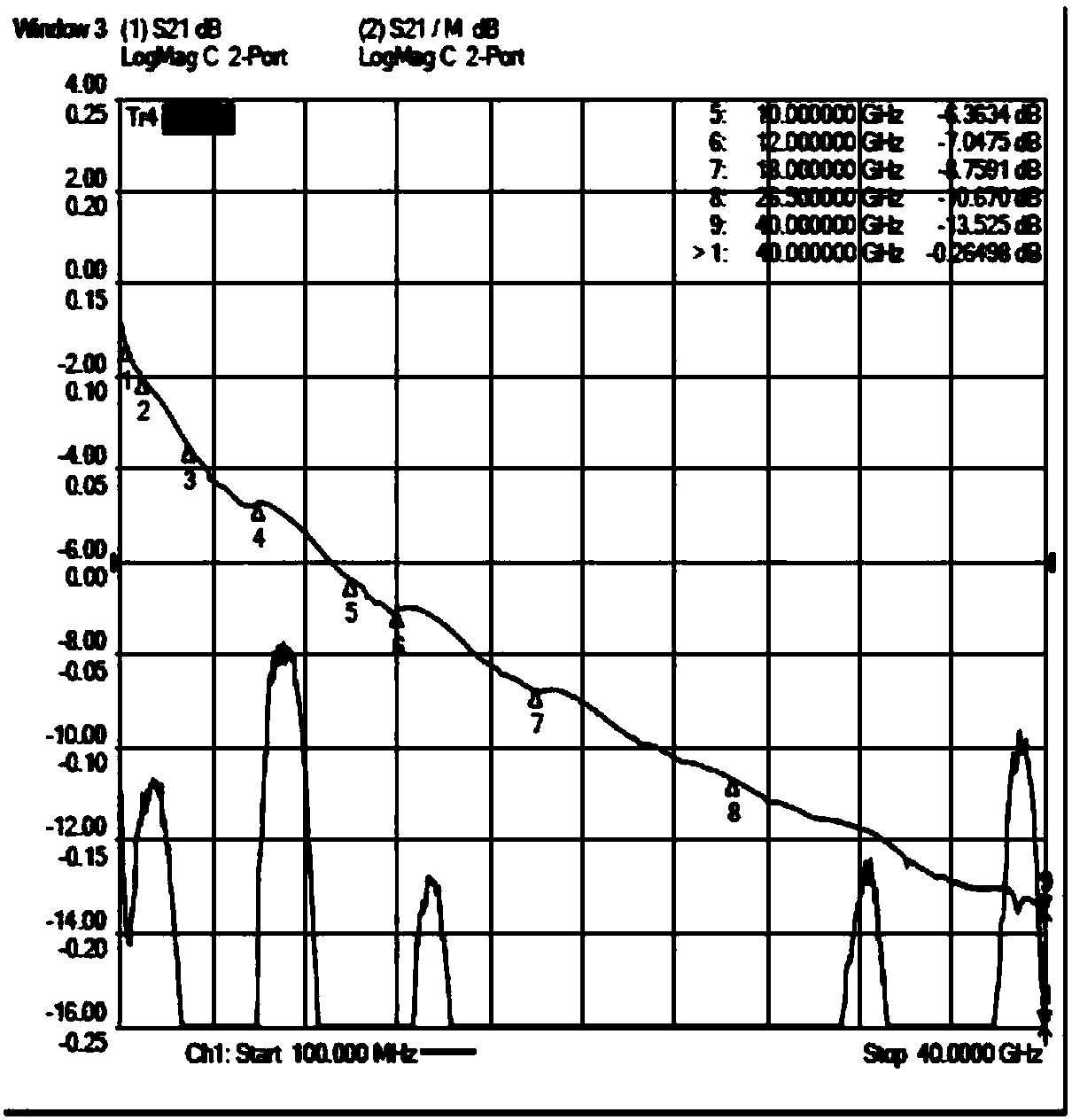

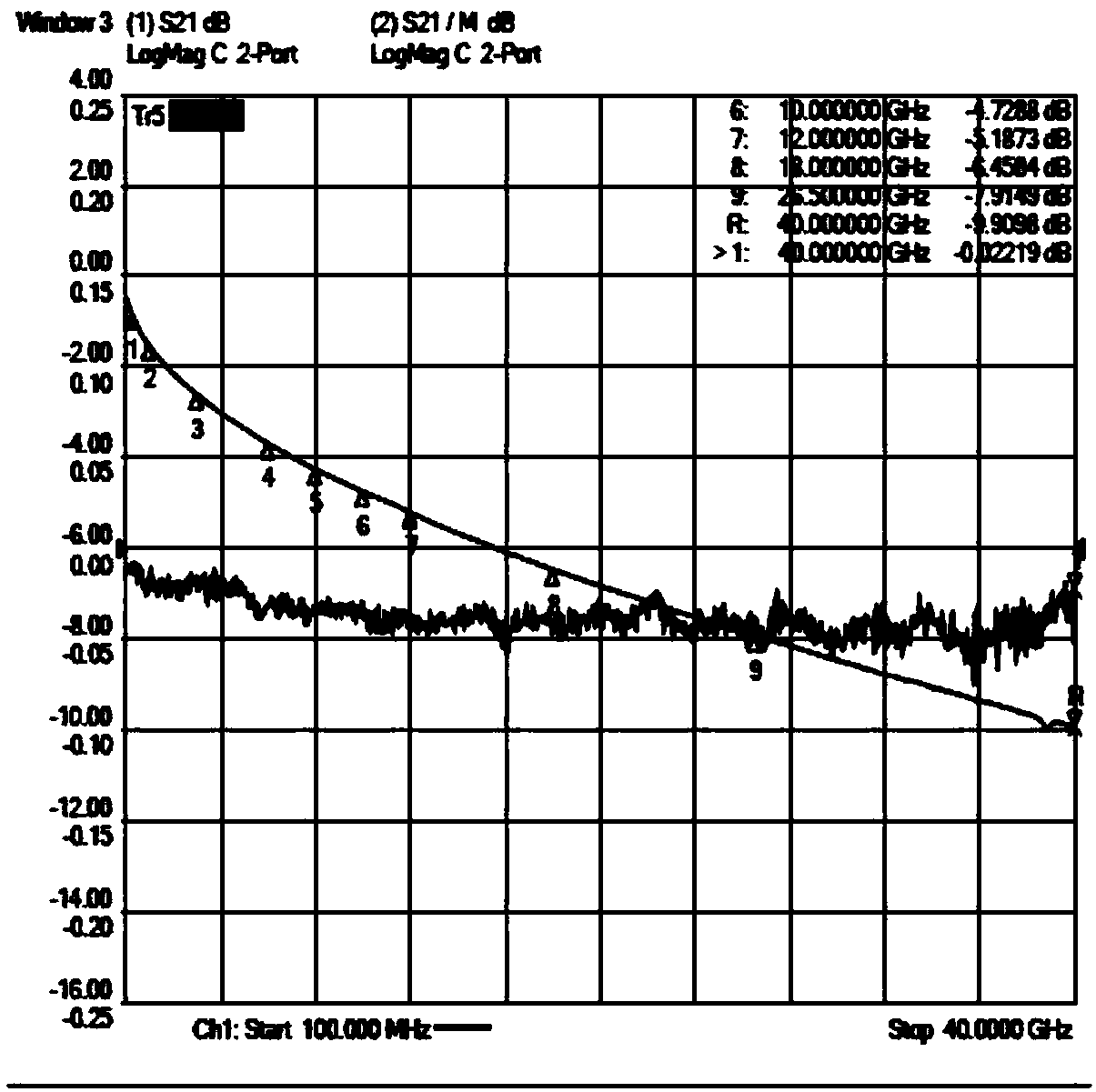

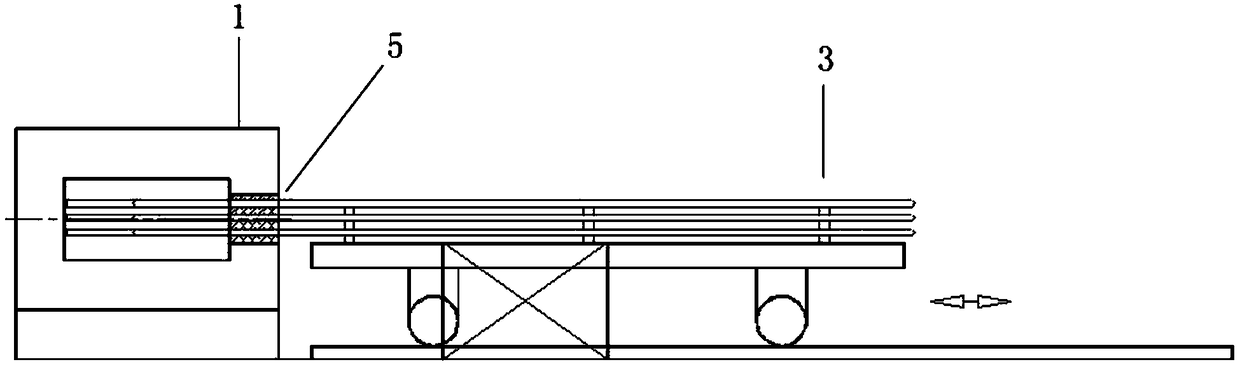

Process treatment method for improving phase-compensated cable amplitude stability

ActiveCN109994284ABoost StabilityRelief of residual stressApparatus for heat treatmentBleed airEngineering

The invention relates to the field of the cable process treatment method, especially a process treatment method for improving phase-compensated cable amplitude stability. The process treatment methodcomprises the following steps: (1) cleaning a phase-compensated cable, and then inversing to an iron plate; (2) placing the phase-compensated cable fallen on the iron plate in a vacuum ageing oven, vacuumizing the vacuum ageing oven, and pumping the atmospheric pressure in the vacuum ageing oven to be -0.1MPa or below; (3) starting the vacuum ageing oven, and baking the phase-compensated cable fallen on the iron plate for 180-300Min at a temperature of 200-240 DEG C; and (4) after the baking is accomplished, bleeding air from the vacuum ageing oven, and adjusting the atmospheric pressure in the vacuum ageing oven to 0MPa; and finally taking out the phase-compensated cable fallen on the iron plate, and naturally cooling. The amplitude stability of the whole product is improved.

Owner:中电航宇(昆山)技术有限公司

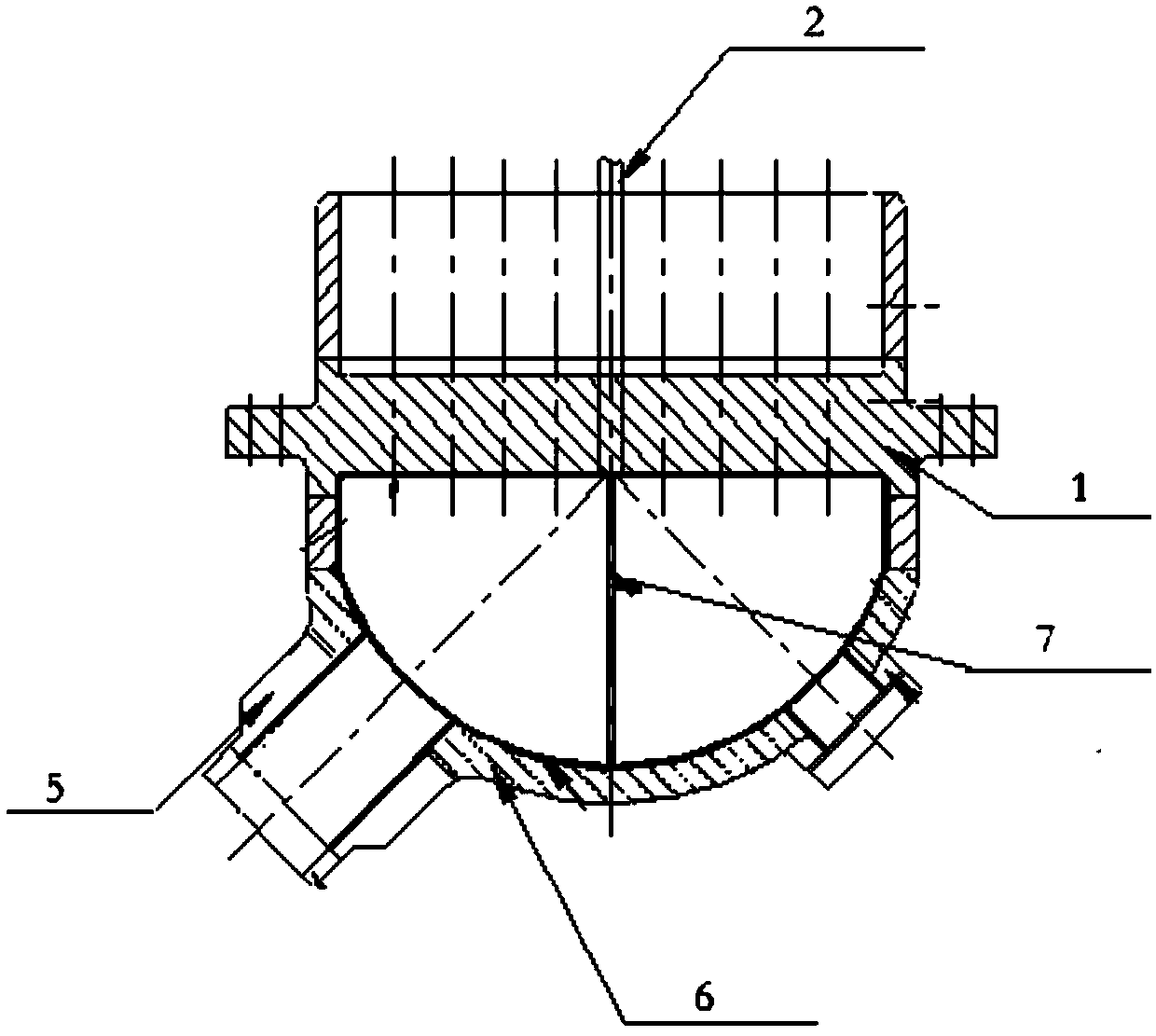

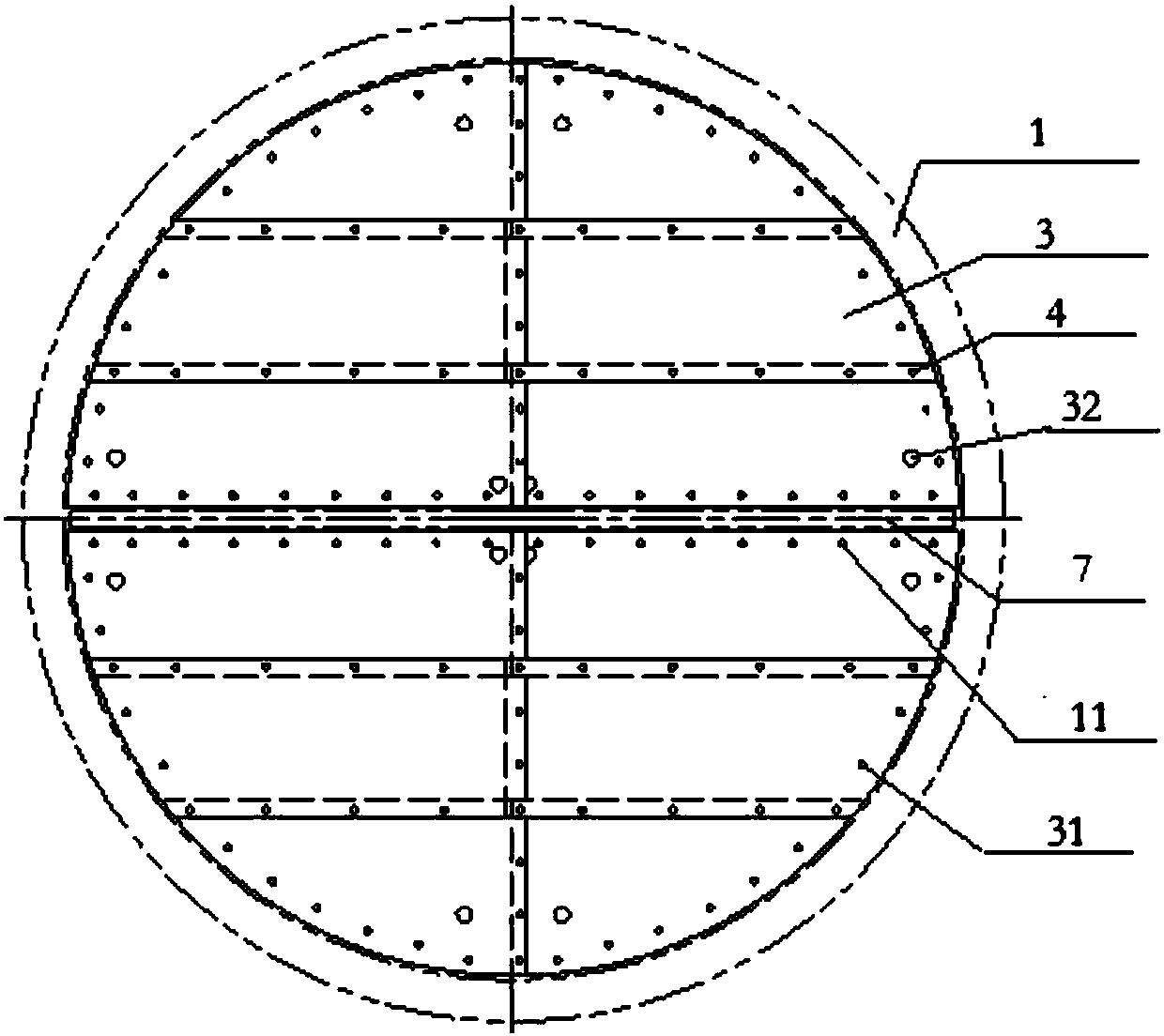

Austenitic stainless steel pipe piece elbow local solid solution treatment method and device

ActiveCN108220572ARelief of residual stressPrevent elbow breakageFurnace typesHeat treatment furnacesAustenitic stainless steelCrystallite

The invention discloses an austenitic stainless steel pipe piece elbow local solid solution treatment method and device. The treatment method is characterized in that a hydraulic manual flatcar is used for feeding a stainless steel pipe piece elbow into an electric heating furnace for heating, homogenizing and heat preservation, the stainless steel pipe piece is quickly far away from the electricheating furnace through the hydraulic manual flatcar after heat preservation, and rapid cooling is achieved through air blowing of a cooling fan. According to the austenitic stainless steel pipe pieceelbow local solid solution treatment method, the deformation temperature and the deformation amount are controlled, so that austenitic stainless steel is uniformly recrystallized, residual stress generated in cold working of a stainless steel pipe is eliminated, and elbow fracture due to stress corrosion and intergranular corrosion is prevented; control is simple, the working procedures are short, and grain refinement efficiency can be greatly improved; and an elbow is continuously bent on one pipe piece, and the elbow on the pip piece is subjected to solid solution treatment at the same time, so that the problems the working amount is large, the flaw detection cost is high and welding deformation is difficult to control due to the fact that the elbow is independently subjected to solid solution and then is welded with the pipe piece are solved.

Owner:HANGZHOU HANGGUO INDUSTRIAL BOILER CO LTD

Method for eliminating residual stress of magnesium alloy deformed processing material

The invention discloses a method for eliminating residual stress of a magnesium alloy deformed processing material. The method comprises the following steps: (1) carrying out multi-stage online quenching treatment on the deformed processing material at an outlet of an extruding machine; (2) carrying out simple pressing and straightening treatment on the part with larger warping degree in the extruded processing material; (3) the deformed processing material is put into a furnace for subzero treatment, the temperature ranges from-150 DEG C to-50 DEG C, the heat preservation time ranges from 4 h to 8 h, and meanwhile an electric pulse energy field is applied to assist heat treatment; (4) ultrasonic impact is carried out on the processed material after heat treatment, the ultrasonic vibration amplitude is 20-50 [mu] m, and the vibration time is 5-20 min; and (5) the processed material is rapidly heated to 80-100 DEG C, heat preservation is conducted for 1-3 hours at the temperature, and then air cooling is conducted to the room temperature. According to the method, the method of subzero treatment, electric pulse auxiliary treatment, ultrasonic vibration and aging coupling is adopted, the residual stress in the rare earth magnesium alloy deformed machined material can be effectively eliminated, and the rare earth magnesium alloy deformed machined material which is more excellent in mechanical property and higher in forming quality is prepared.

Owner:GRIMAT ENG INST CO LTD

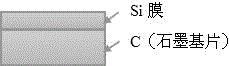

Novel SiC film preparing process

InactiveCN105088174ARelief of residual stressIncreased structural and chemical orderVacuum evaporation coatingSputtering coatingSilicon particleGraphite substrate

The invention discloses a novel SiC film preparing process. The novel SiC film preparing process is characterized in that the process includes the following steps that a resistance-type thermal evaporation device is adopted, silicon particles are evaporated on a graphite substrate, atoms or molecules of the silicon particles can be gasified from the surface under the vacuum condition, a silicon steam flow is formed and enters the graphite substrate with the lower temperature in an incidence manner, and a solid Si film is formed to be annealed in an annealing furnace.

Owner:鞠云

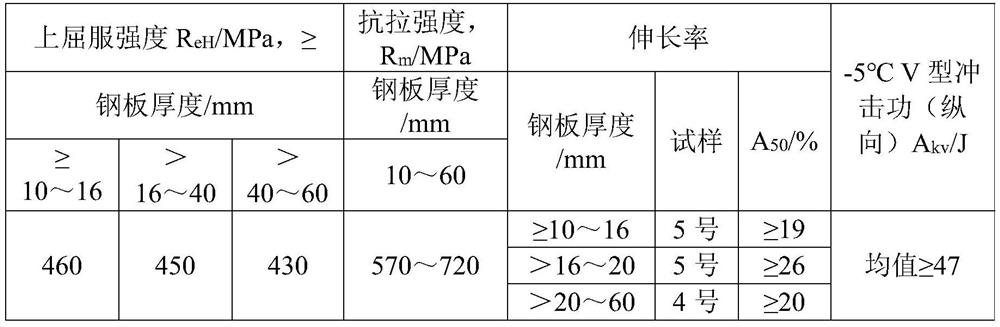

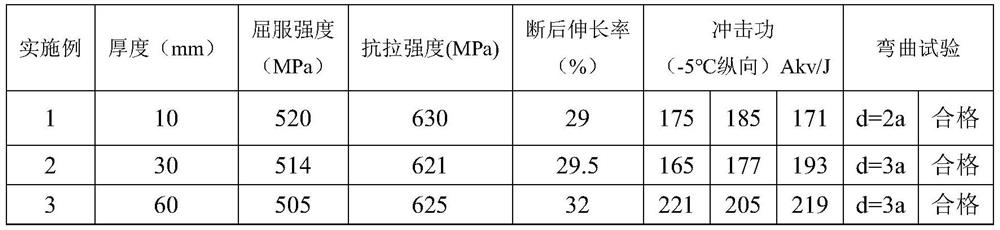

High-strength and high-toughness forklift steel with thickness specification of 10-60 mm and preparation method thereof

The invention provides a high-strength and high-toughness forklift steel with thickness specification of 10-60 mm and a preparation method thereof. The high-strength and high-toughness forklift steel comprises the following chemical components in percentage by weight: larger than or equal to 0.16% and less than or equal to 0.18%of C, larger than or equal to 0.15% and less than or equal to 0.30% of Si, larger than or equal to 1.45% and less than or equal to 1.55% of Mn, larger than or equal to 0 and less than or equal to 0.010% of S, larger than or equal to 0 and less than or equal to 0.018% of P, larger than or equal to 0.025% and less than or equal to 0.045% of Nb, larger than or equal to 0.030% and less than or equal to 0.050% of V, larger than or equal to 0.010% and less than or equal to 0.020% of Ti, larger than or equal to 0.015% and less than or equal to 0.055% of Als and the balance of iron and inevitable impurities, wherein Als is acid-soluble aluminum; the high strength means that the upper yield strength is larger than or equal to 460 MPa, and the tensile strength is 570-720 MPa; and the high toughness means that the longitudinal V-shaped impact energy value at-5 DEG C is larger than or equal to 150J.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Treatment method for eliminating residual stress of stainless steel welding piece

InactiveCN107460282AReduce residual stressRelief of residual stressFurnace typesProcess efficiency improvementWelding residual stressMaterials science

The invention discloses a treatment method for eliminating residual stress of a stainless steel welding piece, and relates to the technical field of welding pieces. The treatment method includes the steps of (1) immersion treatment, (2) quenching treatment, (3) ultrasonication, (4) tempering treatment, and (5) ultrasonication. According to the treatment method for eliminating residual stress of the stainless steel welding piece, after treated stainless steel is welded, the stainless steel welding residual stress can be remarkably reduced, and the service life of the treated stainless steel is prolonged.

Owner:HEFEI ZHENGMING MACHINERY CO LTD

Heat treatment method of automotive body stamping die

InactiveCN105986076ALow tendency to warp and crackRelief of residual stressProcess efficiency improvementQuenchingAutomotive engineering

The invention aims at providing a heat treatment method of an automotive body stamping die. After heat treatment is carried out on the automotive body stamping die by adopting the heat treatment method, the automotive body stamping die is good in surface quality, the rejection rate of an automotive body is low, the service life of the automotive body stamping die is prolonged, and the actual production demand can be met. The adopted technical scheme is as follows: the heat treatment method of the automotive body stamping die comprises the steps of: 1) spheroidizing and annealing: carrying out spheroidizing and annealing on the processed die, wherein the annealing temperature is 700-750 DEG C, and the annealing time is 8-10h; 2) carrying out oil cooling; cooling the die after annealing in coolant oil to room temperature; 3) quenching: quenching the die after air cooling, immersing the die in the oil for quenching, the temperature is 800-960 DEG C, and the time is 2-4 h; 4)tempering: the temperature is 400 DEG C, and the tempering time is 5 h; and 5) carrying out vibration ageing treatment: performing distressing treatment on the die after tempering by a vibration ageing machine with the vibration frequency of 7-11 times each second and exciting force of 40 MPa.

Owner:CHONGQING JUNZHUO MACHINERY

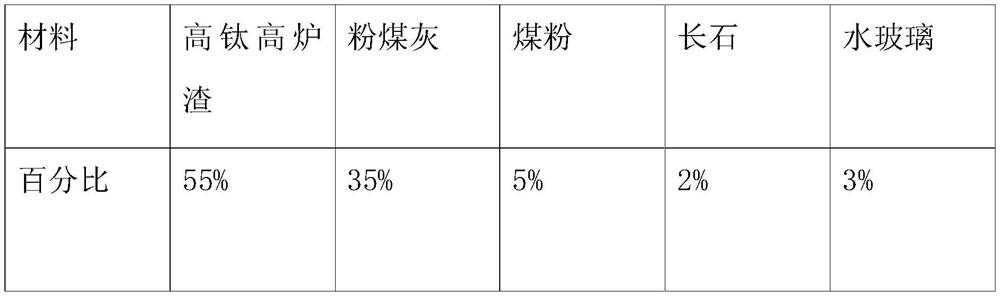

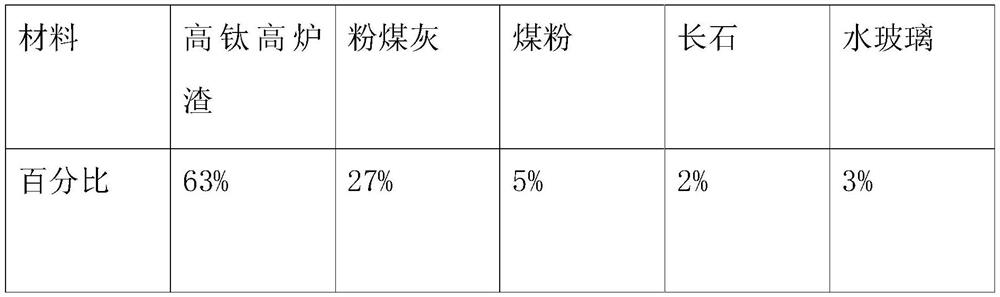

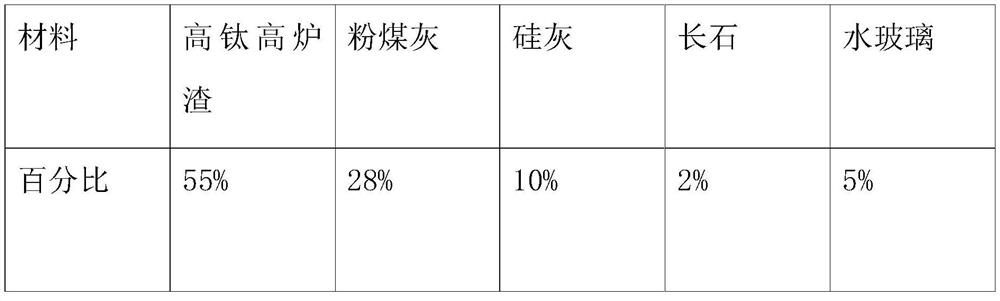

High-titanium blast furnace slag high-strength lightweight aggregate and preparation method thereof

PendingCN113087543AImprove composition and structureRelief of residual stressCeramic materials productionCeramicwareSlagTitanium

The invention discloses a high-titanium blast furnace slag high-strength lightweight aggregate and a preparation method thereof. The high-titanium blast furnace slag high-strength lightweight aggregate is prepared by mixing, by mass, 40%-75% of high-titanium blast furnace slag, 25%-40% of a silicon-aluminum modified component, 3%-8% of an air entraining agent and 2%-12% of a cosolvent. The preparation method comprises the following step of S1, preparing crushed blast furnace slag, a silicon-aluminum modified component, an air entraining agent and a cosolvent. The lightweight aggregate has the beneficial effects that by combining the element composition and structural characteristics of the high-titanium blast furnace slag and optimally designing the mineral composition and structure in the lightweight aggregate finished product, the compressive bearing capacity of the overall structure of the lightweight aggregate is improved, meanwhile, the consumption of the high-titanium blast furnace slag is large, the production process is simple and practical, the comprehensive performance of the obtained lightweight aggregate is remarkably superior to that of ceramsite, the performance requirement of high-strength lightweight aggregate concrete is basically met, and the lightweight aggregate can be used for various large key projects.

Owner:成渝钒钛科技有限公司

Stress relief annealing process of non-quenched and tempered steel for direct cutting

The invention belongs to the technical field of steel heat treatment, and relates to a stress relief annealing process of non-quenched and tempered steel for direct cutting. The process comprises the steps that firstly, the head, the middle and the tail of straightened non-quenched and tempered steel are bundled through packing wires, and then the straightened non-quenched and tempered steel is placed in an annealing furnace; the temperature of the annealing furnace is increased to 450-560 DEG C, and then heat preservation is conducted for 8-20 hours; heating is stopped after the heat preservation time of the annealing furnace is up, and the non-quenched and tempered steel for direct cutting is cooled to 150-300 DEG C along with the furnace; and after cooling, the non-quenched and tempered steel for direct cutting is moved out of the annealing furnace, discharged out of the furnace and cooled to the room temperature. According to the stress relief annealing process of the non-quenched and tempered steel for the direct cutting provided by the invention, the structure and performance of the non-quenched and tempered steel can be improved, residual stress in the machining process is eliminated, new stress is prevented from being generated, the cracking phenomenon is prevented, and the problem that in the prior art, the surface hardness of the non-quenched and tempered steel is high after controlled rolling and controlled cooling and round steel straightening is solved; and meanwhile, the energy consumption and the production cost can be greatly reduced.

Owner:JIANGSU LIANFENG ENERGY EQUIP

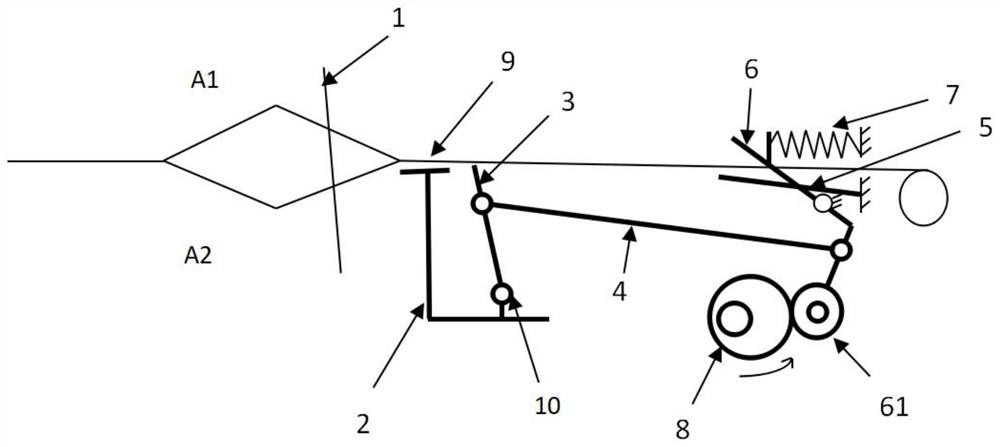

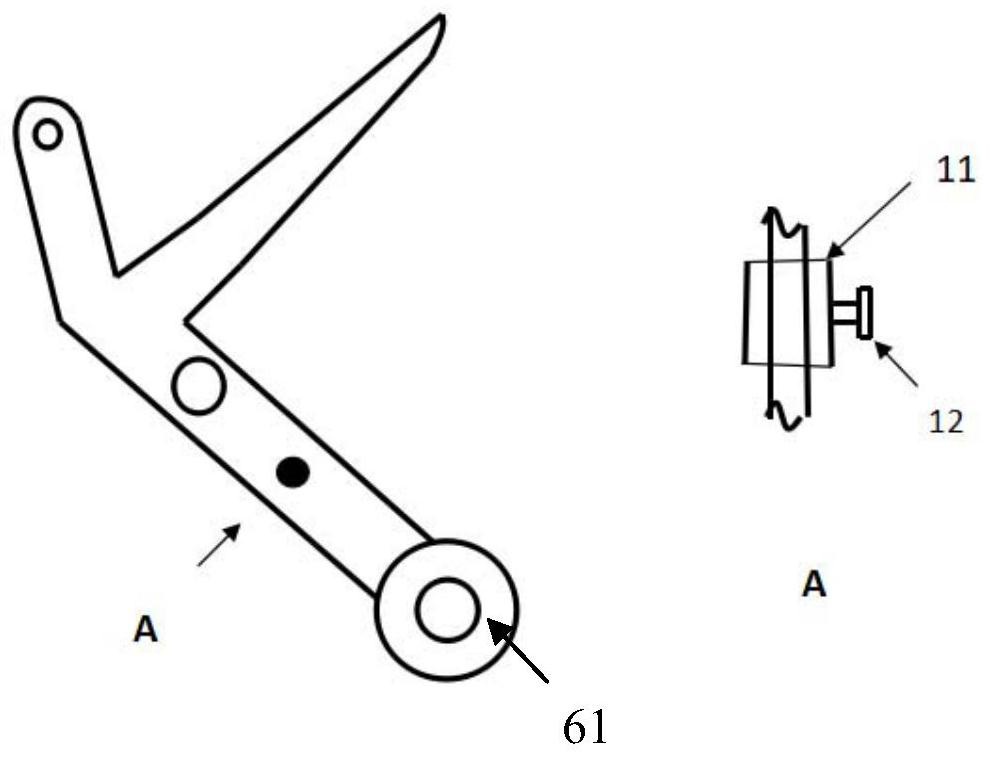

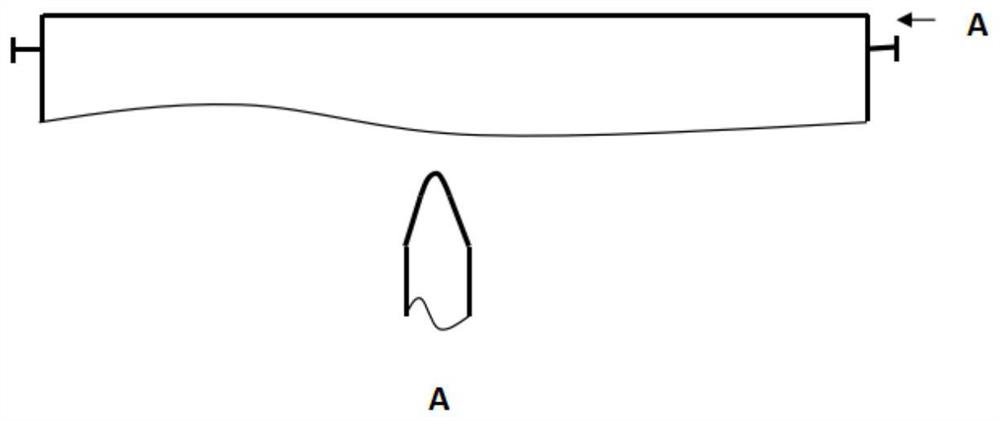

Device for eliminating jacquard embroidery marks and use method thereof

The invention discloses a device for eliminating jacquard embroidery marks. The device is connected between a cloth supporting plate and a winding roller of a jacquard loom and comprises a rocker, a connecting rod, a roller rocker arm and a reset spring, wherein the head of the rocker abuts against gray cloth; the tail of the rocker is hinged to the cloth supporting plate; the middle of the rocker is hinged to one end of the connecting rod; the other end of the connecting rod is hinged to the roller rocker arm; a roller is connected to the tail end of the roller rocker arm and abuts against the winding roller; and the reset spring is connected between the head end of the roller rocker arm and the rack. When the winding roller rotates, the roller rocker arm drives the head of the rocker to swing on the gray cloth in a reciprocating mode; and the light friction effect of swinging the head of the rocker on the gray cloth back and forth can eliminate the residual stress of the edges before and after pattern weaving, and weft yarns return to corresponding normal positions, so that the defects are eliminated and the quality of a cloth cover is greatly improved.

Owner:JIANGSU YUEDA HOME TEXTILE

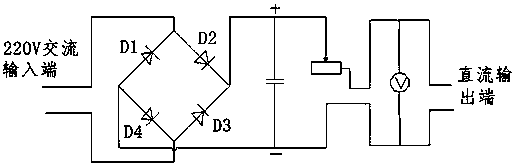

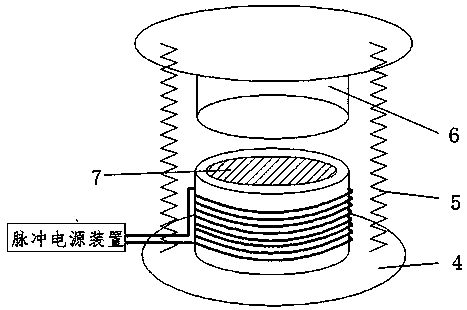

Electromagnetic adsorption resonance vibration device and method

InactiveCN107670947ARelief of residual stressReduce output voltageMechanical vibrations separationTension stressElectromagnetic induction

The invention discloses an electromagnetic adsorption resonance vibration device and a method. The electromagnetic adsorption resonance vibration device comprises a vibration device, a cylindrical shell, an interlayer and an electromagnetic adsorption device II. The electromagnetic adsorption device II comprises an electromagnetic induction device II arranged in the cylindrical shell and a direct-current power supply device connected with the electromagnetic induction device II; the vibration device is arranged above the cylindrical shell; and the interlayer is arranged between the vibration device and the cylindrical shell. The resonance vibration device is adsorbed on workpieces through the electromagnetic adsorption device or is connected with the workpieces through bolts, and differentworkpieces are quantitively applied with a vibration force by adopting the resonance vibration device, so that the aim of eliminating or reducing workpiece weld joint residual tension is achieved. Byadopting the electromagnetic adsorption resonance vibration device and the method provided by the invention, the residual stress can be eliminated after welding by utilizing vibration. An electromagnetic adsorption force, a vibration force, a vibration frequency and an amplitude of the electromagnetic adsorption resonance vibration device can be adjusted. The electromagnetic adsorption resonancevibration device and the method provided by the invention can be applied to eliminate stresses of weld joints of all iron and steel products.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Processing and manufacturing method of cylinder body prepared from alloyed tool steel 5CrNiMn material

The invention discloses a processing and manufacturing method of a cylinder body prepared from an alloyed tool steel 5CrNiMn material and belongs to the technical field of integrated machining. The cylinder body is characterized in that a billet is obtained by forging forming; the billet is subjected to annealing to remove internal stress and subsequently undergoes machining, carbonitriding, deposition treatment and shot peening strengthening; multiple times of upsetting are performed in the forging process of a cylinder body blank, so that the tearing of a forge piece is avoided, structures become uniform and crystal grains are refined; upset billets are formed on an upset place, so that metal is reasonably distributed and is well fully fills a die cavity; the cylinder body is machined by turning, boring and honing; in the processing process, trace atomized tiny water droplet cutting fluid is fed to a cutting zone through low-temperature cold air for cooling and lubricating, so that the outflow direction of a rotary tool is identical with that of cutting chips, the circumferential speed of a cutting edge is greater than the outflow speed of the cutting chips, and further the formation of mechanical tumors is avoided; and then surface treatment and deposition treatment are performed on an engine cylinder body. The cylinder body processed by the manufacturing method is high in wear resistance and long in service life; in addition, the precision accords with standards; and meanwhile, the hardness and bending strength of cylinder body surface are also improved.

Owner:WUXI QIAOYANG MACHINERY MFG

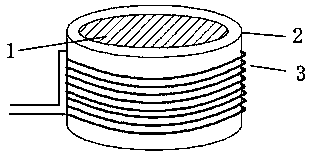

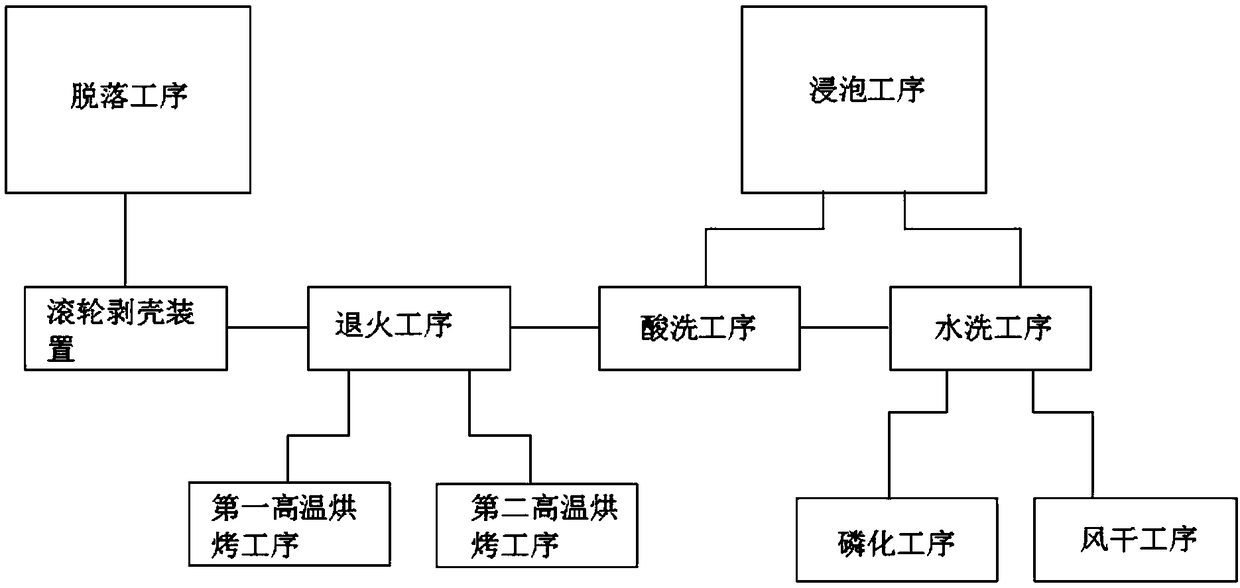

Copper pillar and copper wire oxide layer shelling processing technology

InactiveCN109055950ARelief of residual stressDimensionally stableCleaning using toolsCopper wireOxide

The invention provides a copper pillar and copper wire oxide layer shelling processing technology comprising a copper body, a soaking process and a falling process. The soaking process comprises an acid pickling process and a water washing process, the falling process is characterized in that a roller shelling device is used for shelling of the copper body, the roller shelling device is internallyprovided with a rotating shaft, the two ends of the rotating shaft are correspondingly connected with a first roller and a second roller, the copper body is placed at the position, between the firstroller and the second roller, in the roller shelling device for rolling shelling, the copper body obtained after shelling is subjected to an annealing process, the copper body obtained after the annealing process is placed in an acid pickling tank to be subjected to the acid pickling process, and the copper body obtained after the acid pickling process is placed inside a water washing tank to be subjected to the water washing process. The copper pillar and copper wire oxide layer shelling processing technology effectively solves the problem that a copper material for existing copper pillars, copper wires and the like is difficult to be subjected to the oxide layer treatment process in the recycling process, the processes are complicated and hard, and the copper material is damaged during the oxide layer shelling process.

Owner:鹰潭瑞鑫铜业有限公司

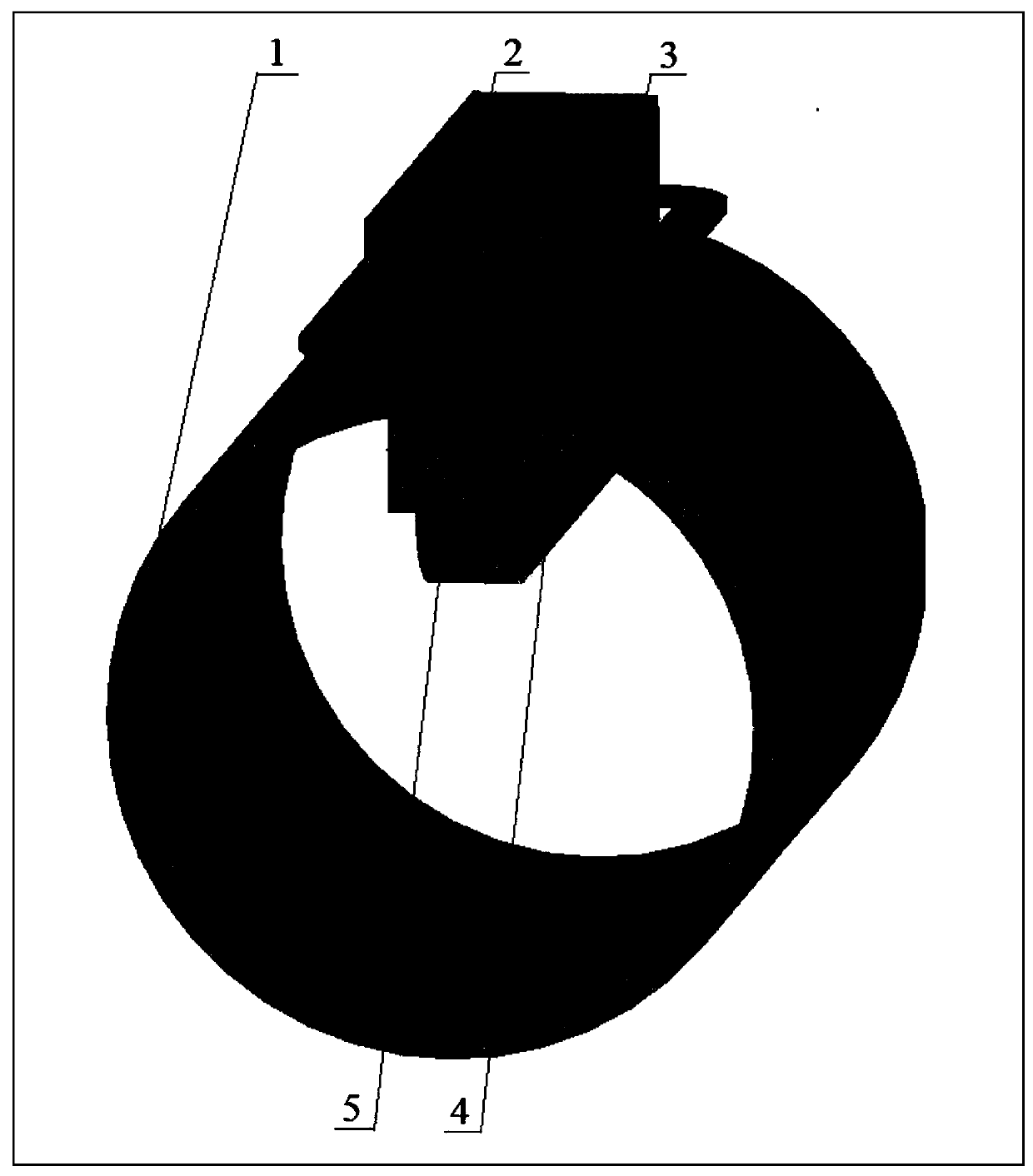

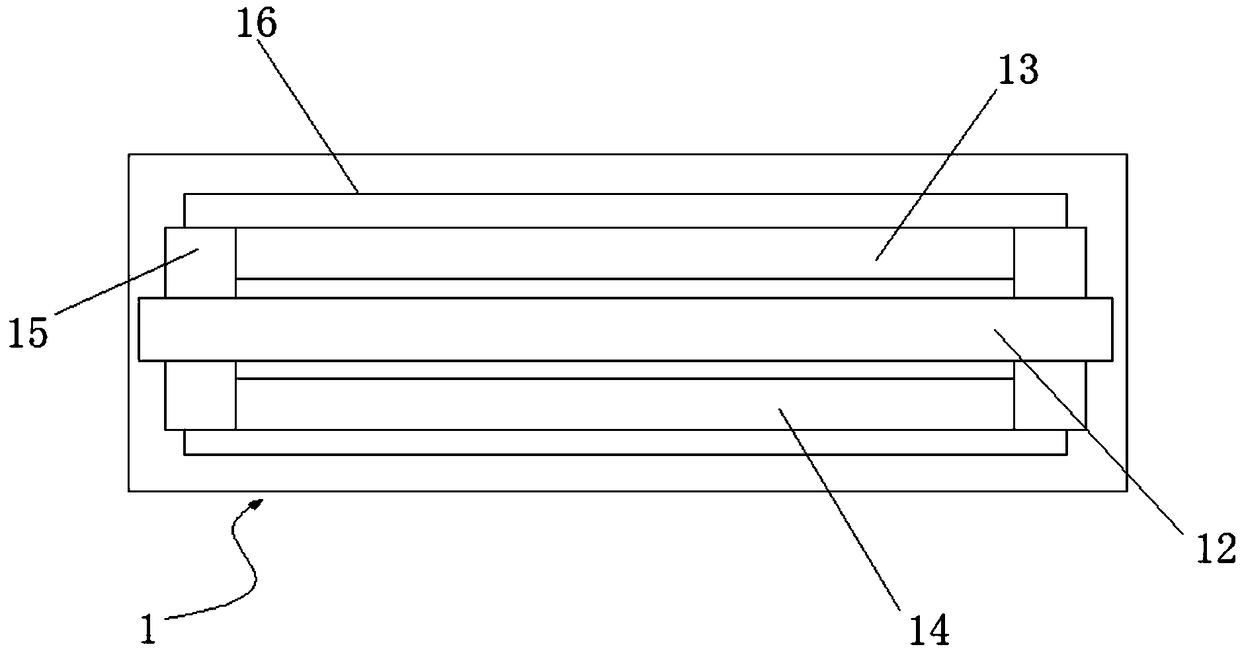

Device and method for eliminating, regulating and controlling residual stress of alloy ring piece

ActiveCN114309231AUniform plastic deformationRelief of residual stressProcess efficiency improvementPhysicsEngineering

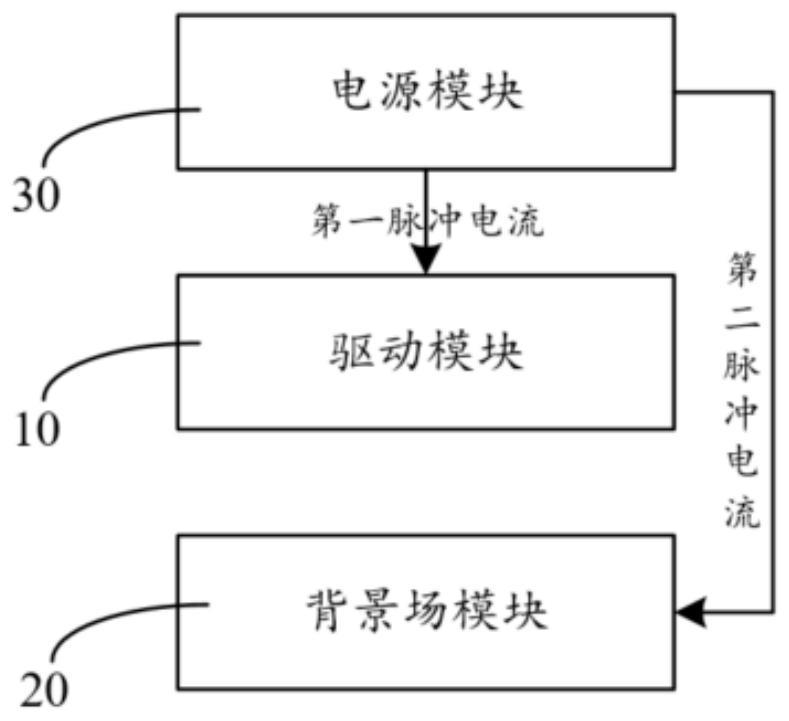

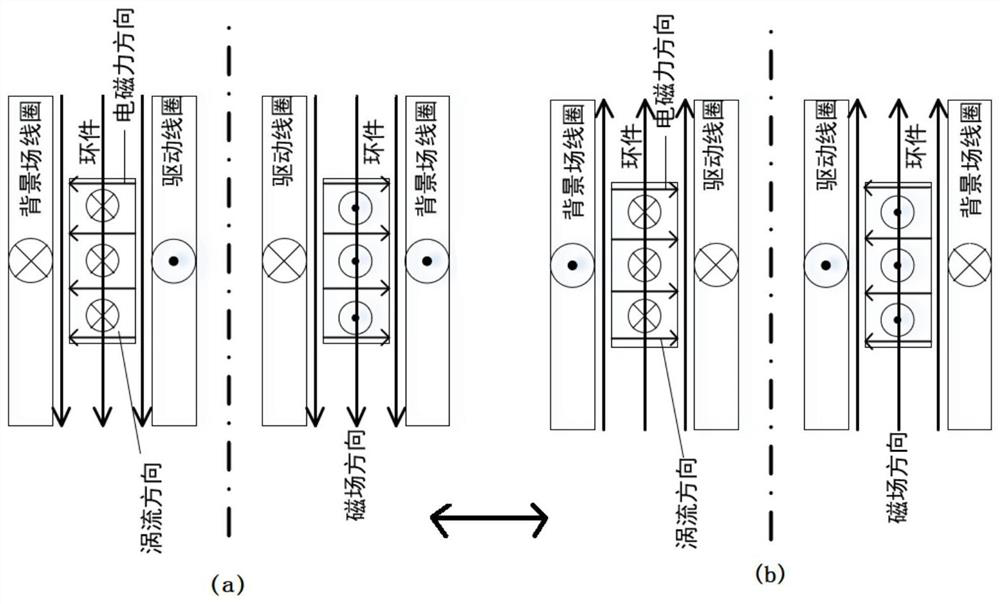

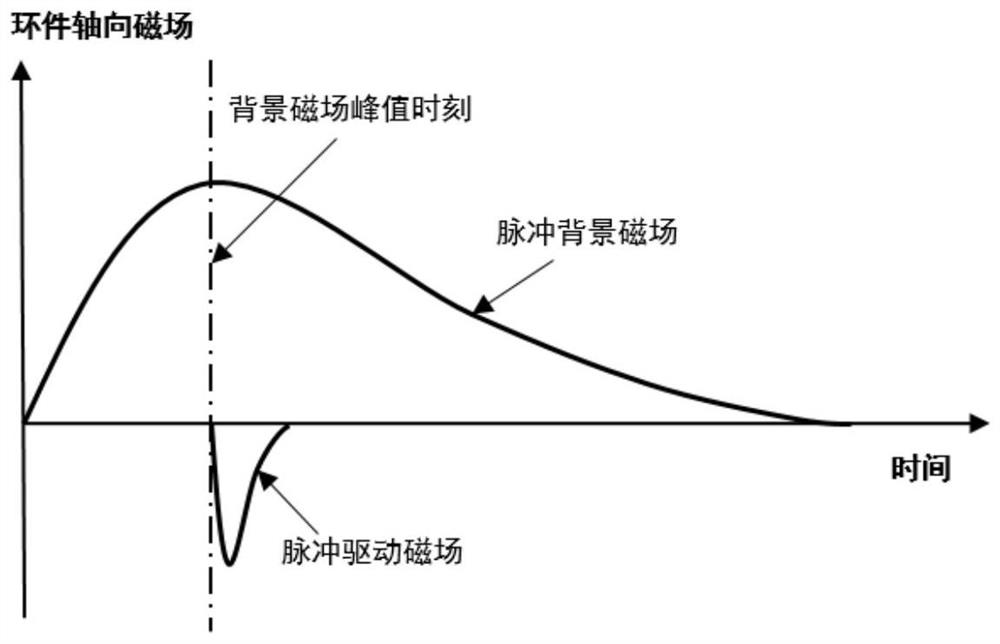

The invention discloses a device and a method for eliminating, regulating and controlling residual stress of an alloy ring piece. The device comprises a driving module which comprises a driving coil electrified with first pulse current and is used for generating an axial pulse driving magnetic field in an alloy ring piece and inducing eddy current, so that the ring piece generates electromagnetic force deformed in the radial direction under the interaction of the pulse driving magnetic field and the eddy current; the background field module comprises a background field coil electrified with second pulse current and is used for generating a background magnetic field in the same direction as the pulse driving magnetic field in the ring piece, and the pulse width of the background magnetic field is more than 10 times that of the pulse driving magnetic field; and the power supply module is used for providing a first pulse current and a second pulse current, and is used for interchanging the functions of the driving module and the background field module, so that the ring piece generates multiple times of oscillation deformation in the radial direction. According to the invention, the deformation of the ring piece is more uniform, the residual stress is better eliminated, regulated and controlled, the electromagnetic force can be effectively improved, and the design difficulty of the coil is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com