Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Uniform plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cerium lanthanum containing high-strength anti-corrosion die-casting magnesium alloy

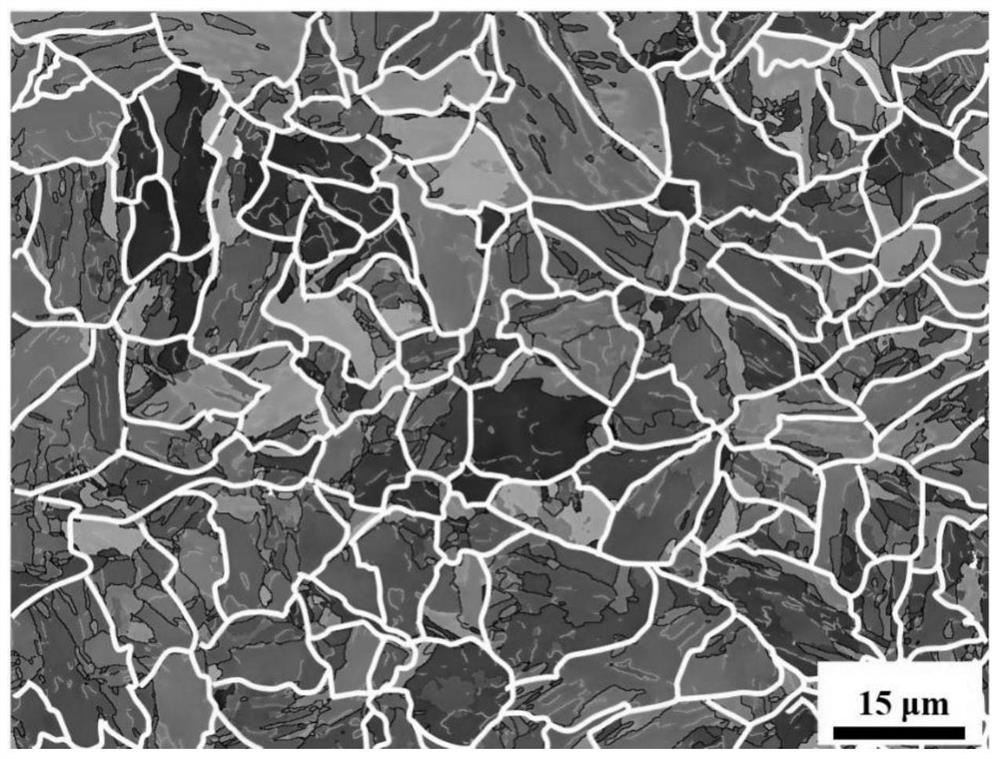

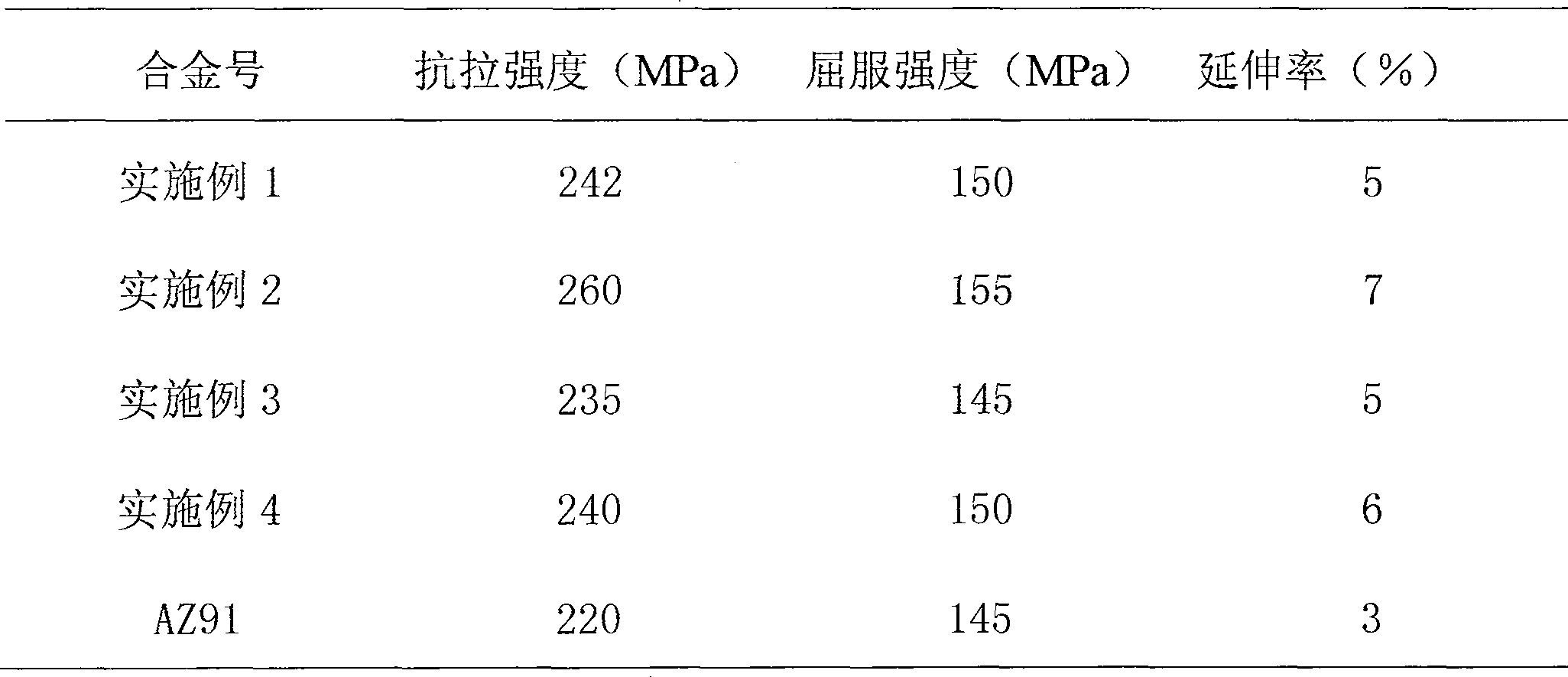

The invention relates to cerium lanthanum high-strength corrosion resistant die casting magnesium alloy and is characterized in that the components and the weight percentage of the alloy are provided as follows: 8.5 to 9.5 percent of Al, 0.4 to 0.9 percent of Zn, 0.2 to 0.6 percent of Mn, 0.01 to 1.5 percent of rare earth Ce, 0.01 to 1.5 percent of La, and impure elements of less than or equal to 0.02 percent of Fe, less than or equal to 0.002 percent of Cu, less than or equal to 0.01 percent of Si, less than or equal to 0.001percent of Ni and the allowance is magnesium. The used alloying materials are cerium lanthanum rare earths which are left after separating Nd and Pr from ordinary cerium-rich mischmetals; at present, the rare earth materials are in a position of cheapness and large overstock in the market. The cerium lanthanum high-strength corrosion resistant die casting magnesium alloy avoids the waste of the rare earth resources; the mechanical properties and plasticity of the alloy are both better than AZ91 alloy and the corrosion resistance can be improved by a plurality of times or dozens of times.

Owner:白山市天安金属镁矿业有限公司

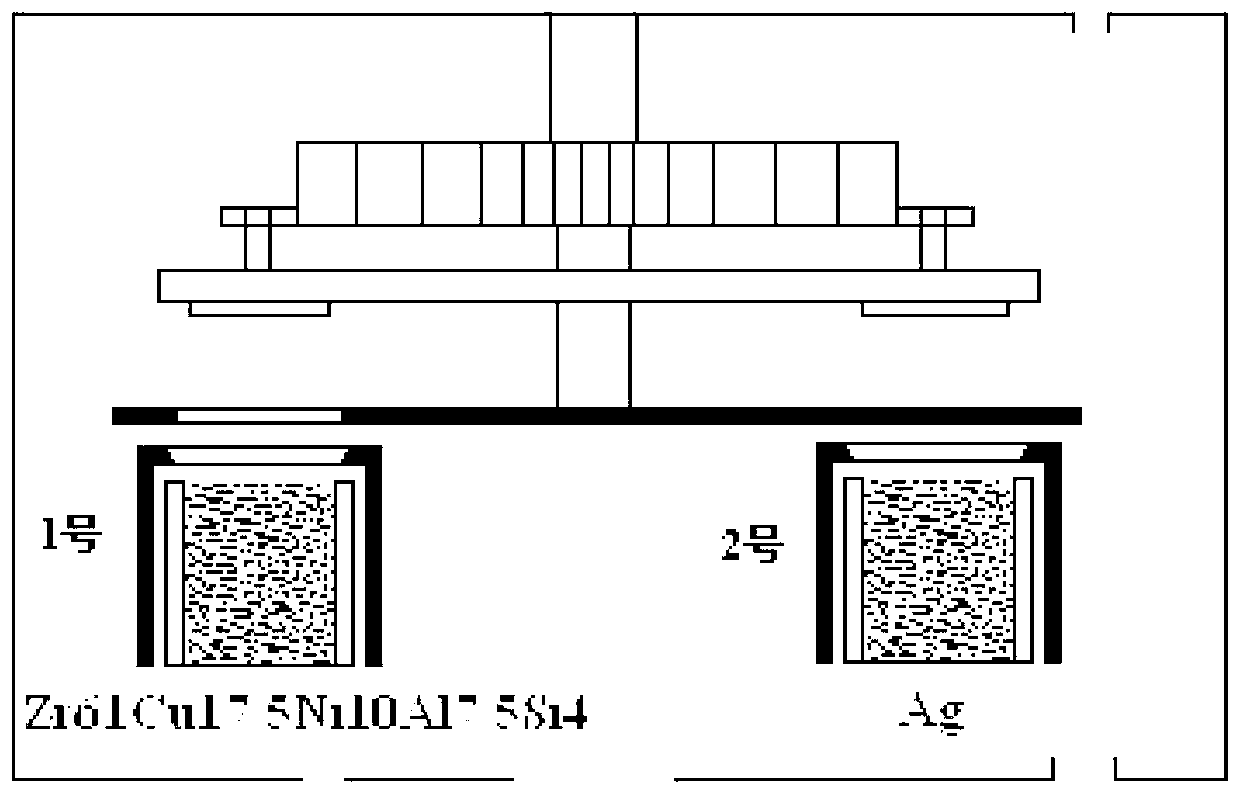

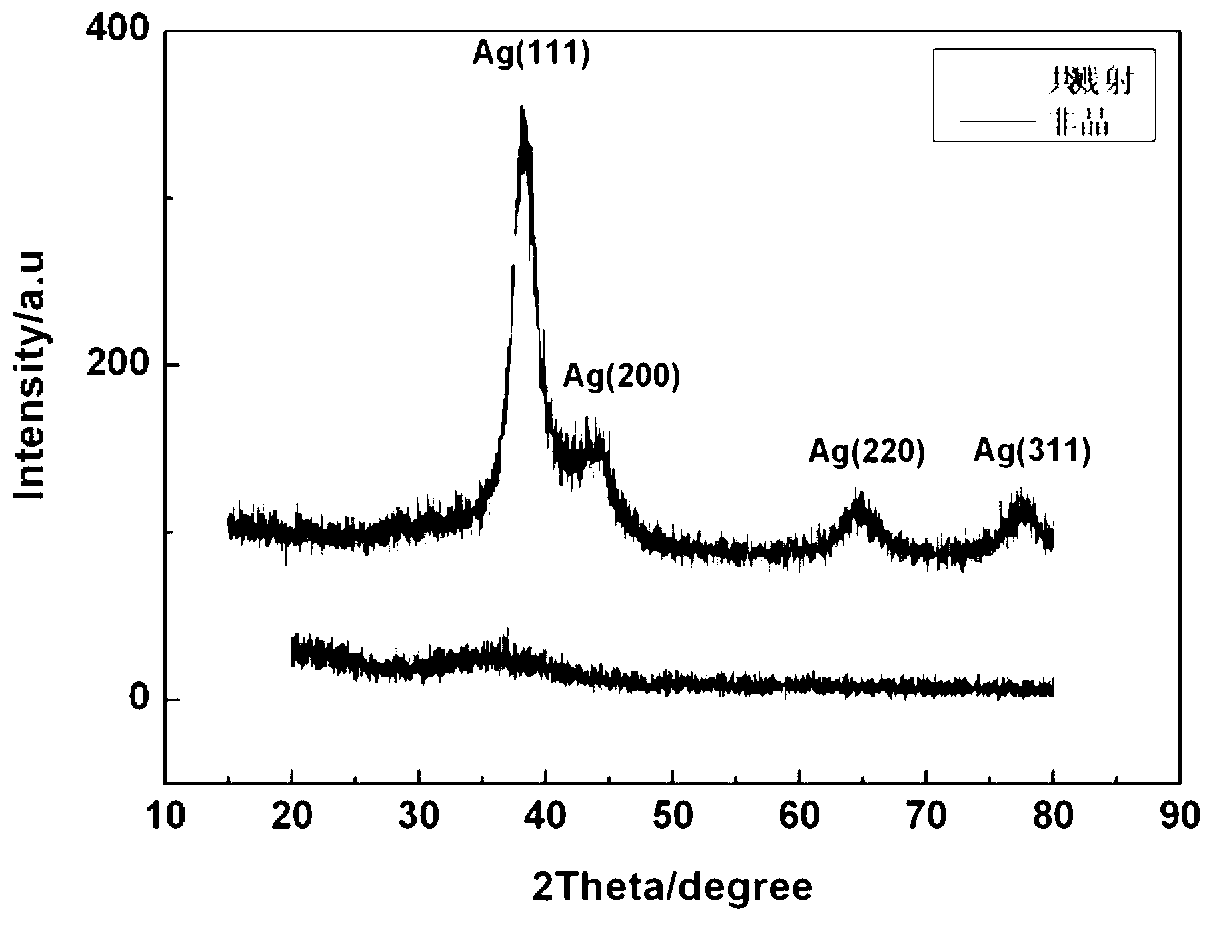

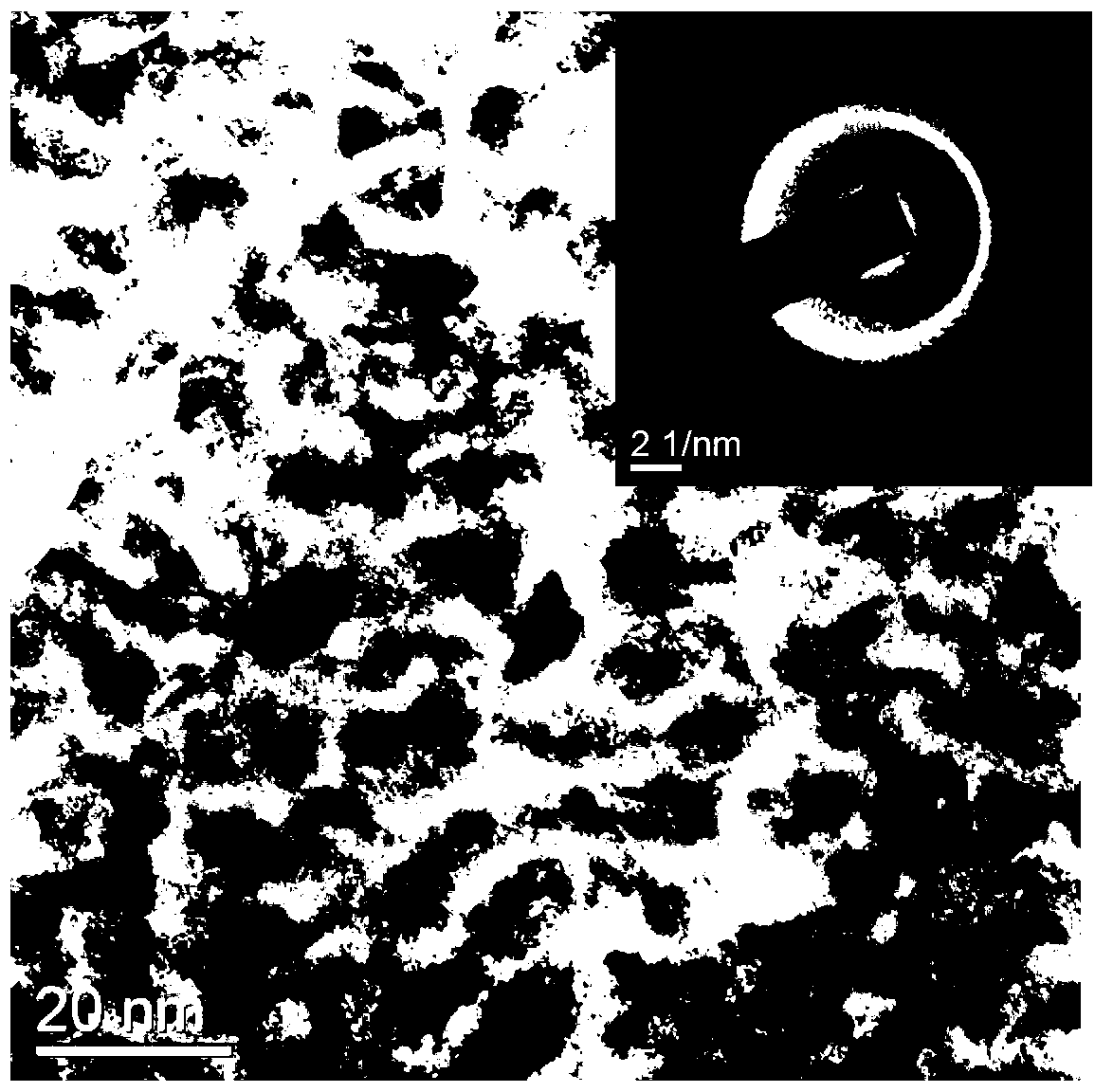

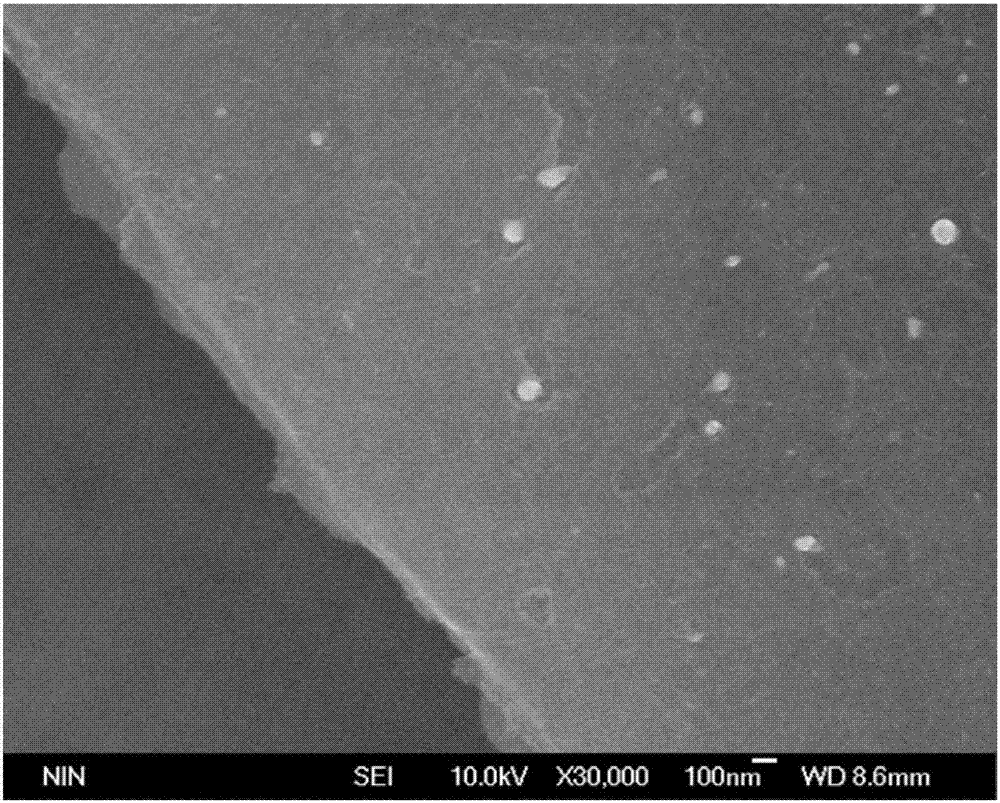

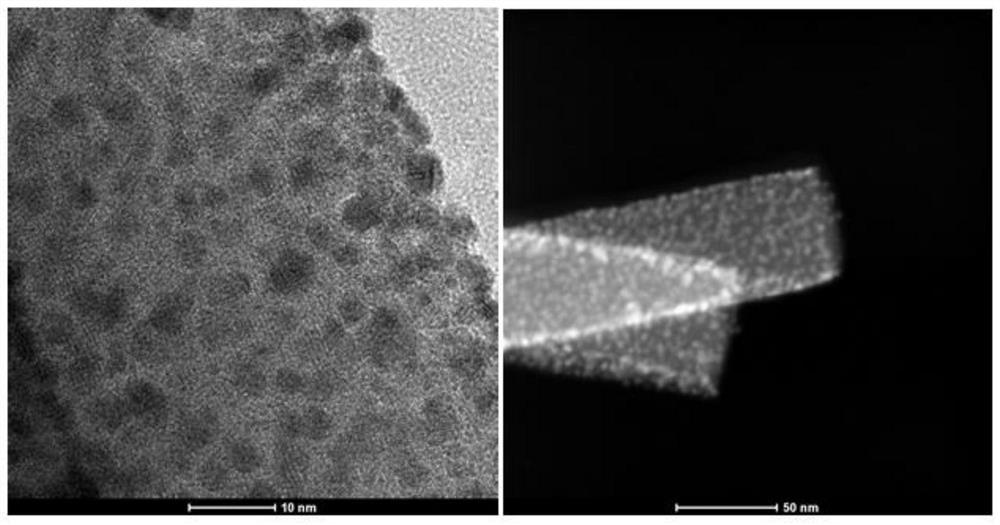

Method for preparing noncrystalline-nanocrystalline composite membrane by adopting co-sputtering method

InactiveCN103215555AAvoid secondary processingEasy to controlVacuum evaporation coatingSputtering coatingSputteringCreep strain

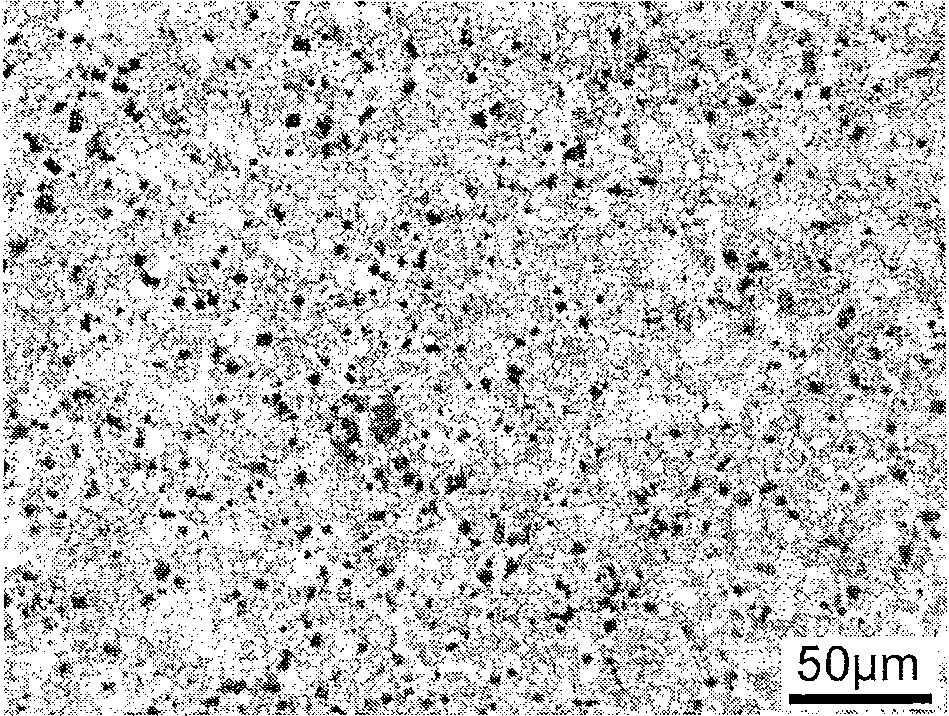

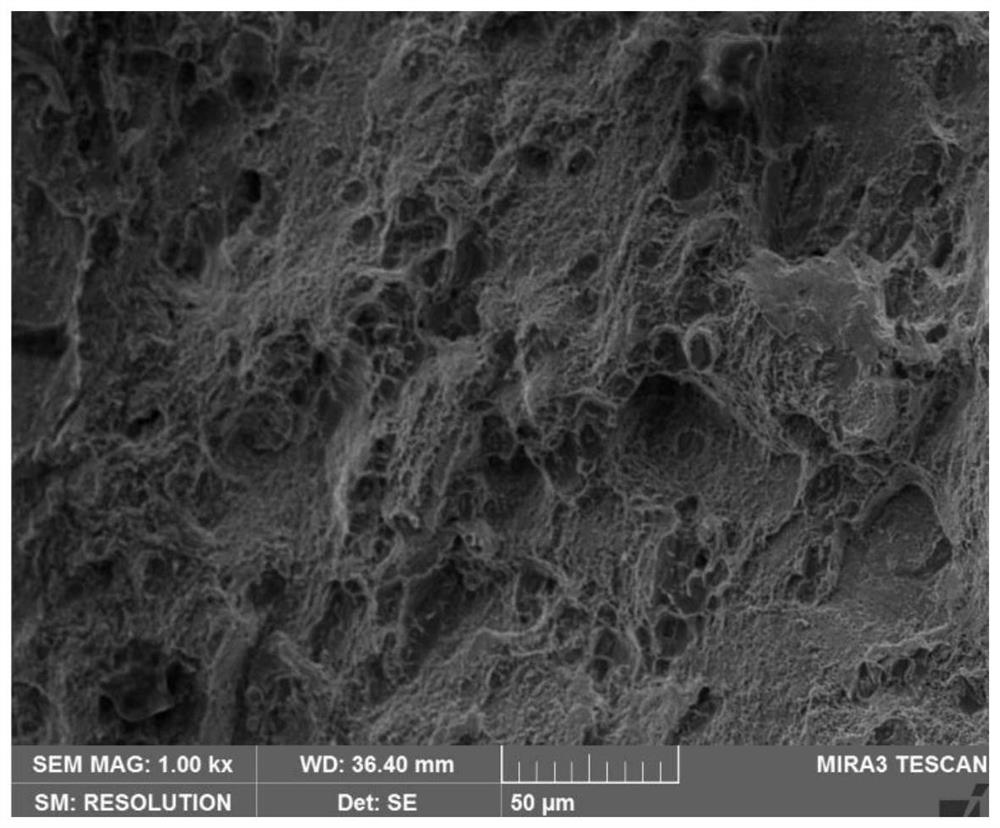

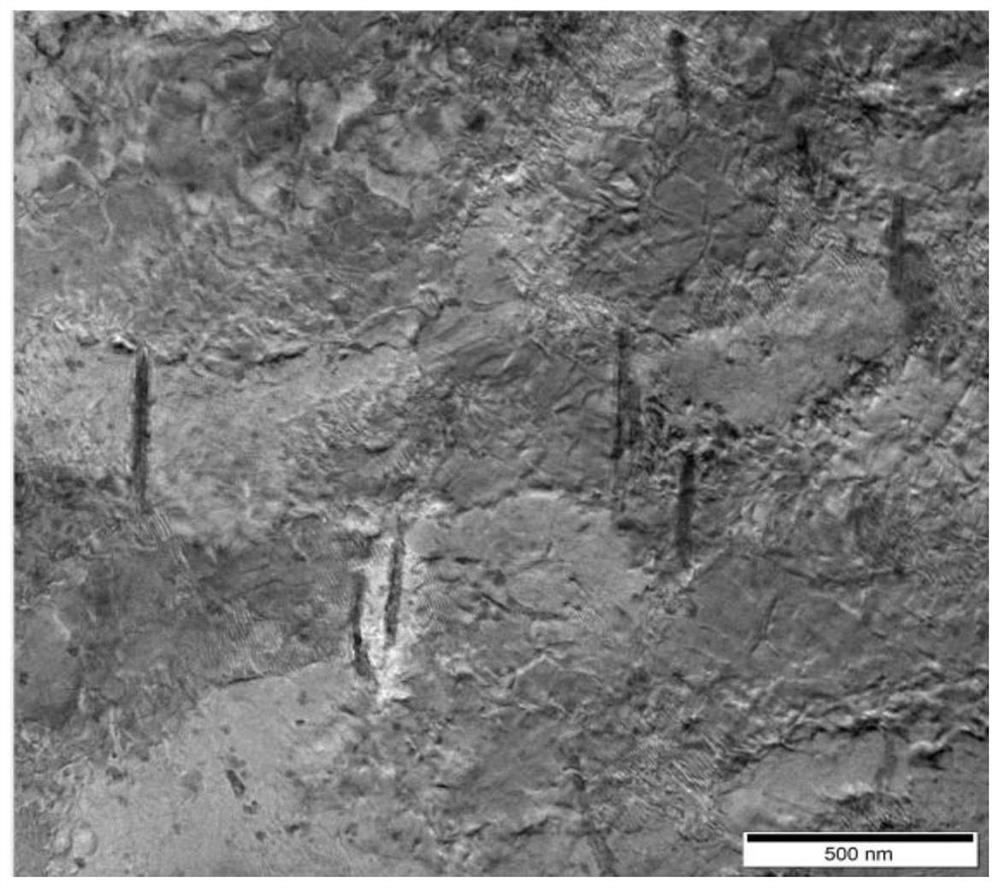

The invention discloses a method for preparing a noncrystalline-nanocrystalline composite membrane by adopting a co-sputtering method, wherein a mixture thin membrane with a noncrystalline phase and a crystalline phase coexisting is prepared by means of implementing double-target magnetron sputtering on a matrix and simultaneously depositing the noncrystalline phase and a nanocrystalline phase. The noncrystalline co-sputtered membrane prepared by the method has a high creep strain rate sensitive value, an excellent mechanical property and uniform plastic deformation. By virtue of the method which is simple and feasible, the noncrystalline mixture thin membrane with the noncrystalline phase and the crystalline phase coexisting is prepared. The thin membrane can be widely applied to the fields of protective coating, functional coating and the like of various precise instruments such as micro electro mechanical systems (MEMS) and nanometer electro mechanical systems (NEMS).

Owner:昆山昊盛泰纳米科技有限公司

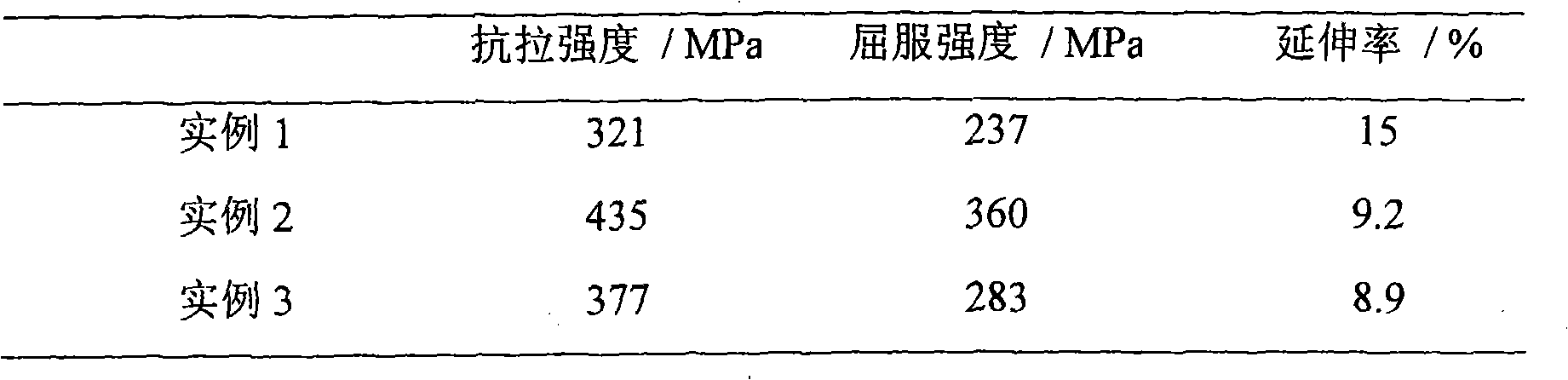

High strength and toughness rare earth magnesium alloy

The invention belongs to the magnesium alloy material field and particularly relates to a high strength and toughness rare earth magnesium alloy. The invention solves the defects of low strength and plasticity of the Mg-Al base alloy which is widely used now. The alloy comprises the following elemental compositions by weight percent: 3-9% of Al, 0.2-0.6% of Zn, 0.1-0.5% of Mn, 0.05-1.0% of Ce, 0.05-1.0% of La, 0.1-3.0% of Y, 0.1-2.0% of Er, 0.1-2.0% of Ho, 0.004% or less of impurity element Fe, 0.002% or less of impurity element Cu, 0.02% or less of impurity element Si, 0.001% or less of impurity element Ni and the balance Mg. Through combined action of the elements and proper homogenizing treatment, the comprehensive performance of the alloy is significantly improved.

Owner:TAIYUAN HUA YIN TAI ALLOY

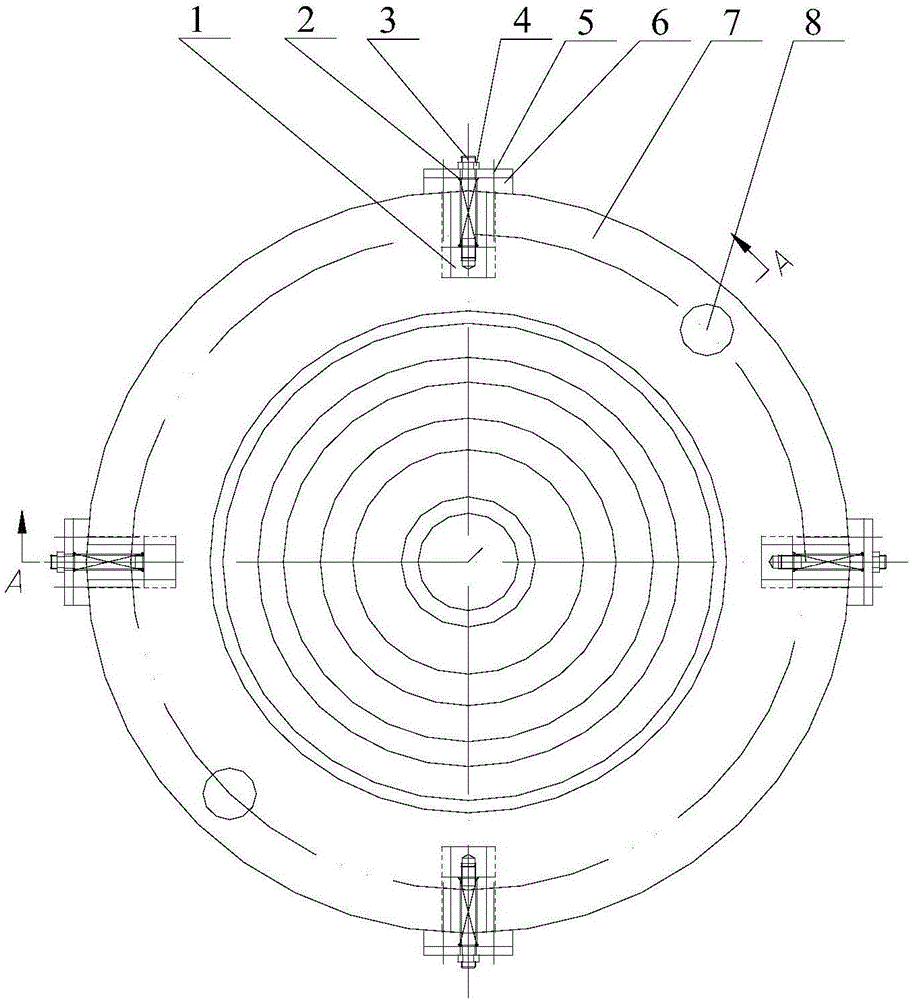

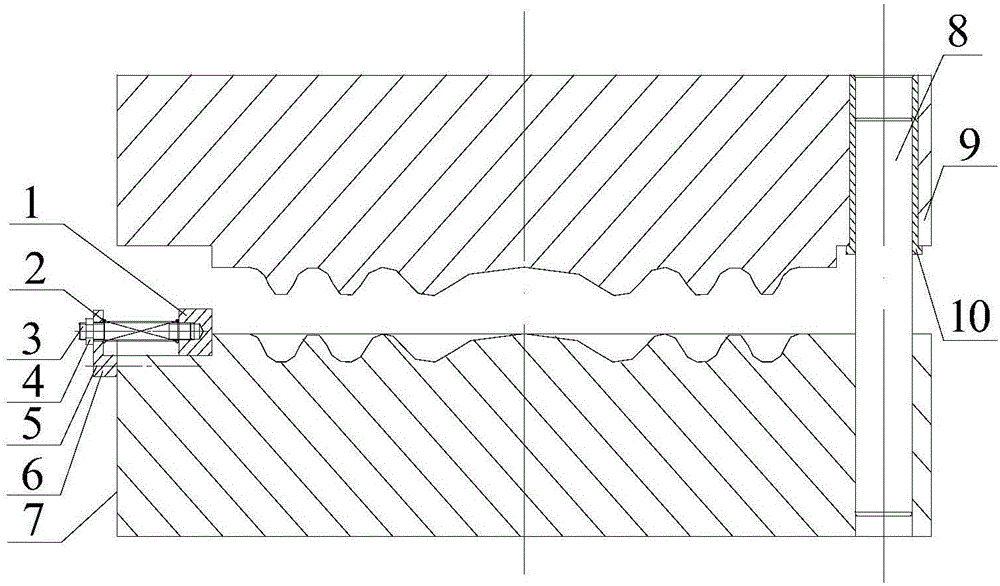

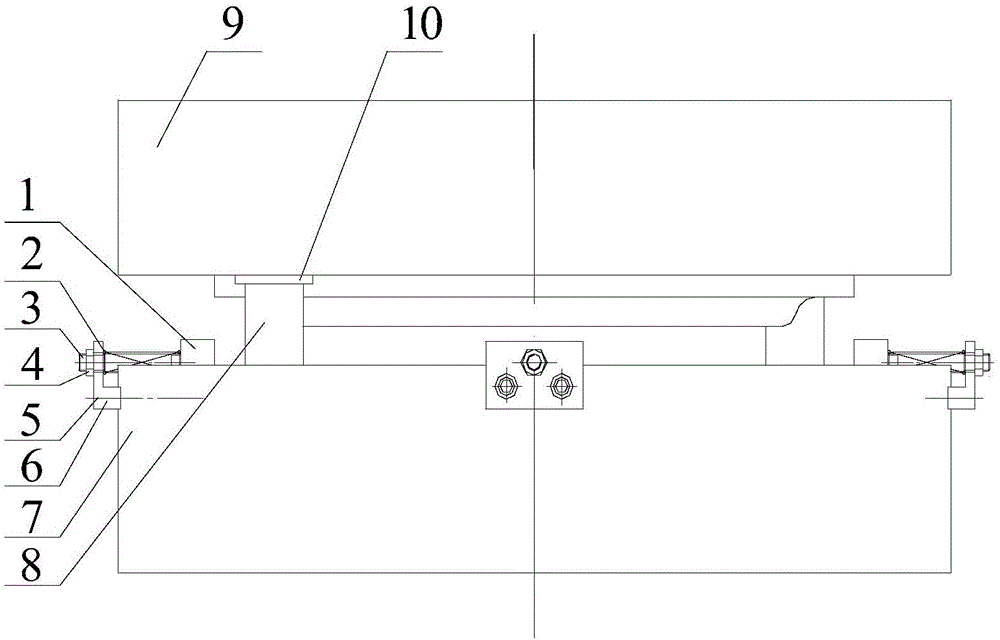

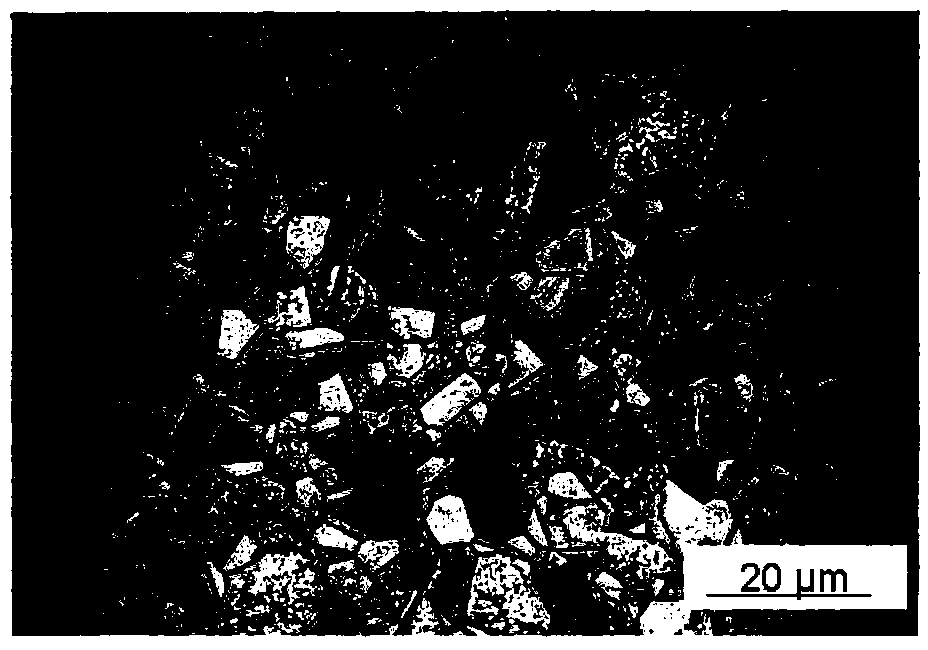

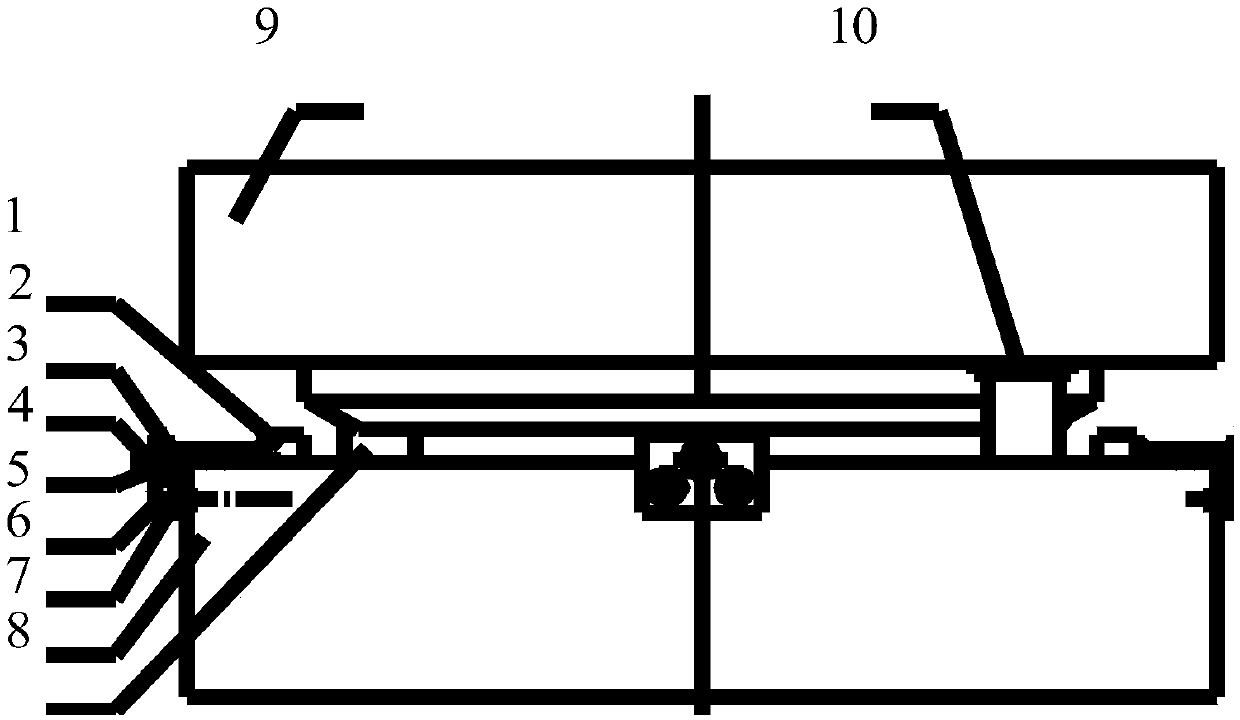

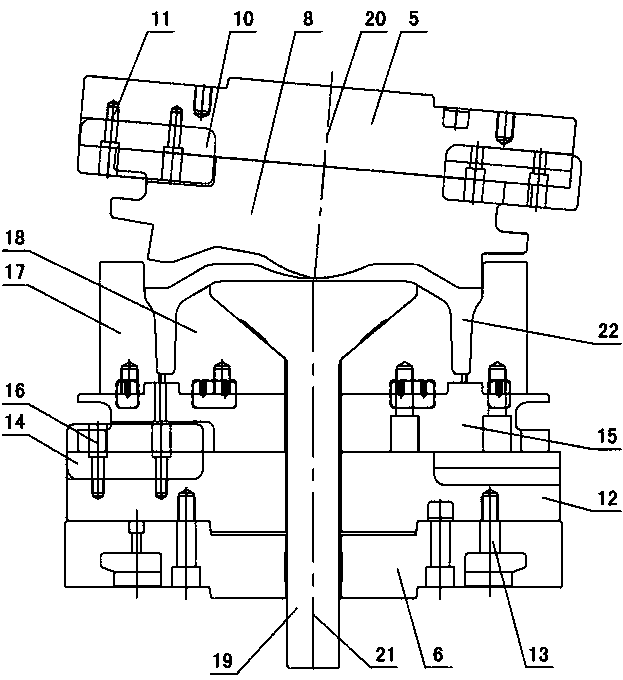

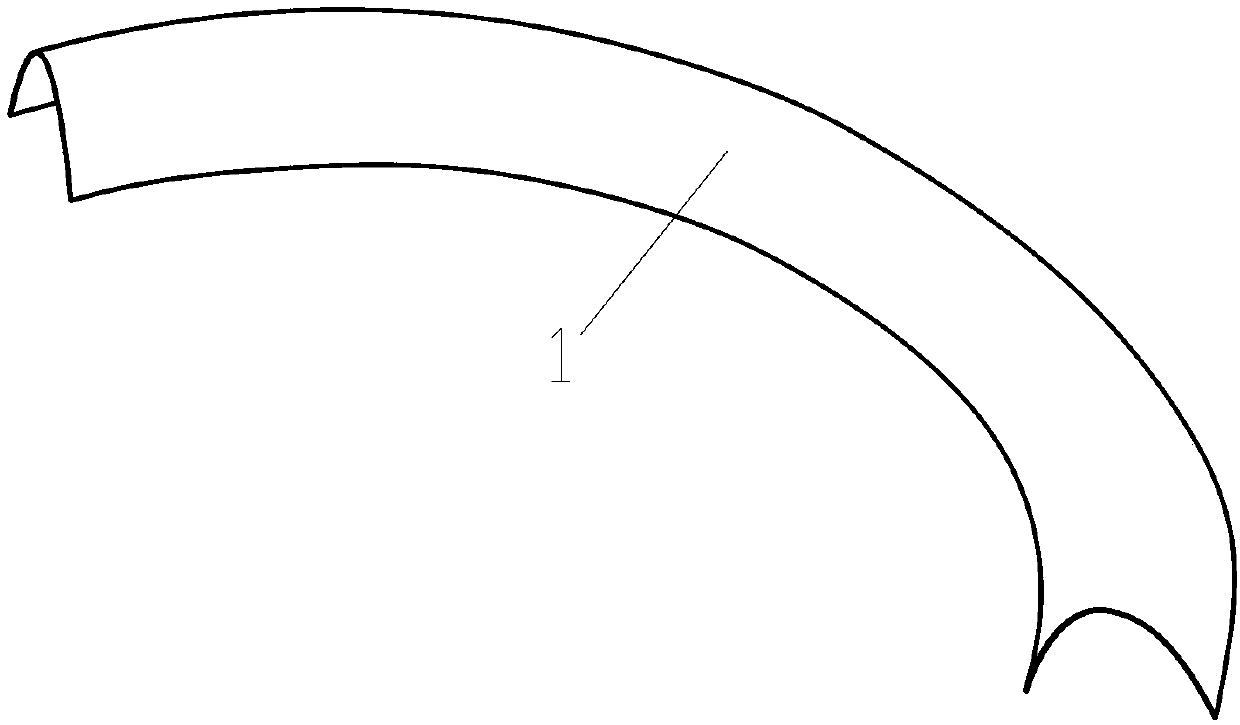

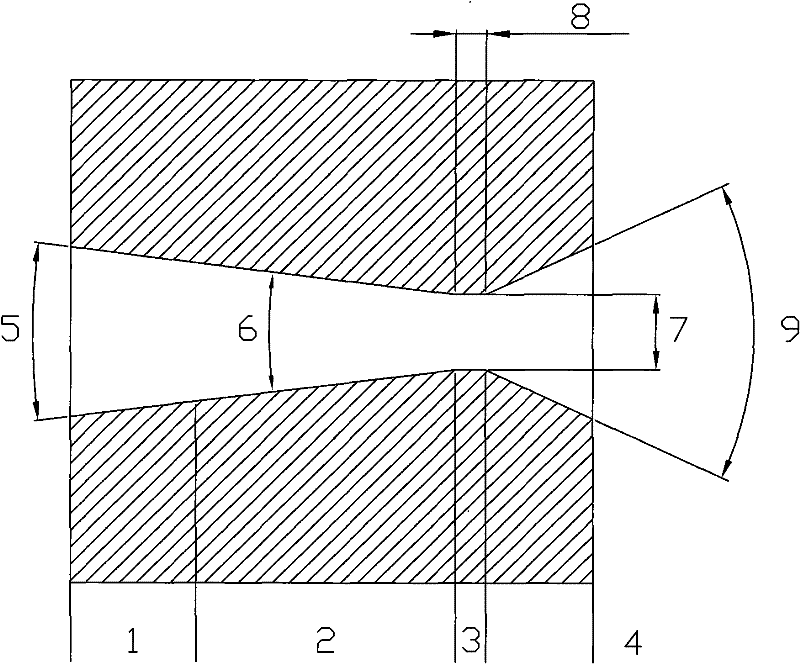

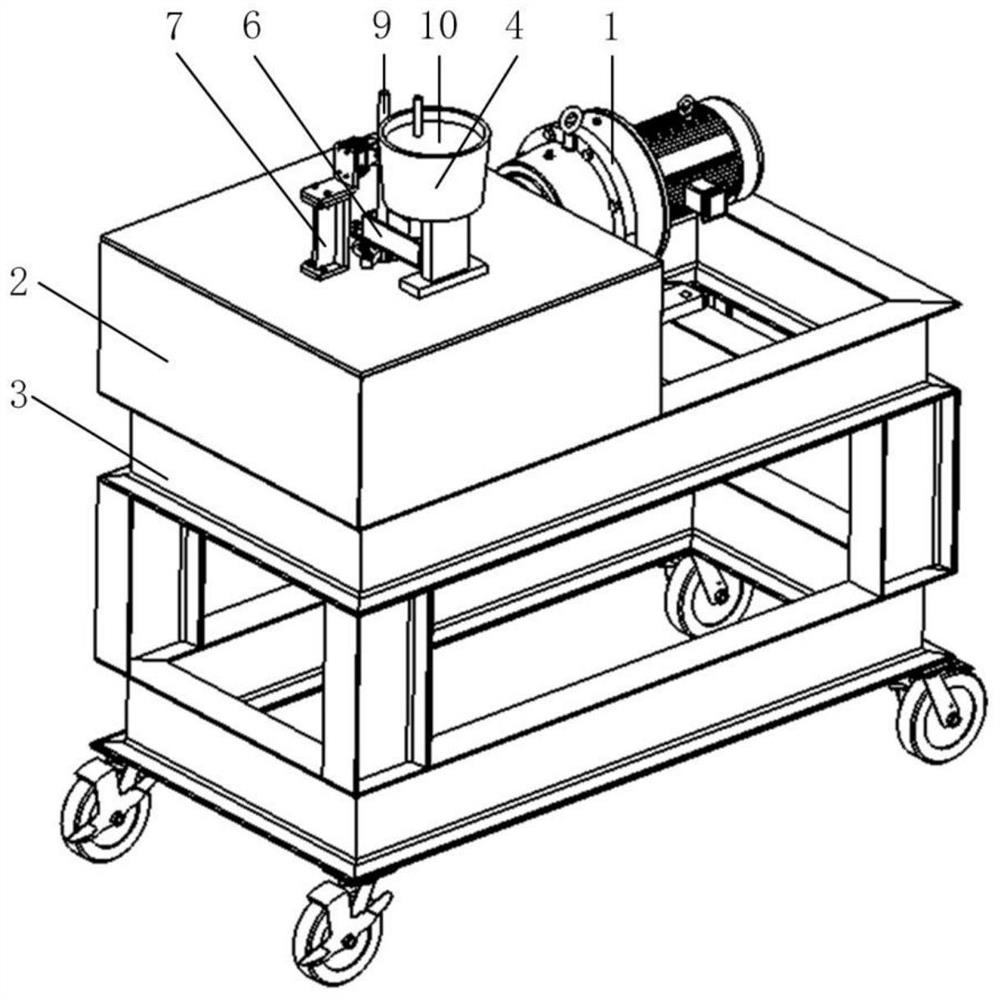

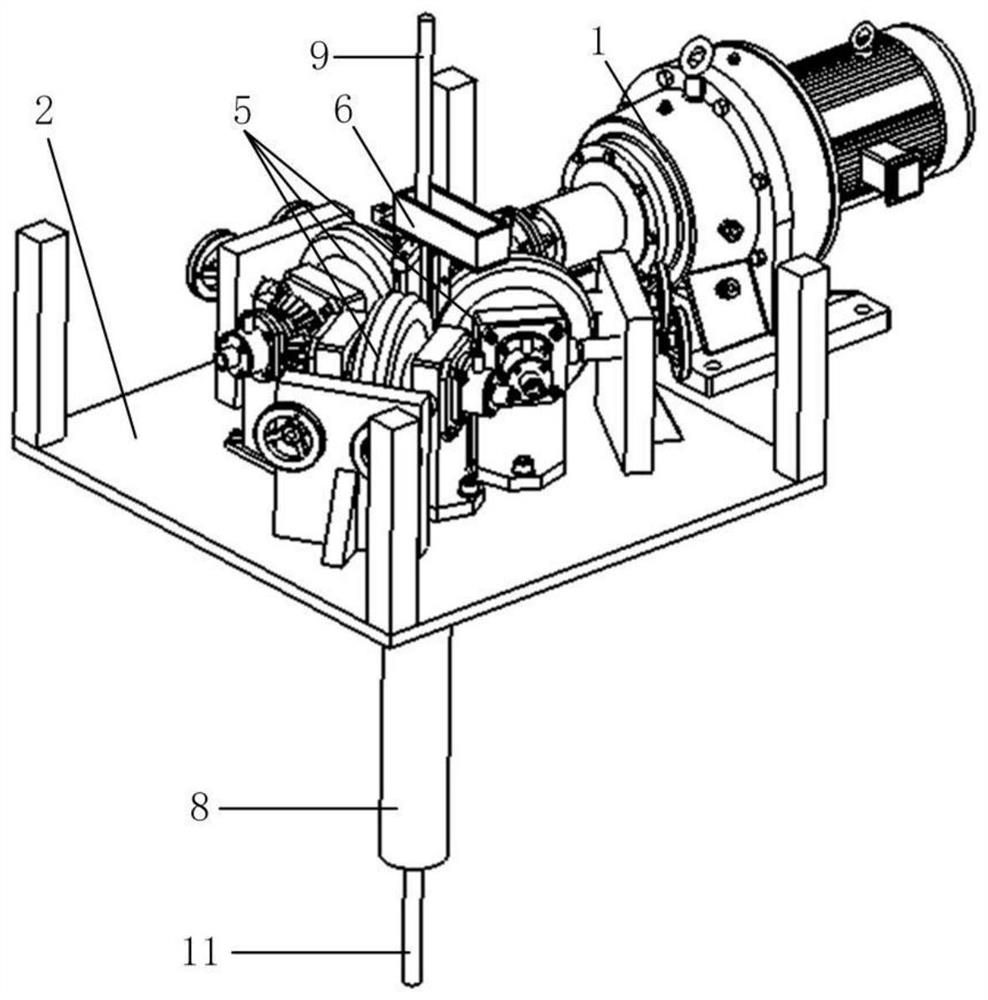

Repeated plate ring wave drawing intense deformation die and technology

InactiveCN106424261AUniform plastic deformationUniform strain distributionShaping toolsMetal-working feeding devicesMicrometerWave shape

The invention discloses a repeated plate ring wave drawing intense deformation die and technology. The die comprises an upper ring wave die body and a lower ring wave die body, wherein the upper surface and the lower surface of the upper ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves, and the upper surface and the lower surface of the lower ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves. The upper ring wave die body is connected with a movable cross beam of a hydraulic machine. The lower ring wave die body is fixed to a working table board. The upper ring wave die body is a movable die, and the lower ring wave die body is a fixed die. Two locating mechanisms arranged symmetrically in the radial direction are arranged at the upper end of the lower ring wave die body and can locate a plate. The upper ring wave die body and the lower ring wave die body are guided through a guide column and a guide sleeve which are arranged symmetrically in the axial direction, and directly participate in formation of the plate. By means of die closing, the plate is drawn to a set ring wave shape. According to the technology, through the die, repeated drawing is carried out for deforming and refining plate grain particles to enable the size of the grain particles to reach the micrometer level or the sub-micrometer level, finally, a flattening die is used for flattening the deformed plate, and a smooth plate is obtained. The die is free of restrictions of the size of the plate, the plate in the large size can be machined, and the comprehensive performance of the aspects such as physics, chemistry and mechanics of the plate are improved greatly.

Owner:河北华杰缝纫机零件有限公司

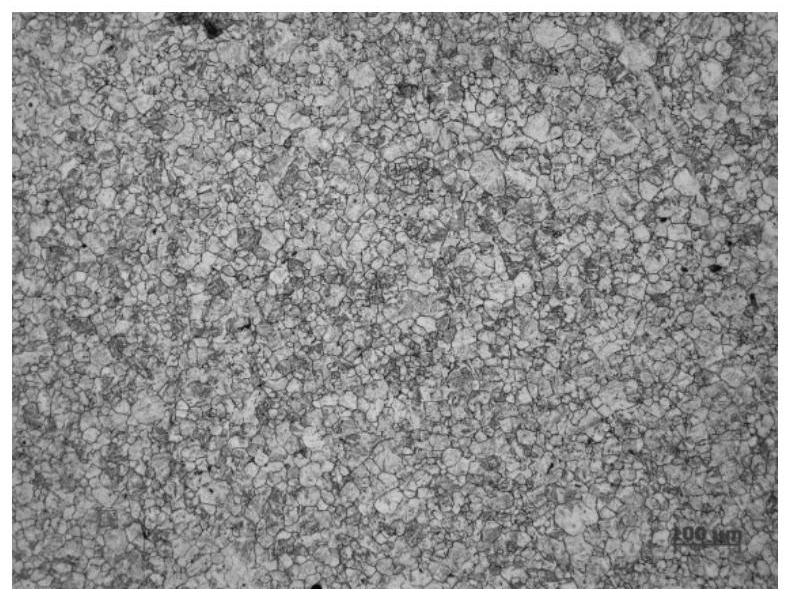

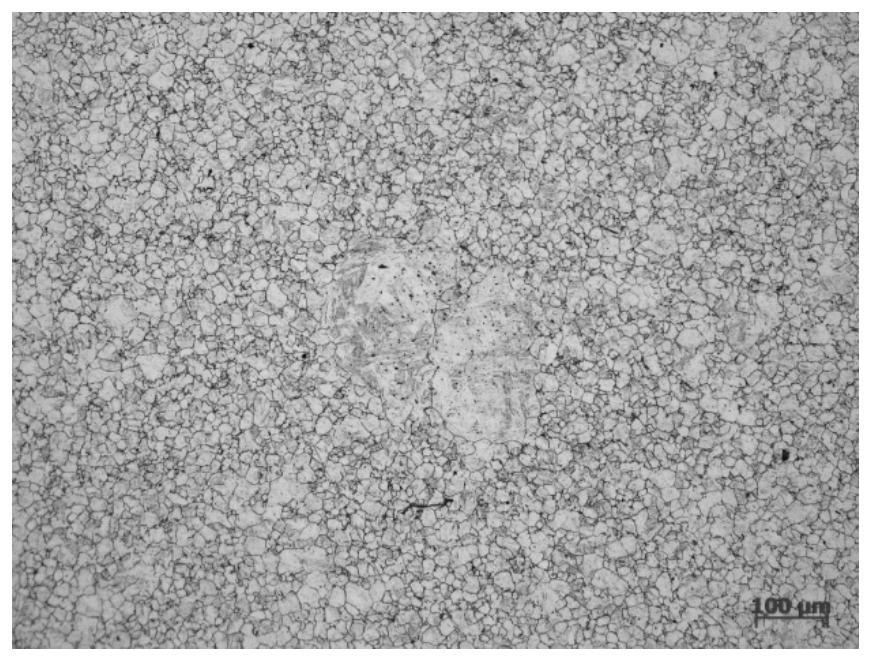

Preparation method for ultrathin magnesium alloy strip

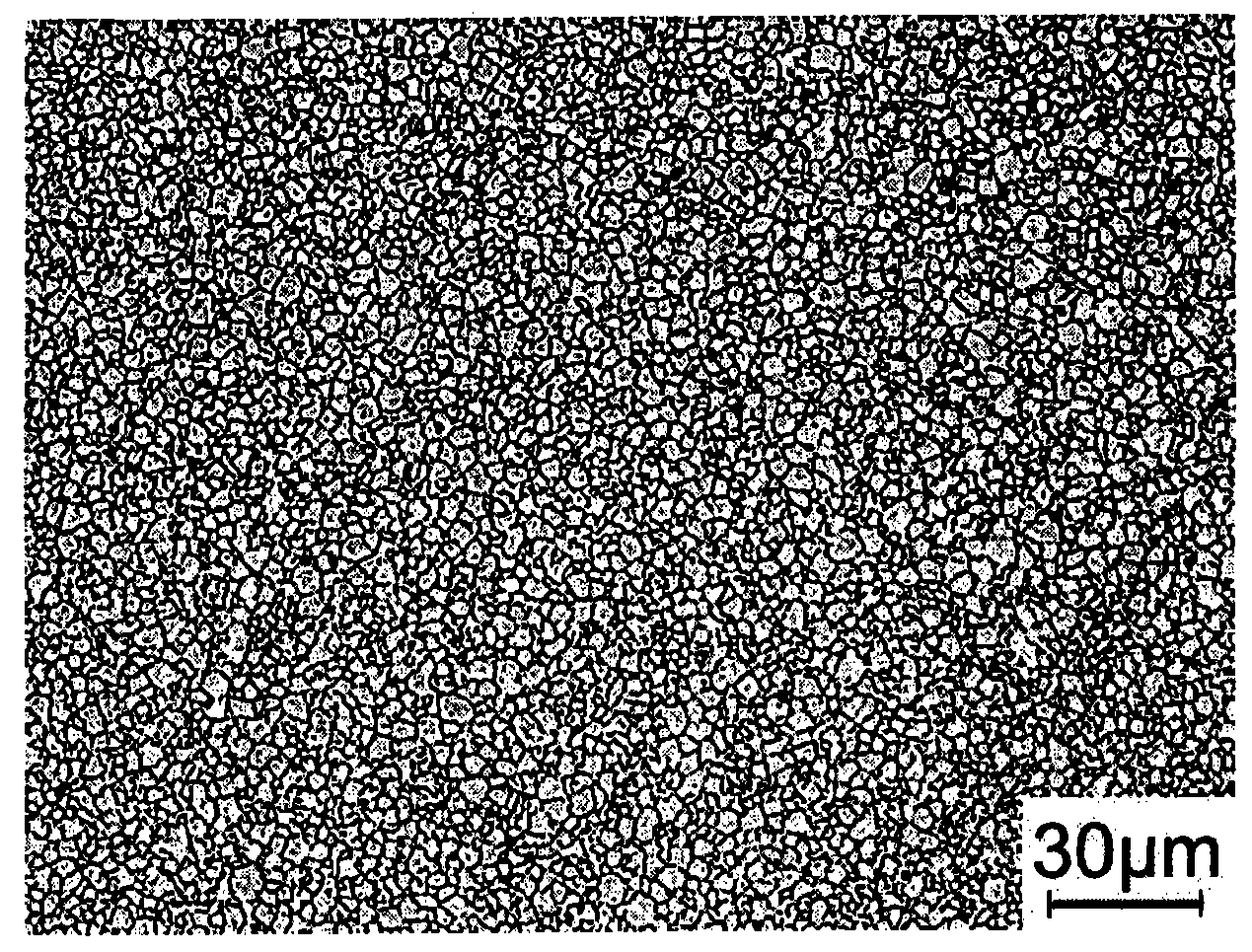

InactiveCN104131143AQuality improvementFine and uniform grainMetal rolling arrangementsIngotHot working

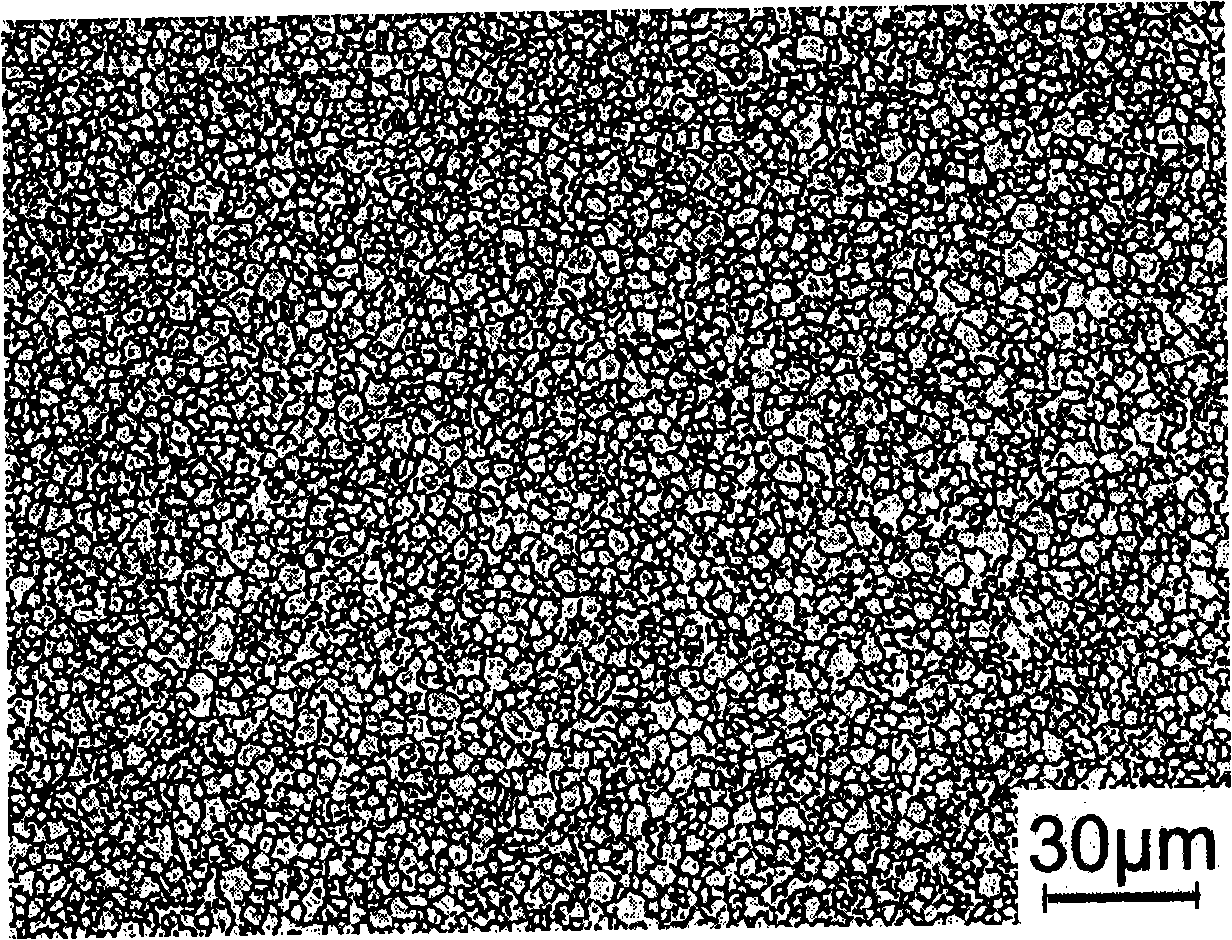

The invention provides a preparation method for an ultrathin magnesium alloy strip. The method comprises the following steps: maintaining a solid solution type magnesium alloy cast ingot at 723 to 803 K for 24 h under the protection of inert gas, carrying out water quenching and then subjecting the ingot blank to solid solution treatment; cutting the cast ingot having undergone solid solution treatment to desired thickness and size, carrying out multi-pass rolling in a hot-working state, wherein the total deformation is greater than 60%, and subjecting a hot-rolled plate to annealing at 673 to 773 K for 30 min; and carrying out first-pass cold rolling with deformation of greater than 50% on the annealed hot-rolled plate, wherein ultrathin strips (foils) with different thickness can be prepared through one or multi-pass cold rolling. Maximum rolling reduction reaches 95%, and percentage of elongation at the rolling direction reaches 1000%. Except edge cracks caused by great rolling reduction, the cold-rolled ultrathin strip has a perfect integral surface. After edge trimming, the ultrathin magnesium alloy strip with uniform thickness and high quality can be obtained. After annealing, a cold-rolled plate has uniform crystal grains and excellent mechanical properties.

Owner:SHENYANG AEROSPACE UNIVERSITY

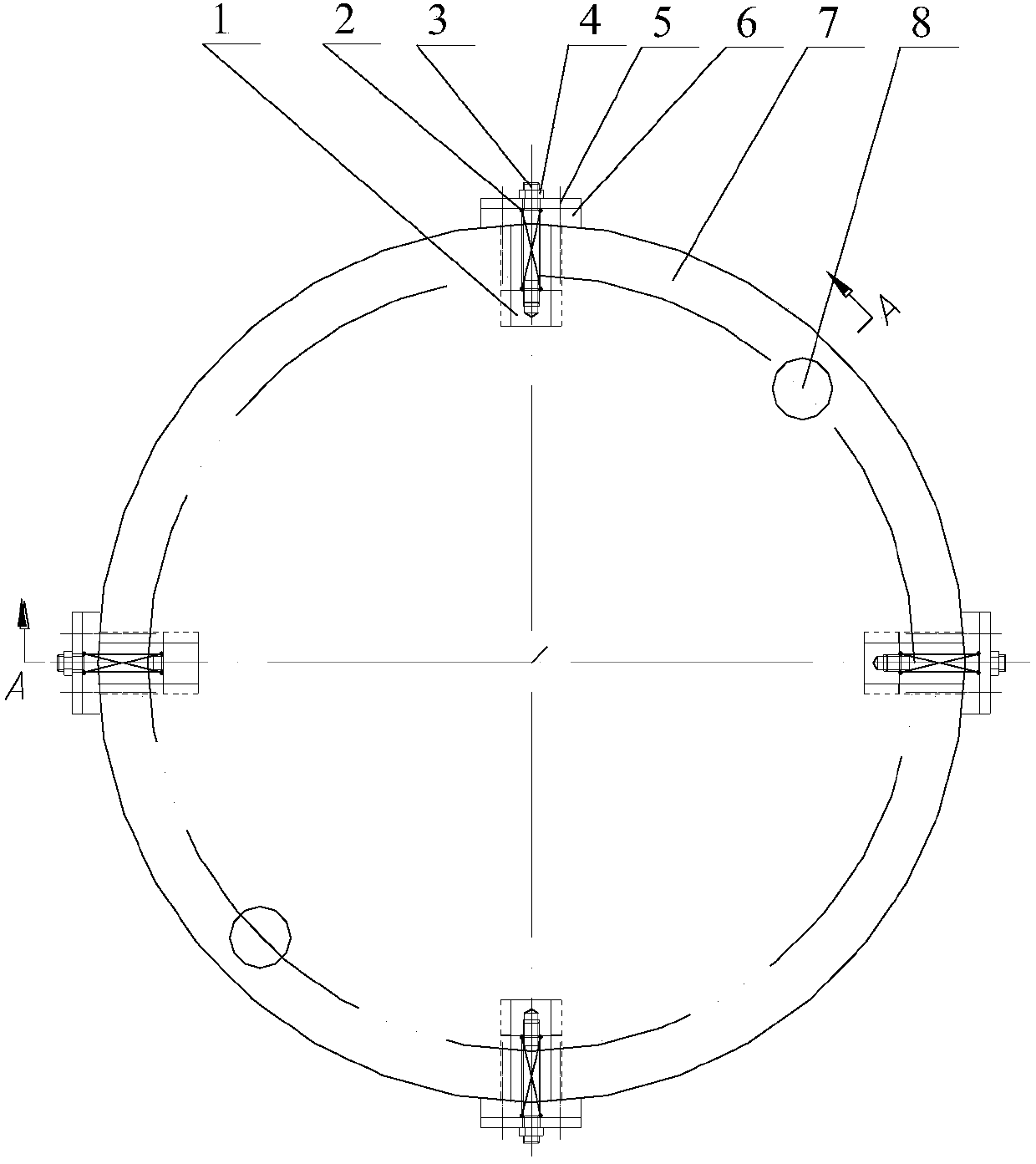

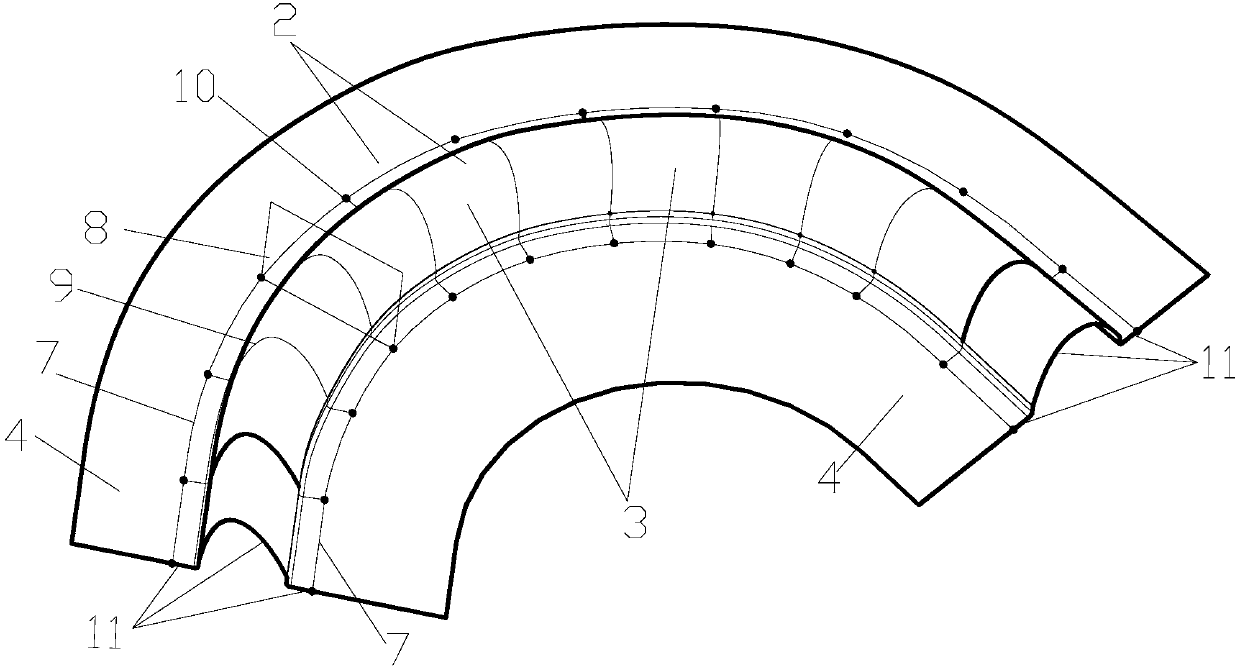

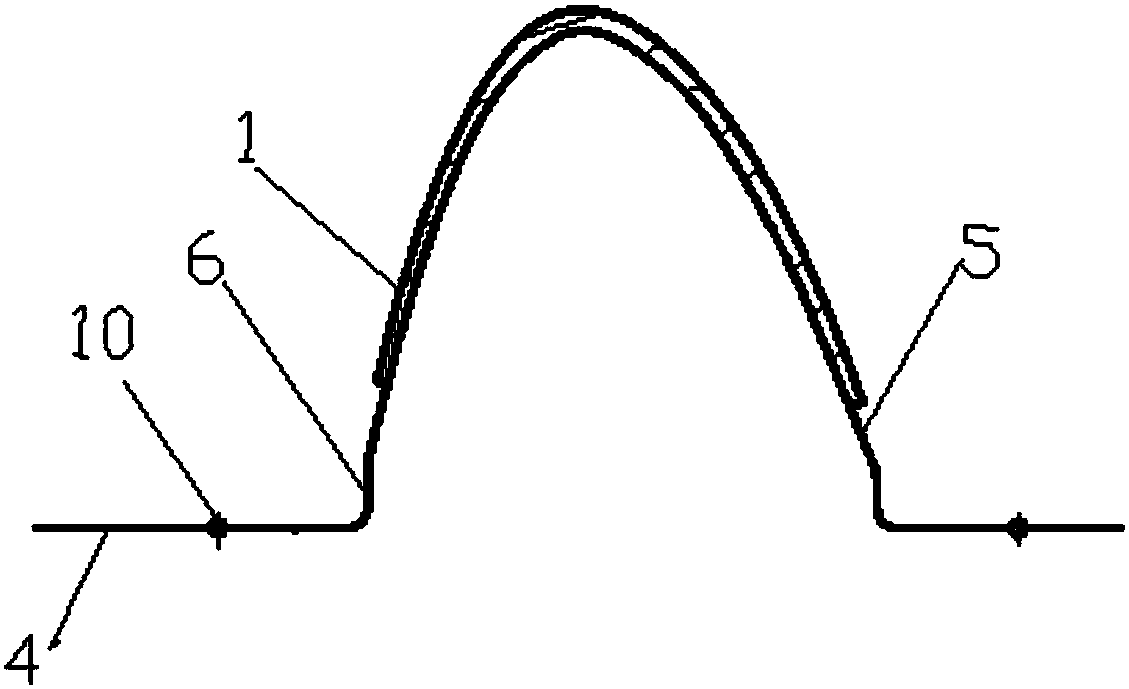

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

Cold machining and molding method of magnesium alloy pipes

InactiveCN101322978ALittle or no lossGood mechanical propertiesRoll mill control devicesMetal rolling arrangementsThermal insulationMechanical property

The invention discloses a method for cold machining and forming of magnesium alloy tubes. Magnesium alloy hot-extruded tube blanks or magnesium alloy cast tube blanks going through a vacuum heat treatment are milled into magnesium alloy tubes by a cold mill. The feeding capacity for tube blank ranges from 5 to 15mm / t, the travel speed of a working frame ranges from 15 to 30t / min, the deformation for pass is controlled to be 5 to 25 percent, the accumulated deformation does not exceed 45 percent and the ratio of the relative wall reduction to the relative sizing reduction is controlled to be 0.8 to 3.2; the magnesium alloy tubes after cold work hardening are put into a vacuum heat treatment furnace or pipe type resistance furnace containing protection atmosphere for performing a recrystallization, anneal and intermediate heat treatment, the temperature for the intermediate heat treatment is 200 to 450 DEG C; after thermal insulation is performed for 0.5 to 14 hours, the magnesium alloy tubes are obtained by machining after air cooling or furnace cooling. The working method of the invention is simple and easy to realize, has low cost and can improve the mechanical property of magnesium alloy tubes and the machined tubes have favorable surface quality and high geometrical dimension accuracy.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

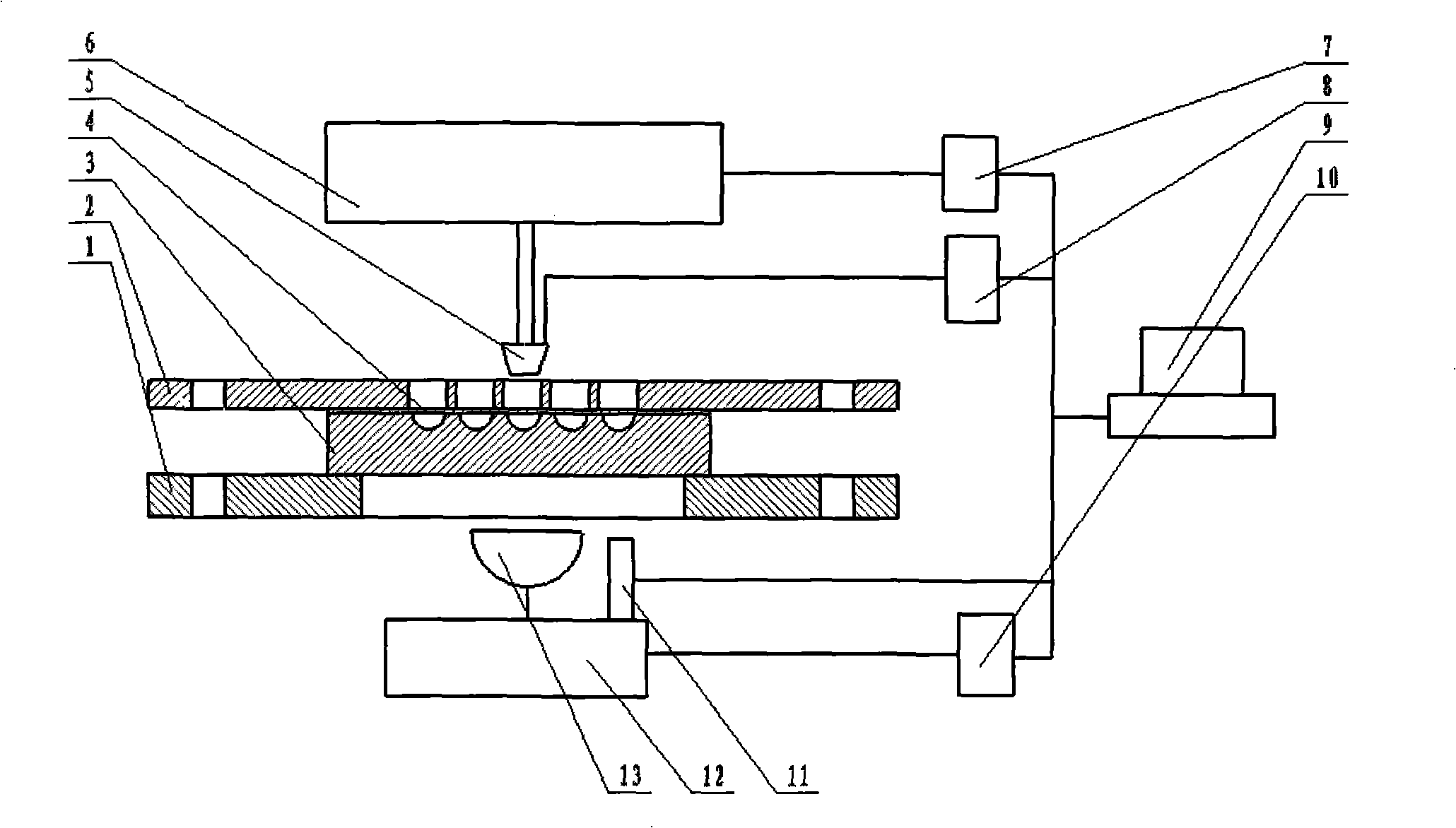

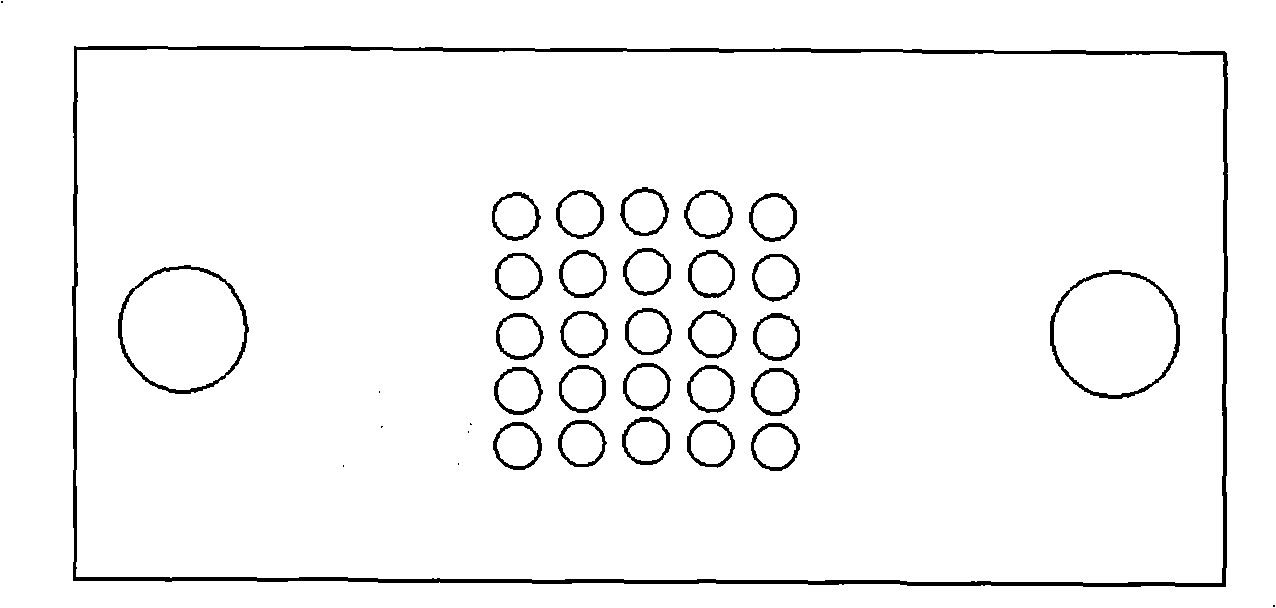

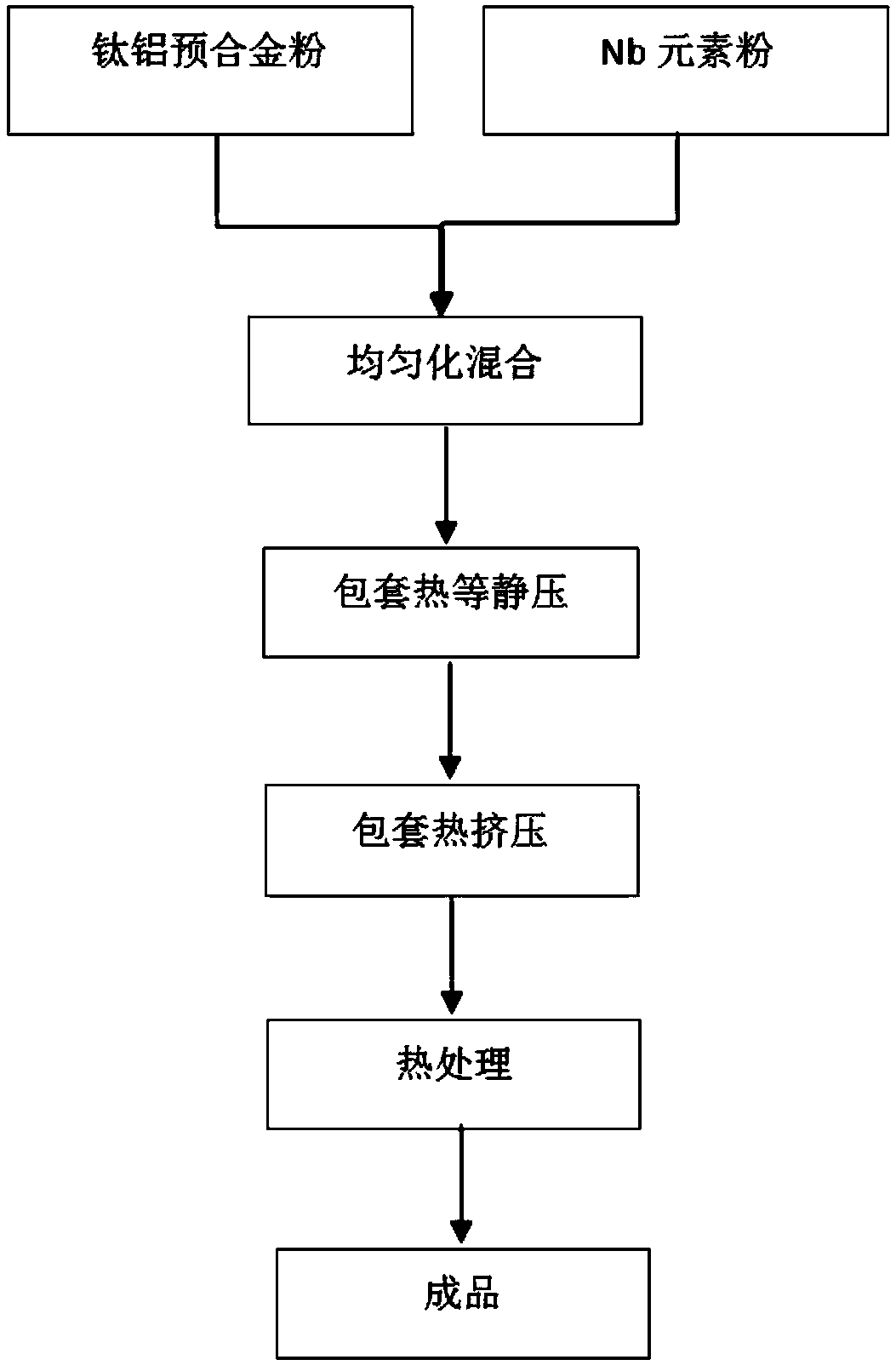

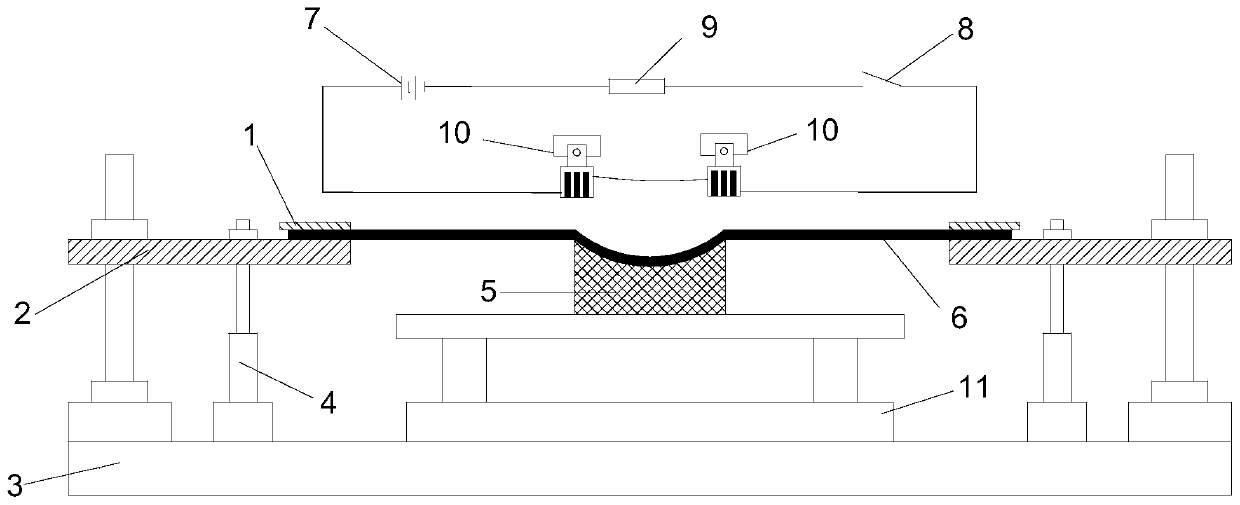

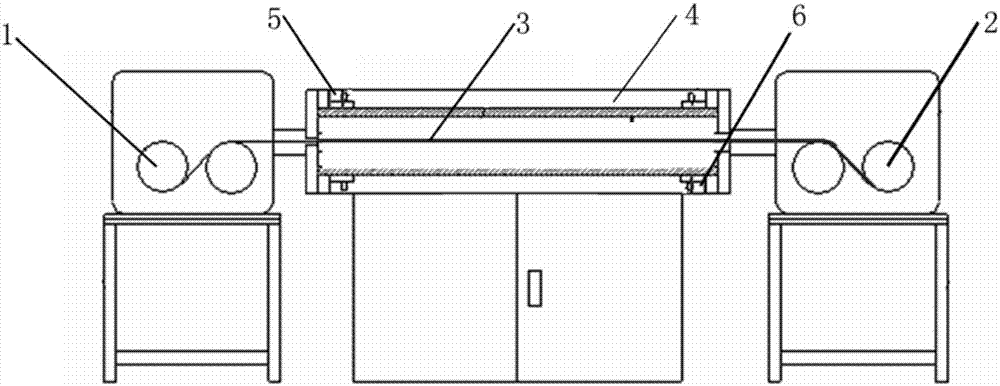

Infra-red heating tinsel plate pneumatic forming method and apparatus

InactiveCN101318204AUniform plastic deformationImprove yieldShaping toolsRadiation thermometerMetallurgy

The invention relates to an air pressure forming method of an infrared heating metal foil plate and a device; wherein, the method includes the steps of accurately heating a metal foil plate with an infrared heat source, applying pressure to the softened metal foil plate with high pressure gas and realizing the precise forming of the metal foil plate by matching a micro mold; the device consists of a bottom plate, an upper pressure plate, a micro mold, a gas pressure nozzle, a three-dimensional mobile platform, a three-dimensional mobile platform controller, an air compressor, a computer, a drive, an infrared radiation thermometer, a three-dimensional worktable and an infrared focusing heating device. The method and the device integrates the technologies of infrared heating, infrared temperature measurement and air pressure forming to a micro-forming process, thus improving the forming performance of the metal foil plate, ensuring the quality of the surfaces of work pieces; the high pressure gas is used for replacing a male mold, thus simplifying the technique, causing the loading pressure to be more even and strengthening the filling ability; the method and the device can realize the low cost and mass production of the metal foil plate by combining an array female mold.

Owner:JIANGSU UNIV

Continuous co-extrusion self-reinforcing equipment and continuous co-extrusion self-reinforcing method for biomass wood plastic foaming floor

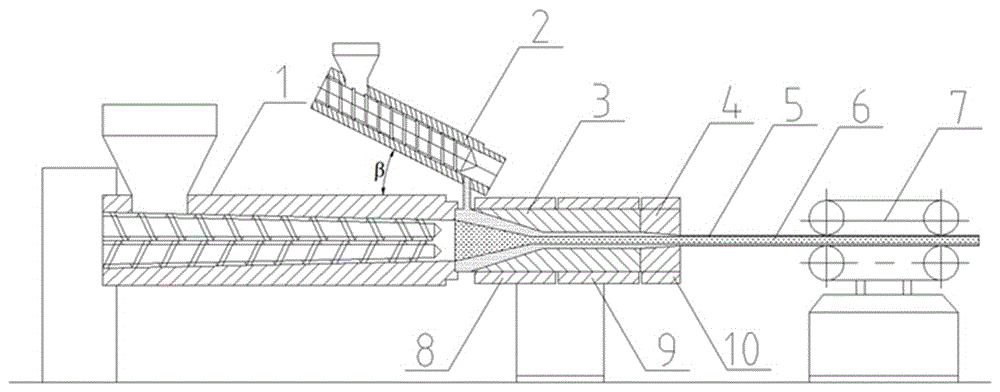

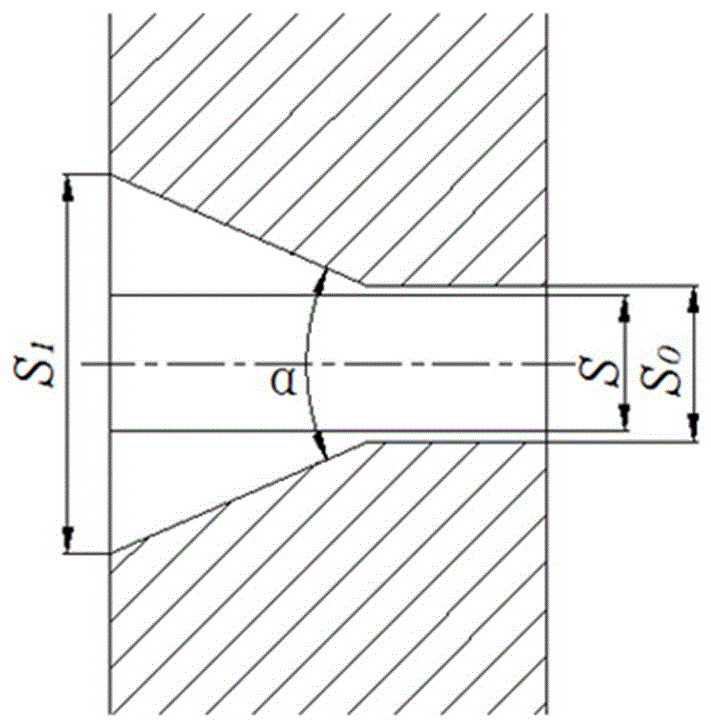

The invention discloses continuous co-extrusion self-reinforcing equipment for biomass wood plastic foaming floors. The continuous co-extrusion self-reinforcing equipment comprises a conical double-screw extrusion main machine, a co-extrusion die, a conical port die and a dragger which are sequentially arranged. The continuous co-extrusion self-reinforcing equipment is characterized by further comprising an extrusion auxiliary machine; the extrusion auxiliary machine is arranged above the extrusion main machine; an included angle beta between the extrusion auxiliary machine and the extrusion main machine is 20 to 60 degrees; and the extrusion ratio R of the conical port die is 2 to 10, and an extrusion conical angle alpha is 15 to 60 degrees (shown in the description). S1 expresses cross section area of an inlet end of the conical port die, S0 expresses cross section area of an outlet end of the conical port die, and S expresses cross section area of a core layer floor. According to the continuous co-extrusion self-reinforcing equipment disclosed by the invention, surface layers of co-extrusion products are stretched by arranged conical port die and dragger, so that the co-extrusion products generate plastic deformation, the tensile strength and ageing-resistant performance of the products are improved, and the service life of the products is prolonged; and meanwhile, the core layer floor adopts a foaming method, so that the weight of the products can be reduced, and the properties such as nail-holding ability and impact resistance of the products are improved.

Owner:浙江钱隆新材料有限公司

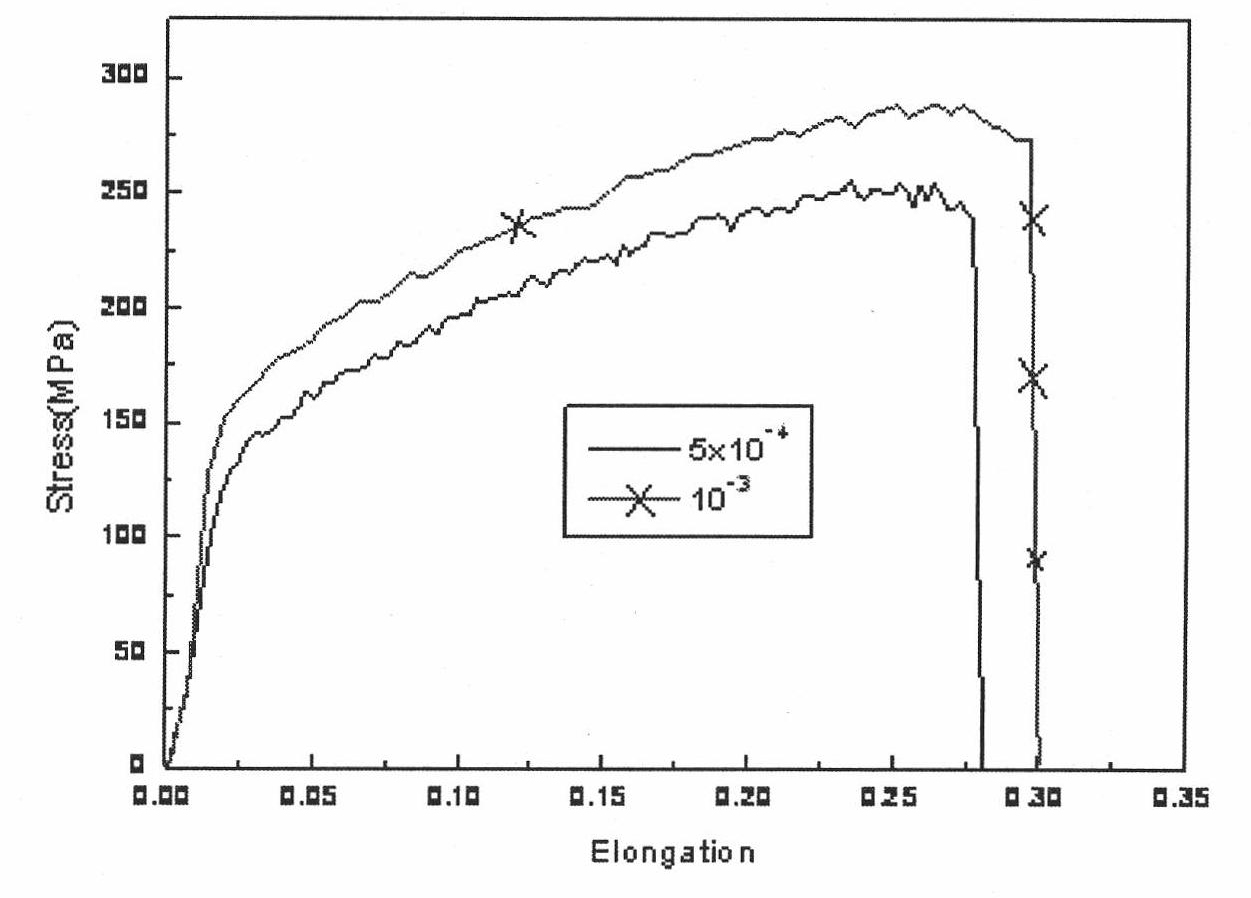

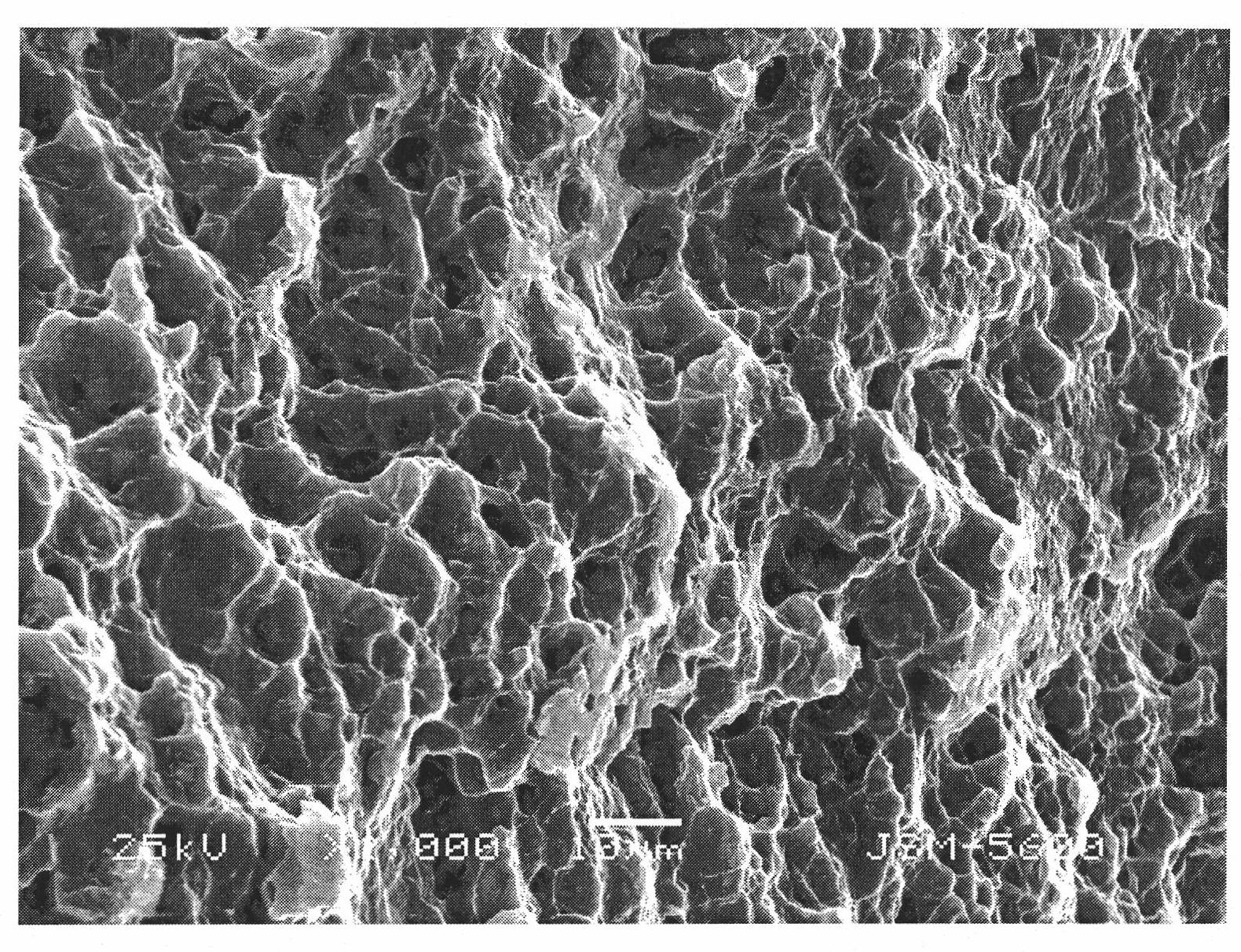

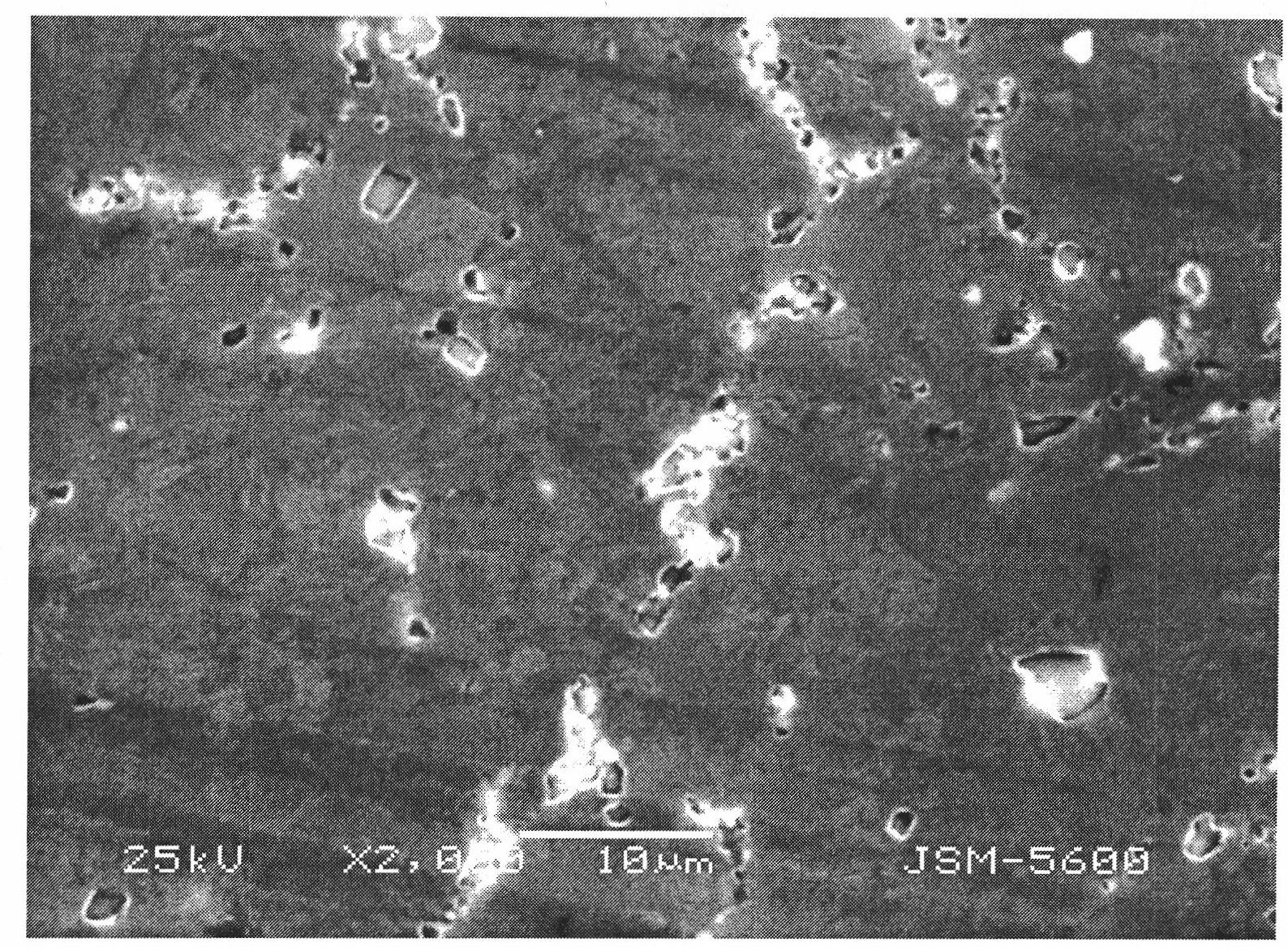

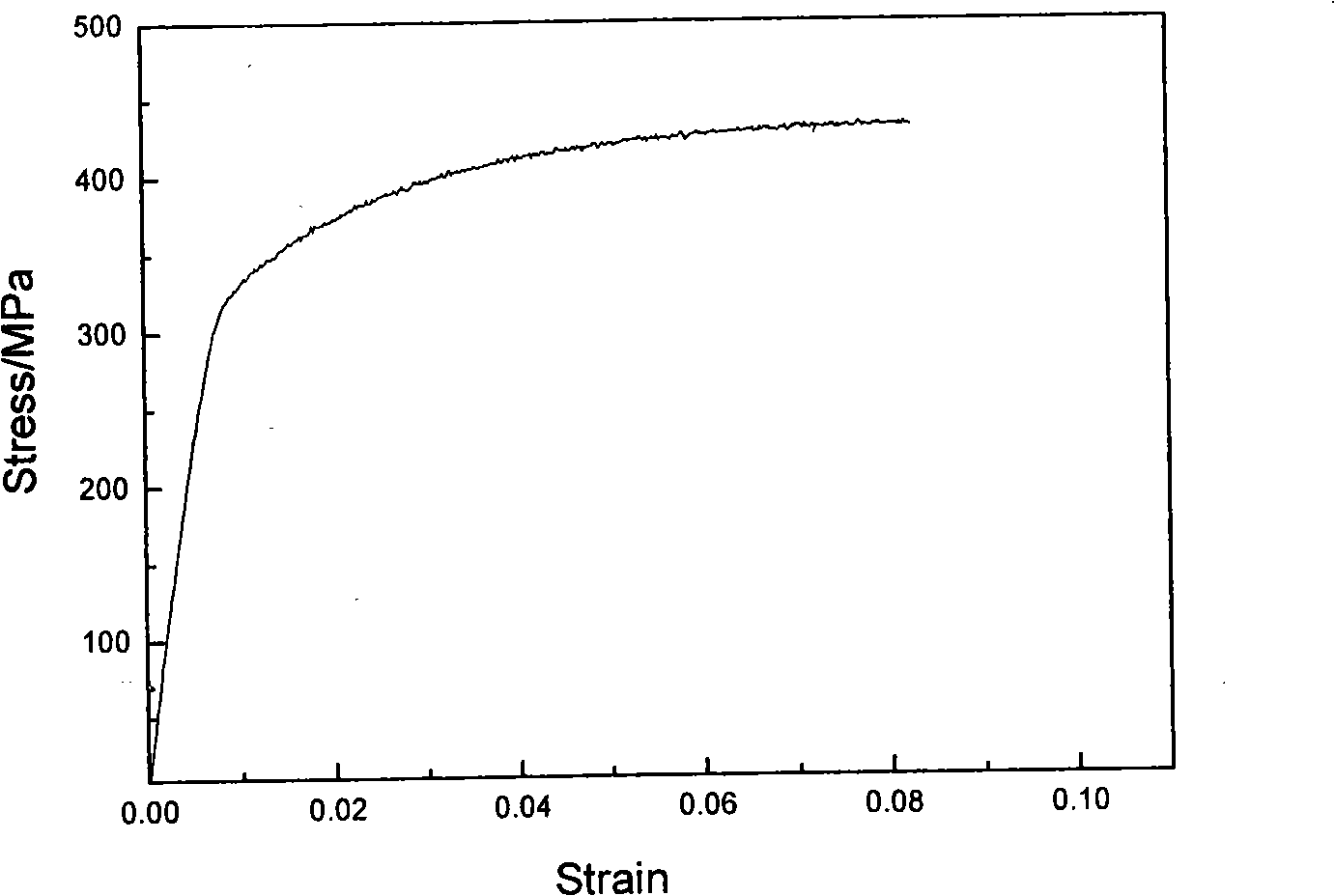

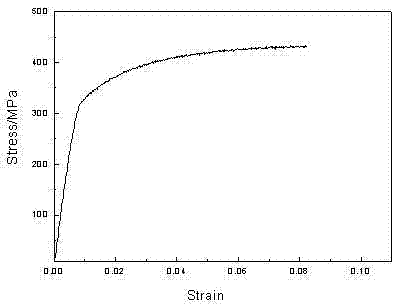

Preparation of magnesium alloy with high strength and ductility

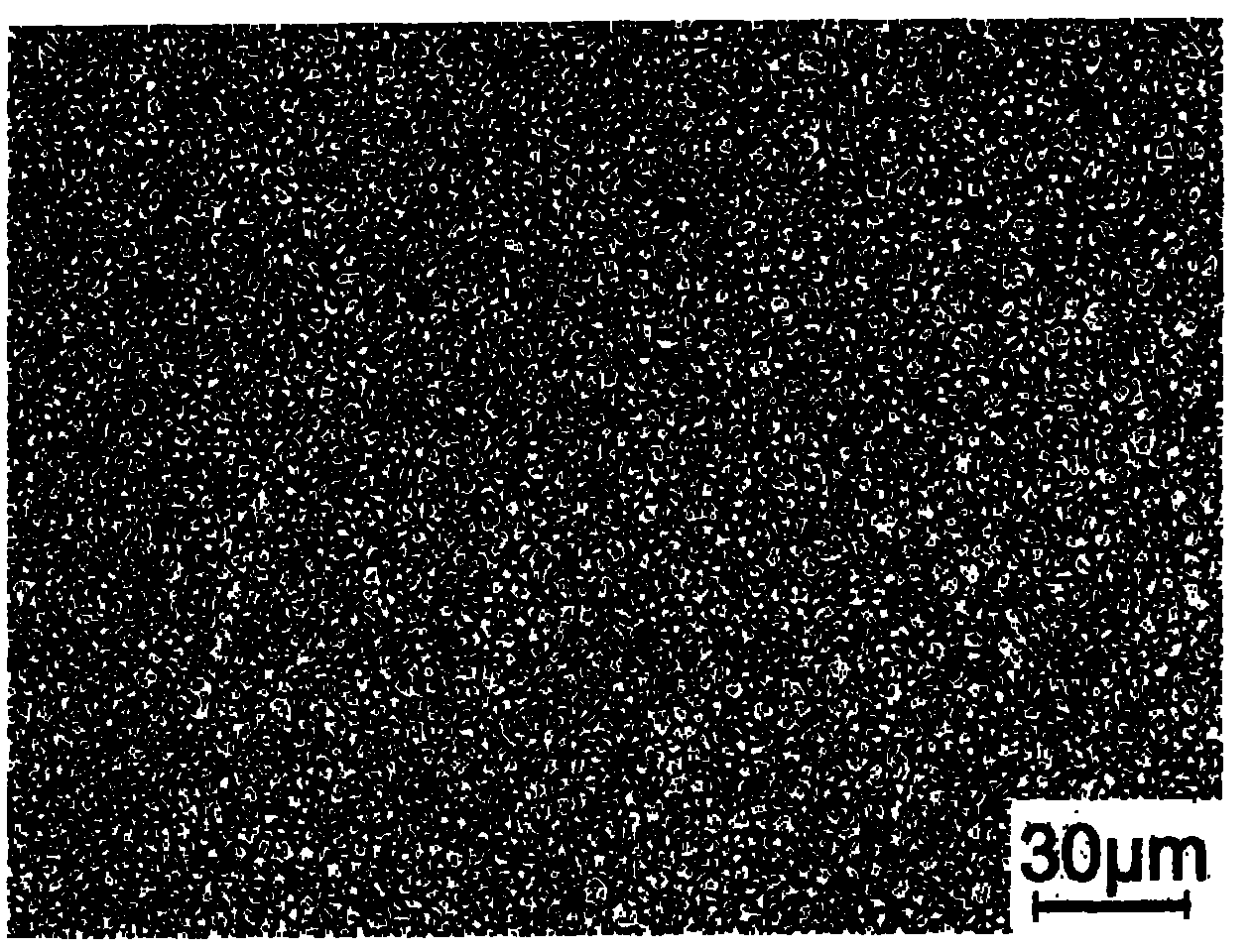

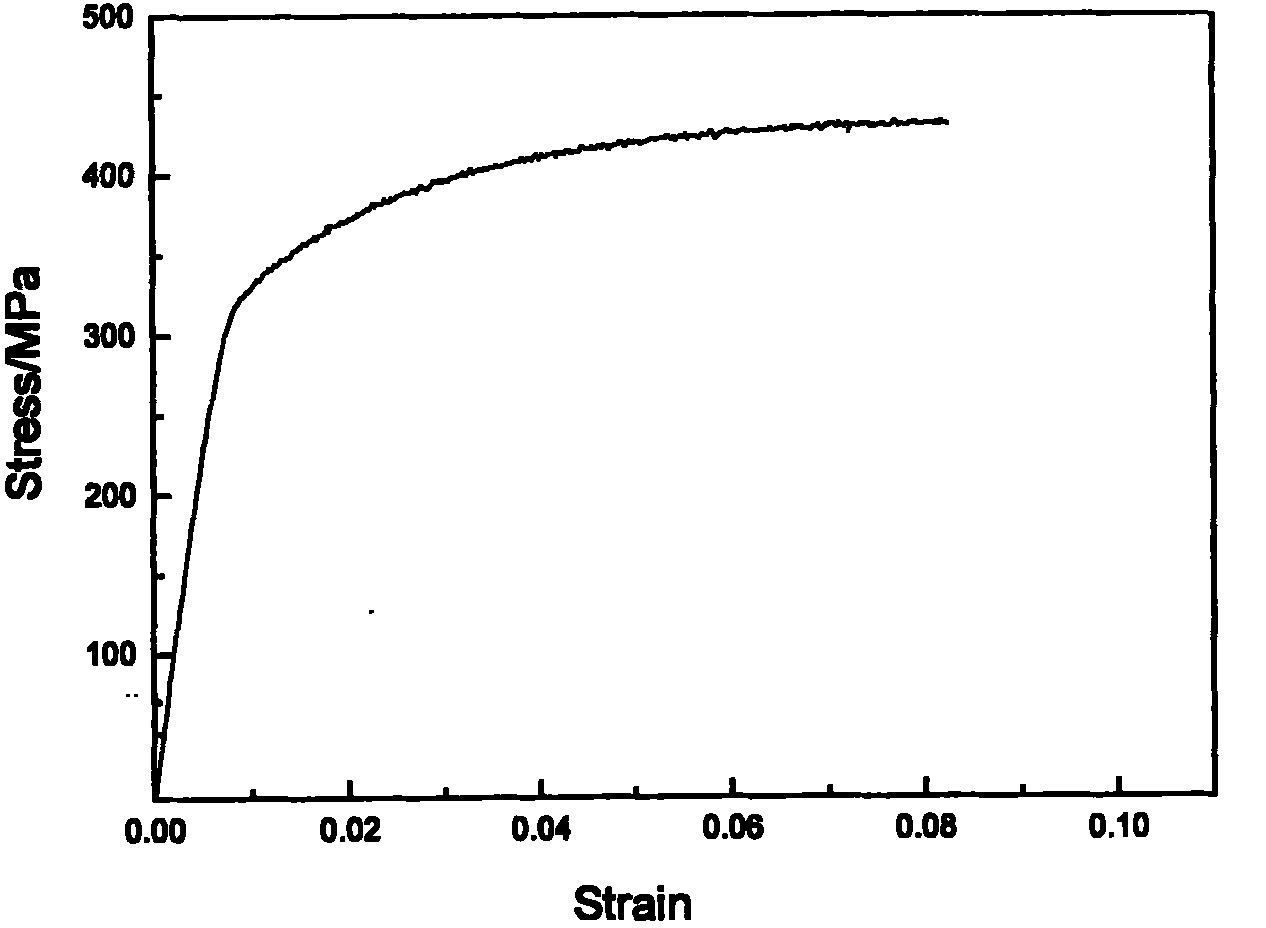

A preparation method of a high-strength magnesium alloy relates to a spray deposition preparation process and proposes the spray forming technology which adopts protective atmosphere, thus solving the problems of volatilization, oxidation and safety etc. of the magnesium alloy, preparing a magnesium alloy deposition blank with complete shape, low segregation, high density and qualified components and ensuring the macro-mechanical properties of Mg-Al-Zn alloy and the plastic deformation capacity to be synchronously improved. The method is that firstly, an alloy ingot is arranged in a melting furnace, the vacuum extraction is carried out, the furnace is washed by argon for 2 to 3 times, when the vacuum degree is 10 to 70 Pa, the argon is filled till the pressure is slightly lower than the outside atmospheric pressure, the ingot is melted, electromagnetically stirred and evenly mixed, after that, the ingot is poured to a middle package when the temperature of the melt is 700 to 770 DEG C and is flown out by a flow guide nozzle, an annular hole type non-limited atomizing nozzle is adopted for high-pressure atomizing N2 gas, the atomization pressure is 0.5 to 0.6MPa, and atomized liquid is deposited on a receiving polar plate to form the columnar magnesium alloy deformation blank. The strength and the toughness of the magnesium alloy material prepared by the invention are both in better levels, thus realizing the synchronous improvement of the strength and the toughness.

Owner:UNIV OF SCI & TECH BEIJING

Manufacturing method of steel for speed reducer gear of electric automobile

PendingCN112981271AHigh strengthUniform plastic deformationProcess efficiency improvementScrapElectric furnaces

The invention relates to a manufacturing method of steel for a speed reducer gear of an electric automobile, belongs to the technical field of iron-based alloys, and particularly relates to steel for gears. According to the element composition design related, the steel comprises, by mass, 0.20%-0.35% of C, 0.05%-0.35% of Si, 1.20%-1.60% of Mn, 1.10%-1.50% of Cr, 0.20%-0.50% of Mo, smaller than or equal to 0.035% of S, smaller than or equal to 0.015% of P, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.20% of Ni, 0.010%-0.080% of Al, 0.0060%-0.0260% of N and the balance Fe and inevitable impurities, wherein Al / N is equal to 1.5 to 3.9. The smelting technological process comprises the following steps of pre-treated molten iron and optimized scrap steel, primary smelting in an electric furnace, refining in an LF furnace, vacuum degassing in a VD furnace, continuous casting of square billets, shot blasting of the continuously-cast square billets, heating in a walking beam furnace, descaling with high-pressure water, rolling of the continuous casting billets, surface flaw detection and internal ultrasonic flaw detection of hot-rolled round steel, quality inspection and warehousing. The element components are matched with the smelting process, and the steel meets the requirements of high strength and long fatigue life of the steel for an electric automobile speed reducer. And remarkable advantages are obtained on the aspects of hardenability and grain uniformity.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

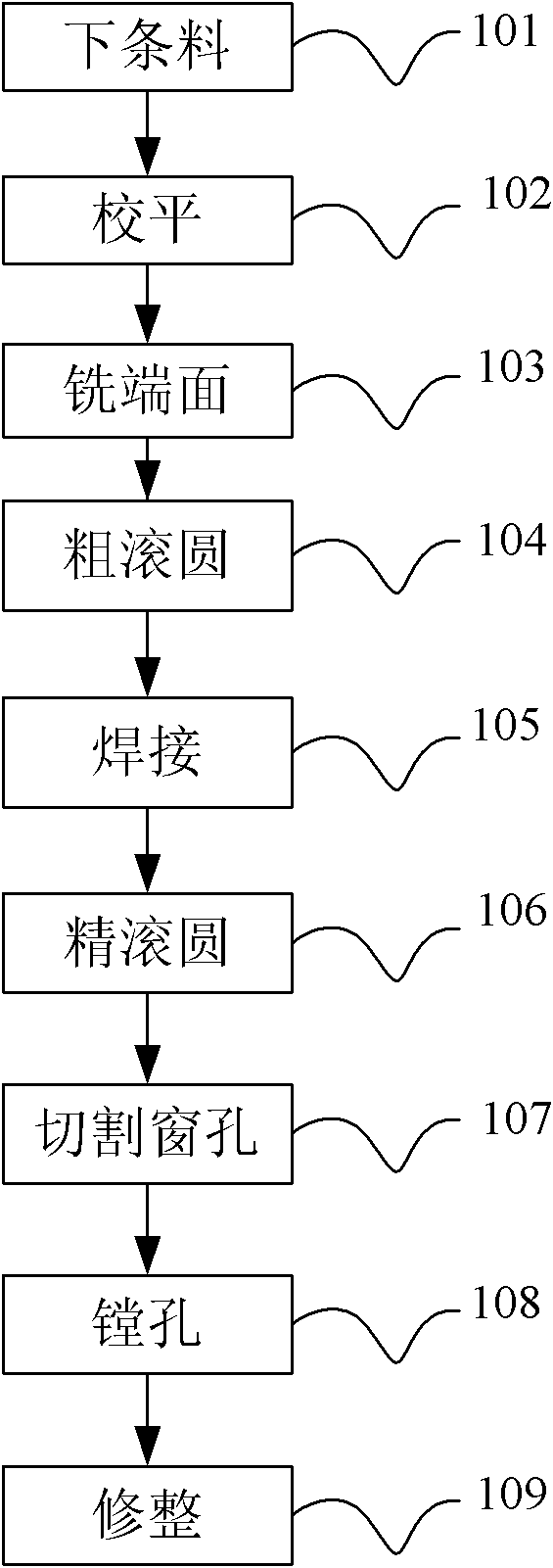

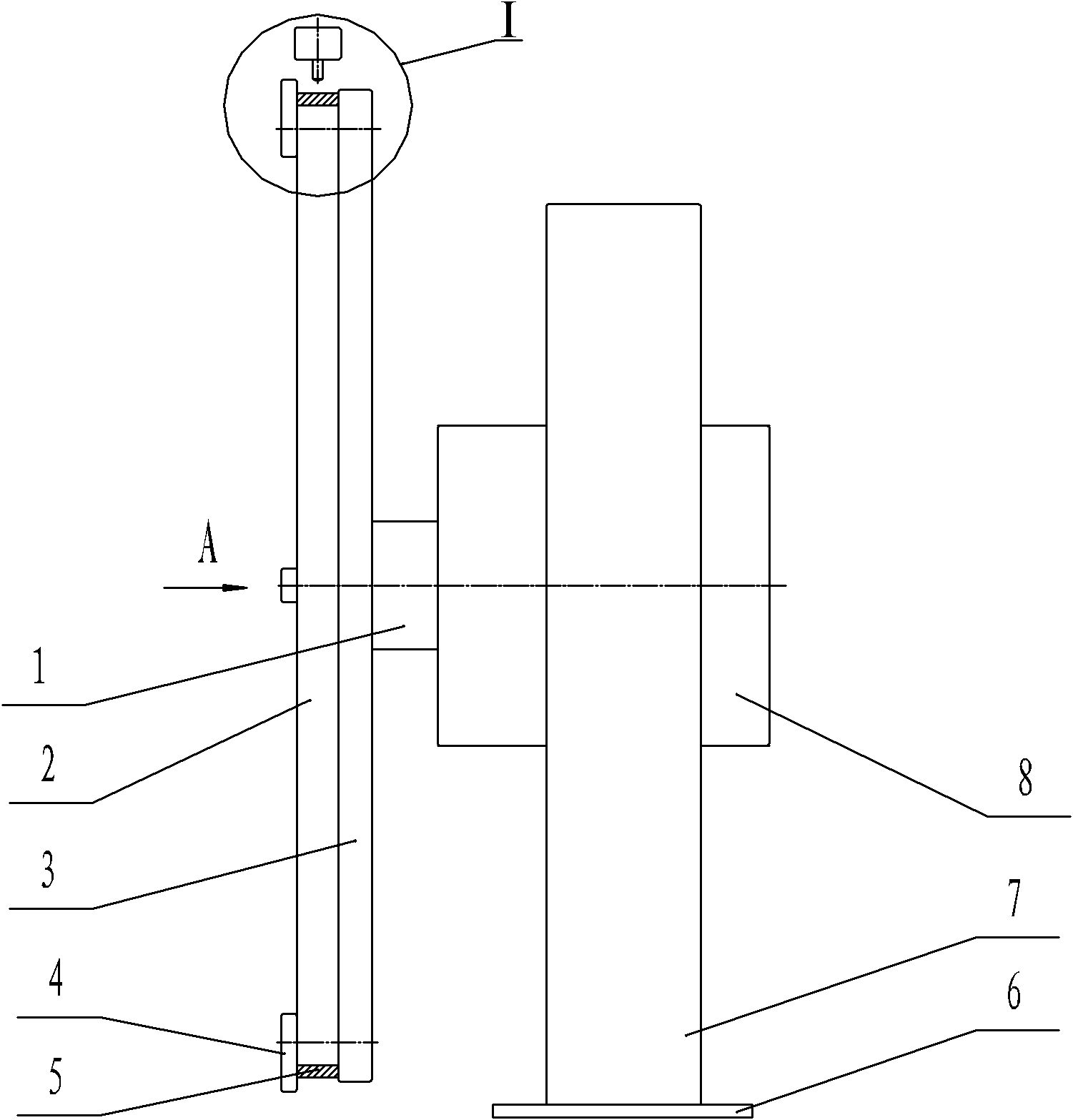

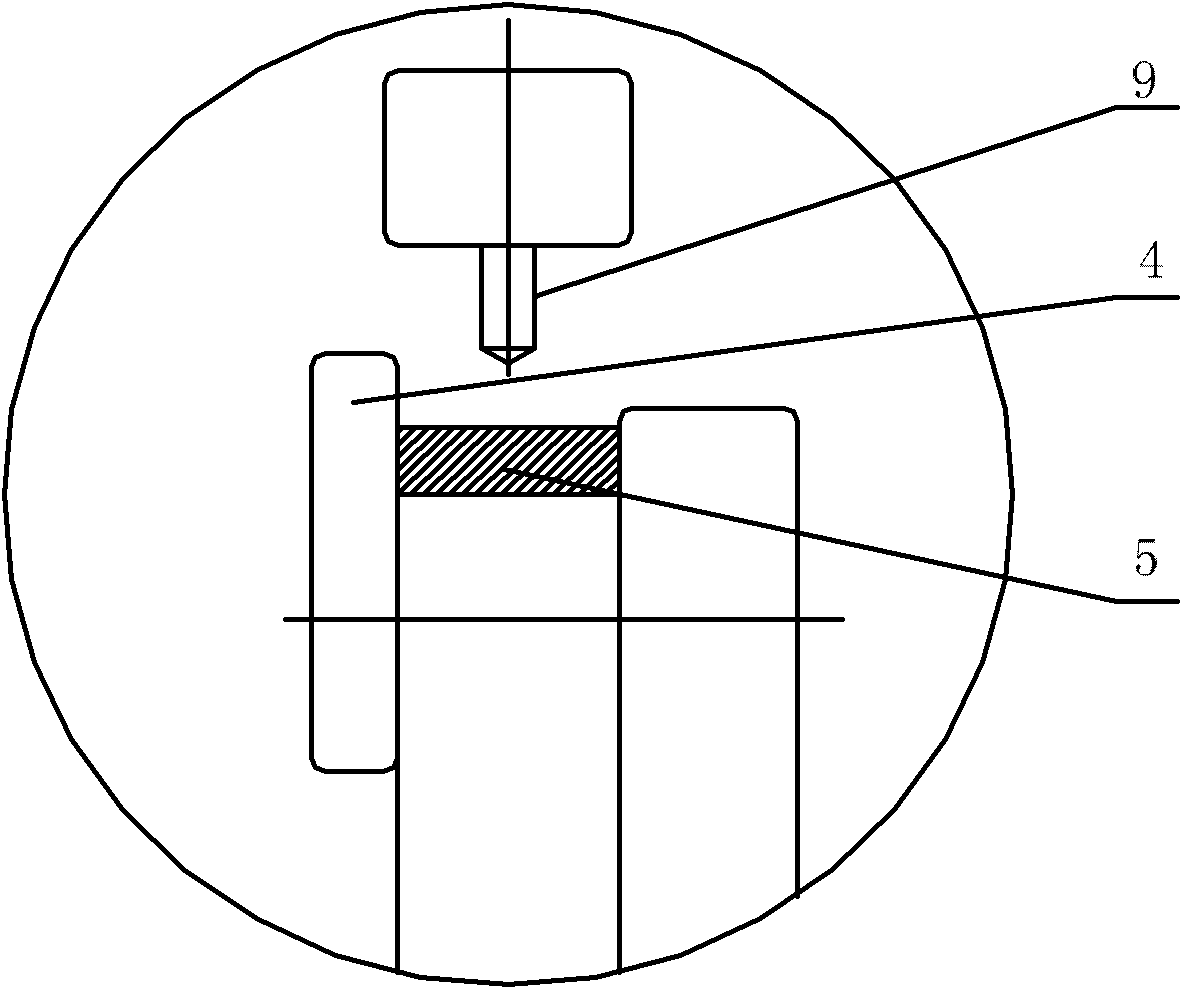

Process for machining isolated steel belt of slewing bearing steel ball

ActiveCN102152080AAvoid Polygonal CirclesConsistent elasticityLaser beam welding apparatusButt weldingRounding

The invention discloses a process for machining an isolated steel belt of a slewing bearing steel ball, comprising the steps of: machining strip materials by the procedures of feeding bar materials, leveling and milling end faces; roughly rounding: roughly rounding the strip materials to process arced strip materials with the radiuses approaching that of product rings; welding: carrying out butt welding on the arced strip materials to obtain rings with the radiuses approaching that of the product rings; finely rounding: finely rounding the rings till a finally required cylindricity of a product is obtained; cutting orifices: sequentially carrying out laser cutting on the finely rounded rings to obtain rolling-body orifices; and boring: boring and trimming the rolling-body orifices to obtain the diameter of the orifice required finally. In the invention, because the process is regulated in that the rolling-body orifices are subjected to laser cutting after fine rounding is carried out, the strength of the strip materials is consistent along the length direction; elastic deformation and plastic deformation of the materials are uniform and consistent in the processes of roughly rounding and finely rounding and no inflection points are generated along an arc direction, so that ribbed roundness of a workpiece is effectively avoided; and reshaping is not needed so that the cylindricity precision of products is ensured.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

Processing method of carrying out rotary forging on forge pieces with high precision of truck hub

The invention relates to a processing method of carrying out rotary forging on forge pieces with high precision of a truck hub. The processing method is characterized by comprising the following steps of (1) heating an aluminium bar: taking the aluminium bar, adopting an aluminium bar heating furnace to heat the aluminium bar for 3 hours, and heating to be 420 DEG C-480 DEG C; (2) upsetting the aluminium bar: taking an oil press, arranging an upper moulded board and a lower moulded board in the oil press, presetting the height of the upper moulded board to be 150mm and the pressure of the upper moulded board to be 2,000 tons, and mould-pressing and upsetting the heat aluminium bar so as to obtain a rough blank; (3) rotary forging: putting the rough blank in a rotary forging machine, contacting the rough blank and a first upper mould line, and gradually mould-pressing to form a workblank; (4) ejecting the workblank: after the rotary forging machine descends to open a mould, ascending a first ejection rod to eject the workblank; (5) punching and chambering: grabbing the ejected workblank into a punching and chambering forging machine through a manipulator, punching and chambering the workblank through the punching and chambering forging machine, and obtaining the forge pieces with high precision.

Owner:浙江宏鑫科技股份有限公司

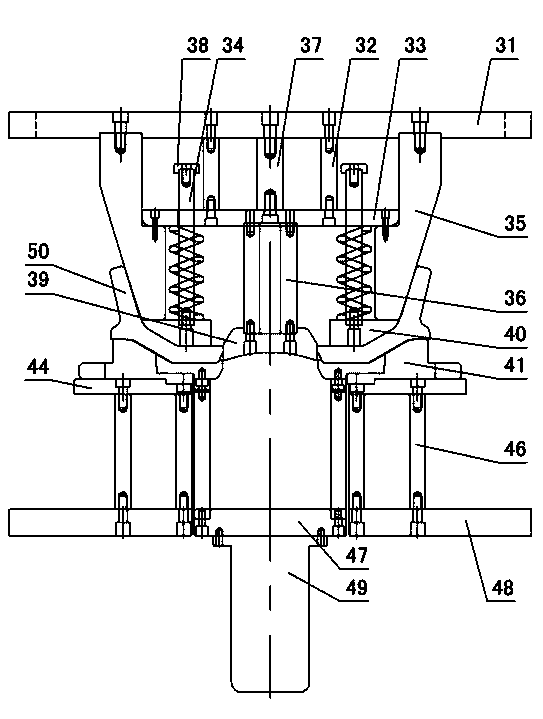

Preparation method of Nb roughening titanium aluminum base alloy composite material

The invention discloses a preparation method of a Nb roughening titanium aluminum base alloy composite material. The preparation method comprises the following steps: (1) titanium aluminum prealloyingpowder and Nb powder are uniformly mixed to form mixed powder, wherein the titanium aluminum prealloying powder comprises Ti, Al, Nb and W; (2) hot isostatic pressing is performed on the mixed powderobtained in the step (1) in vacuum to obtain a hot isostatic pressing blank; (3) high-temperature hot extrusion is performed on the hot isostatic pressing blank prepared in the step (2); and a rod blank is prepared after air cooling; and (4) the rod blank prepared in the step (3) is heated, and is cooled along with a furnace to obtain the Nb roughening titanium aluminum base alloy composite material. The preparation method is simple in process step, shorter in production period, simple and easy-obtained in raw material and low in cost; and prepared products are excellent in performance.

Owner:CENT SOUTH UNIV

Aircraft engine lip low-half section drawing forming method

InactiveCN107695207AUniform plastic deformation of the sectionUniform plastic deformationShaping toolsButt jointEngineering

The invention relates to an aircraft engine lip low-half section drawing forming method. According to a part theoretical model design drawing forming process model, the process model comprises a convex molded surface and flange edges on the two sides, the upper portion of the convex molded surface is coincident with a part theoretical model, the lower portion of the convex molded surface is an extending supplement face, and the supplement face is composed of a theoretical model tangential extending face and a flange edge vertical extending face; center lines of rolling ribs are designed on theflange edges on the two sides of the process model; a die comprises a female die, edge pressing rings and a male die; the edge pressing rings are matched with the flange edges of the process model, and the upper surfaces of the edge pressing rings are provided with the rolling ribs corresponding to the protruding center lines; the female die is provided with a molding cavity, and a butt joint face of the female die and the edge pressing ring is provided with rolling grooves corresponding to the rolling ribs; and the convex molded surface is the same as a convex molded surface of the process model.

Owner:XIAN AIRCRAFT IND GROUP

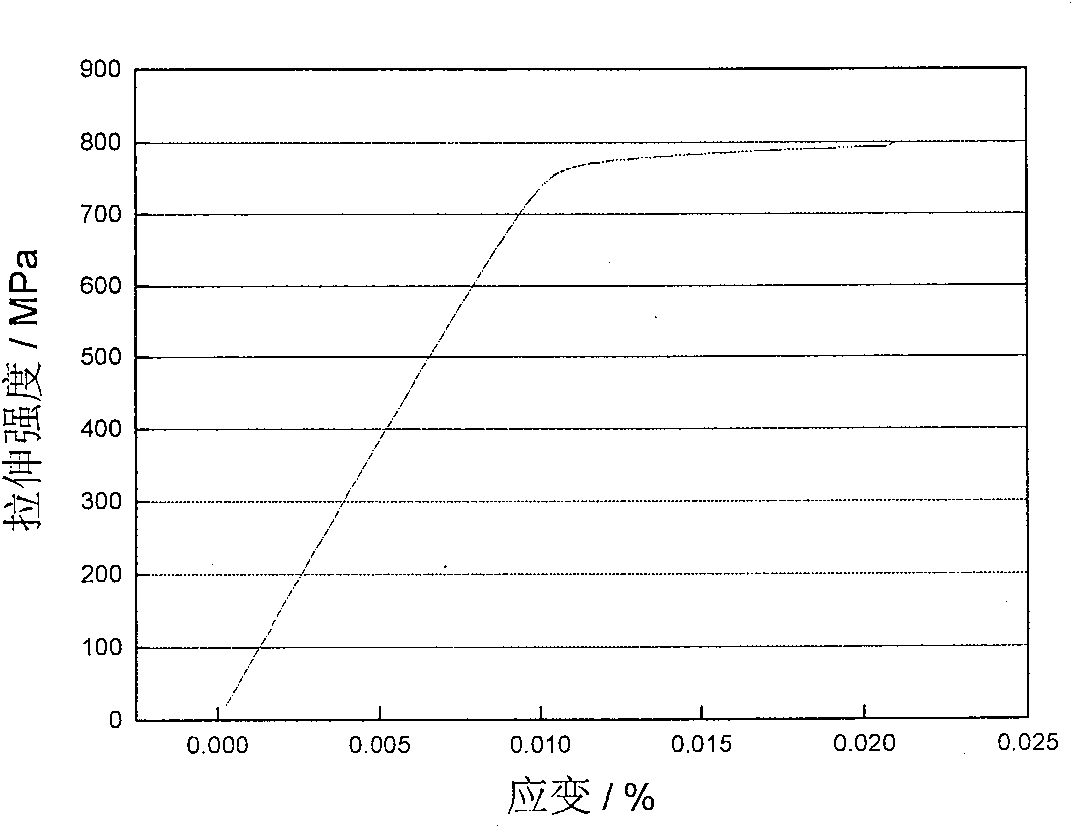

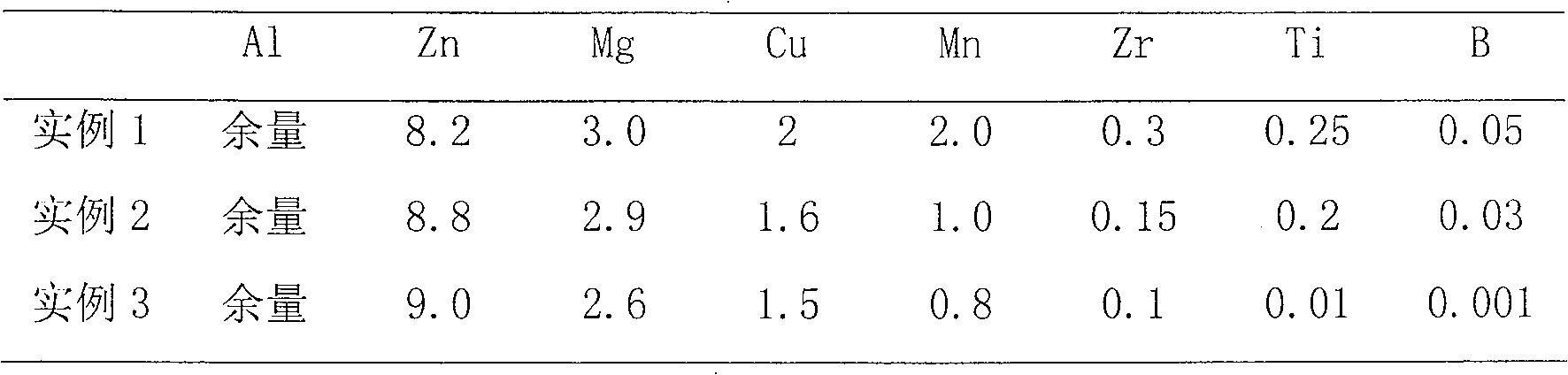

High-toughness manganese-containing aluminum alloy

The present invention relates to a high-strength and tough aluminum alloy, in particular to a high-strength and high-toughness 7000 series aluminum alloy material prepared by spray forming. , Cu: 1.5-2.0wt%, Mn: 0.8-2.5wt%, Zr: 0.1-0.3wt%, Ti: 0.01-0.3wt%, B: 0.005-0.05wt%, Al: balance. In addition to the common G.P zone, η' and η(MgZn2) phases, the strengthening phase of the high-strength aluminum alloy also has a finely dispersed manganese-containing intermetallic compound, which makes it have a tensile strength of more than 800MPa and a content of 5.3% or more. Elongation, with better heat resistance, can improve the structural efficiency and performance of aerospace and transportation materials.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum alloy electric arc additive manufacturing quality control system and method

ActiveCN112008198AEliminate stomataEliminate crack defectsAdditive manufacturing apparatusWelding/soldering/cutting articlesControl systemQuality control

The invention belongs to the field of additive manufacturing, and discloses an aluminum alloy electric arc additive manufacturing quality control system and method. Formed aluminum alloy accumulated metal is machined in a rotational friction plastic deformation manner, the defects of pores, cracks and the like possibly existing in original accumulated metal can be effectively eliminated, and meanwhile, aluminum alloy accumulated metal grains and a precipitation phase are refined, so that the mechanical property is improved, the problem that the forming quality is difficult to effectively control during aluminum alloy electric arc additive manufacturing is solved, the method is completely different from a process optimization and wire selection method in an existing electric arc additive manufacturing aluminum alloy component quality control technology, the manufacturing efficiency is high, the cost is low, and the forming quality is stable.

Owner:HUAZHONG UNIV OF SCI & TECH

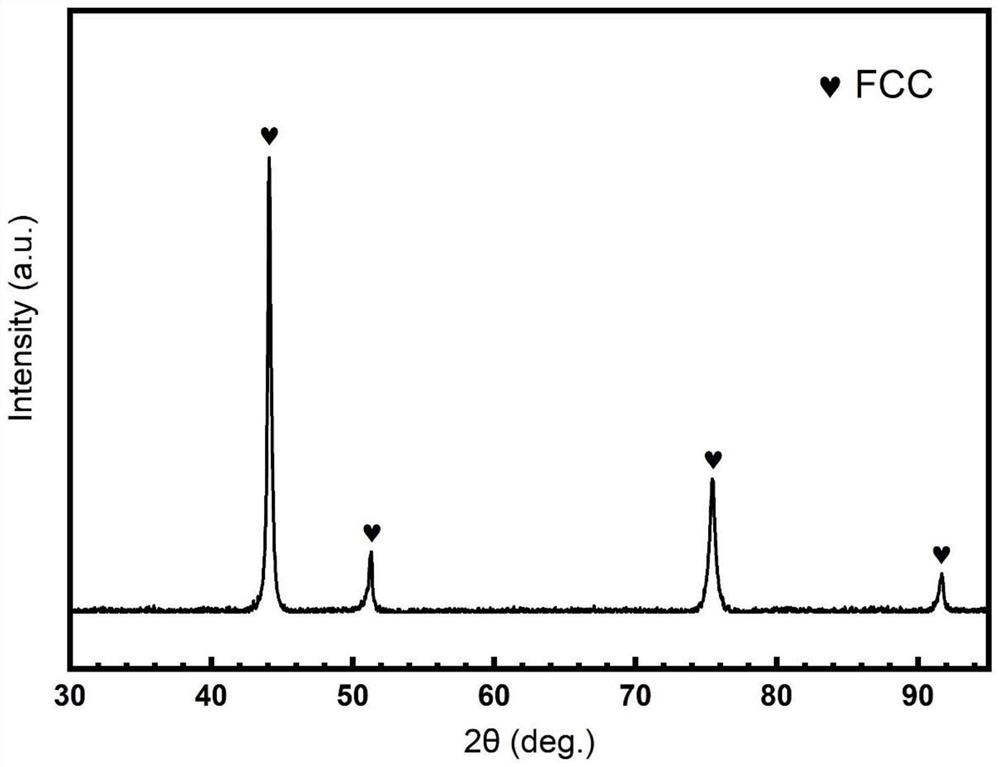

Low-temperature-wear-resistant medium-entropy alloy and preparation method thereof

Owner:NORTHWESTERN POLYTECHNICAL UNIV

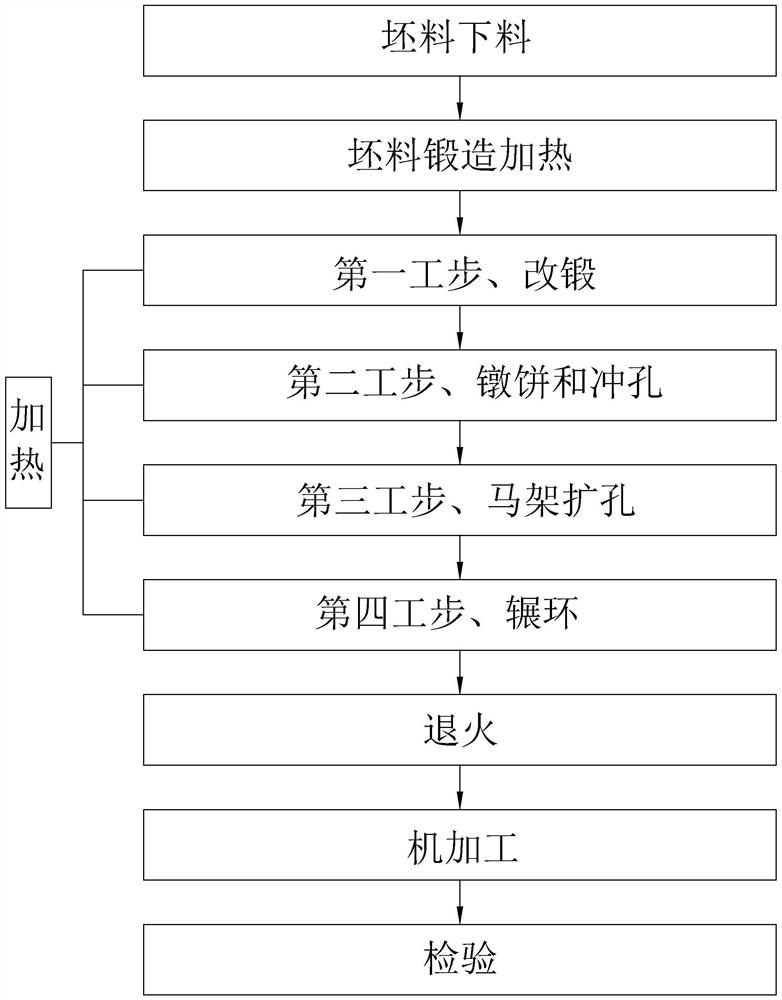

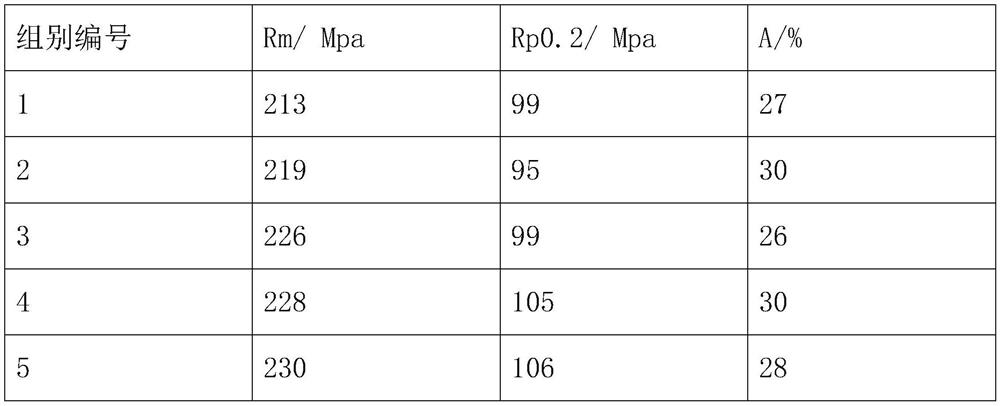

Forging method for improving qualified rate of large-wall-thickness 5754 aluminum alloy forged piece

The invention discloses a forging method for improving the qualified rate of a large-wall-thickness 5754 aluminum alloy forged piece, and belongs to the technical field of aluminum alloy forging. According to the technical scheme, the forging method is characterized by comprising the following steps that S1, a blank is blanked; S2, forging and heating are conducted on the blank; S3, the heated blank is forged to obtain a ring blank; S4, annealing is conducted; S5, machining is conducted; and S6, inspection is conducted. The method has the advantages that the cast ingot applies appropriate plastic deformation, the microstructure is improved, grains are refined, the situation that micro-cracks are formed in the middle of the wall thickness due to non-uniform stress is avoided, and the qualification rate of workpieces is increased.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

Short-process preparation method of high-toughness aluminum-lithium alloy sheet

ActiveCN112981198ASolve oxidation burning lossSolve the suction problemFurnace typesMetal rolling arrangementsThin slabIngot

The invention discloses a short-process preparation method of a high-toughness aluminum-lithium alloy sheet, and belongs to the field of aluminum-lithium alloy rolling forming and deformation heat treatment. According to the method, a 2197 aluminum-lithium alloy cast ingot is prepared through smelting by adopting flux and argon protection and a common gravity casting method, and the high-strength and high-toughness sheet with the thickness of 1-1.5 mm is formed through three-pass rolling (the total rolling reduction is 75%) by adopting deformation, deep cooling and heat treatment regulation and control methods. According to the method, short-process preparation of small-pass and large-rolling-reduction rolling forming and structure property regulation and control is directly carried out on the aluminum-lithium alloy cast ingot, the technical problems that the aluminum-lithium alloy is poor in plasticity and toughness, serious in anisotropy, insufficient in strength and difficult in sheet forming are solved, and the defects that a conventional aluminum-lithium alloy plate thermal mechanical treatment is complex in process, long in production process, low in yield and high in manufacturing cost are overcome.

Owner:TAIYUAN UNIV OF TECH

Preparation of magnesium alloy with high strength and ductility

A preparation method of a high-strength magnesium alloy relates to a spray deposition preparation process and proposes the spray forming technology which adopts protective atmosphere, thus solving the problems of volatilization, oxidation and safety etc. of the magnesium alloy, preparing a magnesium alloy deposition blank with complete shape, low segregation, high density and qualified componentsand ensuring the macro-mechanical properties of Mg-Al-Zn alloy and the plastic deformation capacity to be synchronously improved. The method is that firstly, an alloy ingot is arranged in a melting furnace, the vacuum extraction is carried out, the furnace is washed by argon for 2 to 3 times, when the vacuum degree is 10 to 70 Pa, the argon is filled till the pressure is slightly lower than the outside atmospheric pressure, the ingot is melted, electromagnetically stirred and evenly mixed, after that, the ingot is poured to a middle package when the temperature of the melt is 700 to 770 DEG Cand is flown out by a flow guide nozzle, an annular hole type non-limited atomizing nozzle is adopted for high-pressure atomizing N2 gas, the atomization pressure is 0.5 to 0.6MPa, and atomized liquid is deposited on a receiving polar plate to form the columnar magnesium alloy deformation blank. The strength and the toughness of the magnesium alloy material prepared by the invention are both in better levels, thus realizing the synchronous improvement of the strength and the toughness.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method for magnesium alloy

The invention relates to the spray deposition preparation process, and discloses a preparation method of high-toughness magnesium alloy. According to the preparation method, a spray forming technology in the protective atmosphere is adopted, so that the problems of volatilization, oxidation, safety and the like of the magnesium alloy are solved, and the mechanical property and the plasticity and toughness of the magnesium alloy are synchronously improved. The method comprises the following steps: firstly, putting an alloy ingot into a smelting furnace, extracting the furnace to a vacuum state, carrying out argon gas slugging for 2-3 times, filling the furnace with argon gas when the vacuum degree is 10-70 Pa until the pressure is slightly lower than the atmospheric pressure of the exterior, melting the ingot, electromagnetically stirring and evenly mixing the melted ingot, then pouring the melted ingot into a tundish when the melt temperature is 700-770 DEG C, making the melted ingot flow out through a flow guide nozzle, atomizing the melted ingot, and finally depositing atomized liquid drops on a receiving pole plate to form columnar magnesium alloy deposition blanks, wherein the annular hole type non-limiting type atomizing nozzle is adopted, high-pressure atomization N2 gas is adopted, and the atomization pressure is 0.5-0.6 MPa. The strength and the toughness of the prepared magnesium alloy are both high and are synchronously improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

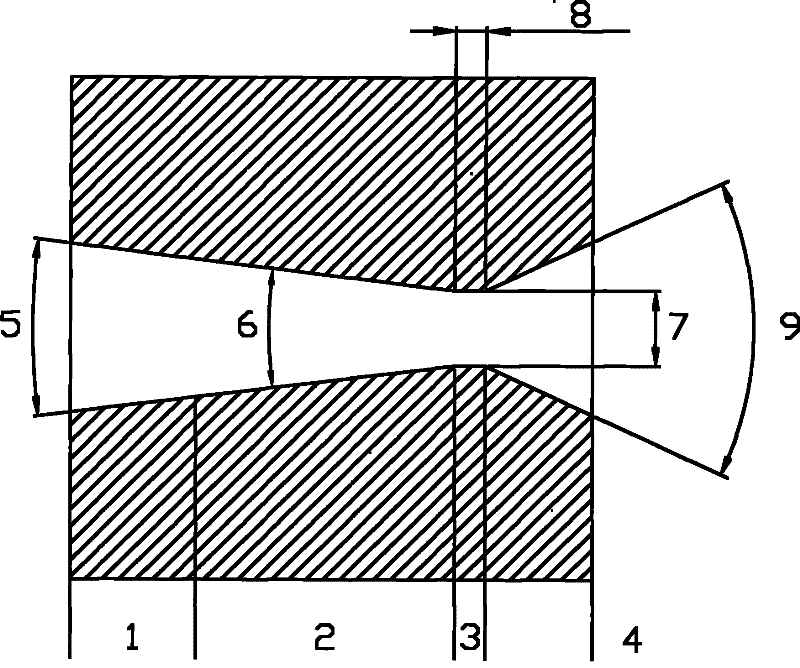

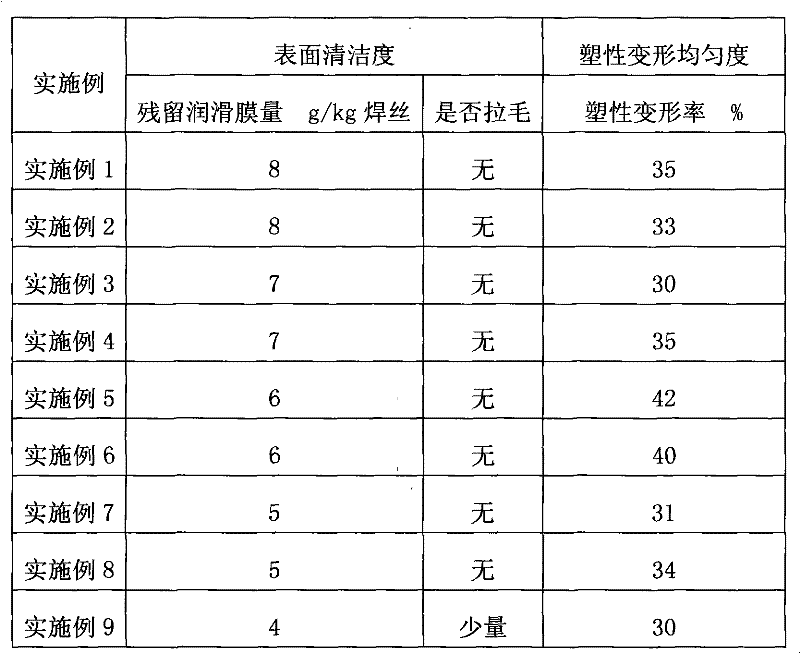

Wire drawing die for welding wires

InactiveCN102233359AIncreased wire feed capacityImprove stabilityDrawing diesSurface cleaningEngineering

The invention discloses a wire drawing die for welding wires. The wire drawing die is equipped with an inner hole in a die core, and the inner hole is formed by connecting an access area, a compression area, a sizing area and a release area, wherein, an access angle, a compression angle and a release angle are correspondingly arranged on the access area, the compression area and the release area; a sizing diameter and a sizing length are set on a corresponding sizing area; the compression angle is 10-16 degrees; and for the corresponding sizing area, the ratio of the sizing length to the sizing diameter is 30%-45%. The welding wires produced by the wire drawing die has the advantages of high surface cleanliness and uniform plastic deformation so as to improve wire feeding property and linear stability of the welding wires and form a smooth and level welding bead; and the access angle is equal to the compression angle so as to prevent lubricating powder from reversely overflowing in case of being obstructed by the compression angle in the compression area after entering the access area, thus the lubricating powder can fully enter the access area.

Owner:KUSN GINTUNE WELDING

Device and method based on electrostatic force gradual advancing and push-and-pull composite forming and used for large aluminum alloy part

The invention relates to the technical field of aluminum alloy forming and provides a device and method based on electrostatic force gradual advancing and push-and-pull composite forming and used fora large aluminum alloy part. The device comprises pressing plates, ejecting plates, a die and solenoid coils. The pressing plates are located above the ejecting plates and used for fixing the aluminumalloy part to the ejecting plates. The solenoid coils are arranged above the die, and the aluminum alloy part is arranged between the die and the solenoid coils. The method comprises the following steps that (1), the aluminum alloy part is put on the ejecting plates and fixed through the pressing plates; (2) the position of the die is adjusted, and the die is arranged below the aluminum alloy part to be formed; and (3), the solenoid coils are electrified, and the solenoid coils and the die located below the aluminum alloy part interact to complete forming of the aluminum alloy part. Accordingto the device and method based on electrostatic force gradual advancing and push-and-pull composite forming and used for the large aluminum alloy part, electrostatic force gradual advancing forming and the traditional push-and-pull technology are combined, thinning of walls can be obviously restrained compared with traditional spinning forming, and wrinkling can be obviously restrained compared with traditional stamping.

Owner:SHANDONG UNIV OF SCI & TECH

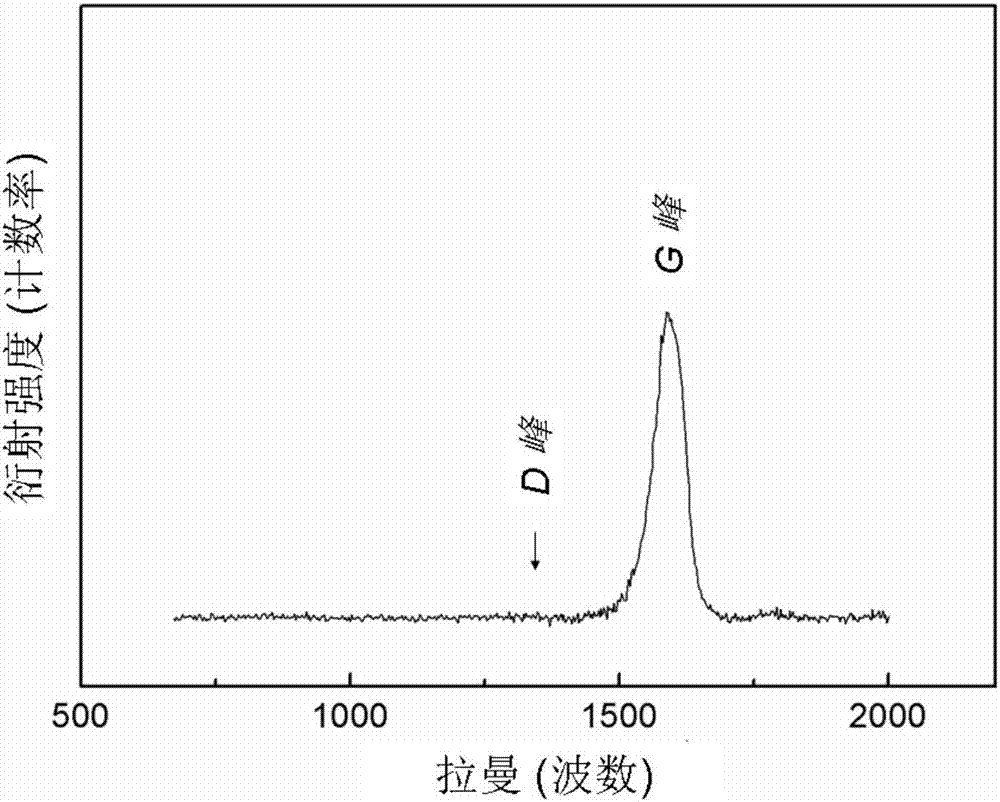

A kind of preparation method of graphene copper composite wire

ActiveCN106548831BSimple methodAdjustable thicknessConductive materialMetal/alloy conductorsVacuum pumpingSolvent

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

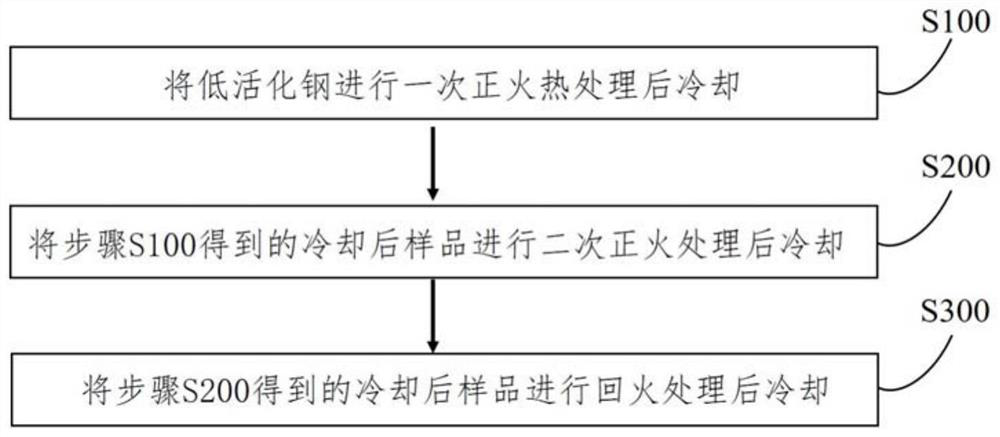

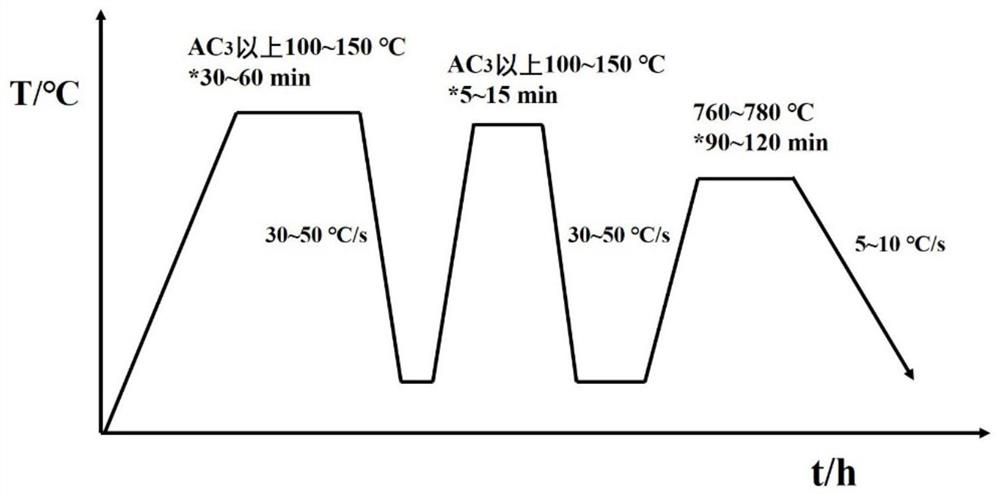

Method for heat treatment of low-activation steel

The invention discloses a method for heat treatment of low-activation steel. The method comprises the following steps: (1) performing primary normalizing treatment on the low-activation steel, and then carrying out cooling; (2) performing secondary normalizing treatment on a cooled sample obtained in the step (1), and then carrying out cooling; and (3) performing tempering treatment on a cooled sample obtained in the step (2), and then carrying out cooling. Therefore, by adopting the method, uniform and fine original austenite grains and tempered martensite lath structures can be obtained, so that when the low-activation steel is subjected to impact stress, the stress is dispersed on a plurality of grains, the plastic deformation is relatively uniform, the stress concentration is relatively small, the grain boundaries generated by the fine grain structures are relatively large, cracks are not easy to expand, and the toughness of the low-activation steel can be improved. In addition, the method can be further applied to performance optimization of the low-activation steel and production of structural materials of commercial fusion power stations.

Owner:TSINGHUA UNIV

Cerium lanthanum containing high-strength anti-corrosion die-casting magnesium alloy

The invention relates to a high-strength corrosion-resistant die-casting magnesium alloy containing cerium and lanthanum. 0.01% to 1.5%, La is 0.01% to 1.5%, impurity elements Fe≤0.02%, Cu≤0.002%, Si≤0.01%, Ni≤0.001%, and the balance is magnesium. The alloying material used is cerium-lanthanum rare earth, and the remaining cerium-lanthanum rare earth is separated from the Nd and Pr in the common cerium-rich mixed rare earth. Currently, the rare earth material is cheap and has a large backlog in the market. The invention avoids the waste of rare earth resources, and the mechanical properties and plasticity of the alloy are better than those of the AZ91 alloy, and the corrosion resistance can be increased several times to dozens of times.

Owner:白山市天安金属镁矿业有限公司

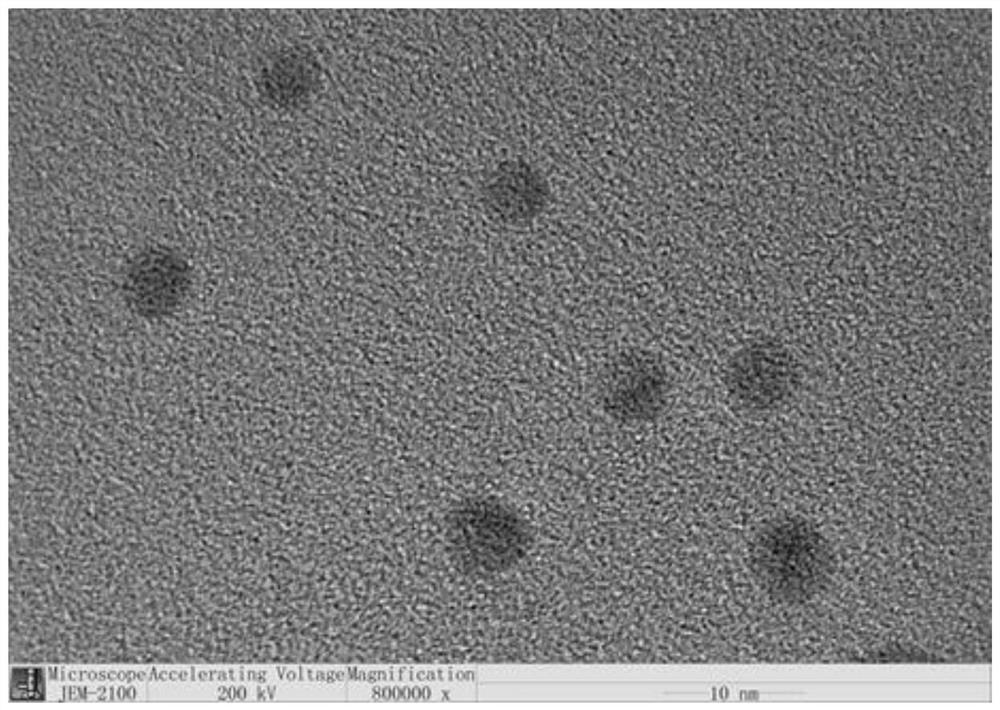

A kind of noble metal quantum dots and preparation method and application thereof

ActiveCN111589444BImprove atom utilization efficiencySmall sizeNanoopticsLuminescent compositionsIon exchangeQuantum dot

The invention belongs to the technical field of quantum dot materials, and in particular relates to a precious metal quantum dot and a preparation method and application thereof. The method comprises the steps of: 1) soaking the vanadate powder of the layered alkali metal cation or transition metal cation into an aqueous solution of a soluble precious metal salt, soaking to perform ion exchange, and then performing solid-liquid separation, washing and drying in sequence, Obtaining the vanadate of the precious metal; 2) calcining the vanadate of the precious metal obtained in step 1) to obtain a mixed powder in which the precious metal quantum dots are dispersed in the vanadium oxide residue; 3) calcining the mixed powder obtained in the step 2) Pickling is carried out to remove vanadium oxide residues to obtain noble metal quantum dots.

Owner:KUNMING UNIV OF SCI & TECH

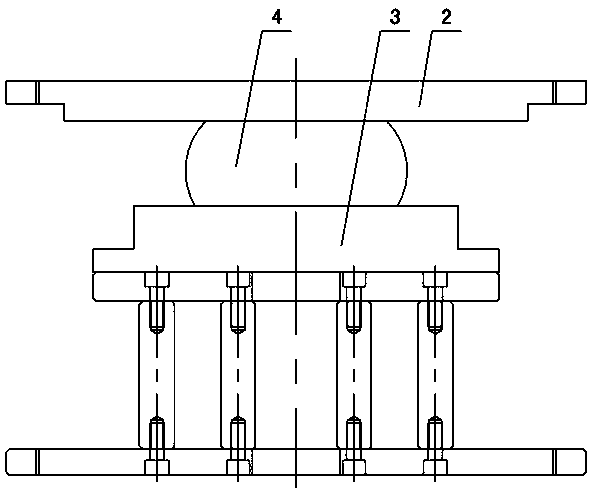

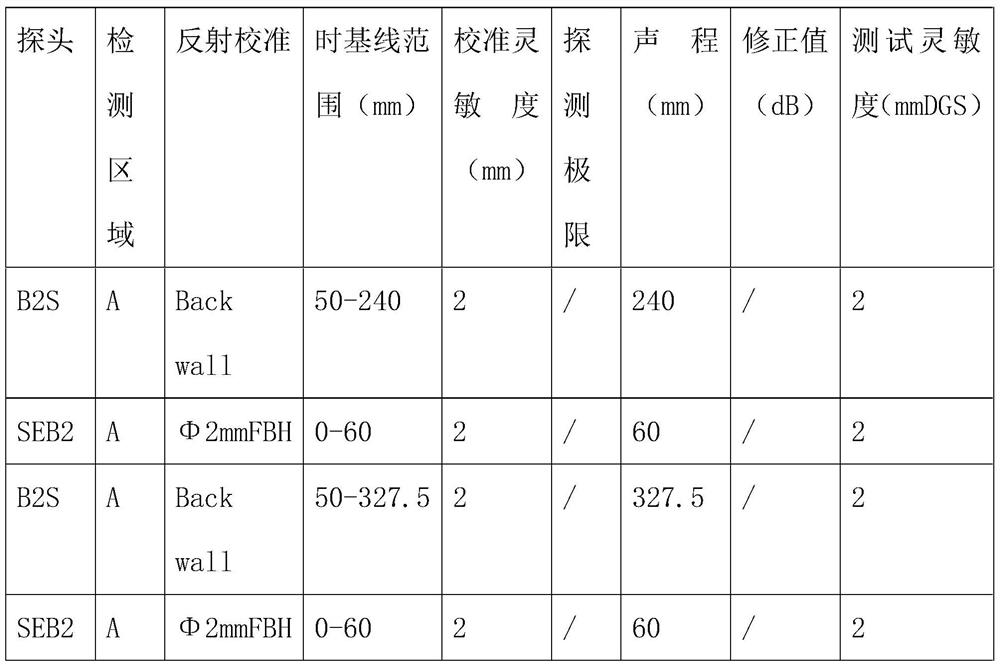

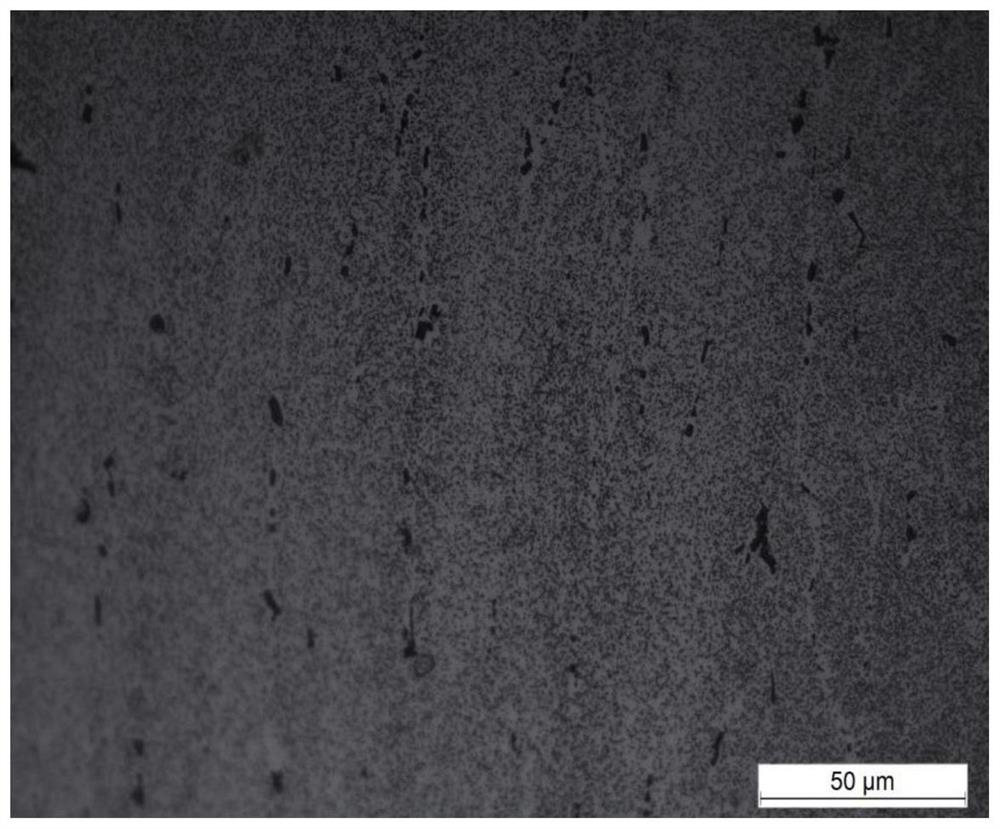

A method of controlling rolling and cooling for fine and homogeneous structure of bearing ring

ActiveCN103341728BUniform plastic deformationInhibition of growth and coarseningTemperature control deviceWork treatment devicesManufacturing technologyCarbide

The invention relates to the bearing manufacturing technology. A bearing ring organization refining-homogenizing rolling-cooling control method is characterized by comprising the following steps that (1) a blank is prepared in a hot-forging mode; (2) hot rolling is controlled, namely the hot-forged bearing ring blank is subjected to hot rolling on a ring rolling machine to form a bearing ring, rolling deformation, deformation speed and deformation temperature are reasonably controlled, the hot-rolled bearing ring is obtained; (3) forced cooling is carried out, namely forced cooling is carried out on the hot-rolled bearing ring by water cooling and air cooling; the hot-rolled bearing ring is immersed into cooling water of 60-80 DEG C to be cooled to 400-500 DEG C, and the hot-rolled bearing ring is cooled to room temperature by a fan in an air-blowing mode after being taken out. According to the method, the grain sizes and carbide particles of the obtained bearing ring are refined, the grain sizes are even, a bearing ring organization can be effectively refined and homogenized.

Owner:WUHAN UNIV OF TECH

Multi-roll continuous casting and rolling equipment and method for preparing high-conductivity metal-clad materials

ActiveCN111715856BGuaranteed mechanical propertiesGuaranteed interface strengthMechanical engineeringContinuous casting

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com