Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Uniform strain distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

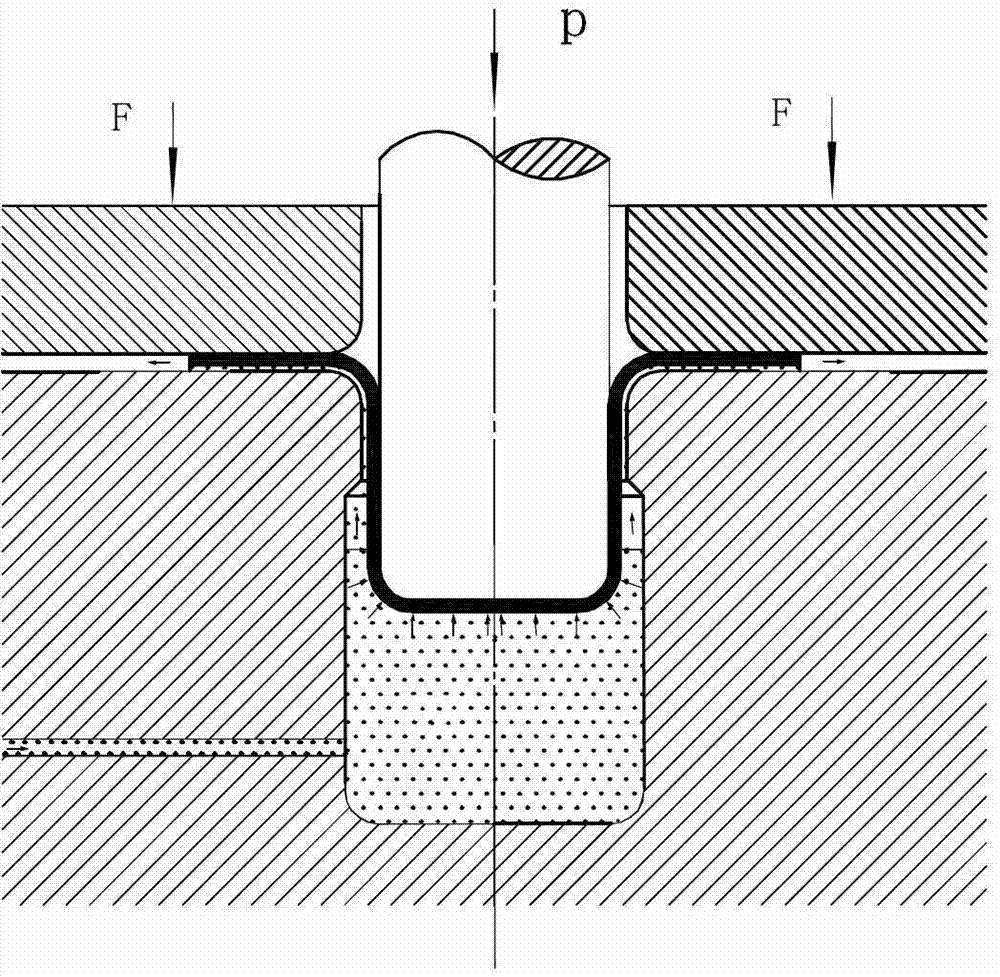

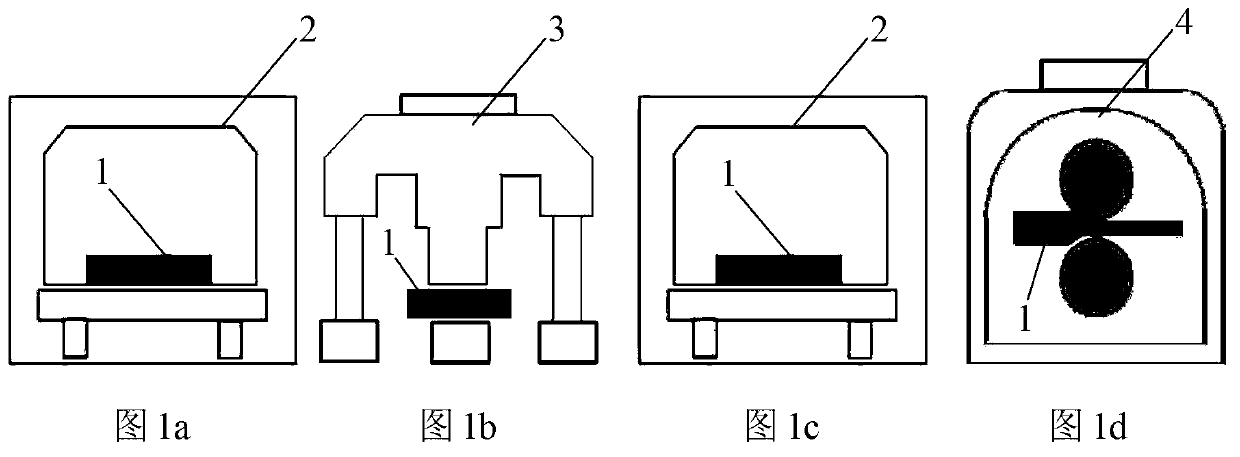

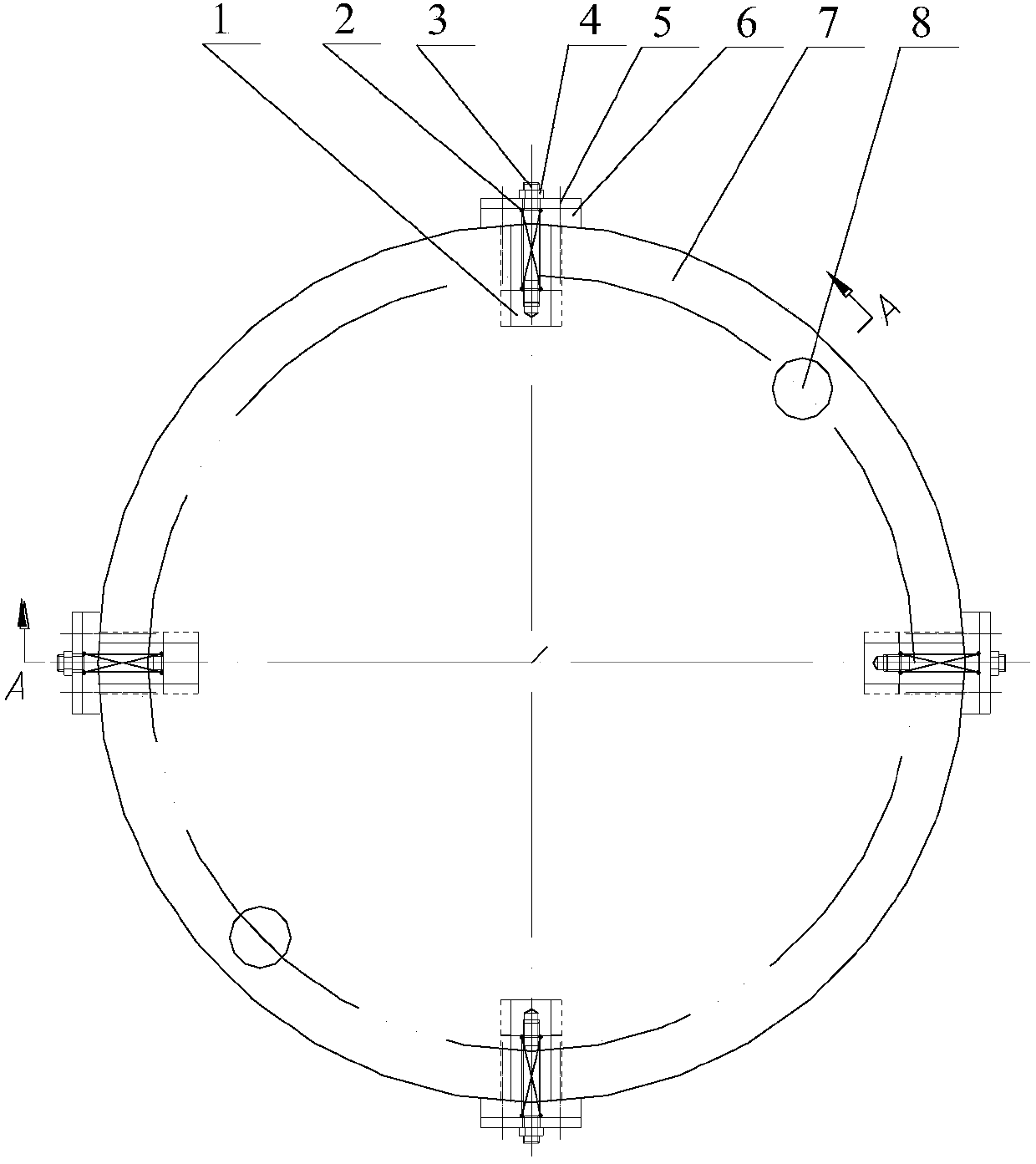

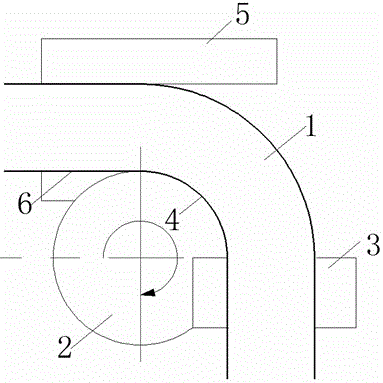

Hot upsetting process for cast ingot with large height to diameter ratio for ultra large ring forging

InactiveCN101972830AUniform stressUniform strain distributionMetal-working apparatusDiameter ratioIngot

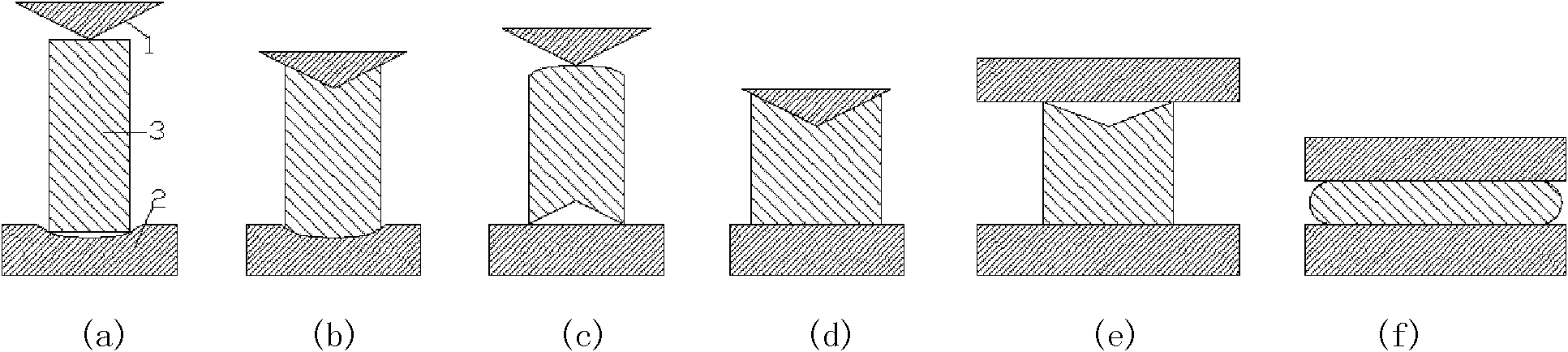

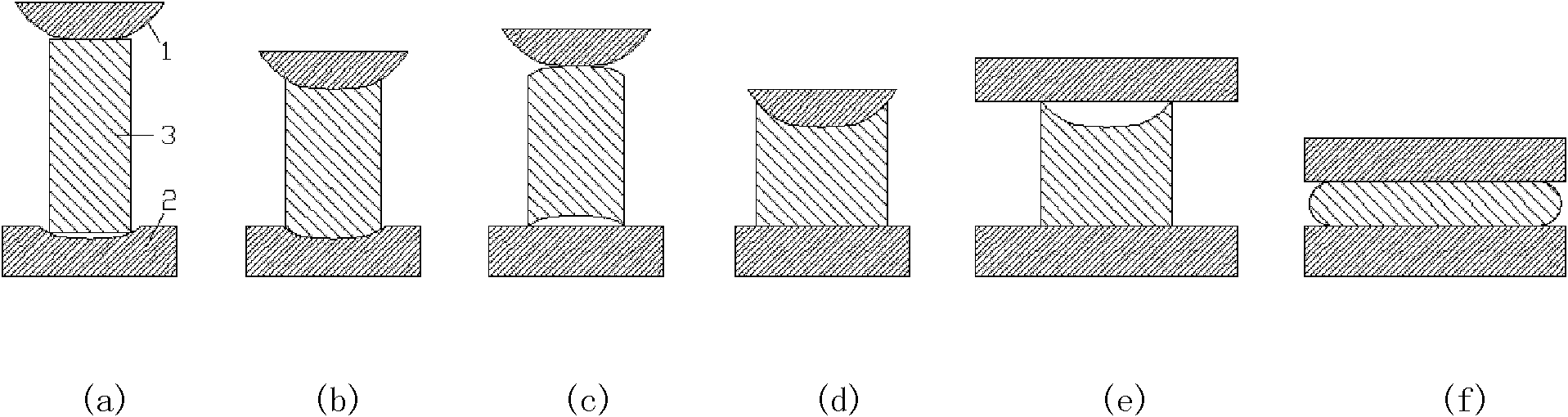

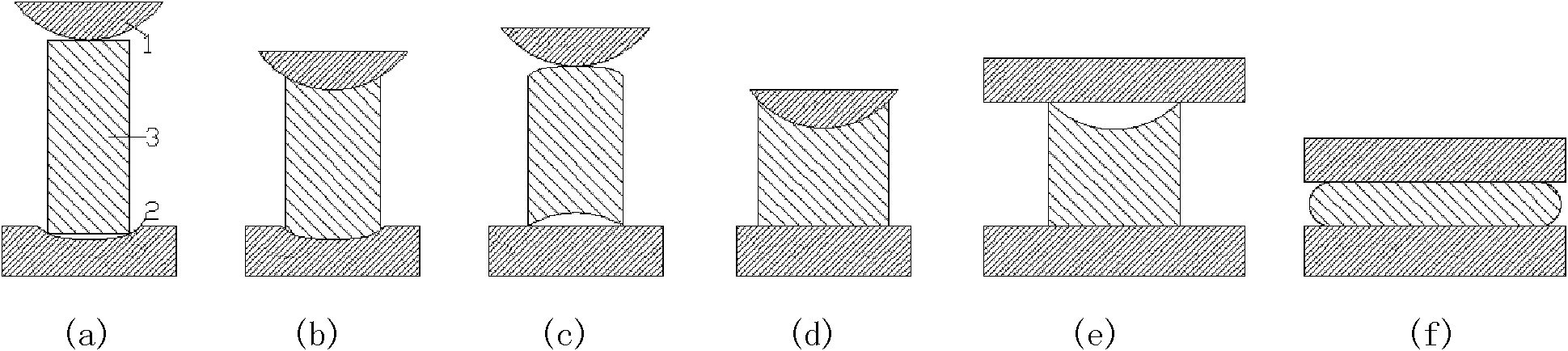

The invention relates to a hot upsetting process, in particular to a hot upsetting process for a cast ingot with a large height to diameter ratio for an ultra large ring forging. The process is characterized by comprising the following steps of: 1) hanging a heated high-temperature cast ingot with a large height to diameter ratio on a lower female die; 2) adjusting the position of an upper male die so as to ensure that the central line of the upper male die is coincided with the central lines of the cast ingot and the lower female die; 3) driving the upper male die to move downward by using a power mechanism; 4) further moving the upper male die downward so as to continuously decrease the height to diameter ratio of the cast ingot; 5) reversing the cast ingot which is in a contact molding state by hot upsetting, replacing the lower female die by using a flat plate die and further lowering the upper male die; and 6) replacing the upper male die by using a flat plate die and further lowering the upper male die until the cast ingot is upset to a cast ingot with a required blank height and size so as to obtain an upset blank. On the premise of ensuring that the hot upsetting process of the cast ingot with the large height to diameter ratio is performed successfully, the process also ensures the stress, uniform strain distribution, small bulge and uniform internal structure of the unset blank after upsetting is finished and provides an unset blank with high performance for the manufacturing of a subsequent forging.

Owner:WUHAN UNIV OF TECH

Electromagnetism-assisted forming device and method for dissimilar metal composite boards

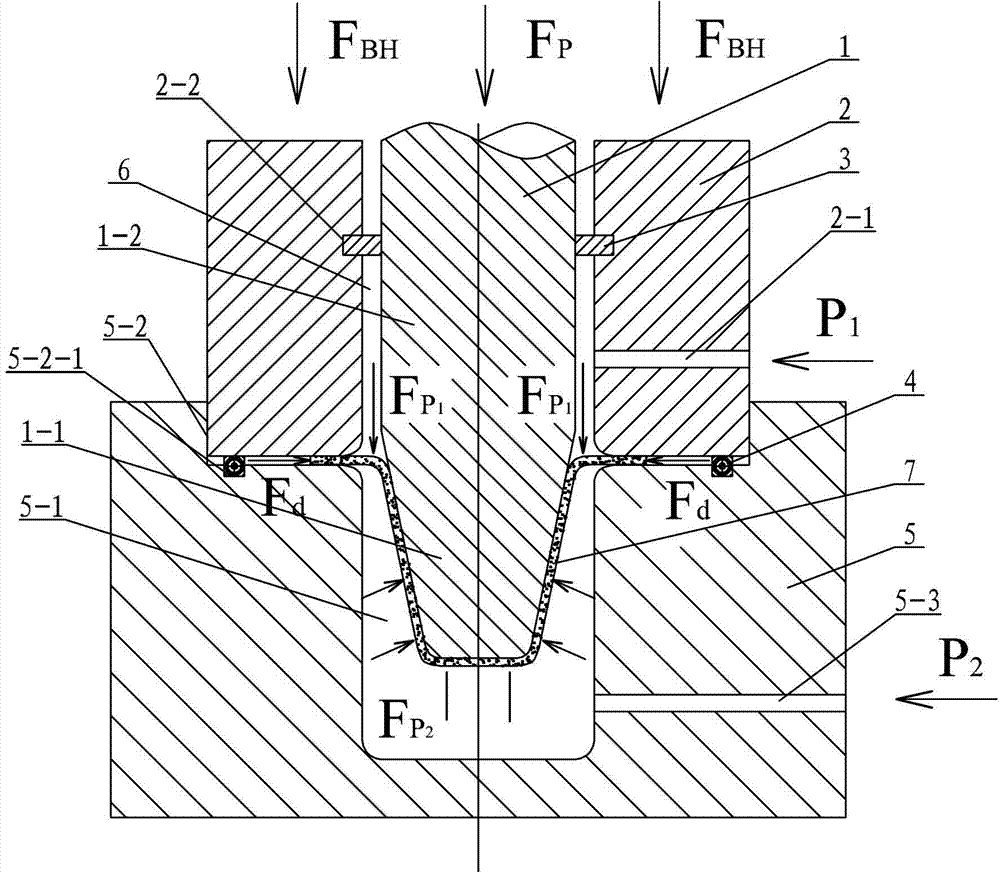

The invention relates to an electromagnetism-assisted forming device and method for dissimilar metal composite boards and aims to solve the problem that existing metal composite boards are severely lapped and even broken in a drawing process. According to the forming device, a coil is arranged in an annular coil groove, a liquid channel is disposed between the inner wall of a blank holder and a cylinder, an upper liquid inlet channel is transversely arranged on the side wall of the blank holder, and a lower liquid inlet channel is transversely arranged on the side wall of a female die. The method includes placing the composite boards on the bottom surface of the blank holder; filling forward liquids into the liquid channel, filling reverse liquids into the female die, and exerting radial electromagnetic force Fd on the periphery of a flange of the composite board through the coil; forming the composite board under the combined action of a reverse pressure Fp2, a forward pressure Fp1 and the radial electromagnetic force Fd; and unloading a forward liquid pressure P1 and then a reverse liquid pressure P2, returning a male die and taking the formed part.

Owner:HARBIN INST OF TECH

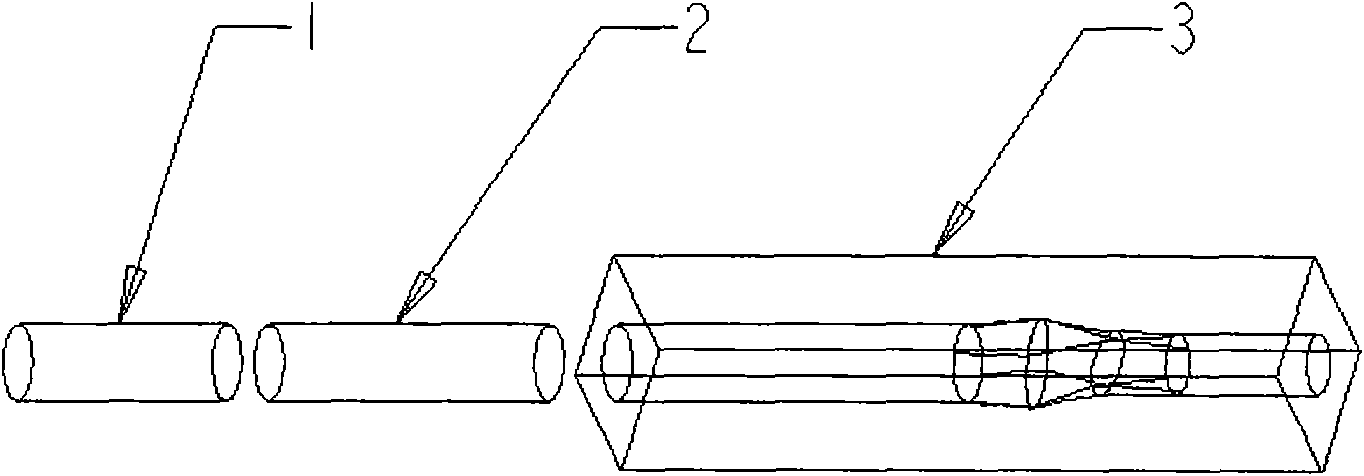

Variable-channel extrusion die and forming method

InactiveCN101823085AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsPowder metallurgyLow load

The invention relates to a variable-channel extrusion die and a forming method. The variable-channel extrusion die comprises a male die (1) and a female die (3), a die cavity of the female die sequentially comprises a feeding section (4), a front forming section (5), a middle forming section (6), a rear forming section (7) and a discharging section (8) from an inlet of a blank (2) to an outlet of the blank (2), wherein the feeding section (4) is a circular equant channel, the front forming section (5) is a circular-elliptical transition channel, the middle forming section (6) is a prismatic elliptical channel, the rear forming section (7) is an elliptical-circular transition channel, and the discharging section (8) is a prismatic circular channel; and the blank (2) enters from an inlet of the female die (3) and is limited by the die cavity of the female die (3) to change a circular cross-section into an elliptical cross-section and change the elliptical cross-section into the circular cross-section in order to form a performed workpiece. The variable-channel extrusion die has simple structure, low load, low cost and high efficiency and can be widely applied to producing rods and wires of steel and nonferrous metal and forging and blanking difficultly deformed materials of large-scale shaft parts, high-speed steel, powder metallurgy, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Piezoelectric vibratory energy harvester

ActiveCN102983781AUniform strain distributionImprove energy conversion abilityPiezoelectric/electrostriction/magnetostriction machinesElectricityEnergy harvester

The invention provides a piezoelectric vibratory energy harvester, which comprises a central mounting structure, four side support beams, piezoelectric layers and a central mass block, wherein the central mounting structure comprises square supporting plates and four centrosymmetric mounting arms; the four side support beams are fabricated by four rectangular metal beams with the same shape; mounting holes for mounting are formed at the two ends; the piezoelectric layers are formed by four piezoelectric ceramic sheets and pasted on upper surfaces of the four support beams; and the central mass block is superimposed by a plurality of metal sheets and mounted in an area formed by the square supporting plates of the central mounting structure. According to the energy harvester, the mass of the central mass block is increased, the structure layout is arranged reasonably, the strain distribution of the piezoelectric layers is improved, and the adaptability of the designed energy harvester to a vibration source is improved, so that the energy harvester has a better practical value.

Owner:BEIHANG UNIV

Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

ActiveCN103273272AUniform strain distributionFine grainTemperature control deviceTension/compression control deviceSteel platesForming processes

The invention belongs to the field of pressure processing of steel materials, particularly relates to a forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks. Numerical simulation technique is adopted to study internal strain distribution of the plate blanks formed by pure rolling, pure forging and the forging-and-rolling compounded forming method, and the forging-and-rolling forming method is provided and includes steps of 1), firstly heating the plate blanks to be cast; 2), subjecting the plate blanks to forging and deforming in a large hydraulic press after heating the same; 3), returning the plate blanks to be forged in a heating furnace for heat preservation after forging and deforming; and 4), delivering the forged plate blanks in a heated manner to a rolling mill to be rolled after heat preservation or cooling the same slowly to room temperature prior to being heated and rolled again. The forging-and-rolling compounded forming method has the advantages that the forging-and-rolling compounded forming method is applicable to forming process of various molded wide and thick plate blanks (slab ingot), especially to blanks with central looseness; by the method, the defect of core density loose of the wide and thick plate blanks can be overcome, micro-segregation can be alleviated, and texture of the plate blanks can be refined and distributed well; and meanwhile, surface quality of the steel plates can be guaranteed, working allowance can be reduced, and the finished wide and thick plate blanks with 'internal solidness and external refinement' can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

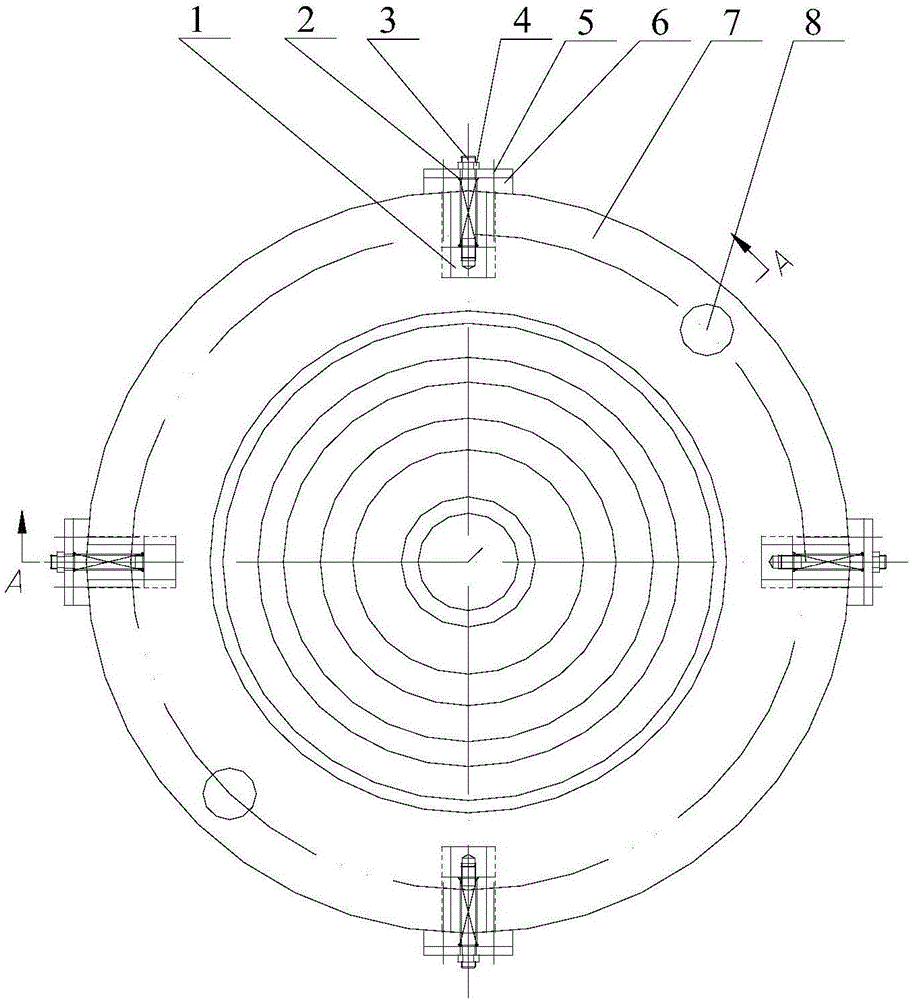

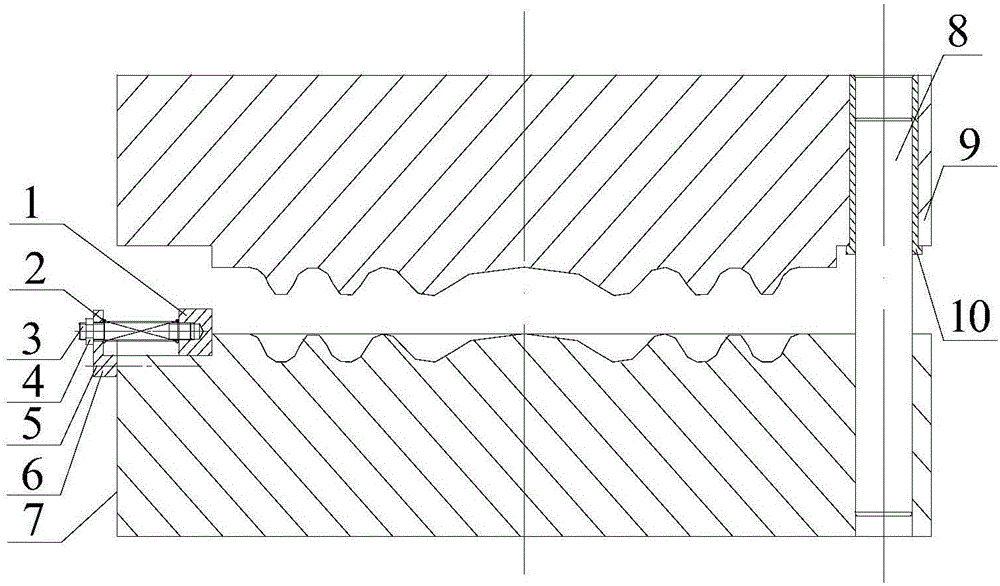

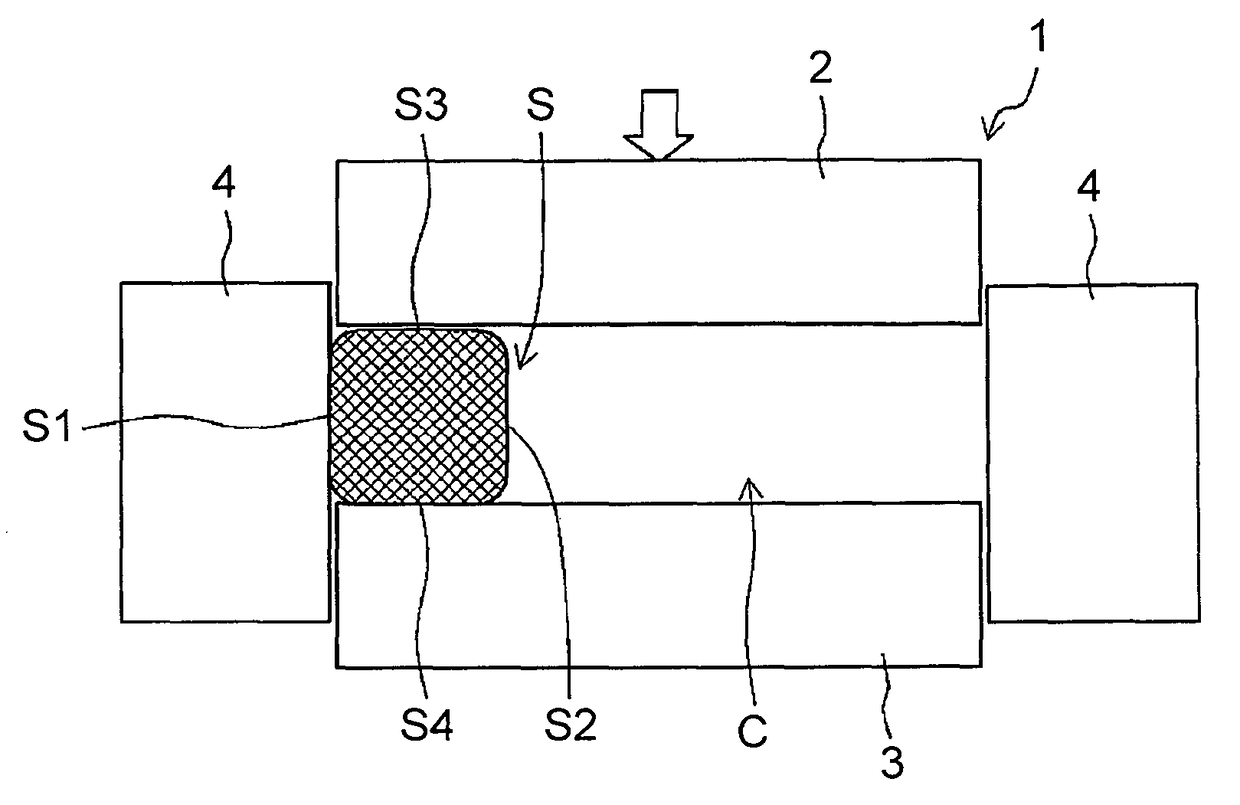

Repeated plate ring wave drawing intense deformation die and technology

InactiveCN106424261AUniform plastic deformationUniform strain distributionShaping toolsMetal-working feeding devicesMicrometerWave shape

The invention discloses a repeated plate ring wave drawing intense deformation die and technology. The die comprises an upper ring wave die body and a lower ring wave die body, wherein the upper surface and the lower surface of the upper ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves, and the upper surface and the lower surface of the lower ring wave die body are formed by a plurality of circles of concave-convex, continuous, alternative and coincident ring waves. The upper ring wave die body is connected with a movable cross beam of a hydraulic machine. The lower ring wave die body is fixed to a working table board. The upper ring wave die body is a movable die, and the lower ring wave die body is a fixed die. Two locating mechanisms arranged symmetrically in the radial direction are arranged at the upper end of the lower ring wave die body and can locate a plate. The upper ring wave die body and the lower ring wave die body are guided through a guide column and a guide sleeve which are arranged symmetrically in the axial direction, and directly participate in formation of the plate. By means of die closing, the plate is drawn to a set ring wave shape. According to the technology, through the die, repeated drawing is carried out for deforming and refining plate grain particles to enable the size of the grain particles to reach the micrometer level or the sub-micrometer level, finally, a flattening die is used for flattening the deformed plate, and a smooth plate is obtained. The die is free of restrictions of the size of the plate, the plate in the large size can be machined, and the comprehensive performance of the aspects such as physics, chemistry and mechanics of the plate are improved greatly.

Owner:河北华杰缝纫机零件有限公司

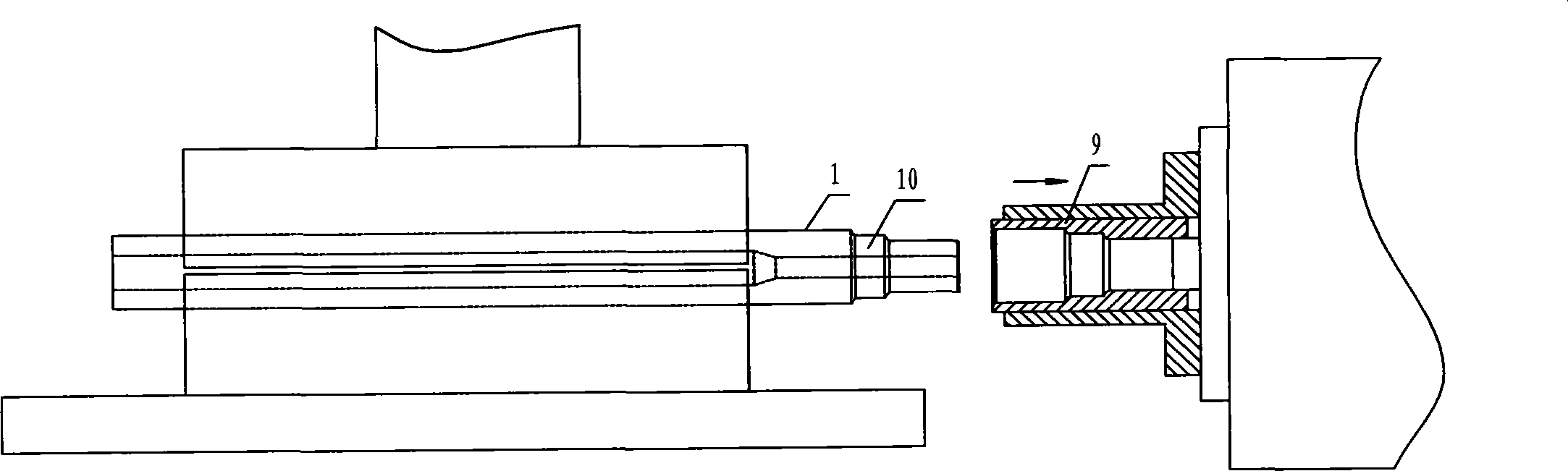

Direct molding process for hot-extruded hollow axle

ActiveCN104043769AIncrease torqueEasy to useMetal-working apparatusEngine componentsUltimate tensile strengthProcess design

The invention discloses a direct molding process for a hot-extruded hollow axle. The process comprises pipe inspection and processing, gradient heating treatment, mold loading, horizontal and radial loading, integral heating after demolding, mold reloading and reloading, wherein direct variable-diameter hot extrusion forming of the hollow axle is effectively finished after repeating the steps are repeated and the inspection treatment is performed. The direct molding process has the advantages of reasonable process design, simple mold structure, high upsetting speed, high yield, good use effect and low cost, and is particularly suitable for large-scale industrial production of high-speed train axles. The weight of the axle is reduced greatly, and the strength and torque force of the hollow axle are effectively enhanced and ensured.

Owner:雷中坤

Ring-wave repeated drawing high deformation mold for plate and machining method

InactiveCN107716668AUniform plastic deformationUniform strain distributionGeometric CADShaping toolsWave shapeLarge size

The invention discloses a ring-wave repeated drawing high deformation mold and technology for a plate. The mold comprises two ring-wave mold bodies including the ring-wave mold body A and the ring-wave mold body B, wherein the two ring-wave mold bodies are both of an axially-symmetrical cylindrical structure, the upper surfaces and the lower surfaces of the ring-wave mold bodies are each composedof a plurality rings of convex-concave continuous alternate matchable ring waves, the ring wave radian and length of the axial center are large, the wave height of the axial center is small, and the ring wave radian and length are decreased ring by ring and the wave height is increased ring by ring from the axial center to the exterior. Ring-wave upper mold bodies are movable mold bodies, ring-wave lower mold bodies are fixed mold bodies, and two groups of positioning mechanisms which are radially and symmetrically arranged are arranged at the upper end of each ring-wave lower mold body; and the plate is drawn to be in a set ring wave shape by the ring-wave upper mold bodies and the ring-wave lower mold bodies through mold closing. According to the technology, crystal grains of the plate can be repeatedly drawn, deformed and refined through the mold, and then the size of the crystal grains reaches the micron grade or the submicron grade. The ring-wave repeated drawing high deformationmold is not limited by the plate size, a large-size plate can be machined, and the comprehensive properties of the plate on the physical aspect, the chemical aspect, the mechanical aspect and the likecan be greatly improved.

Owner:YANSHAN UNIV

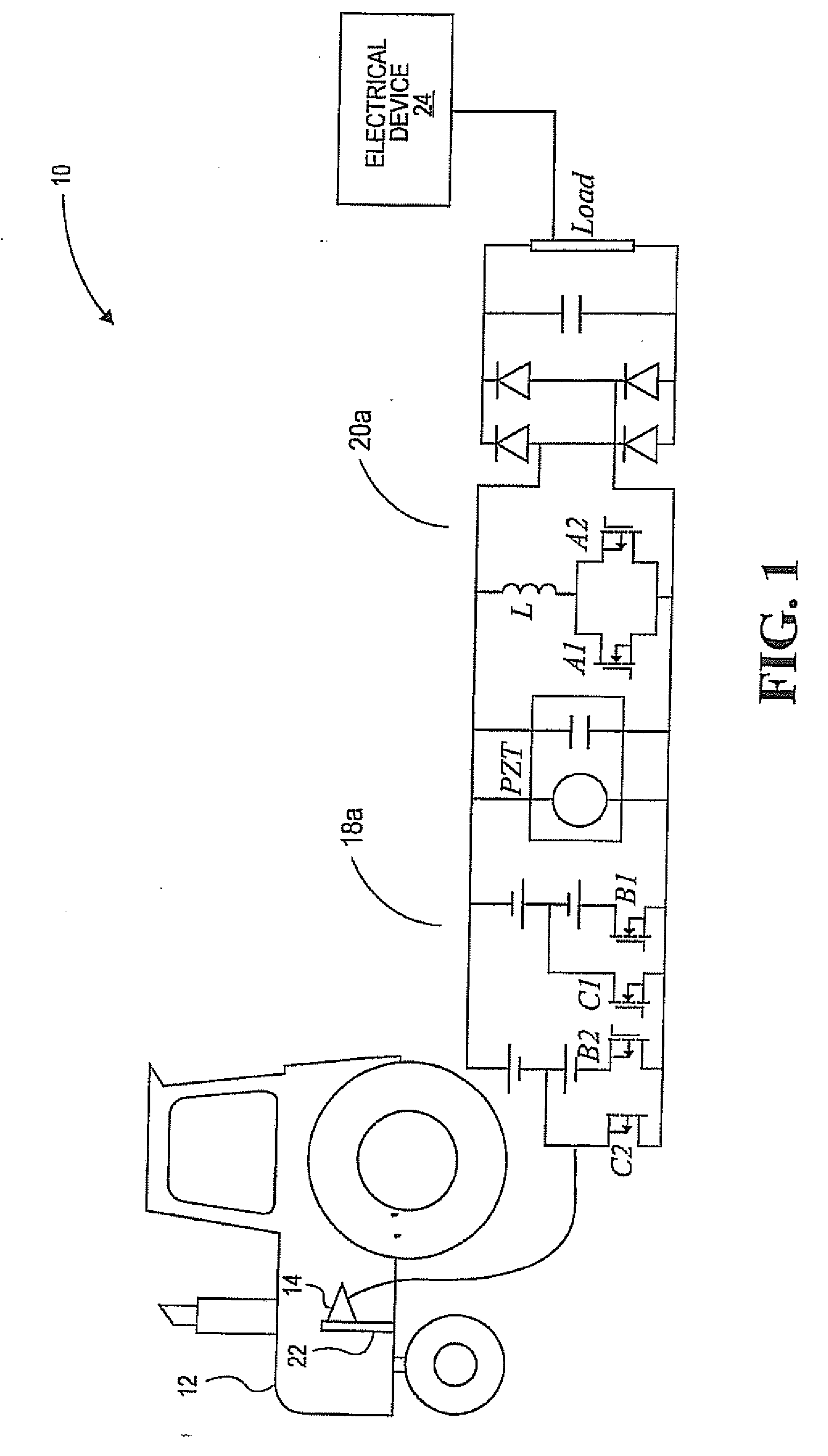

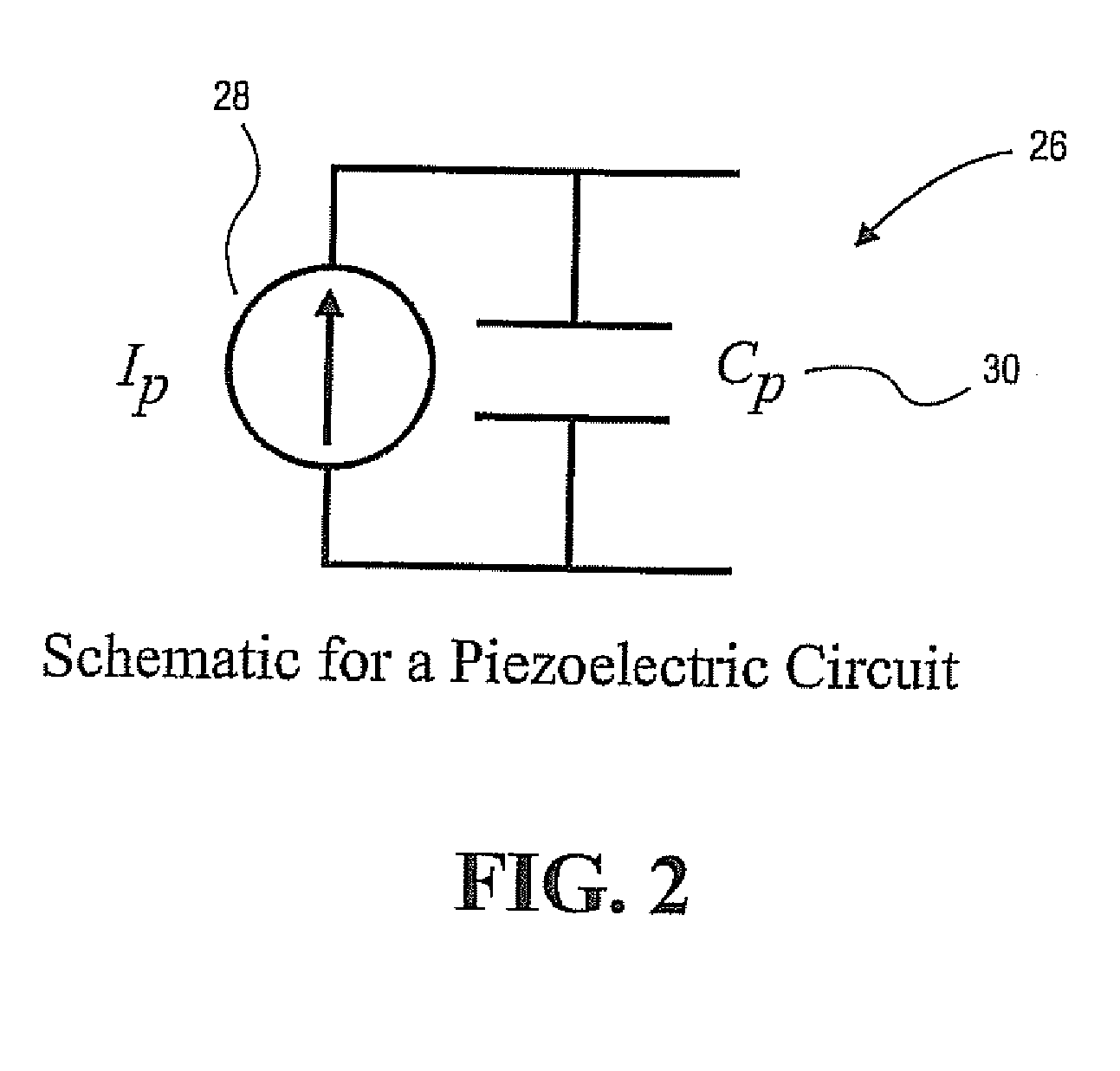

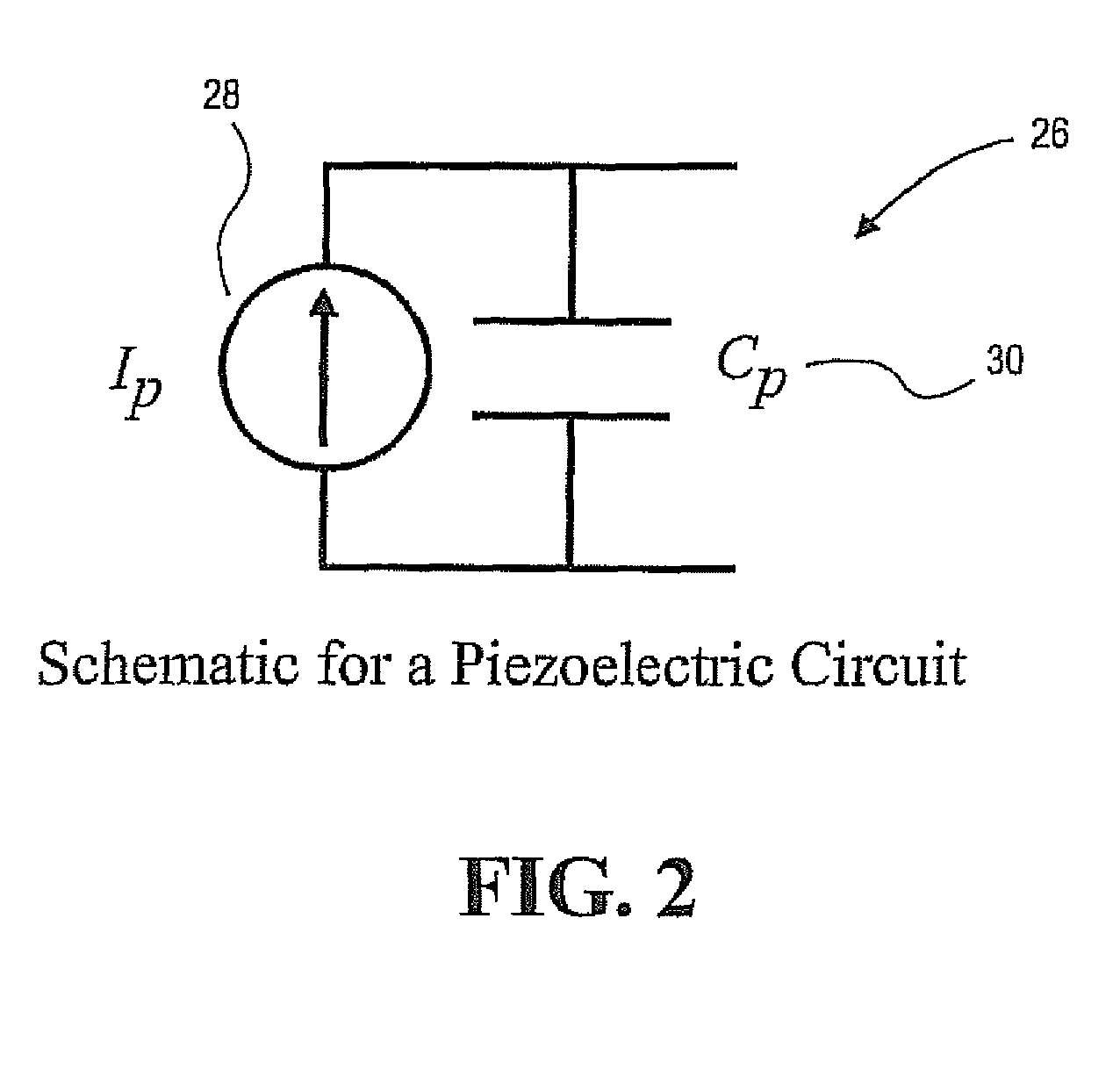

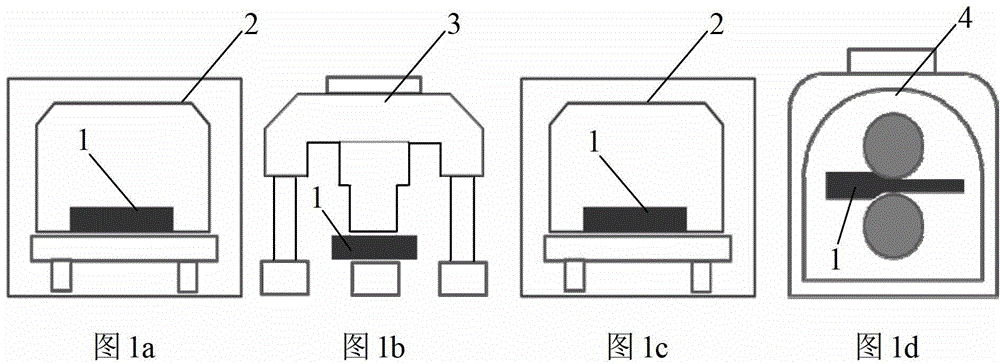

System and method for harvesting energy from environmental vibrations

ActiveUS20100194239A1Uniform strain distributionConstant strain profilePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesState of artEngineering

Embodiments of the present invention provide a system and a method for increasing the harvested energy from a piezoelectric element exposed to environmental vibrations via a two-prong system. In a first prong, a cantilever beam is tapered and shaped so as to increase and provide an approximately uniform strain on and along the beam, thus resulting in increased voltage. In a second prong of the system and method, a voltage compensating circuit, when used with a voltage inversion circuit of the prior art, increases the harvested power by injecting current to the piezoelectric element after each voltage inversion so as to increase the voltage level.

Owner:UNIVERSITY OF MISSOURI

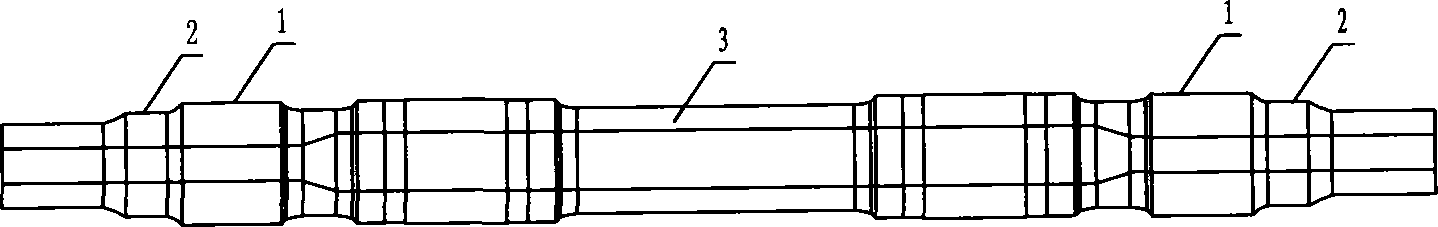

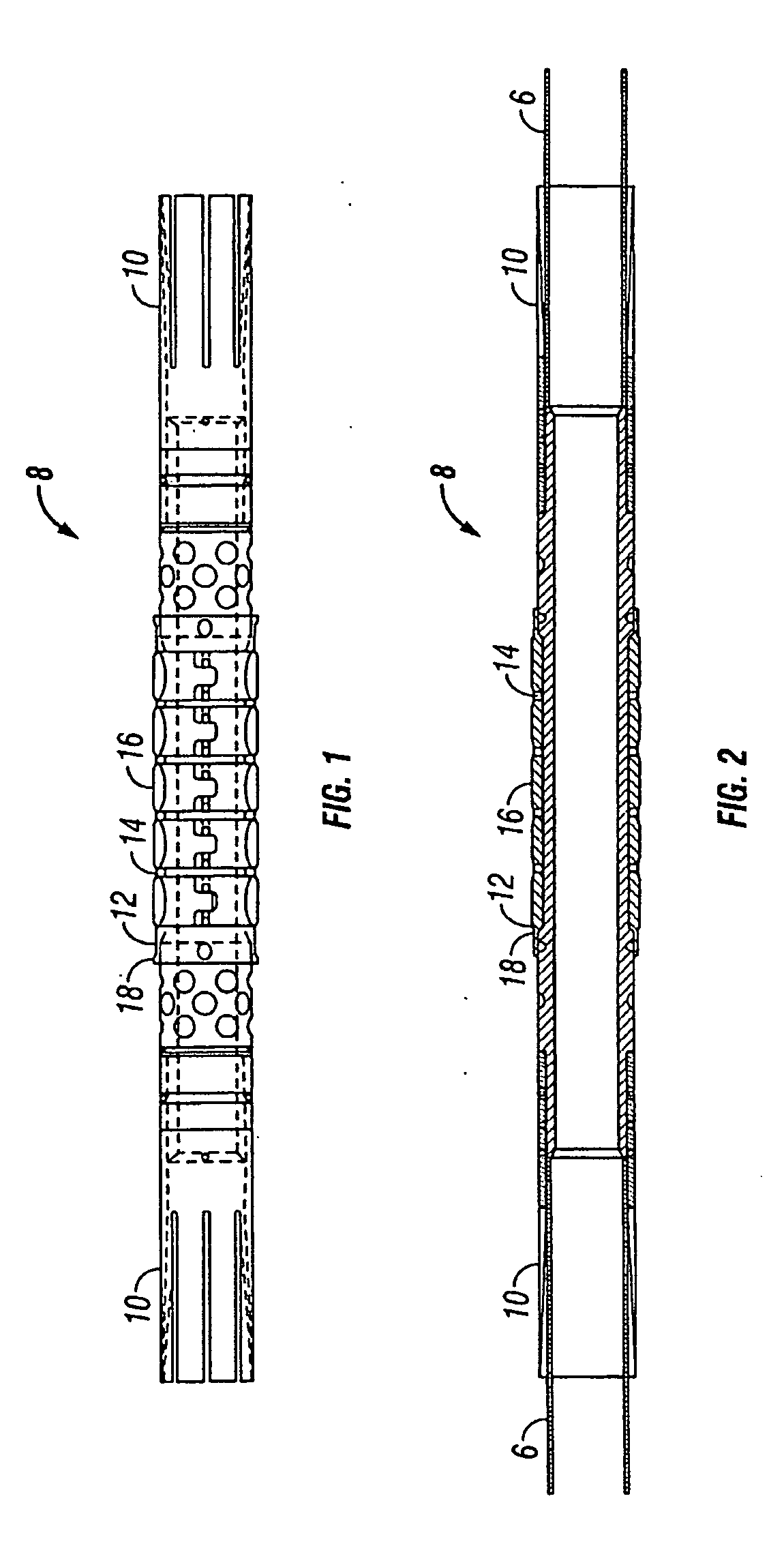

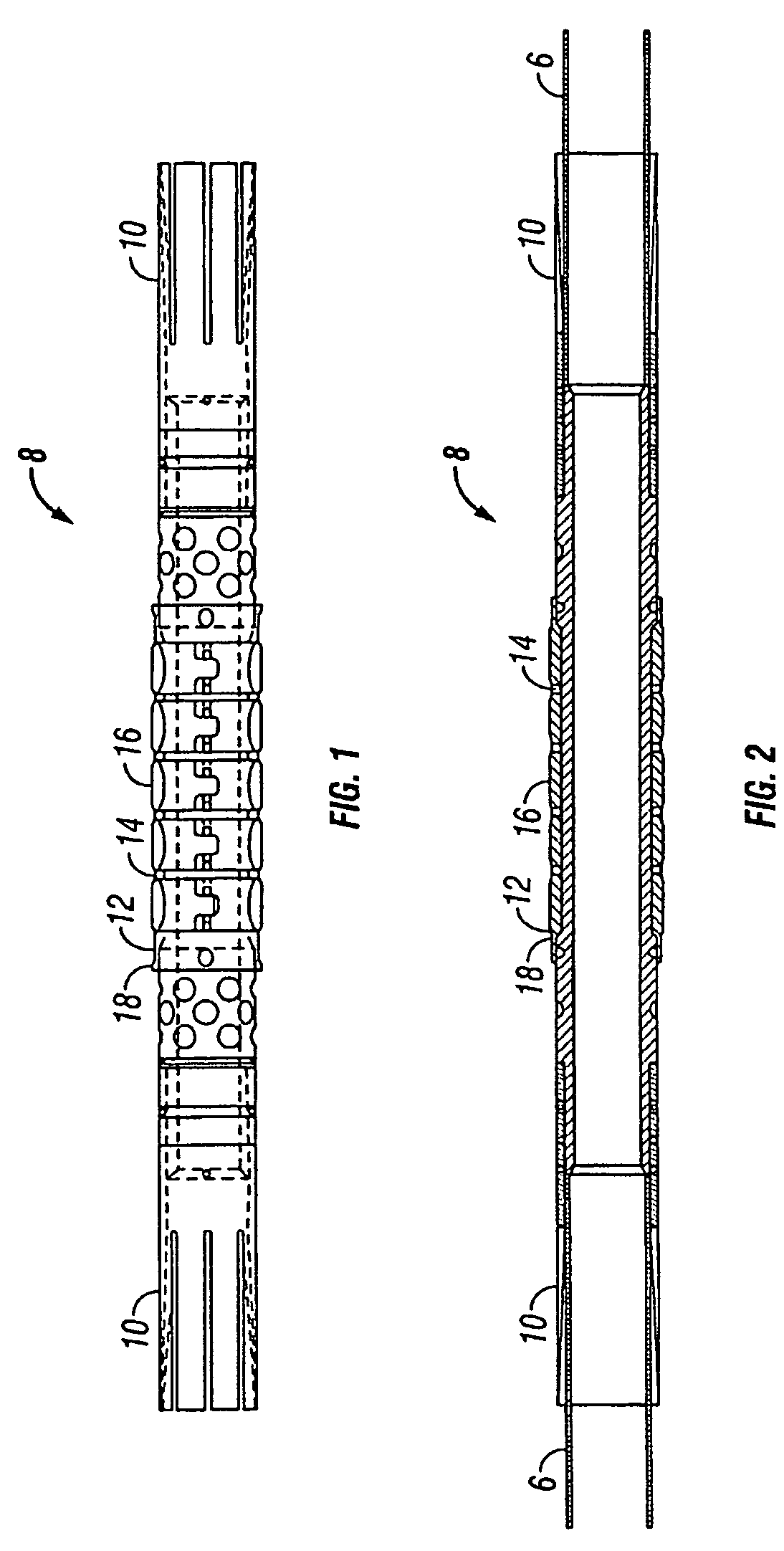

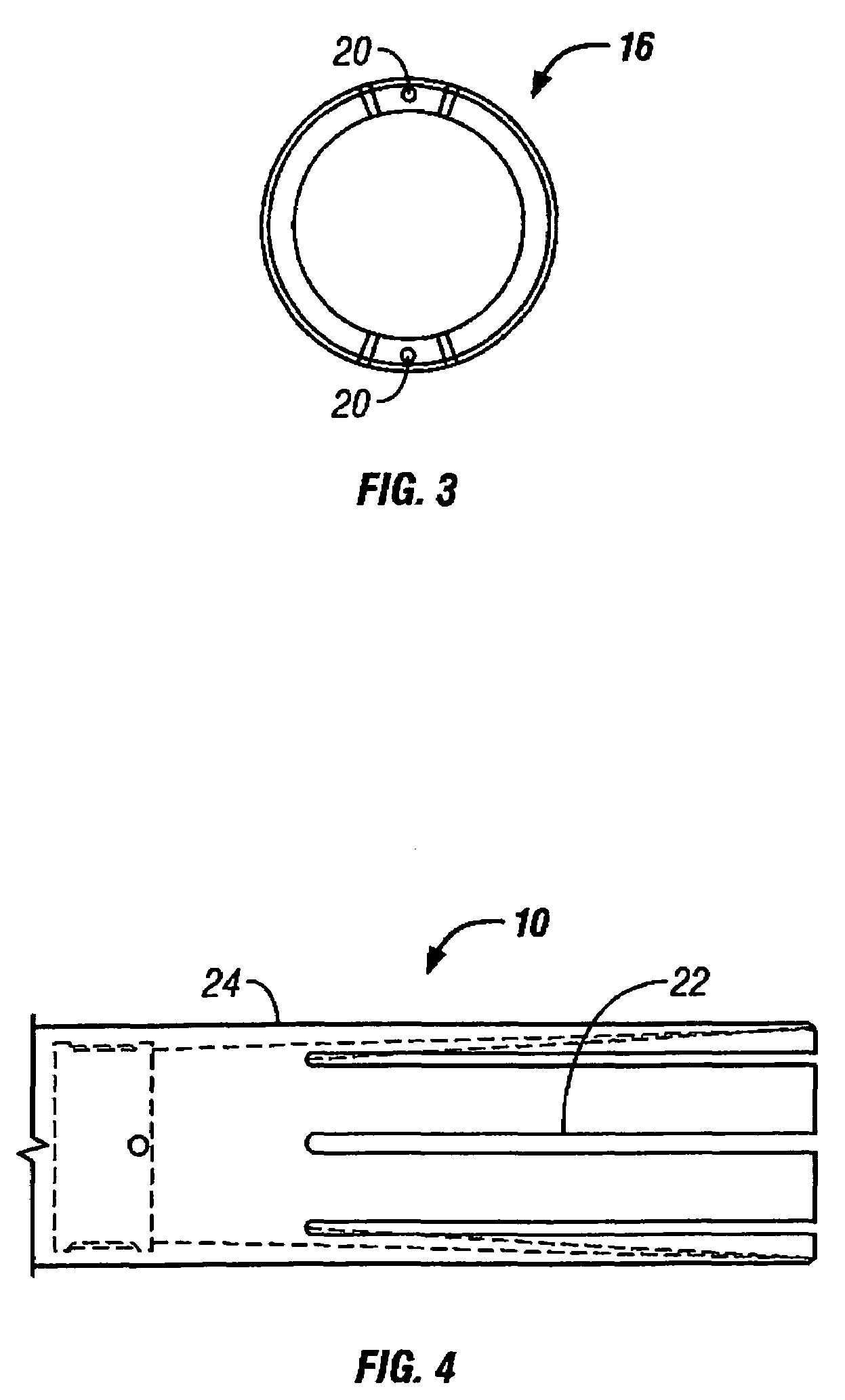

Composite low cycle fatigue coiled tubing connector

ActiveUS20060157974A1Reduce overall outer diameterProlong lifeSleeve/socket jointsDrilling rodsBiomedical engineeringCoiled tubing

A coiled tubing connector having a body and a plurality of entry or transition sections connected to the body wherein the connector has a low cycle fatigue life of at least 30%, more preferably at least 50% of the coiled tubing. A preferred embodiment contains two shoulders that form an annular void, a plurality of centralizers about an exterior of the body, and / or a plurality of elastomer molds separating the centralizers. The connector is preferably longer than the connectors of the prior art and is a composite of fluoroplastics or aluminum alloys.

Owner:BAKER HUGHES INC

Composite low cycle fatigue coiled tubing connector

InactiveUS7562909B2Reduce overall outer diameterProlong lifeSleeve/socket jointsDrilling rodsElastomerCoiled tubing

A coiled tubing connector having a body and a plurality of entry or transition sections connected to the body wherein the connector has a low cycle fatigue life of at least 30%, more preferably at least 50% of the coiled tubing. A preferred embodiment contains two shoulders that form an annular void, a plurality of centralizers about an exterior of the body, and / or a plurality of elastomer molds separating the centralizers. The connector is preferably longer than the connectors of the prior art and is a composite of fluoroplastics or aluminum alloys.

Owner:BAKER HUGHES HLDG LLC

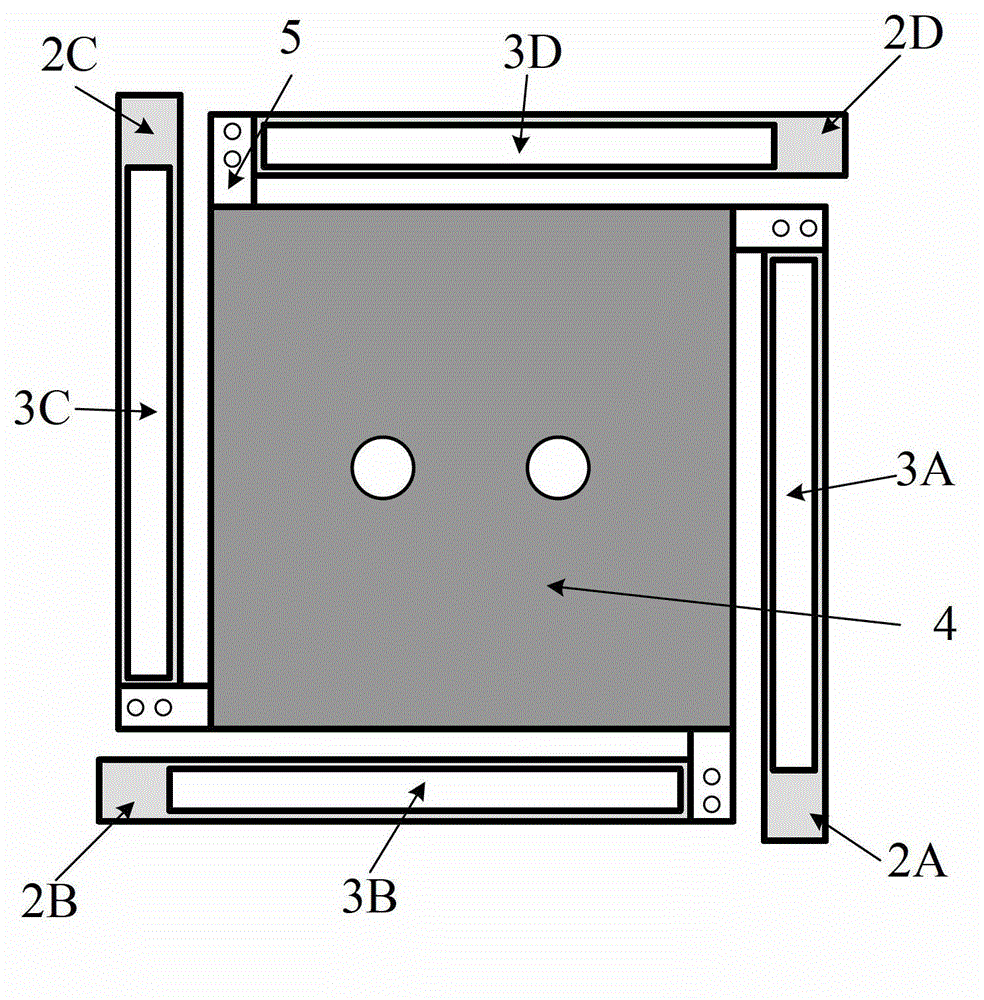

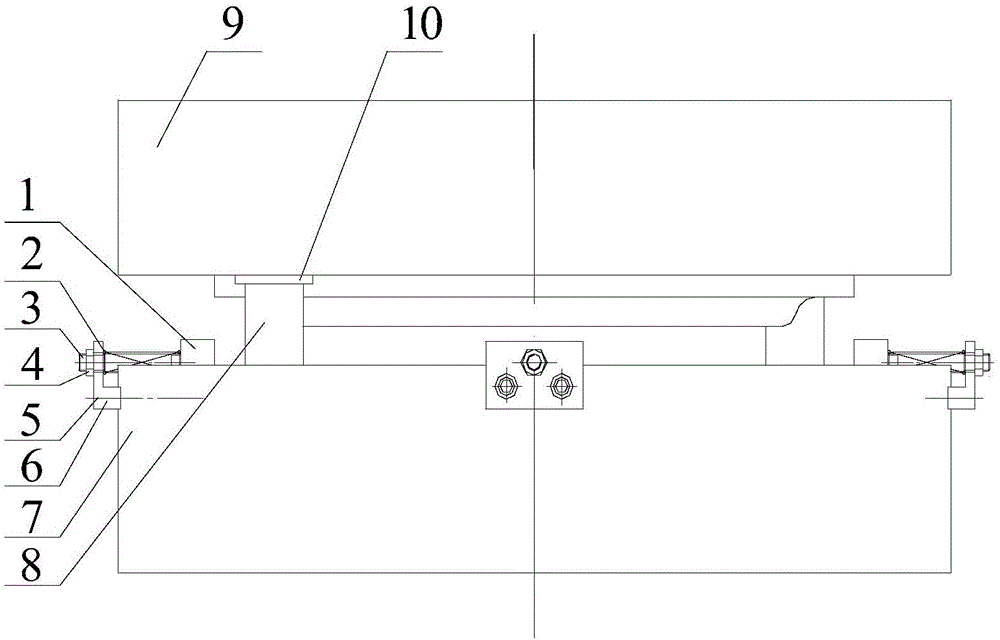

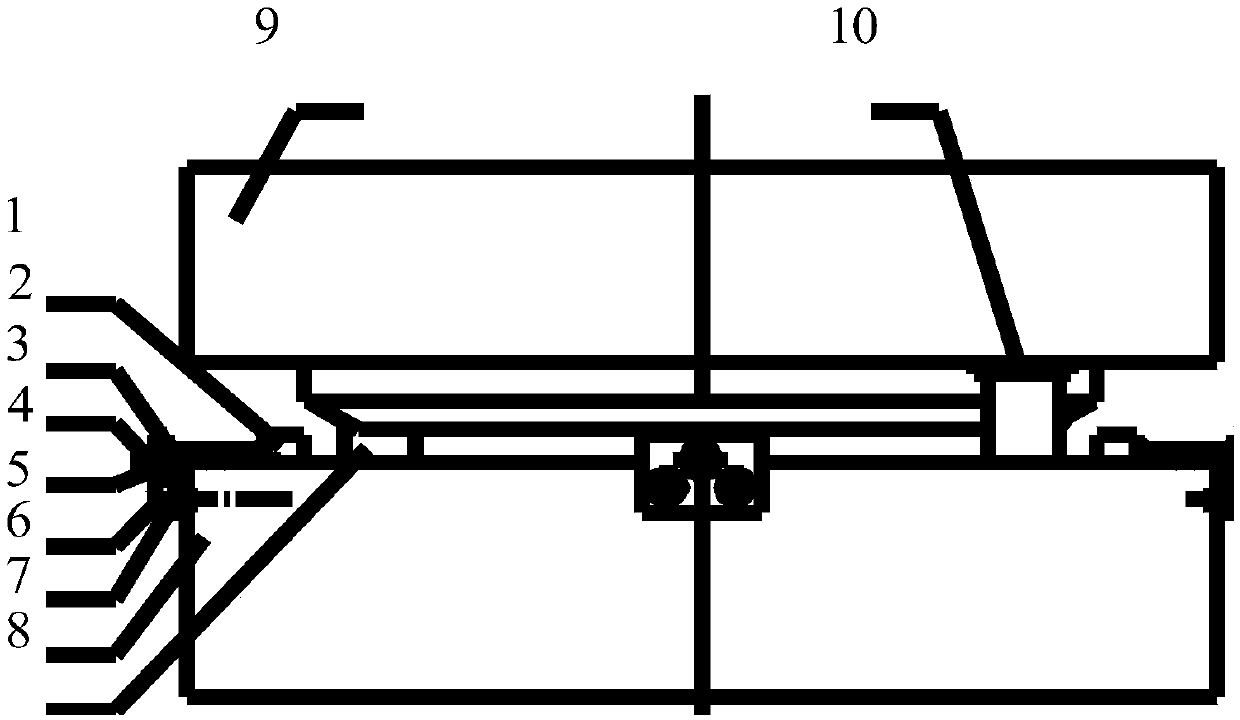

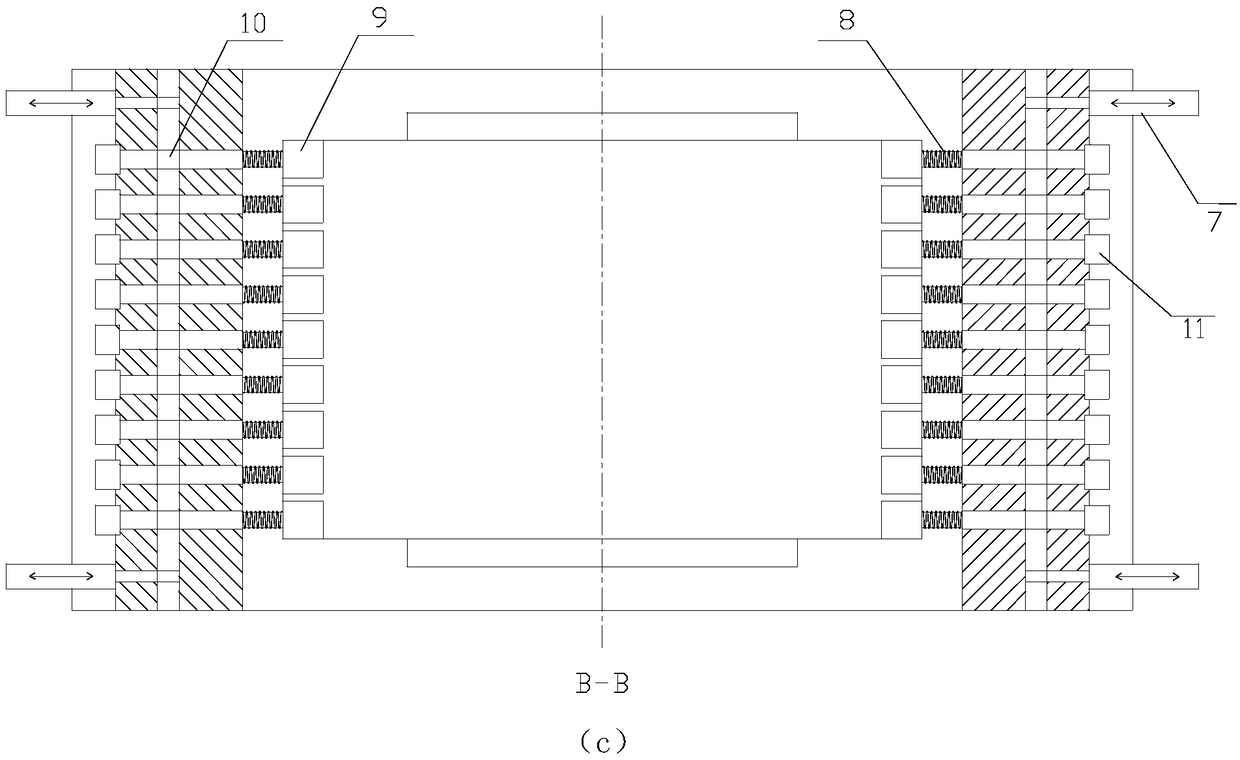

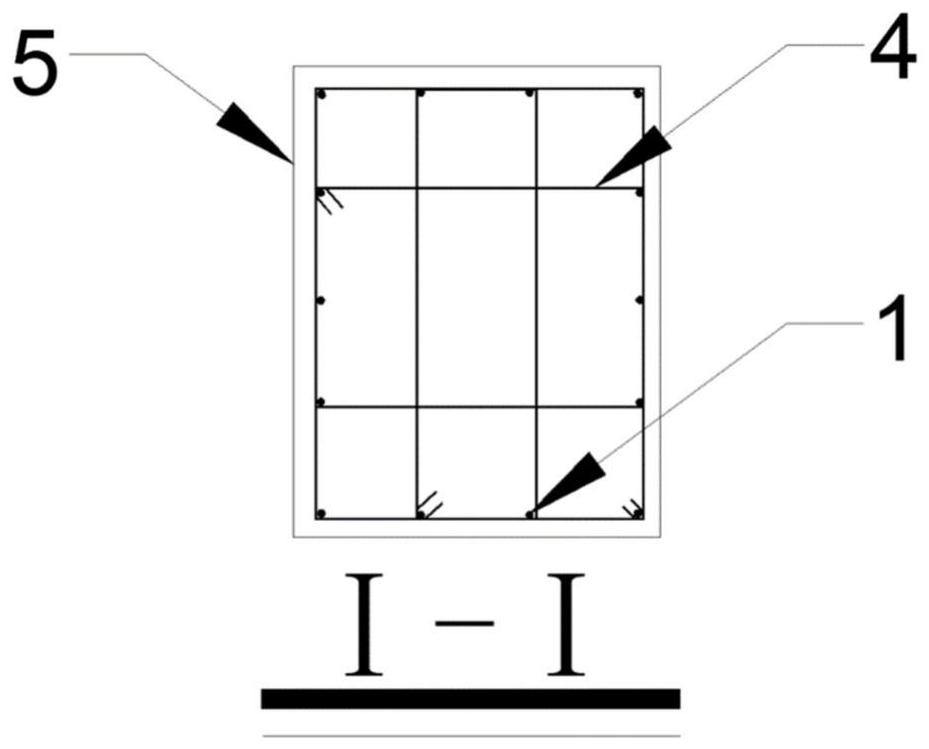

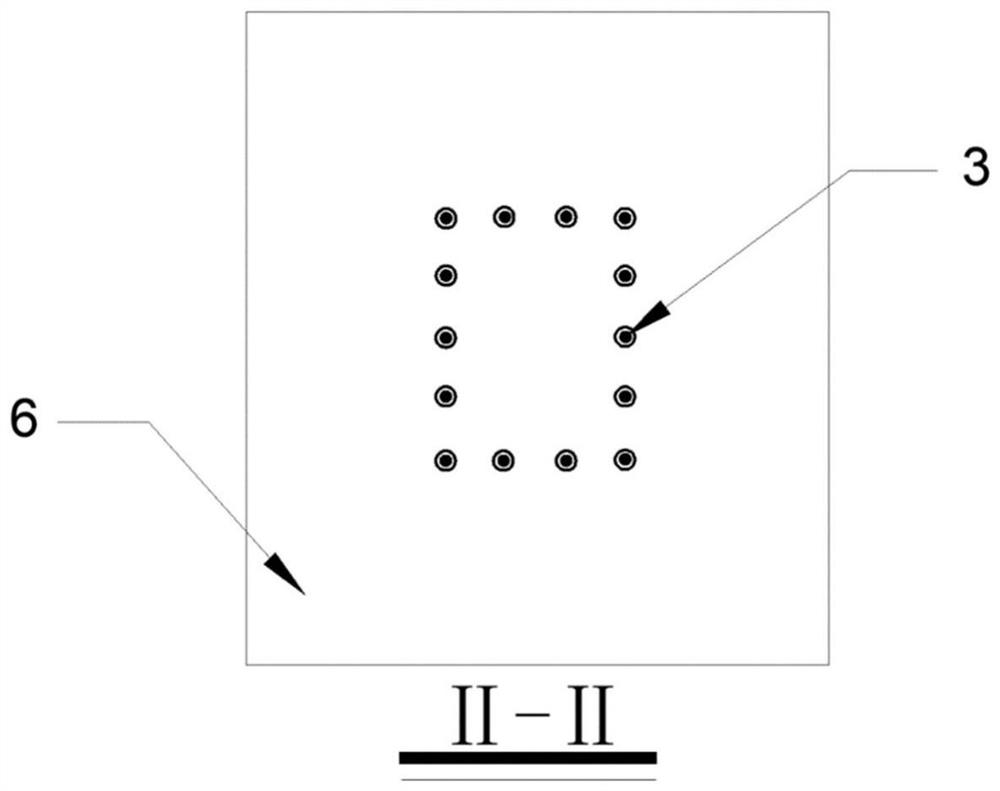

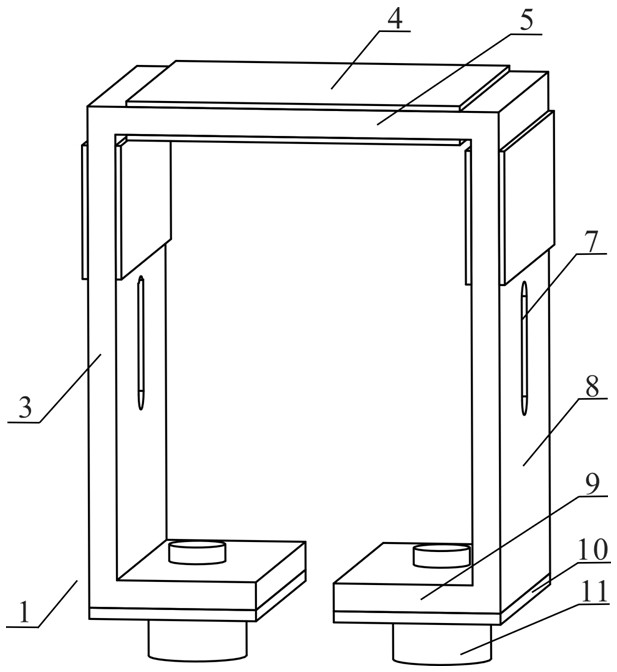

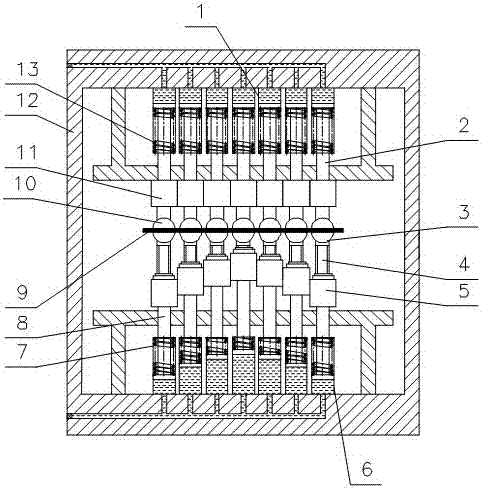

Stretching and pressing combined type plate stretch forming machine

ActiveCN108746332ASimplification of hydraulic control system and electrical control systemEasy to operate and maintainAircraft componentsMetal-working feeding devicesElectrical controlBending force

The invention discloses a stretching and pressing combined type plate stretch forming machine which is plastic working equipment for stretch forming of a plate type three-dimensional curved surface piece, and belongs to the field of mechanical engineering. A first object of the invention is to simplify hydraulic pressure of equipment and an electrical control system to lower the manufacturing cost; and a second object is to eliminate bending force on a plate when a vertical oil cylinder on a previous clamping device is loaded, so that pulling stress and strain of the stretch forming piece aredistributed more uniformly, and the shape stability and material utilization of the formed piece are improved. The stretch forming machine mainly consists of a rack, guide devices, downward pressing devices, clamping devices and horizontal prestretching devices (as shown in figures); the rack and the guide devices support the downward pressing devices, the clamping devices and the horizontal prestretching devices on the two sides; each clamping device consists of a plurality of clamping mechanisms; the downward pressing devices consists of a plurality of downward pushing mechanisms; the clamping mechanisms are arranged on the two sides of a mould in a row correspondingly; the downward pushing mechanisms are arranged on the two sides of the mould in a row correspondingly; and the horizontalprestretching devices consist of four hydraulic oil cylinders and universal joints and are arranged on the guide devices on the two sides.

Owner:JILIN UNIV

Laser composite texture thin-walled tube bending mold and composite texture forming method thereof

ActiveCN105945147AHigh precisionGood friction propertiesShaping toolsLaser beam welding apparatusWrinkle skinInstability

The invention discloses a laser composite texture thin-walled tube bending mold and a composite texture forming method thereof, and belongs to the field of machine manufacturing. The mold comprises a tube bending mold main body corresponding to a bent part of a tube, a clamping block used for being clamped on a vertical section of the tube and a pressing block used for being pressed on a horizontal section of the tube. The mold further comprises a wrinkle-proof plate mounted on one side of the tube bending mold main body. The clamping block, the pressing block, the wrinkle-proof plate and the arc-shaped surface of the tube bending mold main body form the clamping face of the tube bending mold. The clamping face of the tube bending mold is provided with composite shapes. By adopting the structure and the method, the strain distribution, variation of the wall thickness and deformation of cross sections of formed parts are more uniform; side tube walls are prevented from instability wrinkling due to large curvatures and too small thickness and drawing breakage due to small curvatures; and springback of the formed parts is alleviated, the tube bending precision is improved, and the forming quality is improved. Finally, bending forming with the stable precision is achieved.

Owner:ZHENJIANG COLLEGE

System and method for harvesting energy from environmental vibrations

ActiveUS8129887B2Uniform strain distributionConstant strain profilePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesState of artCantilevered beam

Owner:UNIVERSITY OF MISSOURI

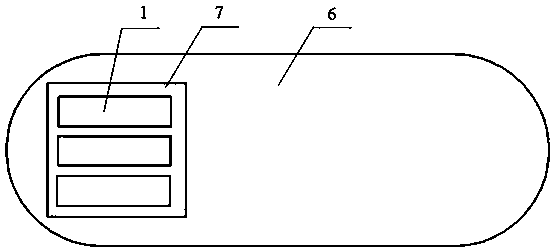

Shoe with curve L-shaped mass block piezoelectric power generation device used

InactiveCN103815610AEven and reasonable strainImprove overall efficiencyPiezoelectric/electrostriction/magnetostriction machinesFootwearCapacitanceElectric energy

The invention provides a shoe with a curve L-shaped mass block piezoelectric power generation device used, and belongs to the technical field of vibration energy recovery power generation. According to the shoe, the curve L-shaped mass block piezoelectric power generation device is installed in the shoe, the structure of a curve L-shaped mass block homogenizes strain distribution on a cantilever beam to some extent, and the energy density of a piezoelectric energy recovery device is improved, so that the recovery efficiency of vibration energy is improved; meanwhile, a rectifying circuit and a capacitor or a battery are arranged in the mass block, therefore, the whole device is compact in structure, the reliability is improved, and stored electric energy can be used for charging electronic equipment through conversion.

Owner:潘瑞

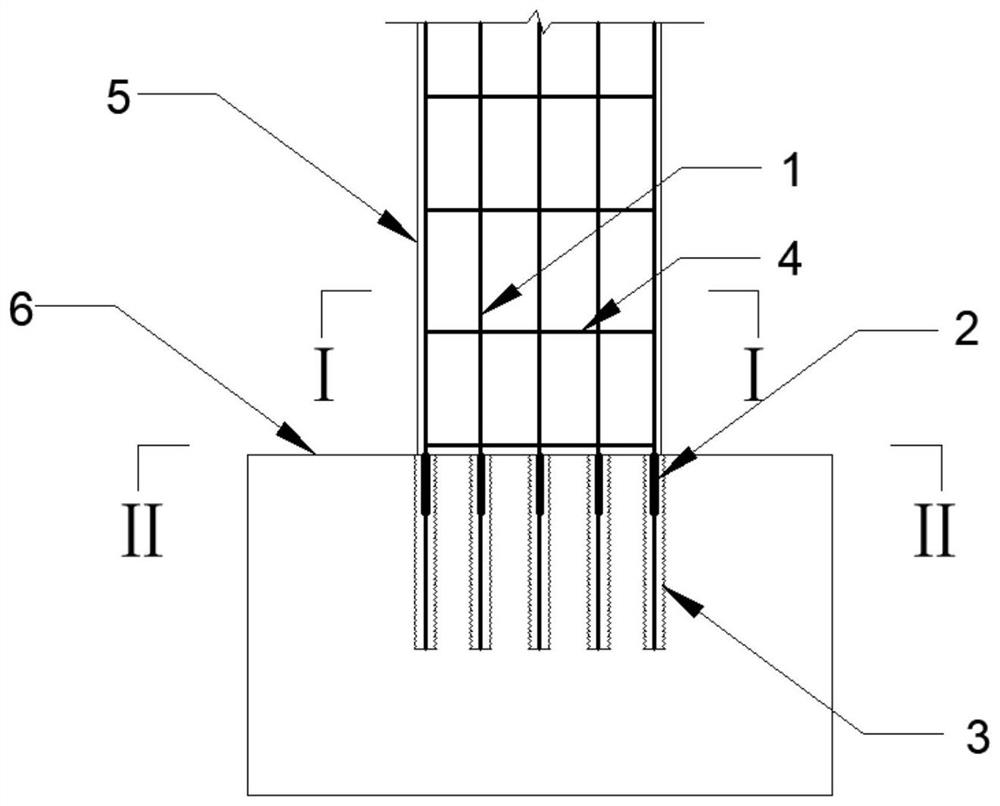

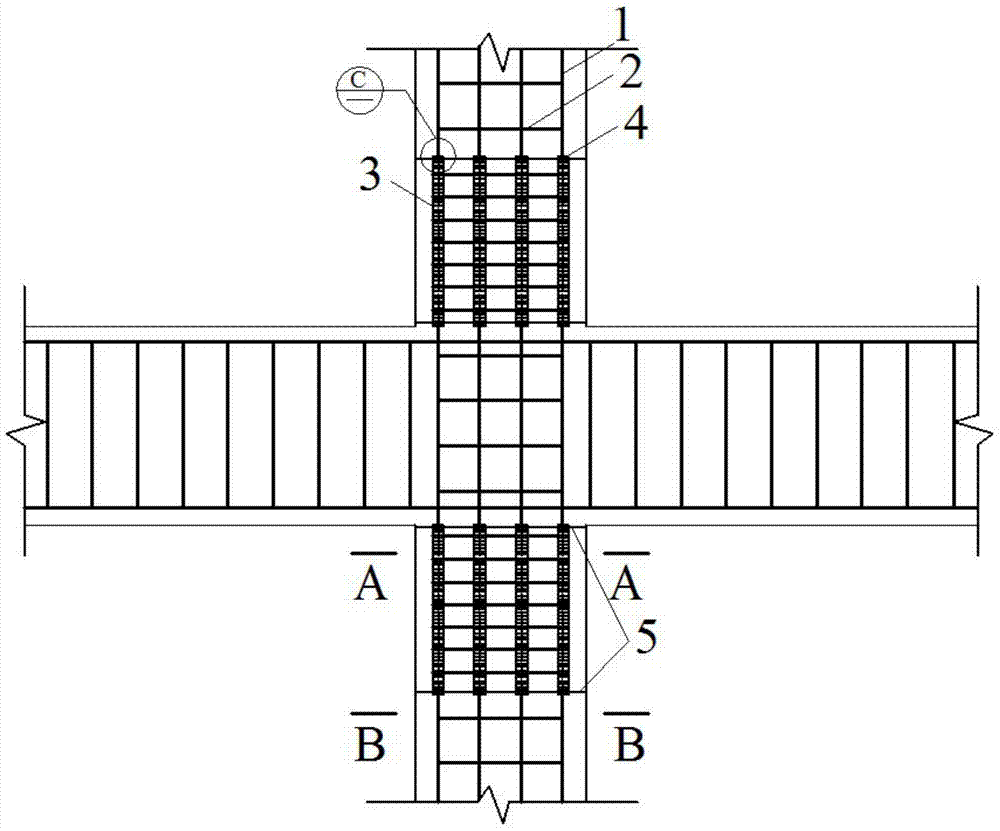

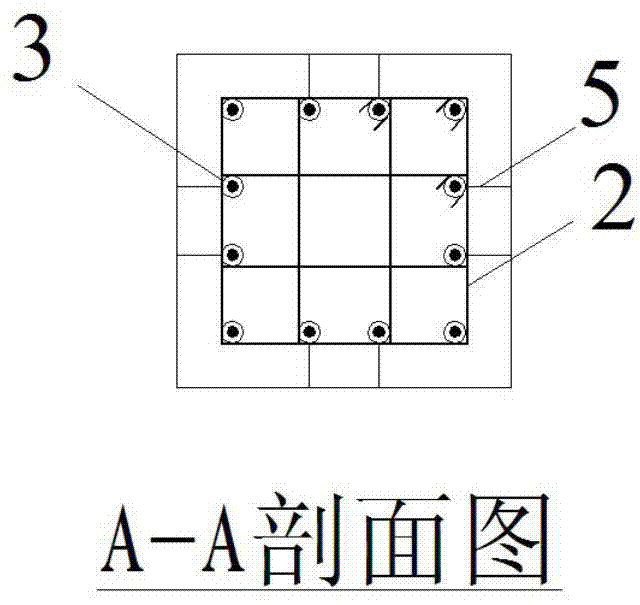

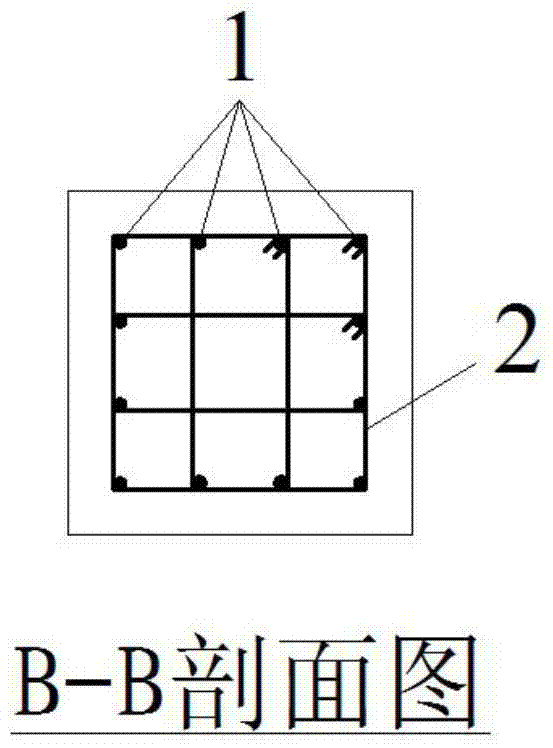

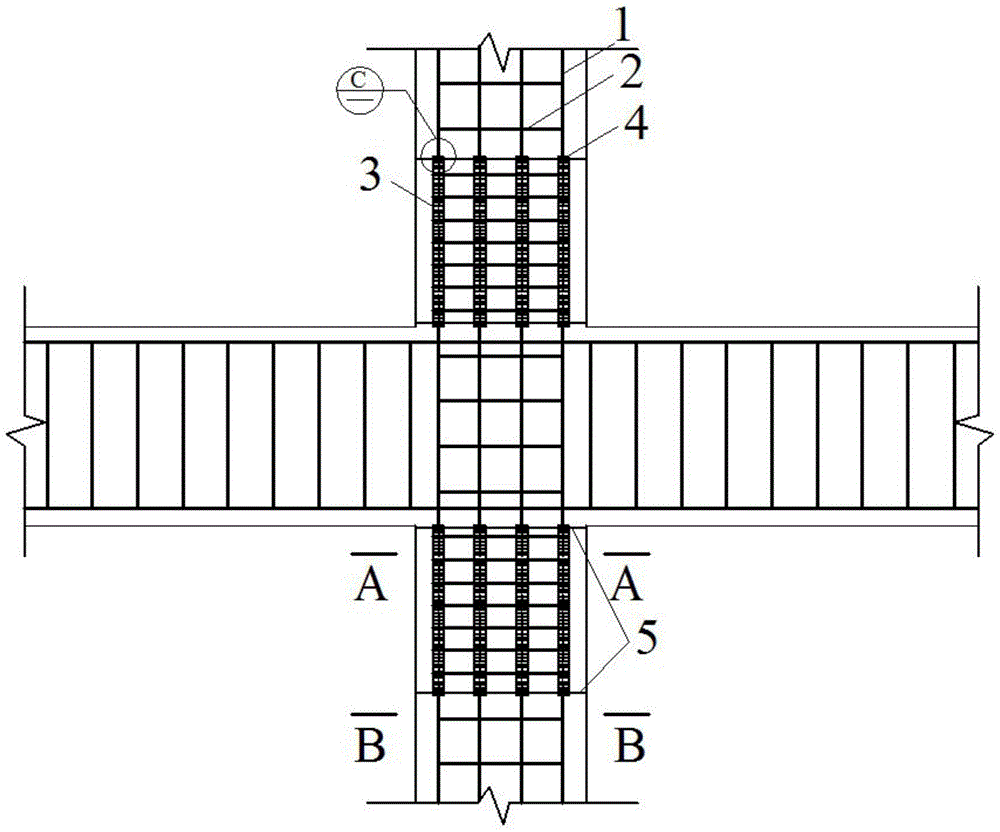

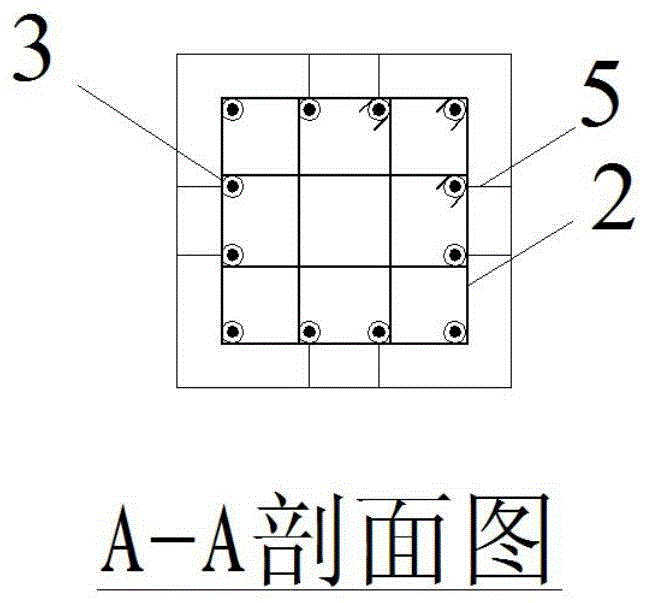

Partial unbonded grouting corrugated pipe prefabricating, assembling and connecting structure and construction method

PendingCN112267373AImprove ductilityImprove energy consumptionBridge structural detailsFoundation engineeringStress concentrationArchitectural engineering

The invention relates to a partial unbonded grouting corrugated pipe prefabricating, assembling and connecting structure and a construction method, the partial unbonded grouting corrugated pipe prefabricating, assembling and connecting structure comprises a main rib, a metal corrugated pipe and a sleeve, wherein the end parts of the main rib need to be anchored in the bearing platform or the bentcap; the metal corrugated pipe is pre-buried in the bearing platform or the bent cap, and the metal corrugated pipe is filled with dense filler in a pressed mode to achieve anchoring connection with the main reinforcements. Main ribs of a certain length, close to the joint side, in the metal corrugated pipe are coated with anti-corrosion lubricating grease, the metal corrugated pipe is sleeved with sleeves of the corresponding length, the two ends of each sleeve are subjected to water sealing treatment through flexible sealant, spring clamps are adopted for fixing before bridge pier pouring, and therefore main rib non-bonding sections are formed on the main ribs. Compared with the prior art, stress concentration at the joint can be relieved, the yield length of the main ribs around the joint is increased, the ductility and the energy dissipation capacity of the prefabricated assembled pier are improved, meanwhile, the strain rate of the main ribs at the joint is reduced, and the fatigue performance is improved; the whole connecting structure is simple in construction, easy to operate, high in economical efficiency and convenient to apply and popularize.

Owner:TONGJI UNIV

Piezoelectric pump driven by tuning fork type actuator with adjustable resonant frequency

ActiveCN113482891AImprove working conditionImprove workabilityPiezoelectric/electrostriction/magnetostriction machinesPositive displacement pump componentsDiaphragm pumpWafering

The invention relates to a piezoelectric pump driven by a tuning fork type actuator with adjustable resonant frequency, and belongs to the technical field of piezoelectric pumps. The piezoelectric pump comprises the tuning fork type piezoelectric actuator with adjustable resonant frequency and a pair of diaphragm pumps, and the tuning fork type piezoelectric actuator comprises an inverted U-shaped tuning fork type body and piezoelectric plates which are bonded and fixed on the surface of the tuning fork type body; and the tuning fork type body is composed of a cross beam, a pair of driving arms, a mass block at the lower ends of the driving arms and an additional mass block fixedly connected to the bottom of the mass block through bolts. The piezoelectric plates are respectively arranged on the top surface and the bottom surface of the cross beam and the inner side surfaces and the outer side surfaces of the pair of driving arms to form three pairs of piezoelectric bimorph structures; and the pair of diaphragm pumps comprises two diaphragm pumps which are fixedly connected together in a back-to-back mode and are fixedly arranged between the pair of driving arms of the tuning fork type body through kidney-shaped holes and bolts. According to the piezoelectric pump, the resonant frequency of the tuning fork type piezoelectric actuator can be adjusted in a large range by changing the size of the additional mass block, so that the resonant frequency is matched with the optimal working frequency of a one-way valve, and the output performance of the piezoelectric pump is improved.

Owner:HEFEI UNIV OF TECH

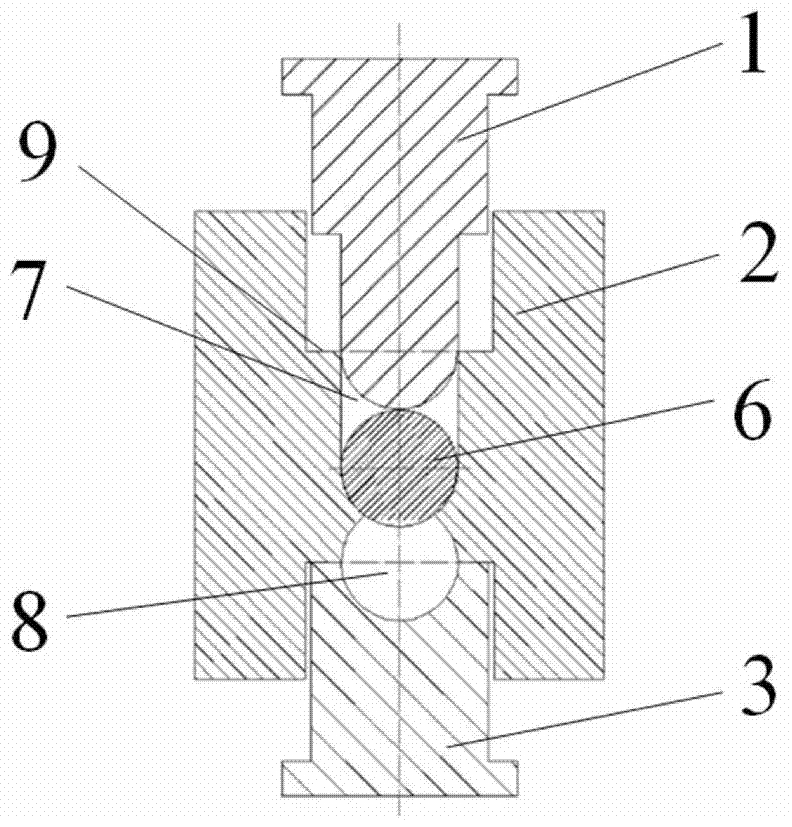

Reciprocating extrusion upsetting device and its using method and application

ActiveCN105033141BSmall dispersionUniform strain distributionForging/hammering/pressing machinesEngineeringExtrusion

The invention provides a reciprocating extrusion and heading device for preparing ultrafine crystal cake-shaped materials, which includes an upper punch, a die, a lower punch and a base, the base is detachably arranged at the bottom of the die, and the die The mold is provided with an upper cavity and a lower cavity that communicate with each other, and the inner side of the bottom of the upper cavity is arc-shaped with an extrusion port, the inner side of the lower cavity is also arc-shaped, and the inner side of the upper cavity is curved. The arc has the same radius as the arc on the inside of the lower cavity. The present invention has the following beneficial effects: the constriction area of the die of the present invention adopts a circular arc transition, which effectively avoids the slow and uneven extrusion dead zone in conventional extrusion, uniform strain distribution, and small grain dispersion.

Owner:SHANGHAI JIAOTONG UNIV

Forging-and-rolling compounded forming method for comprehensively promoting internal and external quality of wide and thick plate blanks

ActiveCN103273272BPromote healingReduce scrapTemperature control deviceTension/compression control deviceThick plateRoom temperature

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Reinforced concrete column with non-adhesive ends and preparation method thereof

ActiveCN103924736AImprove damageAvoid damageStrutsBuilding repairsReinforced concrete columnAdhesive

The invention discloses a reinforced concrete column with non-adhesive ends and a preparation method thereof. All longitudinal reinforcing bars in plastic hinge regions at both ends of the column are respectively sheathed by a steel strip corrugated pipe of which the length is twice of the height of the column section, and a 914 adhesive is utilized to attach foam gaskets to the two ends of the corrugated pipe, so that the foam gaskets and the bars in the region form a closed integral body; and thus, a non-adhesive section with a certain length is formed between the longitudinal bar at partial ends and the concrete. The bar strain distribution at the non-adhesive section of the column ends can be uniform, and a yield section with synchronous and slow stress increase is formed, thereby postponing and even preventing the buckling fracture and resilience degeneration, effectively enhancing the ductility and energy consumption capacity of the column end plastic hinge regions, and obviously improving the damage of the concrete in the region due to binding force. The whole system has the advantages of simple structure and favorable economical efficiency, and is convenient for construction.

Owner:河南绿筑集成科技有限公司

Variable-channel extrusion die and forming method

InactiveCN101823085BImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsNonferrous metalLow load

The invention relates to a variable-channel extrusion die and a forming method. The variable-channel extrusion die comprises a male die (1) and a female die (3), a die cavity of the female die sequentially comprises a feeding section (4), a front forming section (5), a middle forming section (6), a rear forming section (7) and a discharging section (8) from an inlet of a blank (2) to an outlet ofthe blank (2), wherein the feeding section (4) is a circular equant channel, the front forming section (5) is a circular-elliptical transition channel, the middle forming section (6) is a prismatic elliptical channel, the rear forming section (7) is an elliptical-circular transition channel, and the discharging section (8) is a prismatic circular channel; and the blank (2) enters from an inlet ofthe female die (3) and is limited by the die cavity of the female die (3) to change a circular cross-section into an elliptical cross-section and change the elliptical cross-section into the circularcross-section in order to form a performed workpiece. The variable-channel extrusion die has simple structure, low load, low cost and high efficiency and can be widely applied to producing rods and wires of steel and nonferrous metal and forging and blanking difficultly deformed materials of large-scale shaft parts, high-speed steel, powder metallurgy, and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

A kind of manufacture method of molybdenum alloy boat

The invention discloses a method for making a molybdenum alloy boat, which includes the following steps: (1) preparing a molybdenum slab: a. Ingredients: the molybdenum slab is prepared from the following raw materials in weight percentage: Al(NO3)3: 1.0% to 4.0% , La(NO3)3: 0.5-3.0%, TiH2: 0.5-1.2%, polyethylene glycol: 0.4%-0.7%, silicon powder: 0.5-1.5%, and the balance is molybdenum powder and unavoidable impurities; b, Preparation of alloy powder; c. Compacting and sintering: the alloy powder is compacted and sintered to obtain molybdenum slabs; (2) rolling: the molybdenum slabs are processed into blanks, hot rolling, warm rolling, cold rolling and annealing processes Molybdenum alloy; (3) Cutting and bending: Cut out four squares at the four corners of the molybdenum alloy, and bend the four sides respectively; (4) Welding and forming. The molybdenum alloy used in the molybdenum alloy boat has high tensile strength and high elongation, and the manufactured molybdenum alloy boat has high yield and low cost.

Owner:LUOYANG SIFON ELECTRONICS

End unbonded reinforced concrete column and preparation method

ActiveCN103924736BImprove damageAvoid damageStrutsBuilding repairsReinforced concrete columnAdhesive

Owner:河南绿筑集成科技有限公司

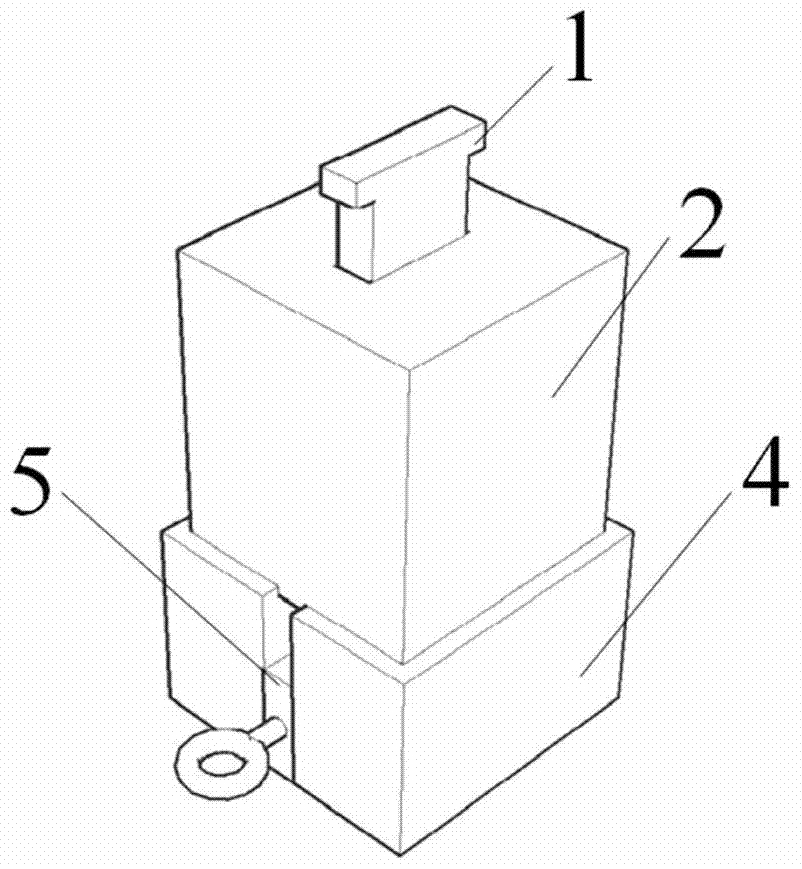

Restrictive molding die and grain refinement method for ultrasonic vibration-assisted demolding

ActiveCN107671159BReduce processing costsUniform strain distributionEjection devicesUltrasonic vibrationUltrasound assisted

The invention discloses a restrictive mold pressing mold for ultrasonic vibration auxiliary demolding and a grain refinement method, and relates to mold machining and manufacturing and an applicationmethod thereof, in particular to a mold capable of enabling workpieces to obtain large accumulation strains and a process method for refining material grain sizes. The restrictive mold pressing mold comprises a mold frame, an ultrasonic auxiliary demolding device and a mold cavity. The ultrasonic auxiliary demolding device and the mold cavity are mounted in the mold frame together. The novel restrictive mold pressing mold for ultrasonic vibration auxiliary demolding and the grain refinement method have the beneficial effects of being novel in structure, easy and convenient to machine and operate, good in workpiece adaptability, uniform in strain distribution and small in wear, facilitating demolding and the like, and integrating economic performance and practicality.

Owner:DALIAN UNIV OF TECH

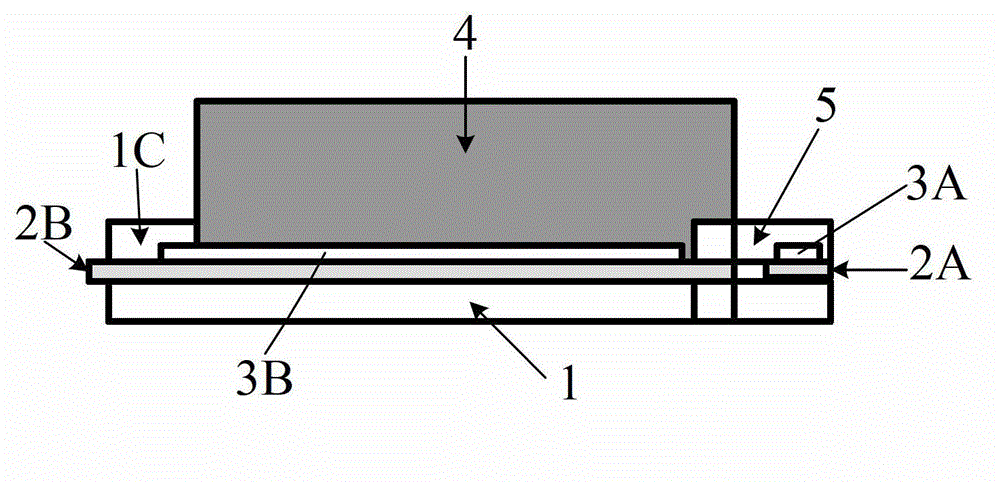

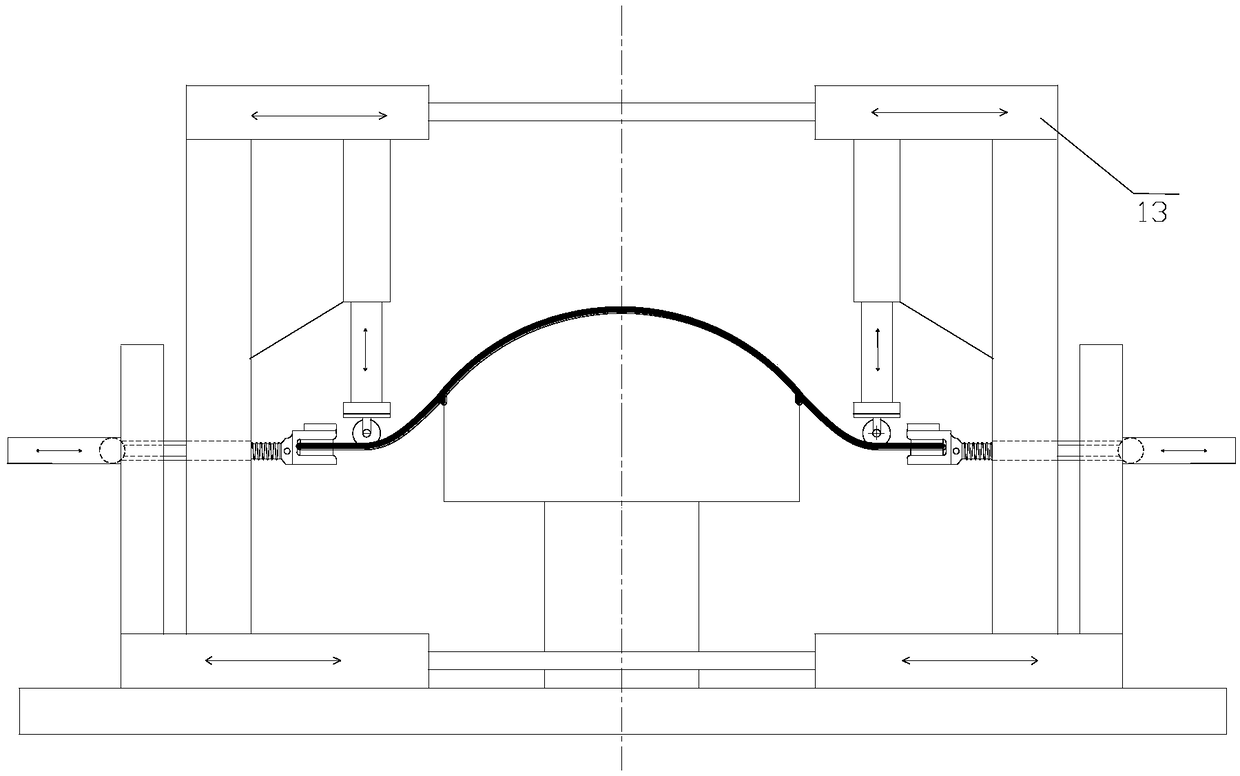

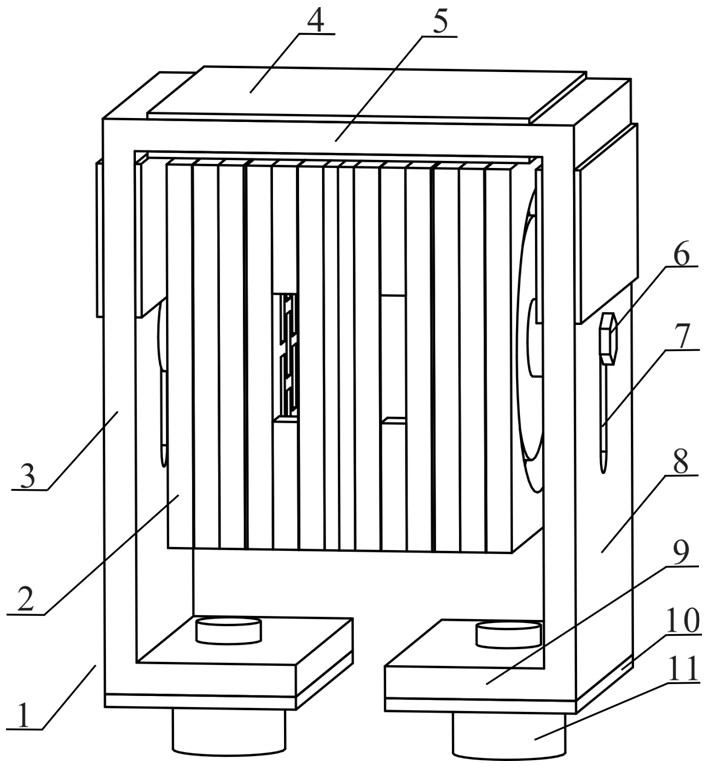

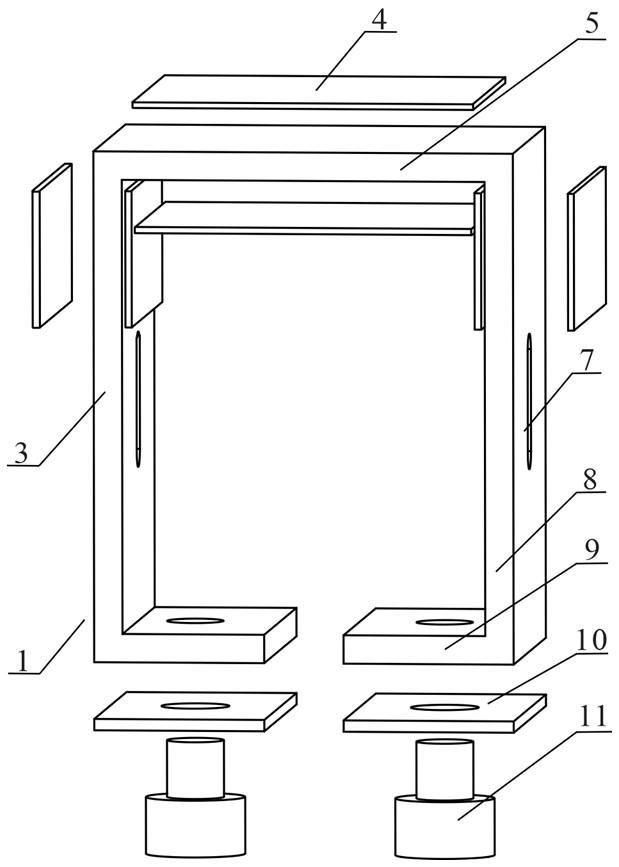

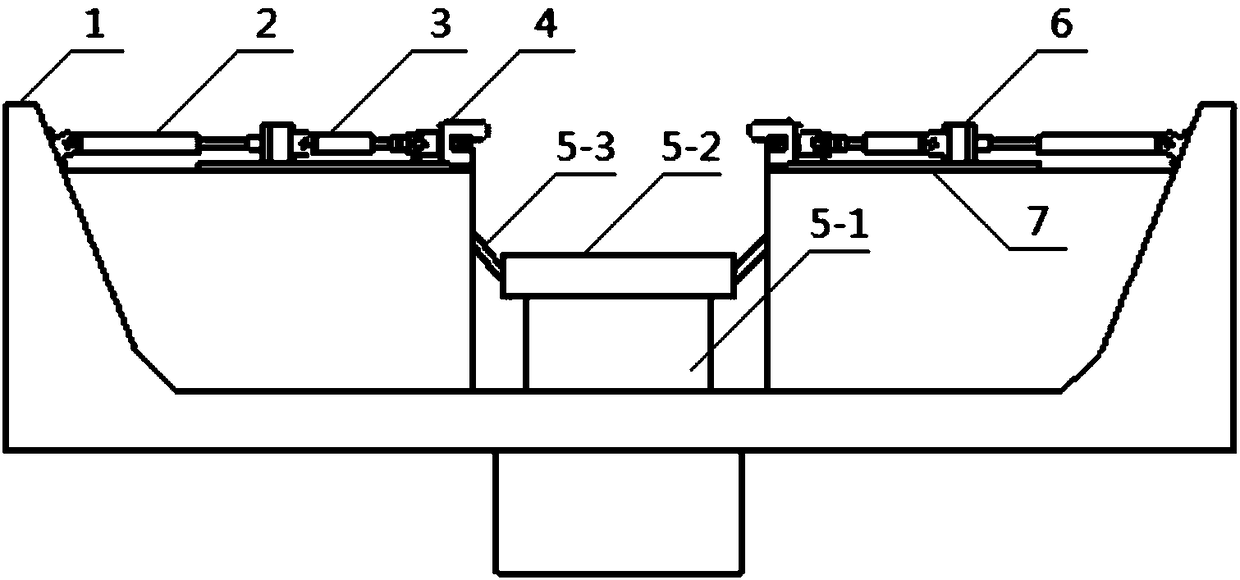

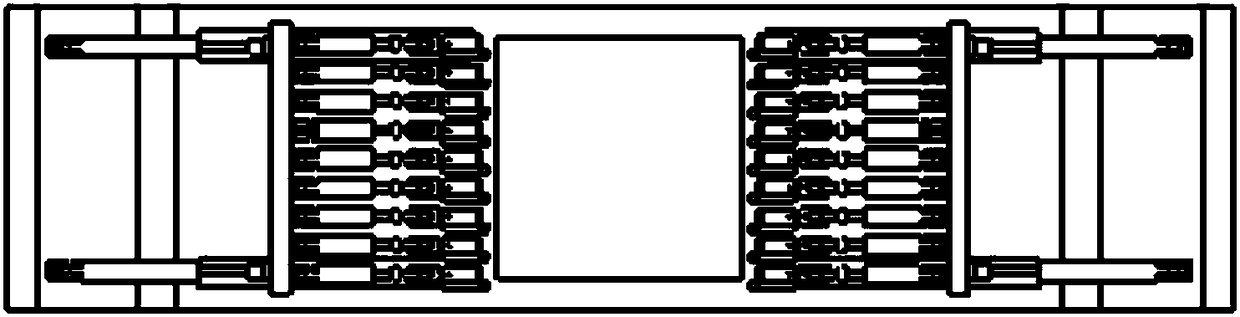

Follow-up pressure-holding flexible stretch forming machine based on vertical loading

The invention relates to a follow-up pressure maintaining type flexible stretch forming machine based on vertical loading. The follow-up pressure maintaining type flexible stretch forming machine is used for plastic machining equipment of plate part three-dimensional curved surface forming. According to the aims of the follow-up pressure maintaining type flexible stretch forming machine, control and operation of the flexible stretch forming machine are simplified, the manufacturing cost is reduced, and intelligent self-adaptive precise control in the plate forming process is achieved; and meanwhile, the stress and strain of formed parts are distributed uniformly, the resilience value is reduced, and the quality of the formed parts is improved. The machine is mainly composed of a rack (1), pre-stretching mechanisms (2), follow-up pressure maintaining mechanisms (3), material clamping mechanisms (4) and a vertical loading mechanism (5). The two ends of the rack (1) are connected with the two horizontal pre-stretching mechanisms (2) and a row of the multiple follow-up pressure maintaining mechanisms (3) and material clamping mechanisms (4) correspondingly. The vertical loading mechanism (5) is arranged at the middle position of the rack (1). One end of each pre-stretching mechanism (2) is hinged to the rack (1), and the other end of each pre-stretching mechanism (2) is hinged to a horizontal movement strip (6). One end of each follow-up pressure maintaining mechanism (3) is hinged to the corresponding horizontal movement strip (6), and the other end of each follow-up pressure maintaining mechanism (3) is connected with the corresponding material clamping mechanism (4) through a semispherical pulling rod.

Owner:江阴中绿冶金设备有限公司

Sheet metal multi-point progressive forming device

ActiveCN105478539BRaise the forming limitSuppress wrinklesShaping toolsPress ramHydraulic cylinderEngineering

The invention relates to a multi-point progressive forming device for sheet materials, which includes a mold base, several driving and pressing units and several shape-adjusting support units. The driving and pressing units are installed on the top plate of the mold base, and each driving and pressing unit is pressed It consists of head, driving basic body, spring, piston and driving hydraulic cylinder. A shape-adjusting support unit is composed of a lower pressing head, a supporting basic body, a spring, an adjusting bolt, and a supporting hydraulic cylinder. Under the action of the hydraulic cylinder, the multi-point progressive forming of the plate between the upper pressing head and the lower pressing head is realized. The invention has a reasonable structure, realizes optimal forming effect by controlling the pressure difference on both sides of the plate, has high forming precision of the plate, and has good surface quality.

Owner:HARBIN INST OF TECH AT WEIHAI

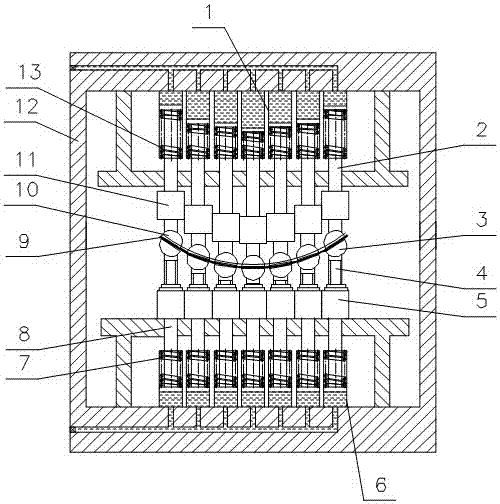

Method of production rare-earth magnet

ActiveUS9847169B2Improve remanenceReduced easeInductances/transformers/magnets manufactureMagnetic materialsHot workingRare-earth magnet

A production method includes producing a rare-earth magnet precursor (S′) by performing first hot working in which, in two side surfaces of a sintered body, which are parallel to a pressing direction and are opposite to each other, one side surface is brought to a constrained state to suppress deformation, and the other side surface is brought to an unconstrained state to permit deformation; and producing a rare-earth magnet by performing second hot working in which, in two side surfaces (S′1, S′2) of the rare-earth magnet precursor (S′), which are parallel to the pressing direction, a side surface (S′2), which is in the unconstrained state in the first hot working, is brought to the constrained state to suppress deformation, and a side surface (S′1), which is in the constrained state in the first hot working, is brought to the unconstrained state to permit deformation.

Owner:TOYOTA JIDOSHA KK

Iron powder for iron powder cores and method for selecting iron powder for iron powder cores

InactiveUS20170018344A1Reduce lossEasy to getTransportation and packagingMetal-working apparatusApparent densityIron powder

Provided is an iron powder for iron powder cores, and a method for selecting the same. The following powder is an iron powder in which orientations are measured in a cross section of a compact formed with a molding pressure of 0.98 GN / m2 by electron backscatter diffraction (EBSD) and the average of KAMs calculated using EBSD analysis software is to 3.00° or less. The Iron powder has a particle size distribution in which particles with a size of 45 μm or less are adjusted to 10% by mass or less, in which the average hardness of powder particles is 80 HV 0.025 or less in Vickers hardness, in which the product of the number (inclusions / m2) of inclusions per unit area and the median size D50 (m) of the inclusions is 10,000 (inclusions / m) or less, and which has an apparent density of 4.0 Mg / m3 or more.

Owner:JFE STEEL CORP

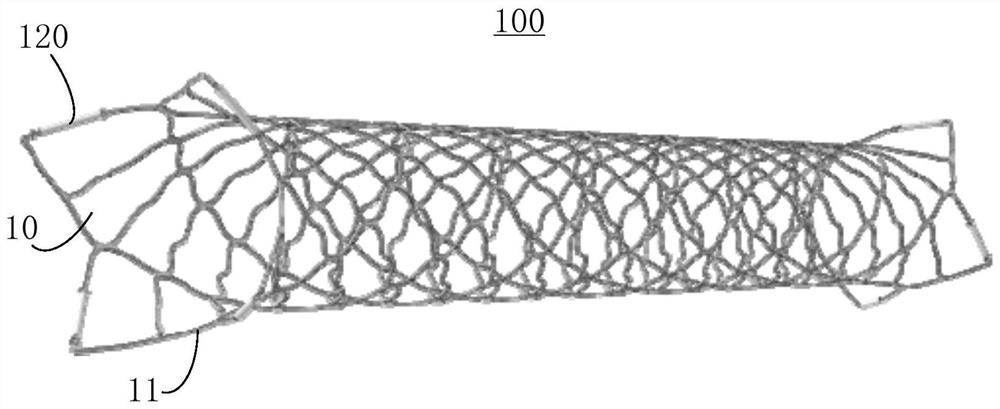

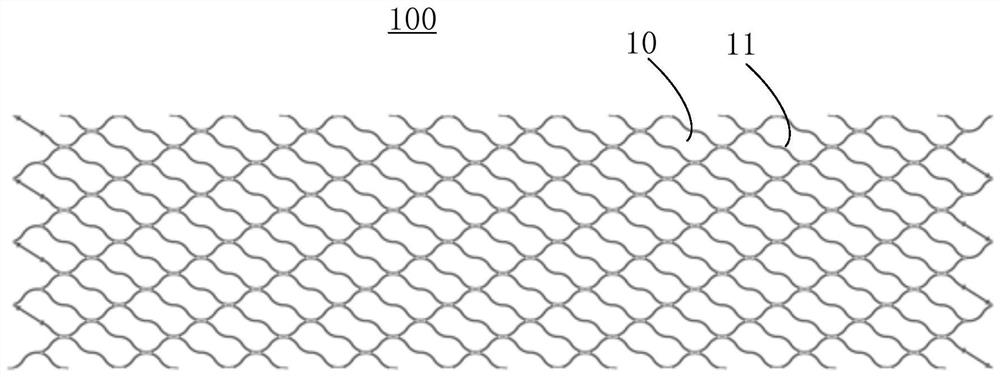

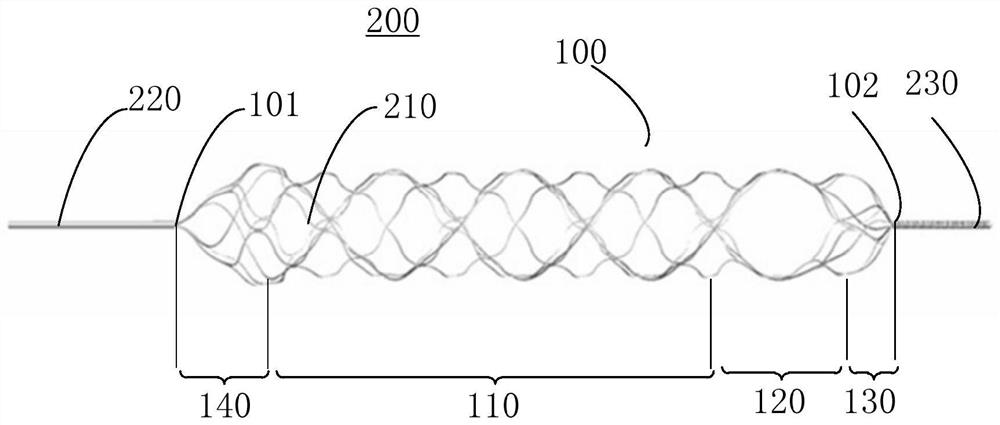

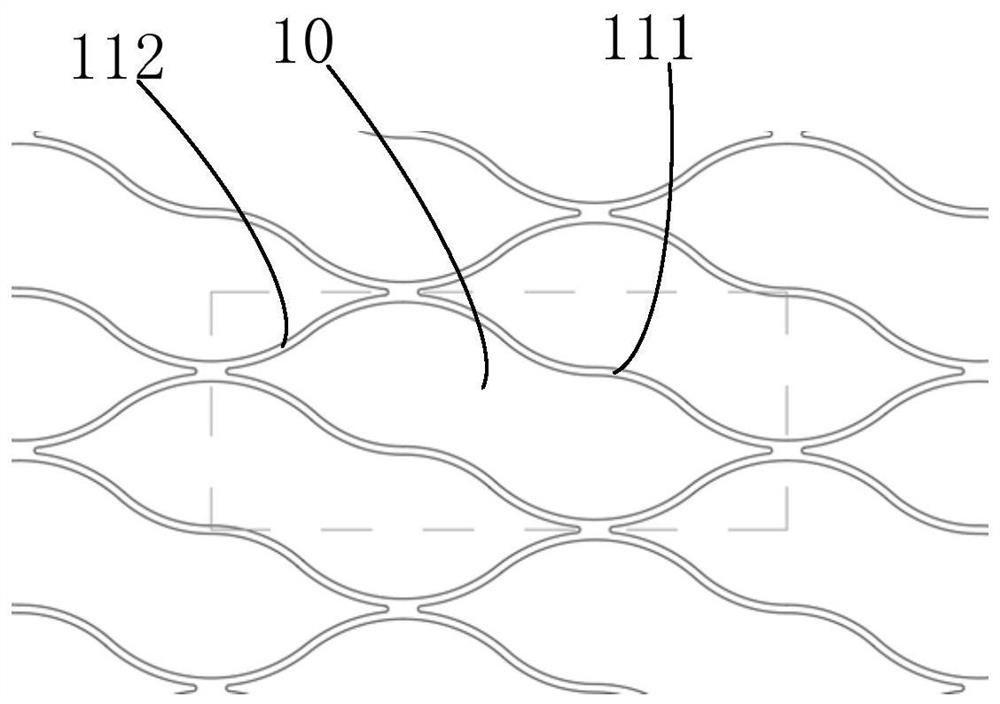

Support

PendingCN114504411AUniform distribution of stress and strainAvoid stress concentrationStentsProsthesisStructural engineeringMechanical engineering

The stent is of a self-expandable tubular grid structure, the two ends of the tubular grid structure are open, the stent comprises a plurality of connected first grid units, each first grid unit comprises a plurality of side rods, and the first grid units are arranged in the direction from the middles of the side rods to the two ends of the side rods. And the sectional area of the side rod is gradually increased. The section area of the side rod of the first grid unit is gradually increased in the direction from the middle to the two ends, so that the rigidity of the side rod is gradually increased in the direction from the middle to the two ends, the dependent variables of the end of the side rod and the area close to the end are reduced, stress and strain are evenly distributed when the support deforms, and the stability of the support is improved. Stress strain concentration in a local area is avoided, deformation of the support is avoided, the size is prevented from being affected, and the rebound resilience of the support is improved.

Owner:SHANGHAI ACHIEVA MEDICAL SUZHOU CO LTD

Thrombectomy stent and thrombus catcher

The present application discloses a thrombectomy bracket and a thrombus catcher, wherein the thrombectomy bracket is a self-expandable tubular grid structure, and the thrombectomy bracket includes a plurality of connected first grid units, and the first grid The unit includes a plurality of side bars, and the cross-sectional area of the side bars gradually increases along the direction from the middle of the side bars to the two ends of the side bars. By setting the side bars of the first mesh unit along the direction from the middle to both ends, the cross-sectional area of the side bars gradually increases, so that the stiffness of the side bars gradually increases along the direction from the middle to both ends, reducing the end of the side bars And the strain amount near the end area makes the stress and strain distribution of the thrombectomy bracket even when deformed, avoids the stress and strain concentration in the local area, and avoids the deformation of the thrombectomy bracket to affect the size, and improves the resilience of the thrombectomy bracket.

Owner:SHANGHAI ACHIEVA MEDICAL SUZHOU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com