Electromagnetism-assisted forming device and method for dissimilar metal composite boards

A composite plate and dissimilar metal technology, applied in the field of composite plate forming devices, can solve the problems of low forming limit, plate thinning, cracking, etc., and achieve the effects of increasing forming limit, increasing tangential compressive stress, and improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

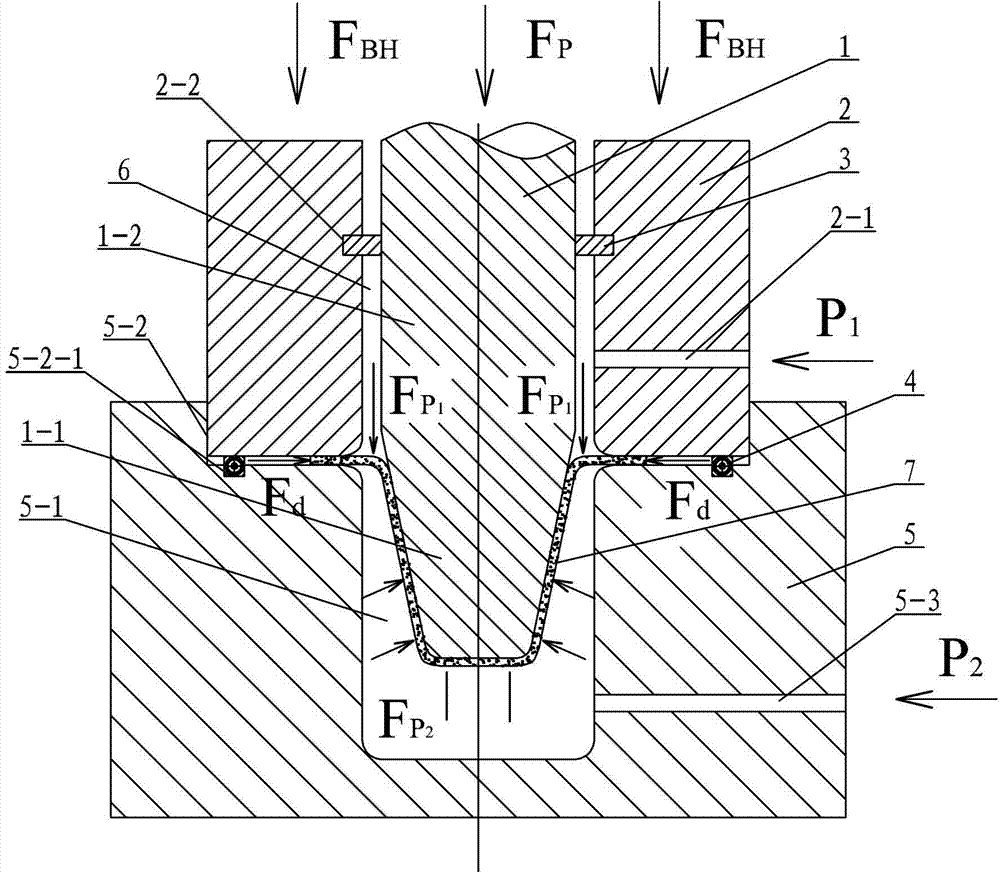

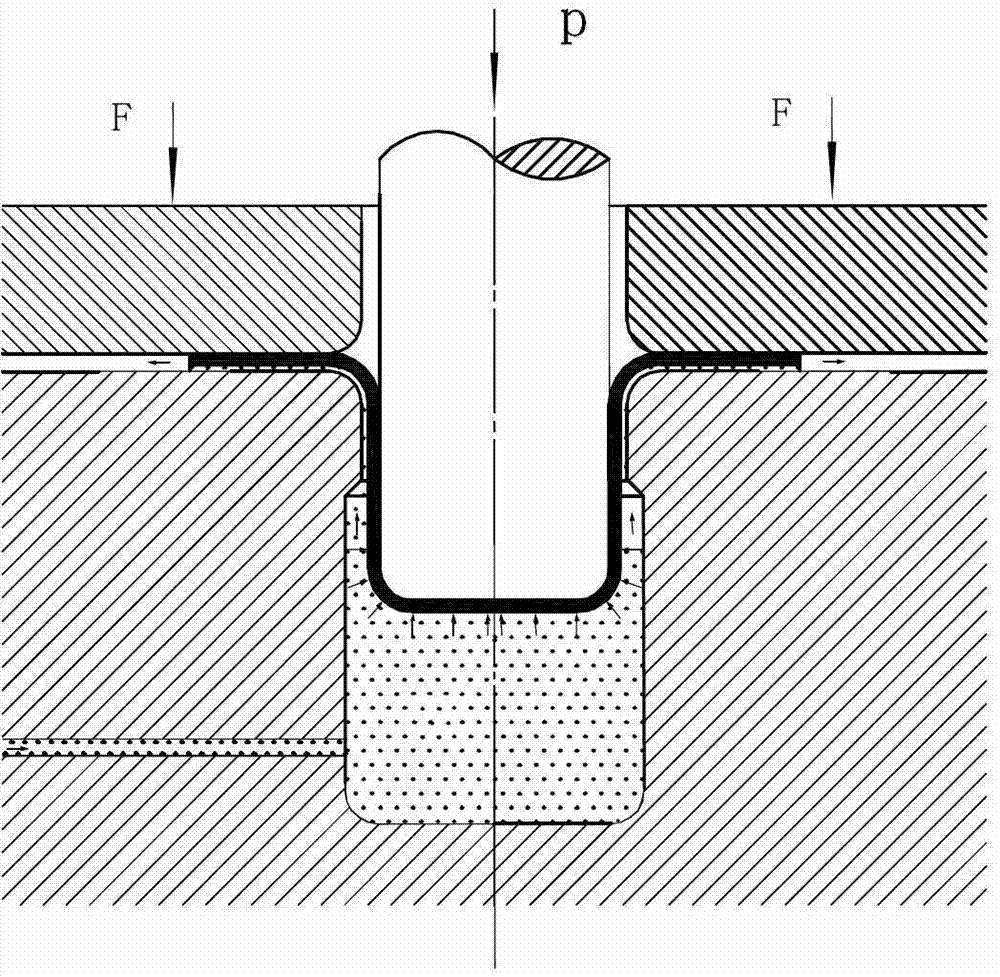

[0018] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment comprises punch 1, blank holder ring 2, sealing ring 3, coil 4 and die 5, and the upper end surface of described die 5 is provided with die cavity 5-1 and The binder ring groove 5-2, the bottom surface of the binder ring groove 5-2 is provided with an annular coil groove 5-2-1, the coil 4 is arranged in the annular coil groove 5-2-1, the inner side wall of the binder ring 2 There is an annular sealing ring groove 2-2, the punch of the punch 1 is a round table 1-1, the tail of the punch 1 is a cylinder 1-2, the blank holder 2 is set on the cylinder 1-2, and the blank holder There is a liquid channel 6 between the inner wall of 2 and the cylinder 1-2, the sealing ring 3 is set on the cylinder 1-2 and arranged in the annular sealing ring groove 3-1, and the side wall of the blank holder 2 is provided with an upward The liquid passage 2-1, the side wall of the die 5 is provided wi...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper liquid inlet channel 2-1 and the lower liquid channel 6-1 of this embodiment are arranged facing each other up and down. Other connection relationships are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 Describe this implementation mode, this implementation mode is realized through the following steps:

[0021] Step 1. Place the composite sheet 7 on the bottom surface of the blankholder groove 5-2, and move the blankholder 2 down to a place where the lower end surface of the blankholder 2 is 0.5mm to 2mm away from the upper end surface of the composite sheet 7. Blankholder 2 applies blankholder force F BH 5kN~200kN;

[0022] Step 2. The punch 1 moves down to the upper surface of the composite sheet 7, and at the same time, the positive liquid is applied to the liquid channel 6 from the upper liquid channel 2-1, and its positive liquid pressure P 1 2MPa~50MPa, the reverse liquid is applied from the lower liquid inlet channel 5-3 to the die cavity 5-1, and its reverse liquid pressure P 2 Should be greater than 1.5 times the positive liquid pressure P 1 , less than 100MPa (that is, 100MPa≥P 2 ≥P 1 ), then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com