Forging method for improving qualified rate of large-wall-thickness 5754 aluminum alloy forged piece

A technology of aluminum alloy and pass rate, which is applied in the field of aluminum alloy forging, can solve problems such as intergranular dislocation, uneven force, and affecting the pass rate of one-time inspection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

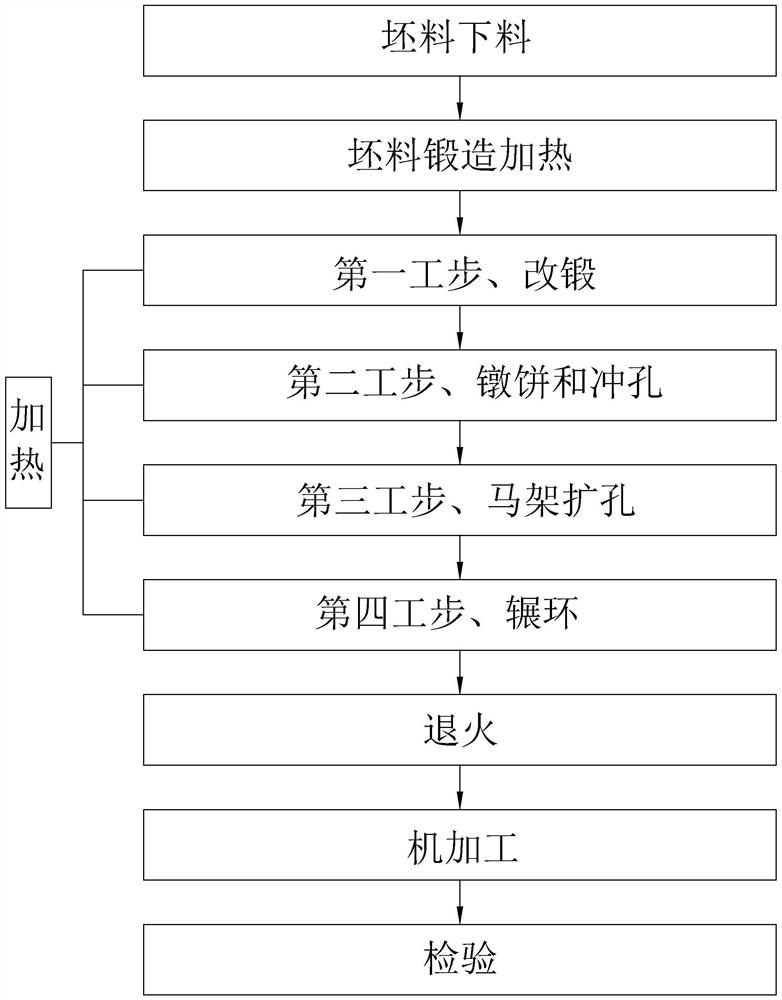

[0025] Embodiment: a kind of forging method that improves the qualified rate of large wall thickness 5754 aluminum alloy forgings, such as figure 1 shown, including the following steps:

[0026] S1. Billet blanking: the size of the raw material is φ770-800mm cast rod, and the length is L. Control the content of Mg and Mn+Cr in the raw material, that is, the forging. The content of Mg is controlled at 2.6%-3.6%. Mg exists in the form of β(Mg2Al3) phase in the aluminum alloy, which serves the purpose of dispersion strengthening. Increasing the content of Mg can increase the strength of the alloy, but it will reduce the plasticity to a certain extent. Appropriately increasing the content of Mn+Cr and internally controlling it at 0.30-0.60% can hinder the grain growth, make the ingot structure compact, and ensure the performance of the forging matrix, welding heat crack resistance and corrosion resistance.

[0027] S2. Billet forging heating: the billet is put into the furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com