Preparation method for ultrathin magnesium alloy strip

A magnesium alloy, ultra-thin technology, applied in metal rolling and other directions, can solve the problems of limited grain refinement effect and waste of energy, and achieve the effect of fine and uniform grain, low investment and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

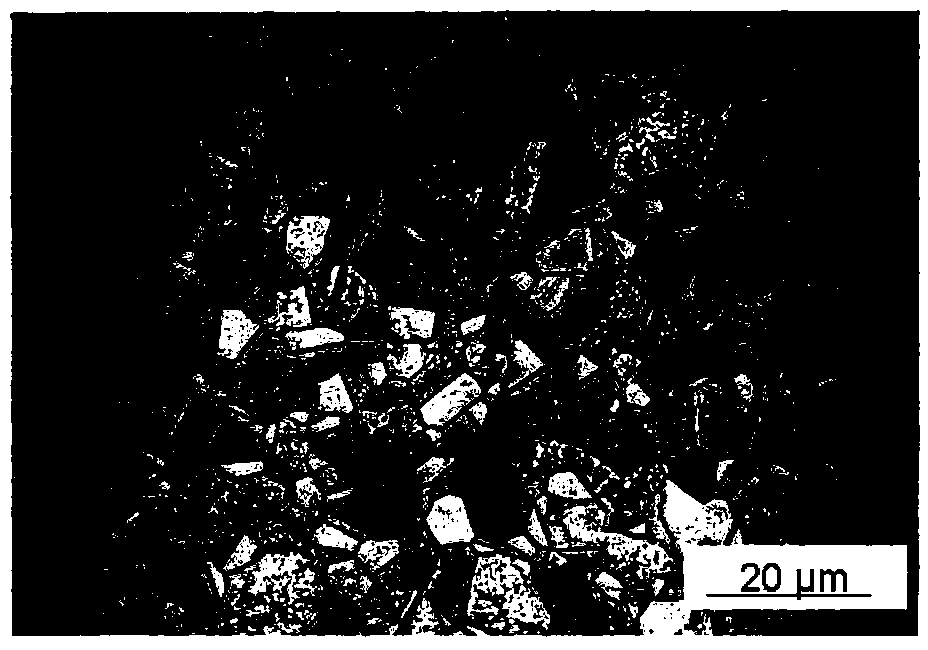

Embodiment 1

[0027] The pure Mg element and Er element are used to prepare the alloy according to Mg-4Er (mass ratio). The solid solution magnesium alloy ingot was kept at 773K for 24 hours under the protection of an inert gas, and then water quenched to perform solid solution treatment on the ingot. Cut the solution-treated billet into 4mm thickness for hot rolling and deformation. The absolute temperature of hot rolling is 667K. The hot rolling is carried out in multiple passes, and the deformation of each pass is controlled at 10%, supplemented by intermediate annealing. The amount of deformation reaches 75%, and the thickness of the plate is rolled to about 1mm, and then annealing is carried out at an absolute temperature of 673K for 30 minutes to improve the plasticity of the plate. Under room temperature conditions, the annealed hot-rolled plate is cold-rolled with a deformation of 50% in the first pass, and can be cold-rolled into an ultra-thin strip (foil) with a thickness of 0.0...

Embodiment 2

[0030] The pure Mg element and Zn element are used to prepare the alloy according to Mg-1Zn (mass ratio). The prepared solid solution magnesium alloy ingot was kept at 723K for 24 hours under the protection of an inert gas, and then water quenched, and the ingot was subjected to solution treatment. Cut the solution-treated ingot into 8mm thickness for hot rolling and deformation. The hot rolling temperature is 800K. The hot rolling is carried out in multiple passes. The deformation of each pass is controlled at 9%, supplemented by intermediate annealing. The total deformation To reach 150%, the plate thickness is rolled to about 1mm, and then annealed at 690K for 30 minutes to improve the plasticity of the plate. Under room temperature conditions, the annealed hot-rolled plate is cold-rolled with a deformation of 60% in the first pass, and can be cold-rolled into an ultra-thin strip (foil) with a thickness of 0.1mm through multiple passes. The maximum reduction can reach 95%,...

Embodiment 3

[0033] The pure Mg element and Dy element are used to prepare the alloy according to Mg-6Dy (mass ratio). The solid solution magnesium alloy ingot was kept at 803K for 24 hours under the protection of an inert gas, and then water quenched, and the ingot was subjected to solution treatment. Cut the solution-treated ingot into 6mm thickness for hot rolling deformation, hot rolling for multi-pass rolling, the deformation of each pass is controlled at 5%, supplemented by intermediate annealing, the total deformation reaches 90%, the plate The thickness is rolled to about 1mm, and then annealed at 773K for 30 minutes to improve the plasticity of the plate. Under room temperature conditions, the annealed hot-rolled plate is cold-rolled with a deformation of 70% in the first pass, and can be cold-rolled into an ultra-thin strip (foil) with a thickness of one pass. The total reduction can reach 95%, and the rolling elongation can reach 1000%. Except for edge cracks caused by large r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com