Device and method based on electrostatic force gradual advancing and push-and-pull composite forming and used for large aluminum alloy part

A compound forming and aluminum alloy technology, which is applied in the field of aluminum alloy parts forming, can solve the problems of poor deformation ability of aluminum alloy, easy thinning of aluminum alloy part wall thickness, easy wrinkling on the surface of aluminum alloy part, etc., to achieve the suppression of wall thickness Effect of thinning and wrinkling suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

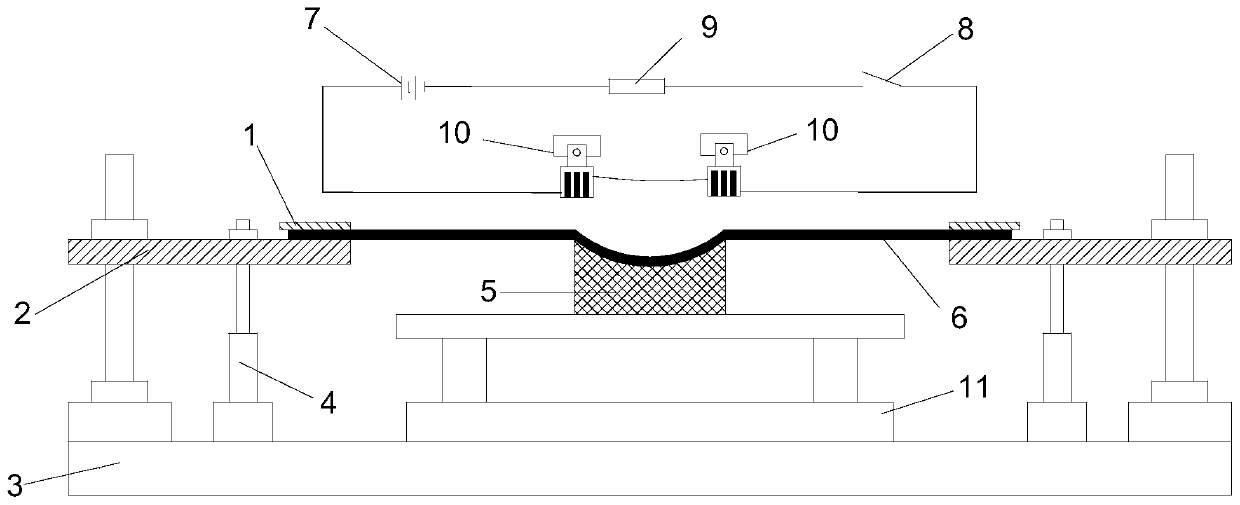

[0029] The present invention is specifically described below in conjunction with accompanying drawing:

[0030] refer to figure 1 , a progressive push-pull composite forming device for large aluminum alloy parts based on electrostatic force, including a press plate 1, a top plate 2, a mold 5 and an electromagnetic coil 10; the press plate 1 is located above the top plate 2, and is used to fix the aluminum alloy part 6 on the top plate 2; the electromagnetic coil 10 is arranged above the mold 5, and the aluminum alloy part 6 is placed between the mold 5 and the electromagnetic coil 10.

[0031] As one of the embodiments, in this embodiment, the electromagnetic coil 10 is connected to the power supply 7 through the switch 8; the power supply 7, the switch 8, and the electromagnetic coil 10 form an electromagnetic circuit.

[0032] As one of the embodiments, in this embodiment, the electromagnetic circuit is provided with an adjustable resistor 9 .

[0033] As one of the embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com