Minor radius bend forming method of ultrathin tubular product

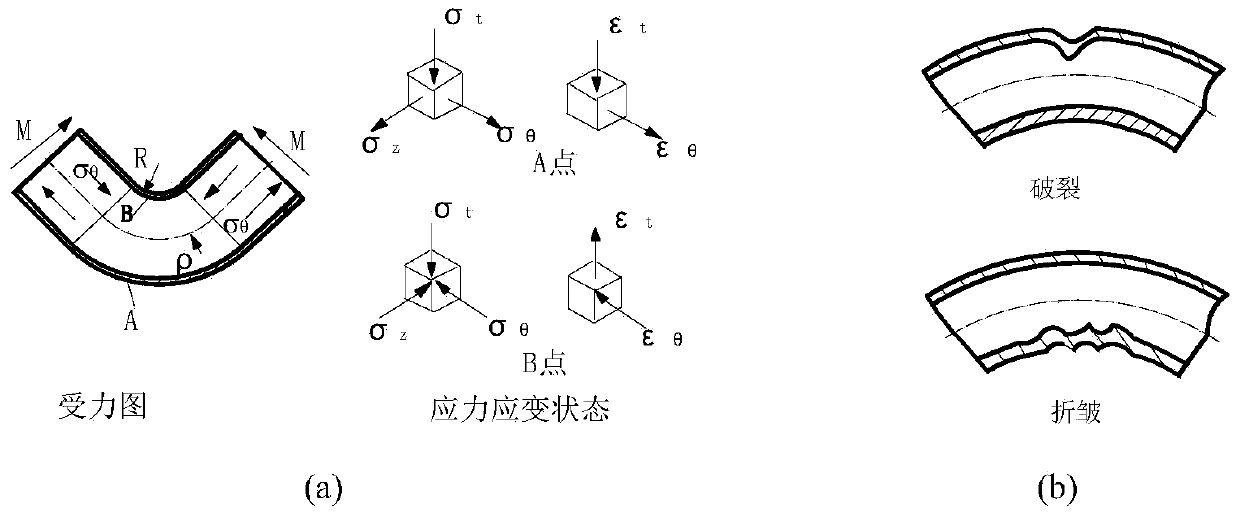

A technology of bending forming and small radius, which is applied in the field of material plastic processing, can solve the problems of increasing the normal compressive stress of the pipe wall, increasing the friction force between the pipe and the mold, and difficult implementation, so as to improve the bending forming limit and suppress the reduction of wall thickness Thin, improve the effect of destabilization and wrinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

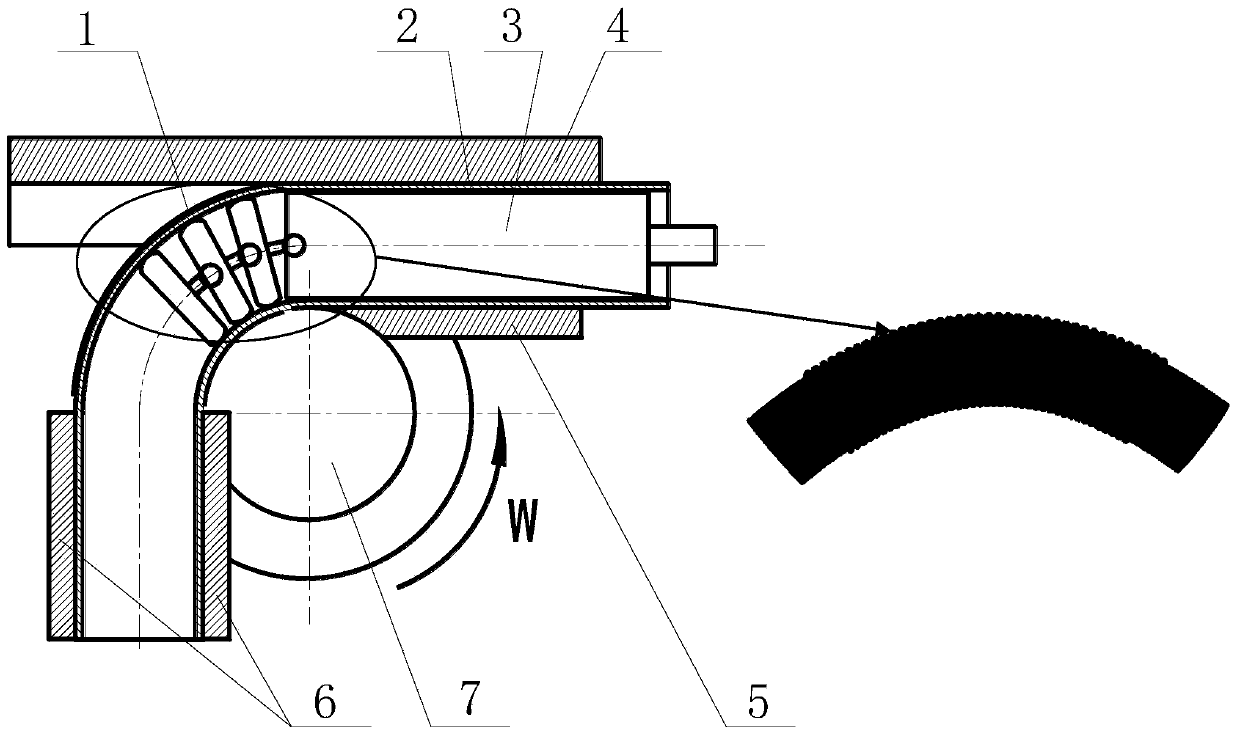

[0030] A method for bending and forming an ultra-thin pipe with a small radius, comprising the steps of:

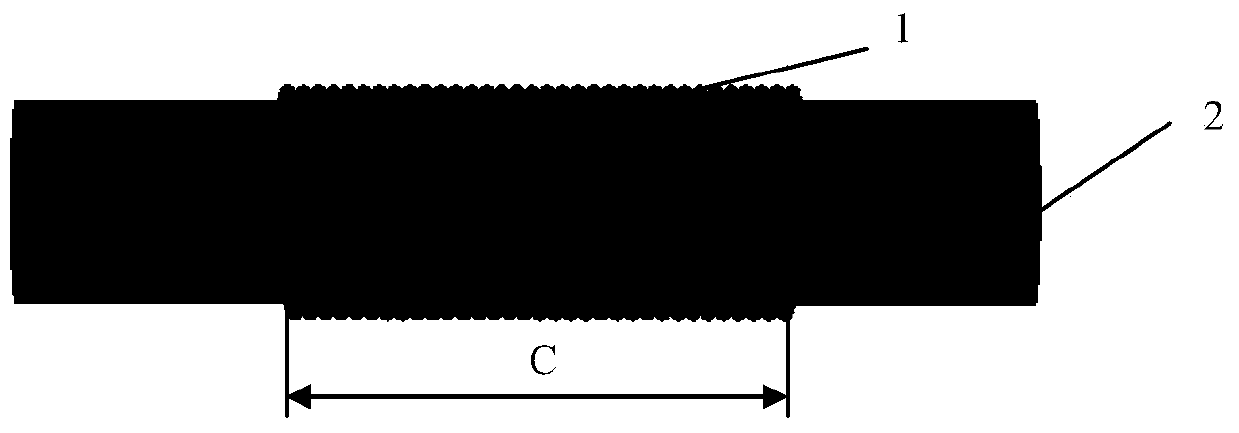

[0031] 1). The diameter of the pipe 2 is 60mm, the thickness is 0.73mm (that is, the ratio of diameter to thickness is 82), and the length is 400mm. The material of the pipe 2 is pipe 201; the steel wire 1 is a round steel wire, and the diameter of the steel wire is 1.5mm. The specific wrapping layer is 1.5mm thick, the bending radius is 90mm, the length of the part C to be bent is 200mm, the outer diameter of the mandrel (multi-ball mandrel) 3 is 57.8mm, and the diameter of the ball contained is 57.4mm. The arrangement form is that the three balls are connected in series on the mandrel through the hinge; figure 1 shown;

[0032] The steel wire 1 is used to tightly wrap the part C to be bent of the pipe 2, and the gap between the wrapped steel wire and the pipe is about 0.1mm (the outer diameter difference between the wrapped steel wire and the pipe is about 0.1mm);

...

Embodiment 2

[0039] A method for bending and forming an ultra-thin pipe with a small radius, comprising the steps of:

[0040] 1). The diameter of the pipe 2 is 60mm, the thickness is 0.73mm (that is, the ratio of diameter to thickness is 82), the length is 400mm, and the material of the pipe 2 is 201; the steel wire 1 is square steel wire, and the square steel wire is equilateral 1.5× 1.5mm, the specific wrapping layer is 1.5mm thick, the bending radius is 90mm, the length of the part to be bent is 200mm, the outer diameter of the mandrel (multi-ball mandrel) 3 is 57.8mm, and the diameter of the ball contained is 57.4mm , the arrangement of the balls is that three balls are connected in series on the mandrel through a hinge; figure 1 shown;

[0041] The steel wire 1 is used to tightly wrap the part C to be bent of the pipe 2, and the gap between the wrapped steel wire and the pipe is about 0.1mm (the outer diameter difference between the wrapped steel wire and the pipe is about 0.1mm); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com