Continuous co-extrusion self-reinforcing equipment and continuous co-extrusion self-reinforcing method for biomass wood plastic foaming floor

A wood-plastic foam floor and biomass technology, applied in the field of extrusion equipment, can solve the problems of poor aging resistance, low impact strength, poor nail holding force, etc., to achieve uniform plastic deformation, prolong service life, and smooth material deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific illustrations.

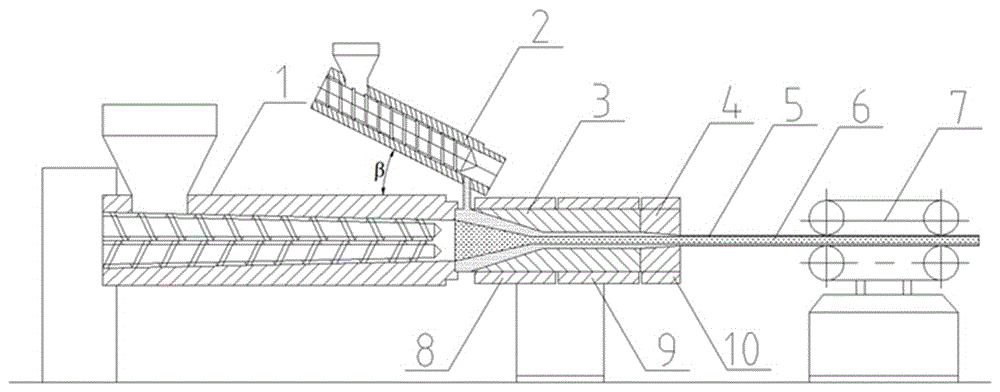

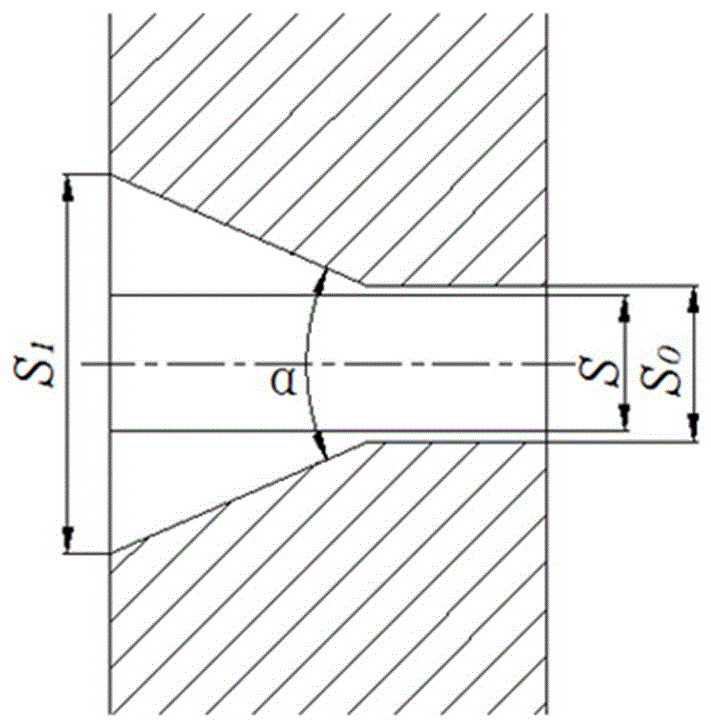

[0023] A continuous co-extrusion self-reinforcement equipment for biomass wood-plastic foam flooring, including a conical twin-screw extruder host 1, a co-extrusion die 3, a conical die 4 and a tractor 7 arranged in sequence, and an extrusion auxiliary machine 2, the extrusion auxiliary machine 2 is arranged vertically above the conical twin-screw extruder main machine 1, and the angle β between the extrusion auxiliary machine 2 and the extrusion main machine 1 is 20°- 60°, the extrusion ratio R of the conical die 4 is 2-10, and the extrusion cone angle α is 15°-60°, wherein:

[0024]

[0025] S 1 : Cross-sectional area of the inlet end of the conical die; S 0 : Cross-sectional area of the exit end of the tapered die; S: Cross-sectional area of the core floor.

[0026] A continuous co-extrusion self-reinforcing method for biomass wood-plastic foam fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com