Laser-pulsed magnetism-based welded-pipe welding residual stress relieving method

A technology of residual stress and pulsed magnetism, applied in the direction of improving process efficiency, etc., can solve problems such as inability to eliminate thermal stress, and achieve the effect of eliminating residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

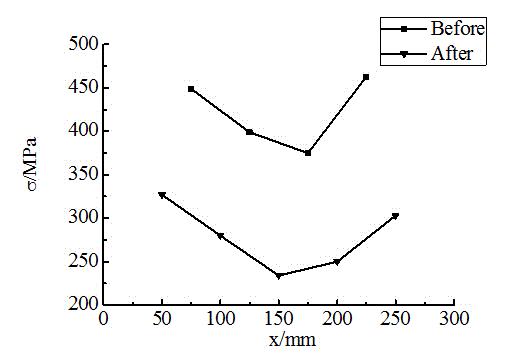

[0039] The test object of the embodiment of the present invention is 45 steel plates of 300 × 150 × 15 mm. The two steel plates are welded by double-sided automatic submerged arc welding, and then laser treatment and pulse magnetic treatment are carried out successively. The residual stress is measured by the blind hole method. Measure the first principal stress values at 50mm, 100mm, 150mm, 200mm and 250mm.

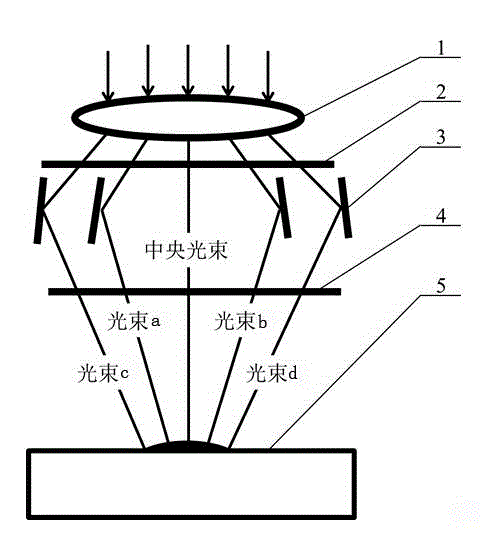

[0040]The laser processing parameters are determined as follows: the output power is 10kW, the moving speed is 20mm / s, the diameter of the central beam spot is 8mm, the spot diameter of beams 1 and 2 is 5mm, the spot diameter of beams 3 and 4 is 2, and the overlapping amount is 0.5mm , the number of scans is 3 times; the pulse magnetic treatment parameters are determined as follows: the pulse magnetic field strength is 10 5 A / m, the frequency is 0.5Hz, the pulse width is 20%, the processing time is 120s, and the number of scans is 3 times. The residual stress measurem...

Embodiment 2

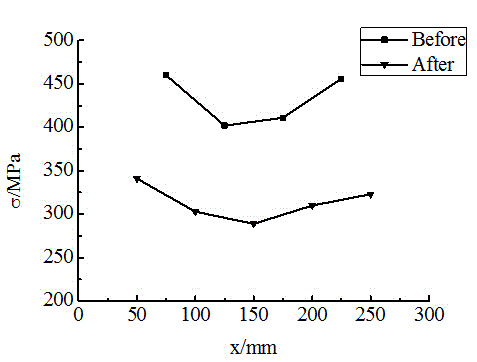

[0042] The pulse magnetic treatment parameters are the same as those in Example 1. Among the laser treatment parameters, the moving speed is 35 mm / s, the number of scans is 5 times, and other parameters remain unchanged. The residual stress measurement results are as image 3 shown.

Embodiment 3

[0044] The laser treatment parameters are the same as those in Example 1. Among the pulse magnetic treatment parameters, the treatment time is 90 s, the number of scans is 5 times, and other parameters remain unchanged. The residual stress measurement results are as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com