Straightening equipment for eliminating unevenness of tungsten-molybdenum composite board after shearing separation

A composite plate and straightening technology, which is applied in the field of straightening equipment for eliminating unevenness of tungsten and molybdenum composite plates after shearing and tensioning, can solve the problems of large longitudinal bending deformation and low work efficiency of tungsten and molybdenum composite plates, and achieves elimination of residual effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

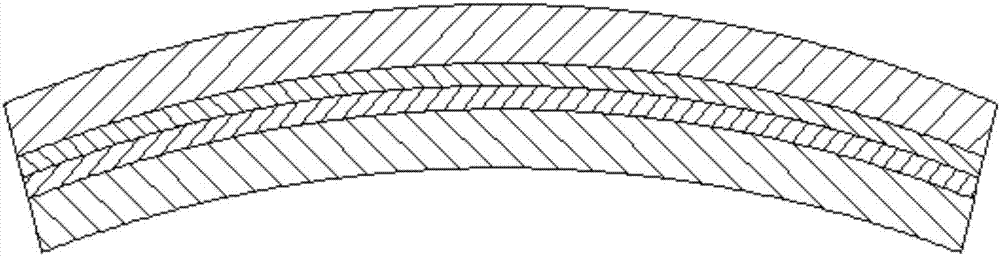

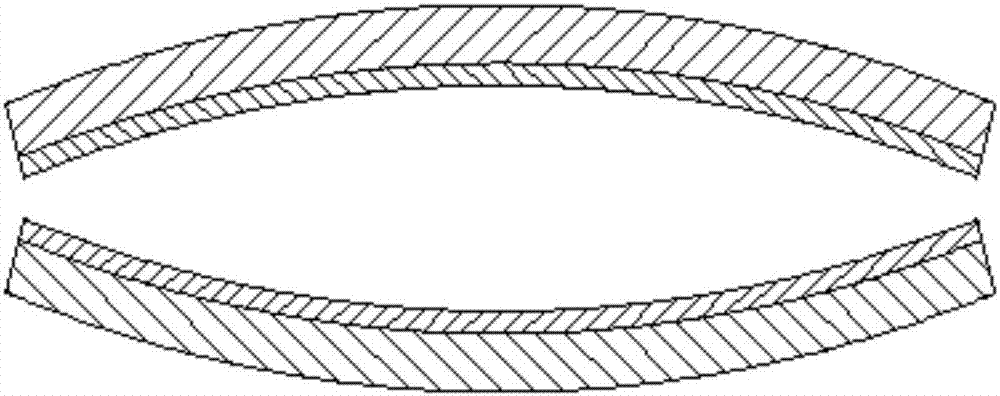

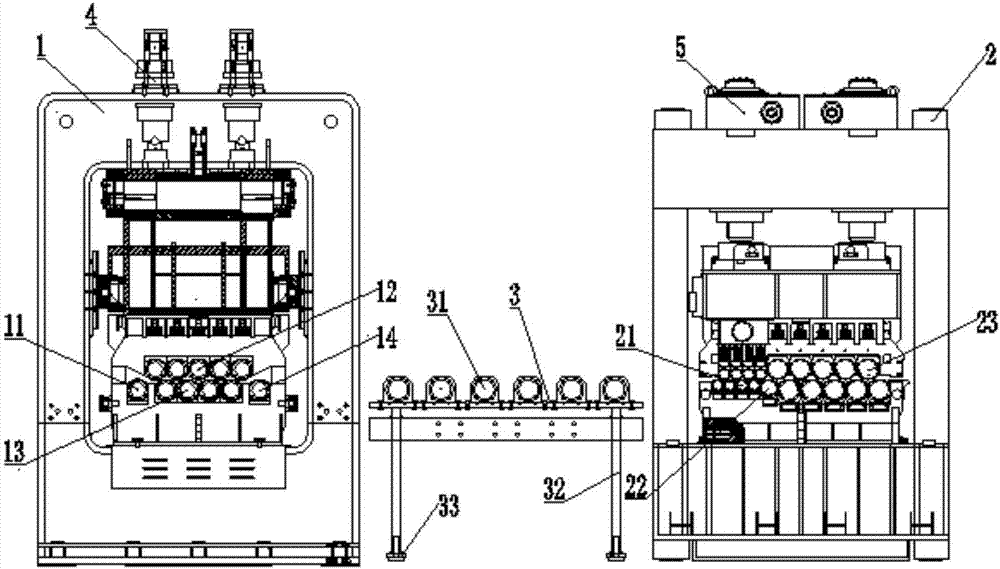

[0027] The present invention realizes through following technical scheme: as image 3 , Figure 4 , Figure 5 As shown, a straightening device for eliminating unevenness after shearing and splitting of tungsten-molybdenum composite plates includes an entrance straightening machine 1 equipped with A straightening and anti-bending rollers, and an exit straightening machine equipped with B straightening and anti-bending rollers. Machine 2 and the track 3 between the entrance straightener 1 and the exit straightener 2.

[0028] It should be noted that, through the above improvements, first measure the total width of the tungsten-molybdenum composite board, then adjust the distance between the two sections of the straightening and anti-bending roller 13 in the lower row of the entrance leveler 1, and then measure the width of the two tungsten-molybdenum composite boards. The total thickness, adjust the roll gap of the entrance leveler 1 and the exit leveler 2, and finally adjust ...

Embodiment 2

[0030] This embodiment is further optimized on the basis of the above embodiments, such as image 3 As shown, the A straightening and anti-bending rolls include a bite-in roll 11, an ejection roll 14, an upper row of straightening and anti-bending rolls 12 and a lower row of straightening and anti-bending rolls 13. 14. The upper row of straightening and anti-bending rollers 12 and the lower row of straightening and anti-bending rollers 13 have the same size and are arranged crosswise; the bite-in rollers 11, ejection rollers 14 and the upper row of straightening and anti-bending rollers 12 are integral structures ; The lower row of straightening and anti-bending rollers 13 is a two-stage structure.

[0031] The nip-in roller 3 and the ejection roller 4 are exactly single integral cylinder rollers.

[0032] The lower row of straightening and anti-bending rollers 13 adopts a two-stage structure, so that during the straightening process, it can be automatically adjusted accordin...

Embodiment 3

[0035] This embodiment is further optimized on the basis of the above embodiments, such as image 3 , Figure 5 As shown, it also includes the outlet straightening machine 2 frame for installing the outlet straightening machine 2 and the B hydraulic device 5 connected with the front straightening anti-bending roller 21 and the rear row straightening and anti-bending roller 23 respectively. The straightening and anti-bending rollers 21 of the front row and the straightening and anti-bending rollers 23 of the rear row are cylindrical rollers. The diameter of the straightening and anti-bending rollers 21 of the front row is equal to the diameter of the biting roller 11, the diameter of the straightening and anti-bending rollers 23 of the rear row is 1.8 times of the diameter of the straightening and anti-bending rollers 21 of the front row, and the transition rollers The diameter of 22 is 1.3 times of front row straightening anti-bending roller 21 diameters.

[0036] It should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com