Method for brazed connection of DD98M single-crystal high-temperature alloy by Pd-Si composite solder

A technology of DD98M and superalloy, applied in welding medium, welding equipment, metal processing equipment, etc., can solve the problems of complex cavity structure, difficult core direct casting, etc., achieve excellent performance, promote the improvement of manufacturing level, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

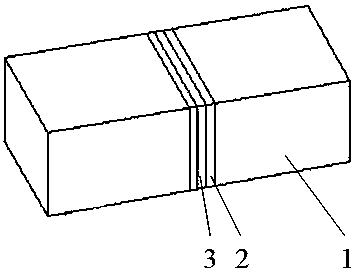

[0028] Example 1: Taking Pd-Si composite solder as an example to connect DD98M single crystal and DD98M single crystal at a brazing temperature of 1060°C and a temperature of 60 minutes, the specific implementation process is as follows:

[0029] 1) Soak the DD98M single crystal superalloy in alcohol and ultrasonically remove the oil stains, then use 400#, 600#, 1000#, 1500# sandpaper to polish the surface to be connected, and then polish until there is no obvious scratch on the surface to be connected;

[0030] 2) Select Pd foil with a thickness of 0.025mm and a purity of 99.9% and Si powder with a particle size of 600 mesh and a purity of 99.99% as solder, cut two pieces of Pd foil with the same shape as the surface to be connected, and weigh them with an analytical balance Si powder, control the mass ratio of Pd and Si in the solder to be 20:1;

[0031] 3) According to the order of DD98M-Pd-Si-Pd-DD98M, firstly paste a piece of Pd foil on the surface to be connected of DD98...

Embodiment 2

[0038] Example 2: Taking the use of Pd-Si composite solder as an example to connect DD98M single crystal and DD98M single crystal at a brazing temperature of 1060°C and heat preservation for 30 minutes, the specific implementation process is as follows:

[0039] 1) Soak the DD98M single crystal superalloy in alcohol and ultrasonically remove the oil stains, then use 400#, 600#, 1000#, 1500# sandpaper to polish the surface to be connected, and then polish until there is no obvious scratch on the surface to be connected;

[0040] 2) Select Pd foil with a thickness of 0.025mm and a purity of 99.9% and Si powder with a particle size of 600 mesh and a purity of 99.99% as solder, cut two pieces of Pd foil with the same shape as the surface to be connected, and weigh them with an analytical balance Si powder, control the mass ratio of Pd and Si in the solder to be 20:1;

[0041]3) According to the order of DD98M-Pd-Si-Pd-DD98M, firstly paste a piece of Pd foil on the surface to be co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com