Fatigue resistant steel wire rope and manufacturing method thereof

A steel wire rope and fatigue-resistant technology, which is applied in the field of metal product processing, can solve the problems of low fatigue performance of steel wire ropes, achieve good stress relief, increase creep resistance, and improve fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0015] The following is a detailed description of a steel wire rope with fatigue resistance and its manufacturing method according to the present invention in conjunction with the accompanying drawings:

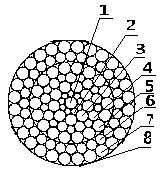

[0016] The invention is attached figure 1 , The steel wire rope structure is 1+9+9+18+18+28+28, consisting of central steel wire 1, first layer of 9 steel wires 2, second layer of 9 steel wires 3, third layer of 18 steel wires 4, and fourth layer of 18 wires The steel wire 5, the fifth layer of 28 steel wires 6 and the sixth layer of 28 steel wires 7 are twisted at one time. After the steel wire rope is twisted and formed, it is pre-tensioned and stabilized, and then the high corrosion-resistant plastic coating 8 is applied. The diameters of the steel wires in the same layer of the steel wire rope are equal. The steel wire rope is twisted once instead of layered. The wires in the steel wire rope are in line contact, which reduces the bending stress of the steel wire.

[0017] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com