Manufacture method of ceramic lining composite square steel tube

A ceramic lining and production method technology, applied in the direction of heating inorganic powder coating, etc., can solve the problems of square tubes being easily twisted and deformed, ceramic coatings are easy to fall off, and coating thickness is uneven, so as to achieve fewer production processes and synthesis reactions The effect of rapid process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

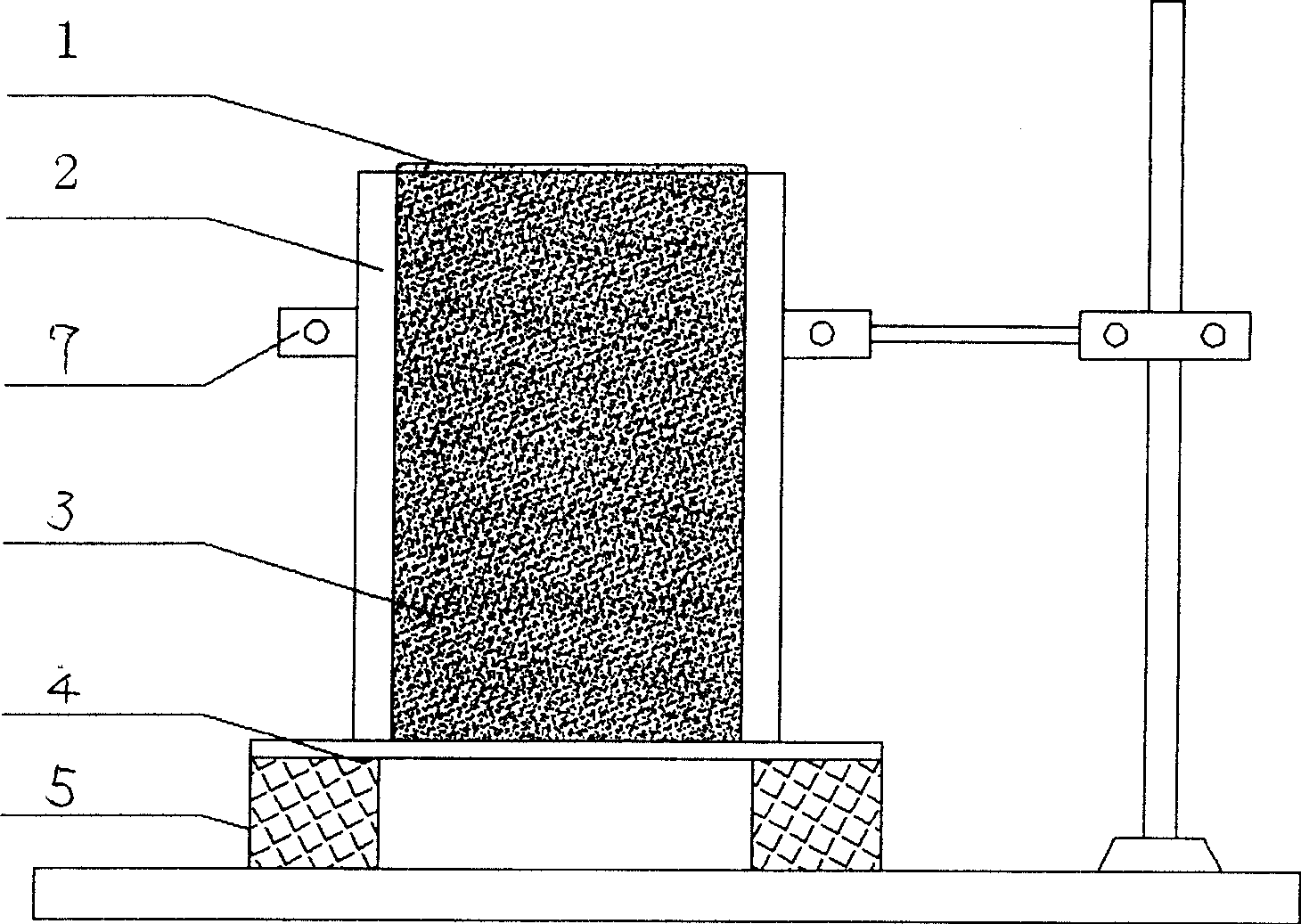

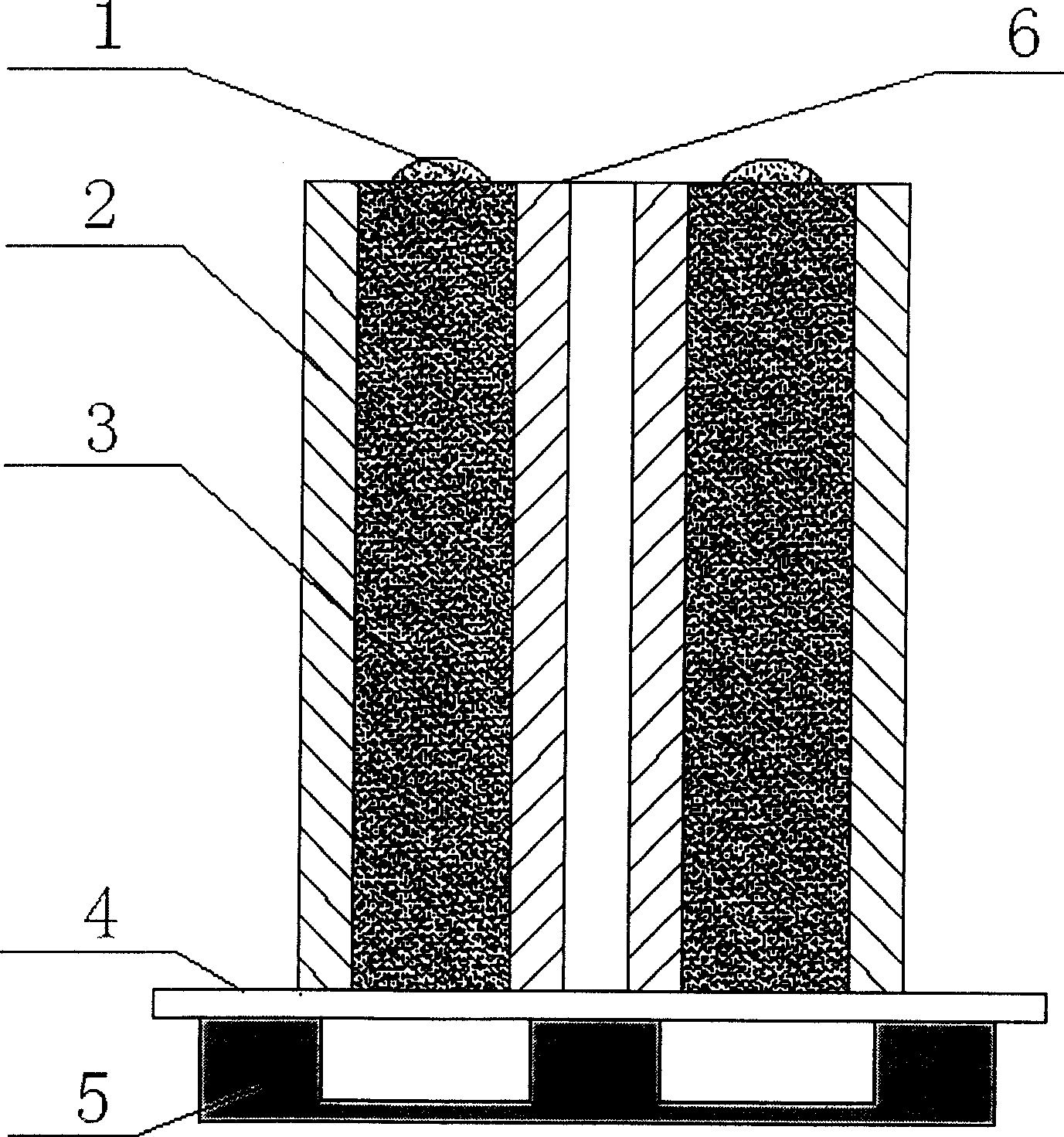

[0064] The substrate is a square steel pipe of 30×30×1.5mm, and the length is 200mm.

[0065] The particle size of Al powder is 200±20 mesh, Fe 2 o 3 Particle size 150-250 mesh, SiO 2 Particle size 200±20 mesh, packing density 1.5~2.0g / cm 3 , the ratio of powder weight to matrix is 3.0~5.5g / cm 3 , the ratio of reagents is Al:Fe 2 o 3 SiO 2 =24.2%:71.8%:4%.

[0066] React at room temperature and cool naturally to produce ceramics with uniform thickness, smooth surface, and a thickness of about 1.5-2.5 mm. The average hardness value is 1200-1400 (HV0.2), and the highest can reach 1415 (HV0.2). The combination of ceramic and metal matrix is firm and not easy to fall off.

Embodiment 2

[0068] The substrate is a square steel pipe of 30×30×1.5mm, and the length is 200mm.

[0069] The particle size of Al powder is 100-200 mesh, Fe 2 o 3 Particle size 100-200 mesh, SiO 2 Particle size 100-200 mesh, CrO 3 Powder particle size 100-200 mesh, filler density 1.5-2.0g / cm 3 , the ratio of powder weight to matrix is 3.0~5.5g / cm 3 , the ratio of reagents is Al:Fe 2 o 3 : SiO 2 :CrO 3 =26%:68%:4%:2%.

[0070] React at room temperature and cool naturally to produce ceramics with uniform thickness, smooth surface, and a thickness of about 1.5-2.5 mm. The average hardness value is 1200-1400 (HV0.2), and the highest can reach 1415 (HV0.2). The combination of ceramic and metal matrix is firm and not easy to fall off.

Embodiment 3

[0072] The substrate is 60×60×4mm square steel pipe, the length is 100mm, and the material is Q235.

[0073] The particle size of Al powder is 100-200 mesh, Fe 2 o 3 Particle size 100-200 mesh, SiO 2 Particle size 100-200 mesh, filler density 1.4-1.8g / cm 3 , the ratio of powder weight to matrix is 3.0~5.5g / cm 3 , the ratio of reagents is Al:Fe 2 o 3 :SiO2 2 =30%:66%:4%.

[0074] In the experiment of preparing a large cross-section ceramic composite square tube, in order to improve the density of the ceramic layer, SiO was added to the thermite 2 , due to its dual effect on coating quality, we determined a reasonable SiO 2 The amount added is 4%. The core is a Φ30mm round steel pipe, reacting at room temperature and cooling naturally. A ceramic composite square tube sample with smooth surface and uniform coating thickness is prepared, which can be used directly; it can also be cut into ceramic composite steel plate, which is a new and effective method for preparing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com