Hot runner injection nozzle tip structure

A technology of hot runner and nozzle body, which is applied in the field of hot runner injection nozzle tip structure, which can solve the problems of easy wear and tear, and achieve the effects of high corrosion resistance, high wear resistance, good production effect and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

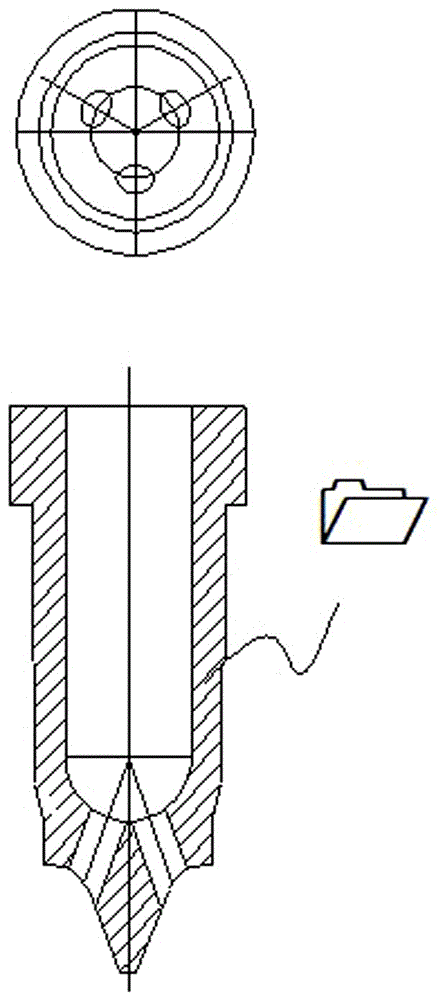

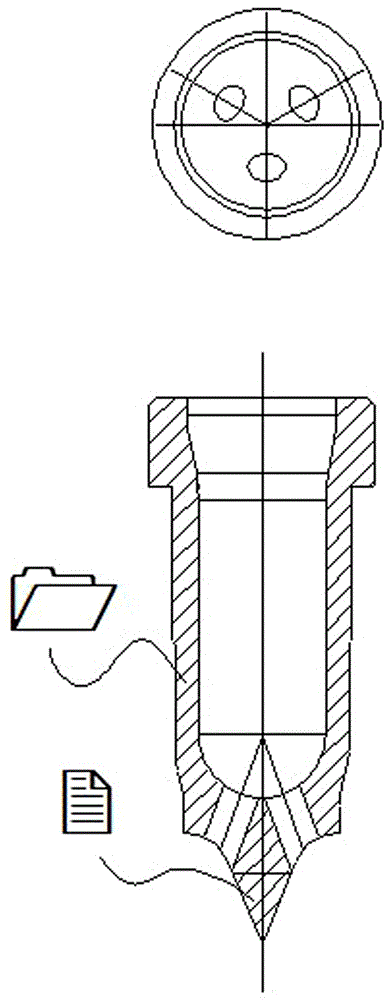

[0010] See attached figure 2 , a tip structure of a hot runner injection nozzle, comprising an injection nozzle body 1 and a nozzle tip 2, and the nozzle tip 2 and the injection nozzle body 1 are solidly connected as one.

[0011] The tip 2 is 3D printed.

[0012] The tip 2 is composite ceramics.

[0013] When using the present invention, since the nozzle tip 2 of high wear-resistant and corrosion-resistant material is printed and attached to the injection nozzle body 1 made of beryllium copper through 3D printing technology, the nozzle tip 2 of this material has high wear resistance and high corrosion resistance. And good thermal conductivity, resulting in good production effect and economic benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com