Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Reduce brazing temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

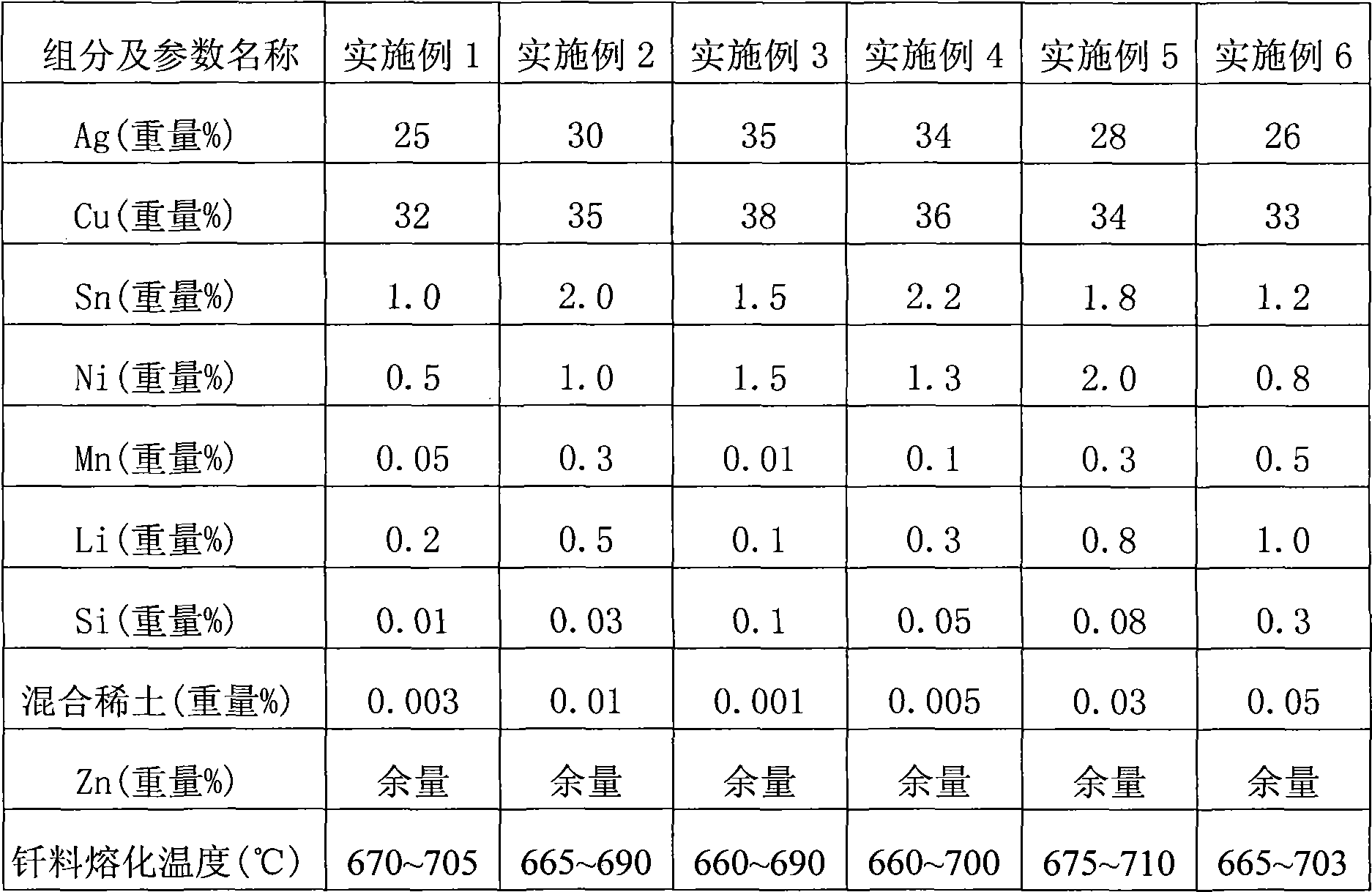

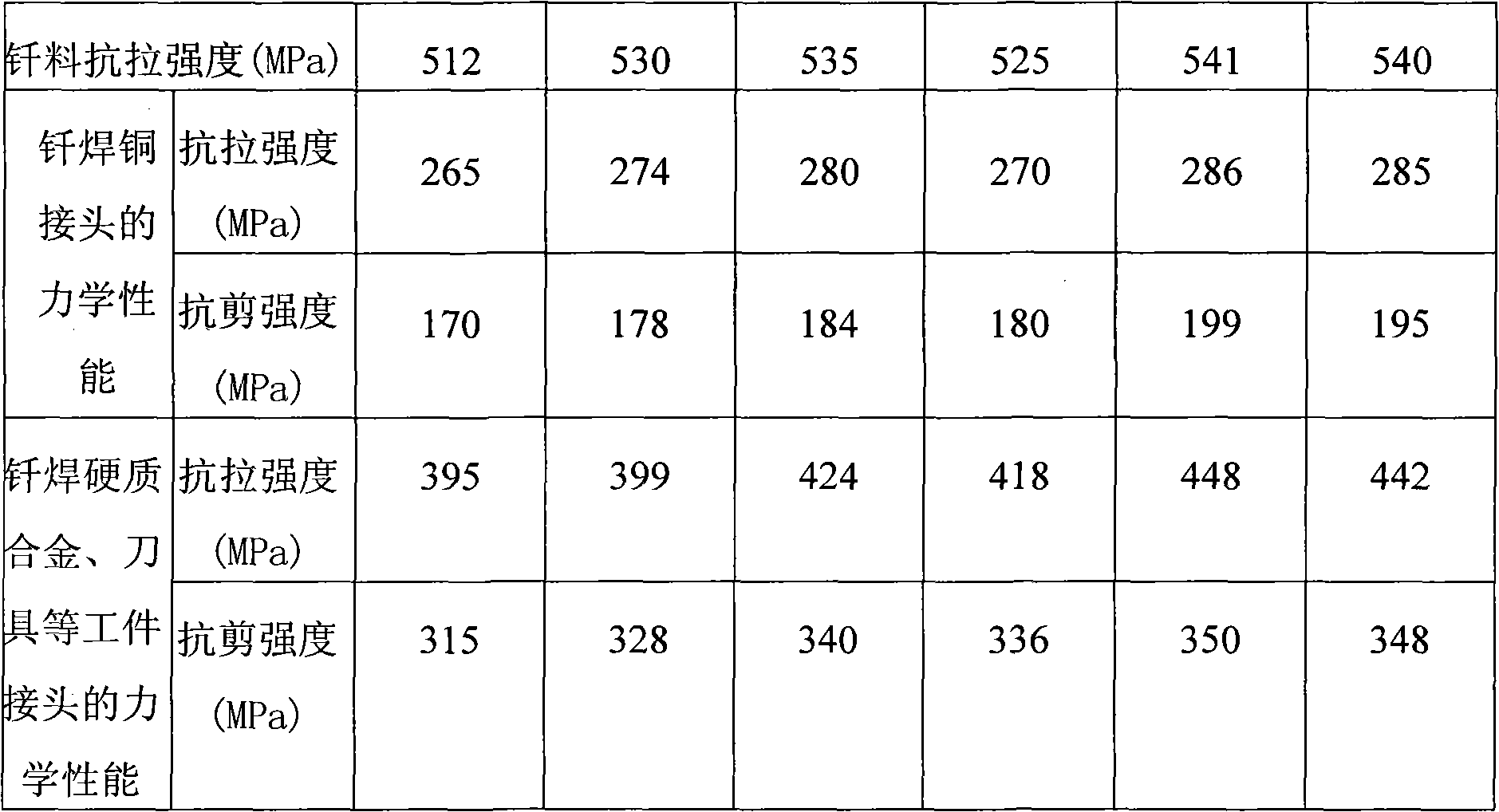

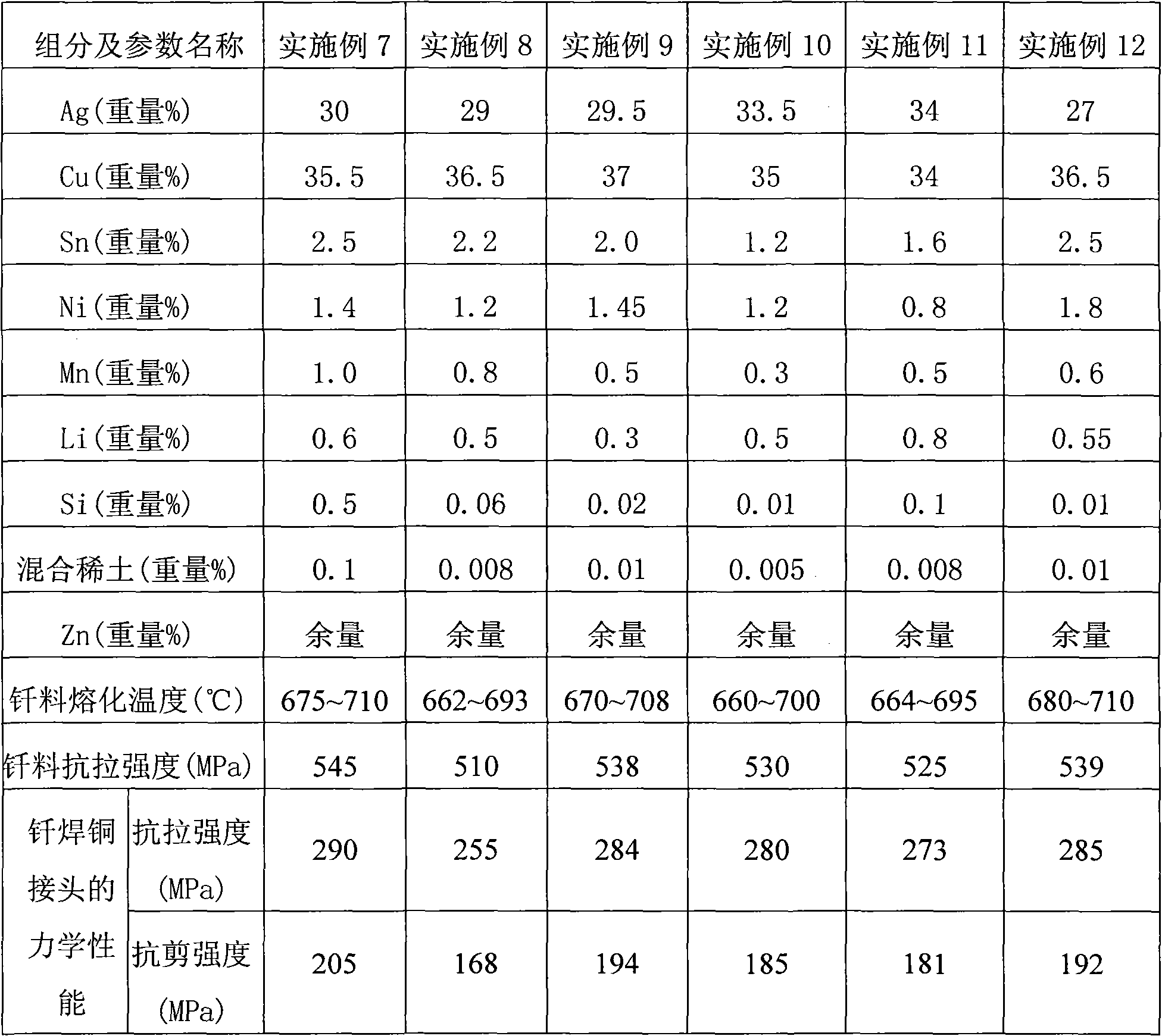

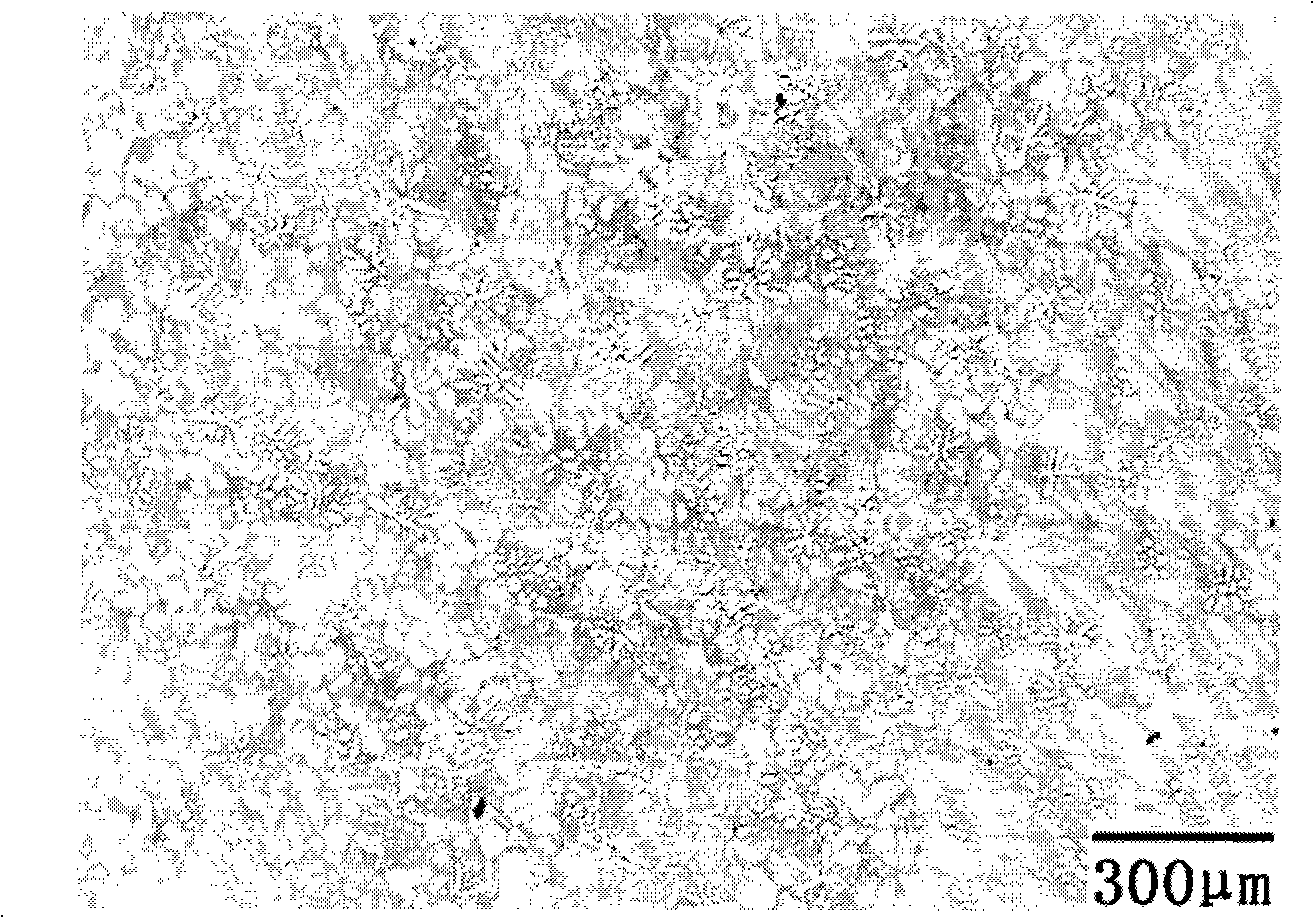

Special rare earth alloy silver-brazing filler metal

ActiveCN101780613AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaCeriumLanthanum

The invention relates to a special rare earth alloy silver-brazing filler metal applied to the brazing of the metal workpieces such as copper and copper alloy, cemented carbide, carbon steel, stainless steel, nickel-based alloy and the like, and belongs to a moderate temperature brazing material. At present, no silver-brazing filler metal has excellent performance and low price, so that the development of the brazing field is obstructed. The special rare earth alloy silver-brazing filler metal comprises the following components in percentage by weight: 25 to 35 percent of Ag, 32 to 38 percent of Cu, 1 to 2.5 percent of Sn, 0.5 to 2.0 percent of Ni, 0.01 to 1 percent of Mn, 0.1 to 1.0 percent of Li, 0.01 to 0.5 percent of Si, 0.001 to 0.1 percent of mixed rare earth, and the balance of Zn, wherein the mixed rare earth consists of lanthanum and cerium. The special rare earth alloy silver-brazing filler metal has the advantages of high cost performance, low fusion temperature of brazing filler metals, good wettability and fluidity, high mechanical strength of soldered joint, and good soldering technological property.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

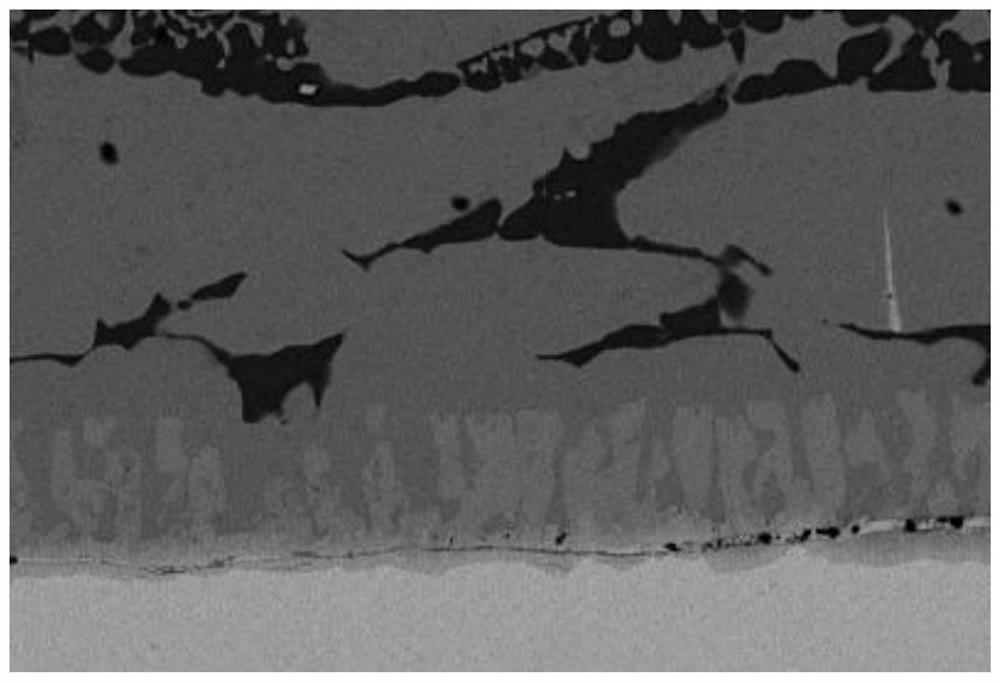

Vacuum brazing connection technology for tungsten copper composite block

ActiveCN103658904AImprove wettabilityImprove bindingWelding/cutting media/materialsWelding/soldering/cutting articlesButt jointTungsten

The invention belongs to the technical field of heterogeneous material welding, and particularly relates to a method for vacuum brazing connection of tungsten and copper. The method is applied to connection of a tungsten copper composite block of a high-heating-load component of a fusion device. The method comprises the following steps that (1) brazing connection materials and brazing filter metal are determined; (2) a welding surface is preprocessed, a tungsten block and a chromium-zirconium-copper alloy block are cleaned, impurities, oil contamination and an oxidation film of the welding surface are removed, and dewatering and drying are conducted; (3) the ribbon copper-based brazing filter metal is cleaned; (4) assembly is conducted, connection is conducted in a butt-joint mode, the copper-based brazing filter metal is placed between the preprocessed surface to be welded of the tungsten and the preprocessed surface to be welded of copper alloy, assembly is conducted through a clamp and the pressure of 0.01MPa-0.1MPa is perpendicularly exerted; (5) welding is conducted, the assembled tungsten block-ribbon copper-based brazing filter metal-chromium copper alloy welding piece is placed in a vacuum brazing device for welding. According to the technical scheme, the obtained pure tungsten and the chromium-zirconium-copper alloy are welded in a butt joint mode, welding-seam forming is good, deformation of the welding piece is avoided, and shortages of microscopic cracks, air holes and impurities and the like are avoided.

Owner:SOUTHWESTERN INST OF PHYSICS

Magnesium alloy middle temperature brazing material

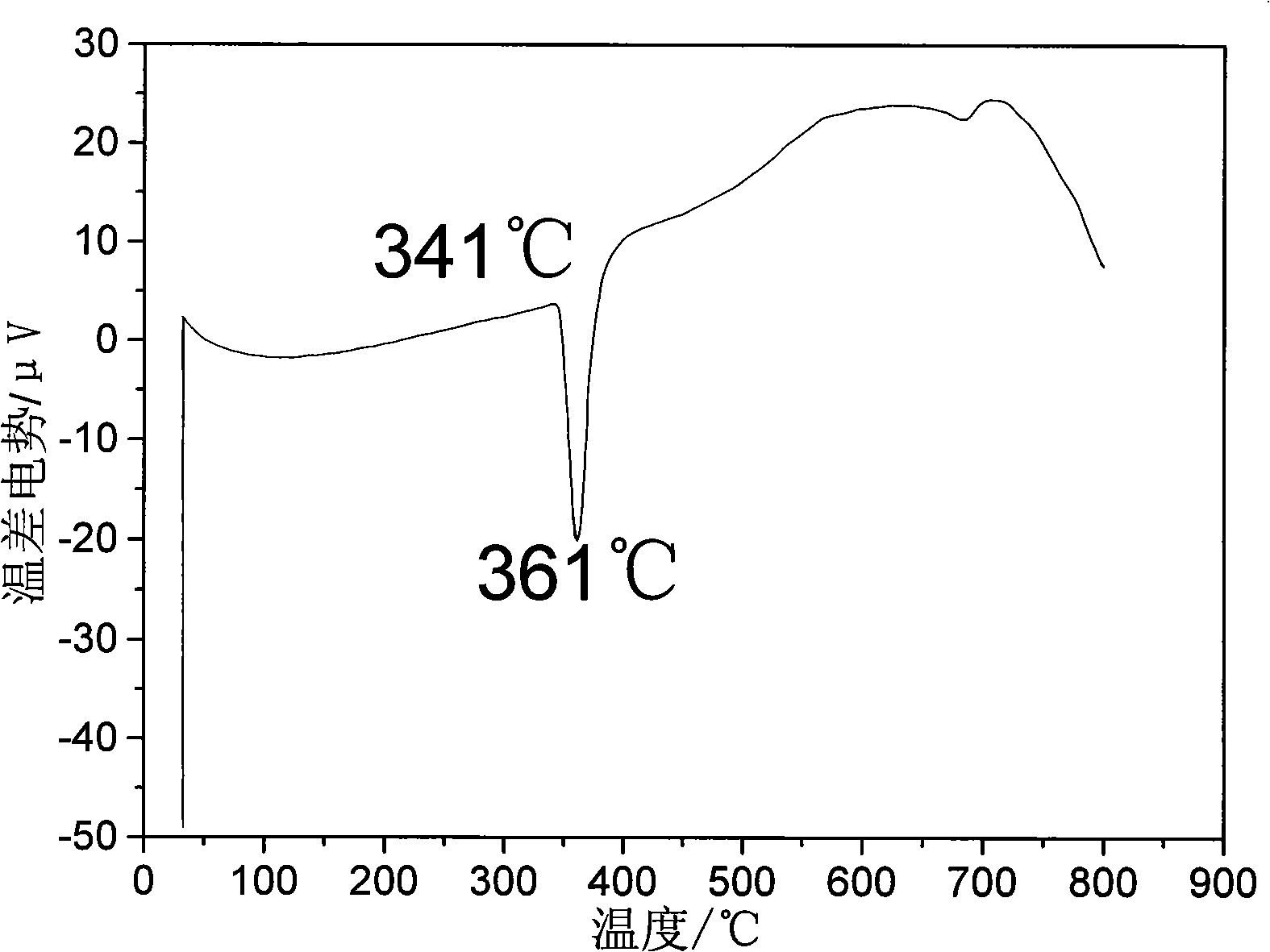

InactiveCN101323060AReduce brazing temperatureGood spreadabilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthMelting temperature

The invention relates to a magnesium alloy mid-temperature solder, belonging to the technical field of magnesium alloy welding. Most of the existing magnesium alloy solders have poor manufacturability, poor joint properties and other technical problems. The weigh percentage range of the components of the magnesium alloy mid-temperature solder of the invention is that: 1-2.5 percent of Al, 46-52 percent of Zn and the rest of Mg. The solder is smelted by a flux protection method; by using mechanical division, precision casting and a gas shielded ball milling method, the solders can be acquired in the forms of block, strip, powder and other forms. The melting temperature range of the solder is 336-361 DEG C; brazing temperature is low, which is 380-400 DEG C, and is suitable for magnesium alloy brazing having a solidus temperature over 400 DEG C. The solder of the invention has the advantages that brazing characteristics are good, and under the brazing temperature, spreading property and gap filling property are good; proper brazing methods include protective atmosphere brazing, induction brazing, furnace brazing and the like; the joint shear strength of brazing AZ31B magnesium alloy of the solder is more than 52 MPa, and the joint tensile strength is more than 72 MPa.

Owner:BEIJING UNIV OF TECH

Low silver copper base medium temperature brazing filler metal

ActiveCN101524798AConserve limited resourcesReduce use costWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention relates to a low silver copper base medium temperature brazing filler metal applicable to braze welding of workpieces such as copper and copper alloy, copper and steel, belonging to the field of medium temperature brazing material. The formula and content of the low silver copper base medium temperature brazing filler by weight percentage is as follows: Ag: 1.8-5%, P: 5.5-7.5%, In: 0.5-2.5%, Ni: 0.01-1%, the rest: Cu. The invention has the advantages of rational design of formula, low manufacture cost, relatively low melting temperature of the brazing filler metal when welding copper and copper alloy and copper and bundy tubes, good wetting property and fluidness, smooth and bright surface of soldered connection, high mechanical strength, fine processing property of braze welding, stable quality and good uniformity and capability of replacing noble metal silver brazing filler metal BAg25CuZnSn.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Brass brazing alloy

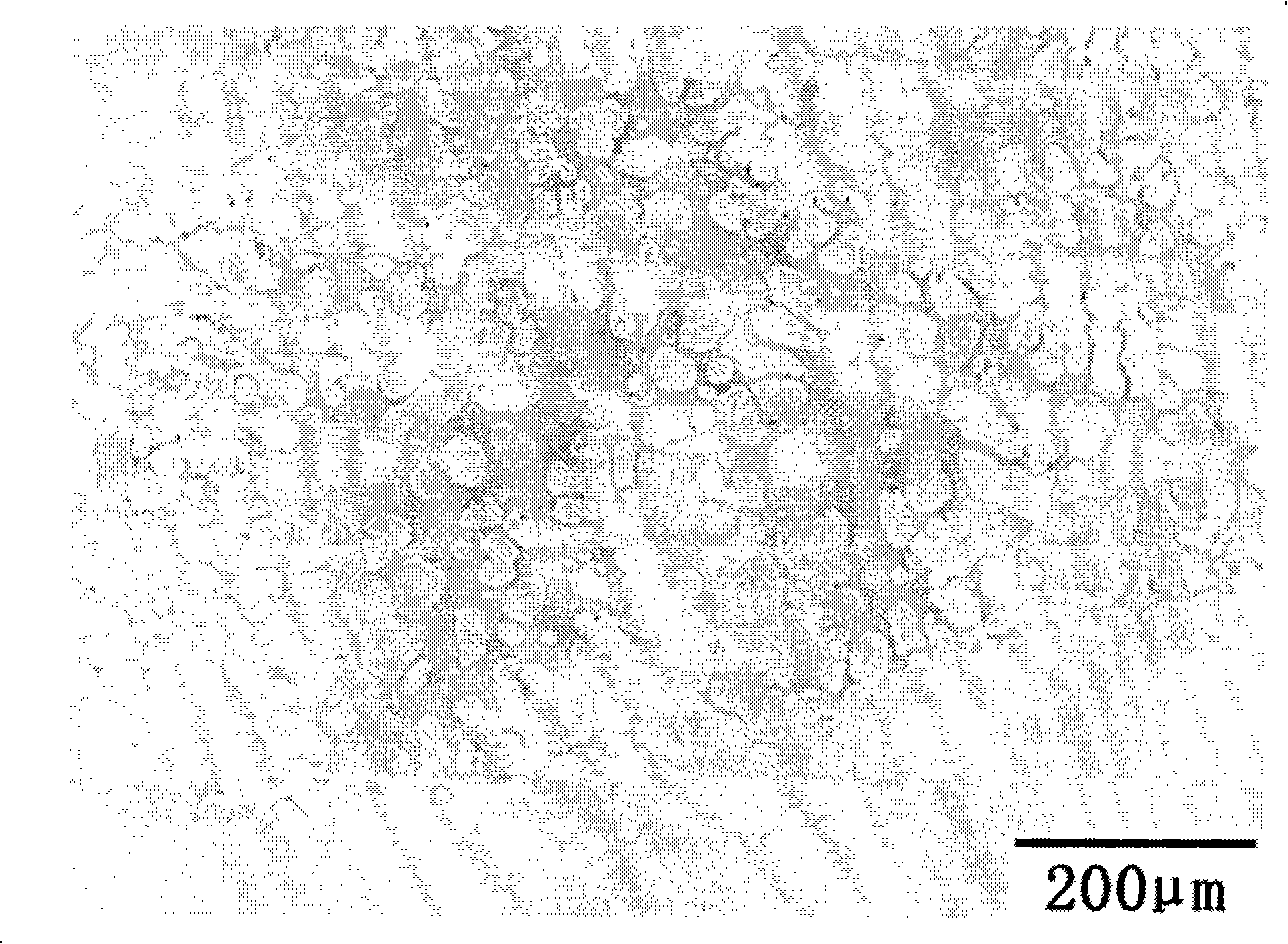

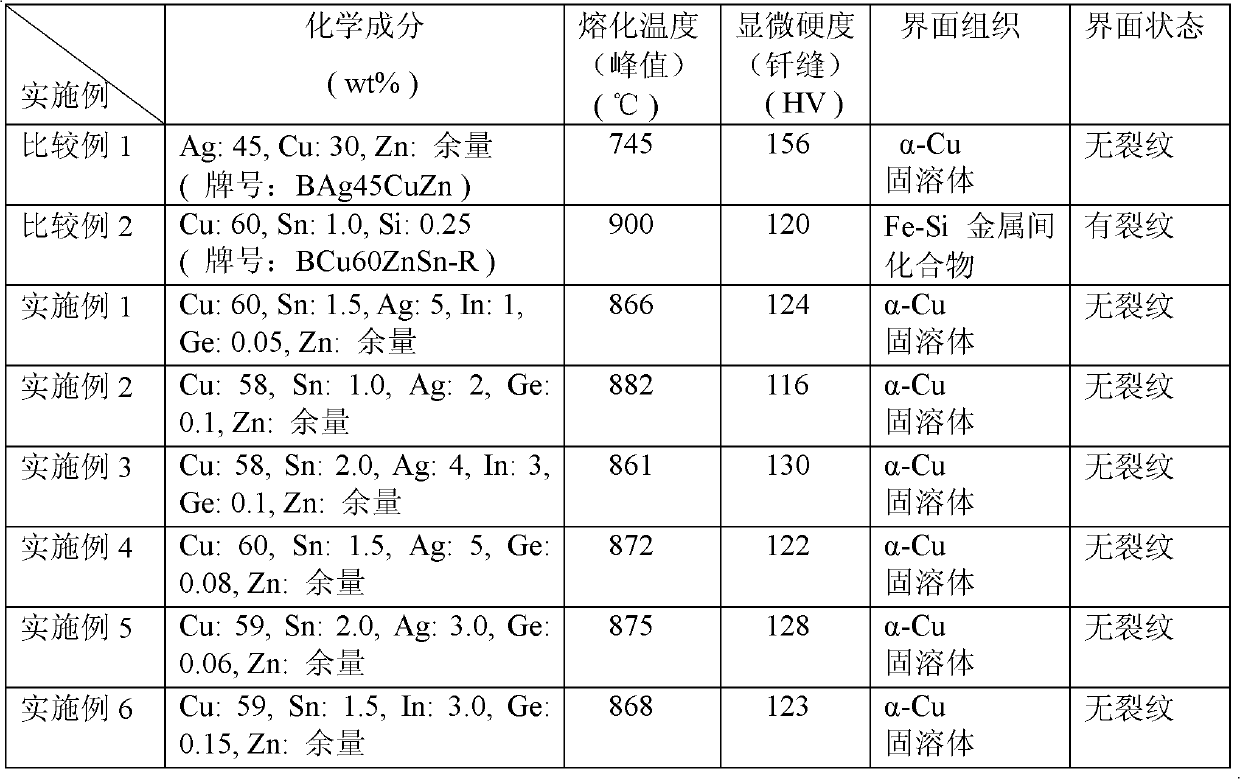

InactiveCN102601542AImprove reliabilityLow Ag contentWelding/cutting media/materialsSoldering mediaBraze alloyMelt temperature

The invention discloses brass brazing alloy, which comprises Cu, Zn, Sn, Ge, Ag and / or In. The brass brazing alloy consists of components including, by mass percentage, from 58 to 60% of Cu, from 0.5 to 3.0% of Sn, from 1.0 to 6.0% of Ag and / or from 1.0 to 5.0% of In, from 0.05 to 0.3% of Ge and the balance Zn. Compared with an existing brass brazing material, the brass brazing alloy has the advantages that melting temperature is low, the brass brazing alloy can replace a silver brazing material to be used for brazing steel / copper joints, and cost is low due to the fact that Ag content of the brass brazing alloy is low.

Owner:SOUTH CHINA UNIV OF TECH

Low-melting-point and high-intensity aluminum alloy powder brazing filler metal and preparing method of low-melting-point and high-intensity aluminum alloy powder brazing filler metal

ActiveCN104227263APrevent corrosionImprove performanceWelding/cutting media/materialsSoldering mediaSiluminSolidus

The invention discloses a high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C and a preparing method of the high-intensity aluminum alloy powder brazing filler metal with the melting point being lower than 490 DEG C, and belongs to the technical field of aluminum alloy brazing. The brazing filler metal comprises the following ingredients in parts by weight: 8.6 to 9.5 percent of Si, 16.5 to 17.5 percent of Cu, 8.5 to 9.5 percent of Ge, 4.5 to 5.0 percent of Ni, 4.0 to 5.0 percent of Zn, 0.70 to 0.75 percent of Sr, 0.35 to 0.40 percent of Bi, 0.40 to 0.45 percent of La, 0.40 to 0.55 percent of Ce, 0.10 to 0.20 percent of Yb and the balance Al. The brazing filler metal is prepared by adopting a flux rapid cooling-ball milling technology, the melting point is lower than 490 DEG C, the brazing temperature is 500 to 520 DEG C, and the brazing filler metal is applicable to aluminum alloy brazing with the solid phase line temperature higher than 500 DEG C, such as in-furnace brazing, vacuum brazing, induction brazing and flame brazing. The brazing filler metal is matched with QJ201 for brazing 3003 aluminum alloy, and the shearing intensity of a brazing joint is greater than 74MPa.

Owner:ZHEJIANG UNIV

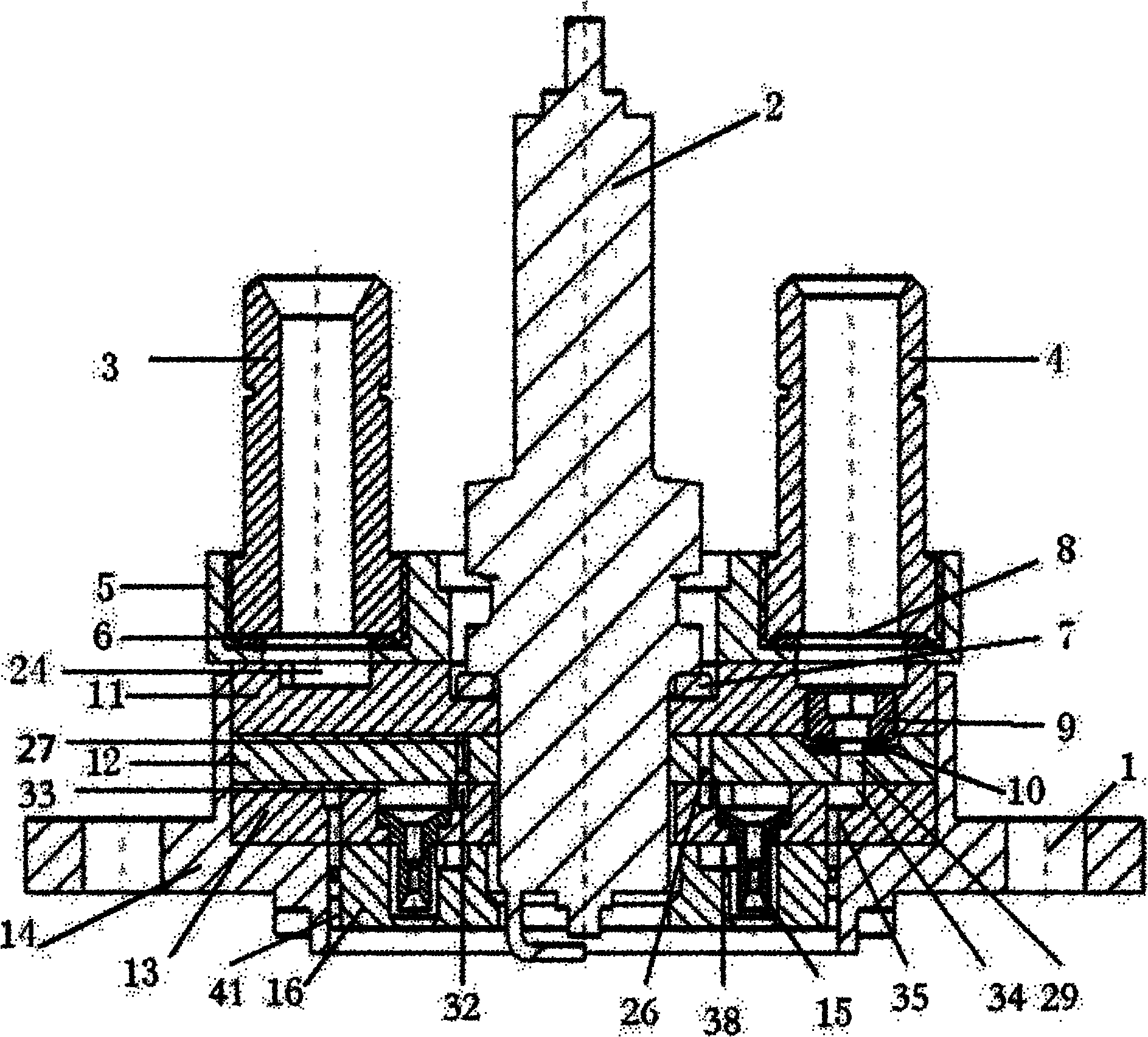

Soldering preparation method for stainless steel laminate type inspirator

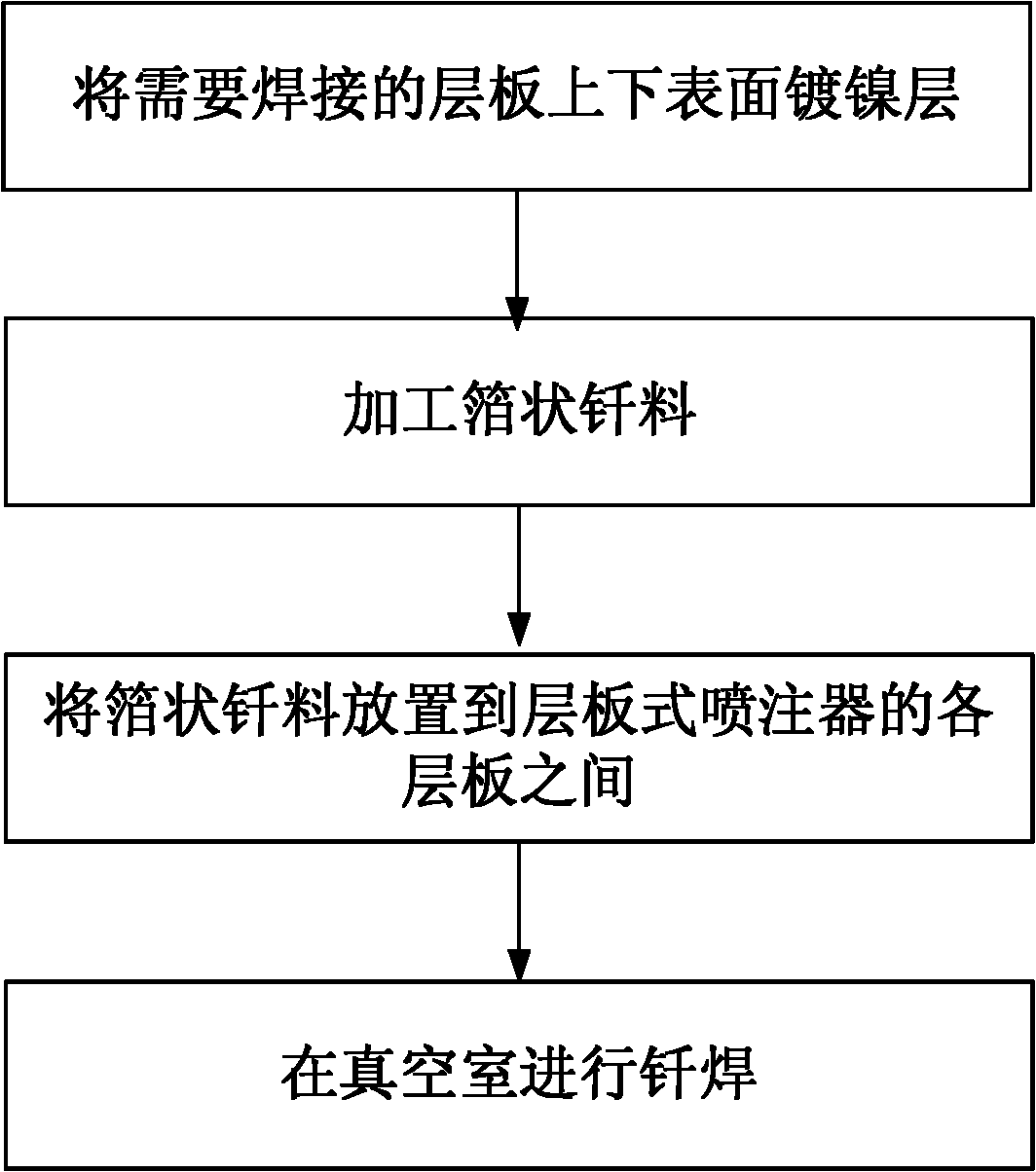

InactiveCN102179586AReduce brazing temperatureRelieve pressureWelding/cutting media/materialsSoldering mediaInspiratorFiller metal

The invention provides a soldering preparation method for a stainless steel laminate type inspirator. The method comprises the following steps of: 1, plating nickel layers on the upper and lower surfaces of each laminate required to be soldered of a laminate type inspirator to be soldered; 2, machining a foil-shaped brazing filler metal according to the shapes of two adjacent layers in the laminate type inspirator; 3, placing the foil-shaped brazing filler metal between laminate parts of the laminate type inspirator; and 4, placing the laminate type inspirator into a vacuum chamber, heating and pressurizing to perform soldering. By the method, the technical problem of plastic deformation of a hole and a circulation channel between the surfaces of laminates due to overhigh temperatures andpressure in the soldering preparation process in the prior art is successfully solved by controlling the thickness and the process parameters of the brazing filler metal. In the invention, a stainless steel laminate is well dampened by the brazing filler metal, so that the probability of soldering quality problems caused by non-uniform pressure existing in the diffusion soldering process can be reduced.

Owner:BEIHANG UNIV

Medium-temperature aluminum-based foil strap brazing material and preparation method thereof

InactiveCN103008909AGood brazing processSimple preparation processWelding/cutting media/materialsSoldering mediaTorchShear strength

The invention discloses a medium-temperature aluminum-based foil strap brazing material and a preparation method thereof. The brazing material comprises the following components by mass percentage: 6.5-9.6 of Si, 16.0-20.0 of Cu, 8.0-10.0 of Ge, 2.0-6.0 of Zn, 0.5-1.0 of La and the balance of Al. The brazing material is prepared by rapid cooling of a melt, the melting point is lower than 495 DEG C, a foil strap is suitable for brazing of aluminum alloy with the solidus temperature higher than 520 DEG C, torch brazing, induction brazing, furnace brazing, gas protection brazing and the like can be performed, the brazing temperature is 510-520 DEG C, and the brazing material can be applied in brazing of precision components made of aluminum alloy. When the brazing material is used with 5083 aluminum alloy for QJ201 brazing, the shear strength of a brazed joint is higher than 80MPa.

Owner:ZHEJIANG UNIV +1

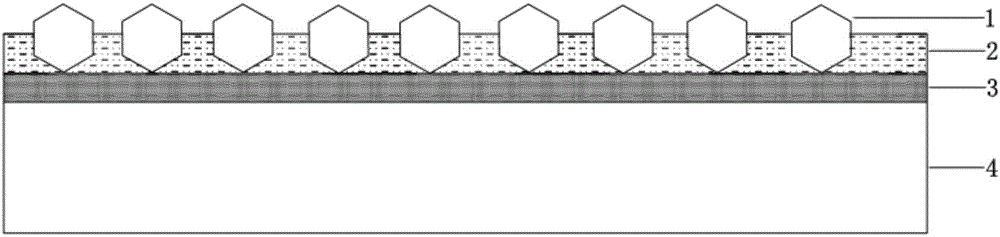

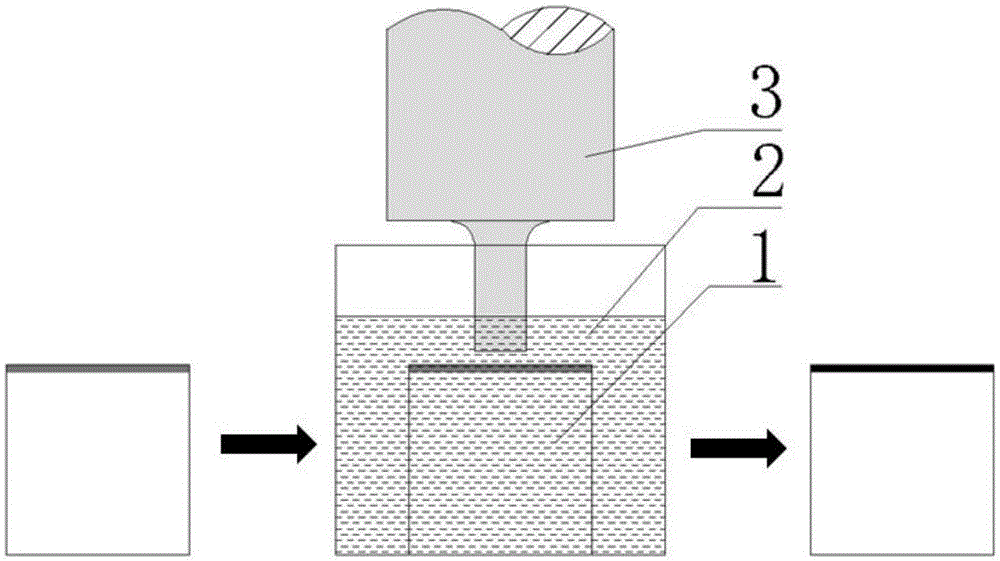

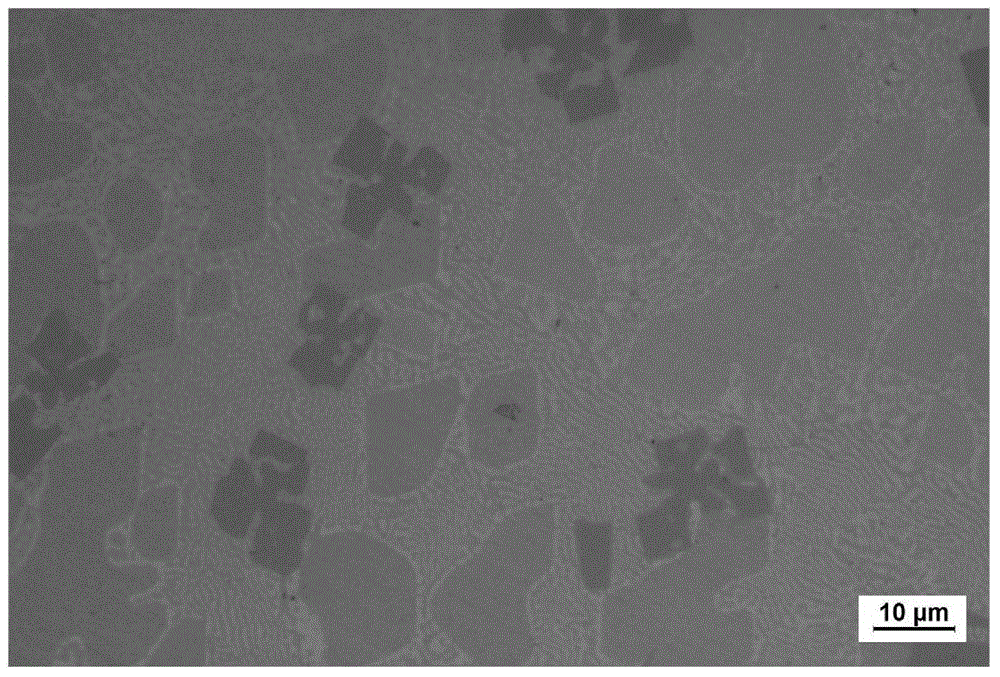

Brazed superhard abrasive tool and preparation method thereof

ActiveCN106737244AReduce heat damageReduce bond strengthBonded abrasive wheelsGrinding devicesSuperhard materialCopper

The invention belongs to the technical field of superhard material products, and particularly relates to a brazed superhard abrasive tool and a preparation method thereof. The brazed superhard abrasive tool comprises a substrate and a brazing filler metal layer arranged on the substrate. The brazing filler metal layer comprises a nickel-based brazing filler metal layer close to the substrate, and a copper-based brazing filler metal layer arranged on the surface of the nickel-based brazing filler metal layer. Superhard abrasive grains are embedded in the copper-based brazing filler metal layer. The thickness of the copper-based brazing filler metal layer is smaller than the grain size of the superhard abrasive grains. According to the brazed superhard abrasive tool, the substrate, nickel-based brazing filler metal, copper-based brazing filler metal and superhard abrasive composite structure is formed, the bonding strength between the substrate, the brazing filler metal and the superhard abrasive is improved, and meanwhile the brazing temperature is low, so that thermal damage to the superhard abrasive during brazing is reduced.

Owner:FUNIK ULTRAHARD MATERIAL

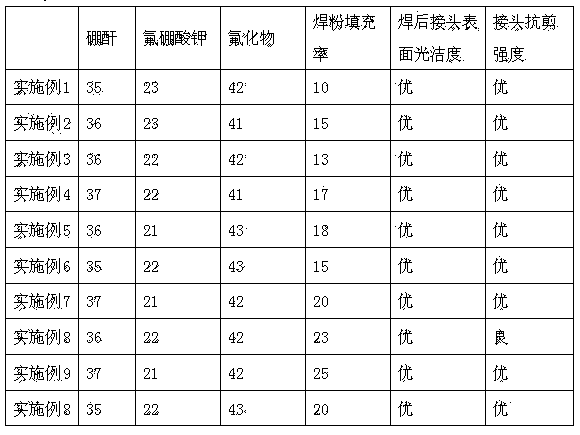

Preparation method for flux-cored electrode

InactiveCN104384744AAdd lessThe amount of addition is difficult to controlWelding/cutting media/materialsSoldering mediaConveyor belt% diameter reduction

The invention relates to a preparation method for a flux-cored electrode. The method comprises the following steps of preparing a strip with a thickness of 0.1 to 0.5mm from silver solder containing 20 to 45 percent of silver, annealing and cleaning the strip, bending and deforming the strip to form a U-shaped strip with an upward opening by virtue of a roller, vibrating the silver solder to a conveyor belt from a funnel, conveying the silver solder to the U-shaped strip by virtue of the conveyor belt, rolling the U-shaped strip to form a flux-cored wire of an overlapped tubular structure by virtue of the roller, cleaning the surface of the flux-cored wire by virtue of a brush wheel and a brush, performing diameter reduction treatment, straightening the flux-cored wire in a low-temperature resistance heating or cold machining way, and cutting and forming the flux-cored wire, wherein the silver solder is placed in the transparent funnel, and is sufficient; the overlapped part of the flux-cored wire is 0.1 to 2mm wide. The method is simple and reasonable; a conventional soldering process is simplified, the quality of a soldered joint is improved, and the using cost of the solder is effectively lowered by over 30 percent.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

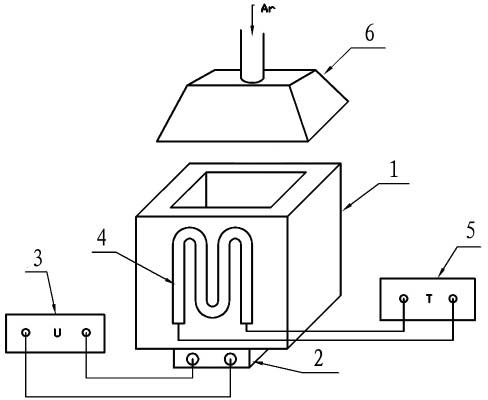

Copper-zinc-nickel-cobalt-indium alloy and preparation method thereof

The invention relates to a copper-zinc-nickel-cobalt-indium alloy and a preparation method thereof. The alloy comprises the following raw materials by weight percent: 43-65% of Cu, 28-45% of Zn, 1-15%of Ni, 0.3-4% of Co, 0.1-2% of In, 0.08-4% of Mn, 0.05-0.3% of Si, 0-2% of Sn, 0-2% of Ag and 0.03-0.07% of Re containing Ce and La in a weight ratio of 2:3. The preparation method comprises the following steps: smelting high melting point metals -- Ni, Co, and Cu to obtain an intermediate alloy A, smelting deoxidizing elements -- Si, Mn and Cu to obtain an intermediate alloy B, smelting oxidablemetals -- Ce, La and Cu in a vacuum furnace to obtain an intermediate alloy C, melting Cu in a medium frequency furnace, adding the intermediate alloy A in the medium frequency furnace to fully fuse,covering the obtained product with a mixture of cullet and cryolite, fully fusing, adding the intermediate alloy B, then adding metal Ag, Zn, Sn and In, adding the intermediate alloy C to perform full deoxidation and fusion, standing for 50min and performing continuous casting to form copper-zinc-nickel-cobalt-indium alloy ingots.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Zn-Al-Cu-based solder for aluminum/copper brazing and preparing method thereof

InactiveCN103317253AImprove machinabilityImprove corrosion resistanceWelding/cutting media/materialsSoldering mediaRare earthCerium

The invention relates to a Zn-Al-Cu-based solder for aluminum / copper brazing and a preparing method thereof. The Zn-Al-Cu-based solder can be used for furnace brazing and flame brazing of aluminum / copper dissimilar metals. The Zn-Al-Cu-based solder, by mass percent, contains 5-16% of aluminum, 3.5-12% of copper, 0.5-5% of germanium, 0.01-0.1% of titanium, 0.01-0.2% of strontium, 0.01-0.1% of rare earth lanthanum or cerium, and the balance zinc. The melting point of the solder is 370-410 DEG C. The solder can be formed by smelting simple substances of Al (99.995%), Cu (99.99%), Zn (99.99%), Ge (99.99%) and intermediate alloy Al-10Ti, Al-10Sr, Al-10La or Al-10Ce under protection of covering agents. Al / Cu joints brazed through the Zn-Al-Cu-based solder have high strength and good corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING +1

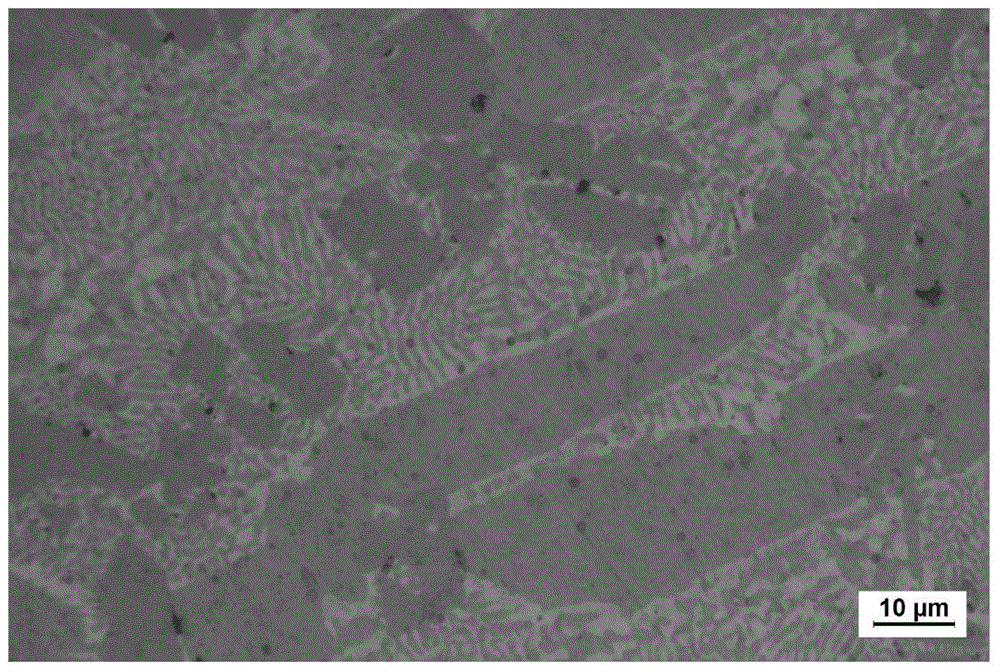

Method for preparing Ag-Cu/W nanometer multilayer film solder for brazing stainless steel

ActiveCN106271214AImprove practicalityThe biggest advantage lies in the practicality and low brazing temperatureVacuum evaporation coatingSputtering coatingTotal thicknessSilver copper

The invention relates to a method for preparing Ag-Cu / W nanometer multilayer film solder for brazing stainless steel. The multilayer film solder contains 16.7 percent to 37.5 percent of silver, 12.5 percent to 33.3 percent of copper and 50 percent of tungsten. A silver-copper layer and a tungsten layer are alternately sputtered by utilization of a magnetron sputtering method. The silver-copper layer is sputtered by simultaneously sputtering a silver target and a copper target, and a tungsten target is used for independently sputtering. The thickness of each silver-copper layer is 8 nm to 14 nm, and the thickness of each W layer is smaller than 10 nm. The atom proportion of Ag to Cu in each silver-copper layer is (0.5 to 1) to (3 to 1). Alternating deposition is performed for 200 to 400 periods, so that the total thickness of a final film is 4 microns to 8 microns. The method provided by the invention has the advantages that the solder uniformity can be guaranteed; moreover, the solder thickness can be easily controlled through a sputtering period; the melting point of a nanometer particle is dramatically decreased by utilization of a melting point decreasing effect of the nanometer particle; during a brazing process, a reactive layer and a matrix can be formed into an eutectic structure with a low melting point or a hypo-eutectic structure with a low melting point, so that the brazing temperature is effectively lowered.

Owner:BEIJING UNIV OF TECH

Spelter solder

InactiveCN106695164ALow melting pointTroubleshoot microcracksWelding/cutting media/materialsSoldering mediaSpelterManganese

The invention provides spelter solder. The spelter solder comprises, by weight percent, the flowing raw materials: 52%-58% of copper, 0.5%-1.1% of tin, 0.3%-1.2% of bismuth, 0.05%-0.15% of silicon, 0.03%-0.09% of manganese, 0.02%-0.06% of germanium and the balance zinc. The spelter solder can reduce the melting point of traditional spelter solder and solves the problem of microcracks caused by addition of Si.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

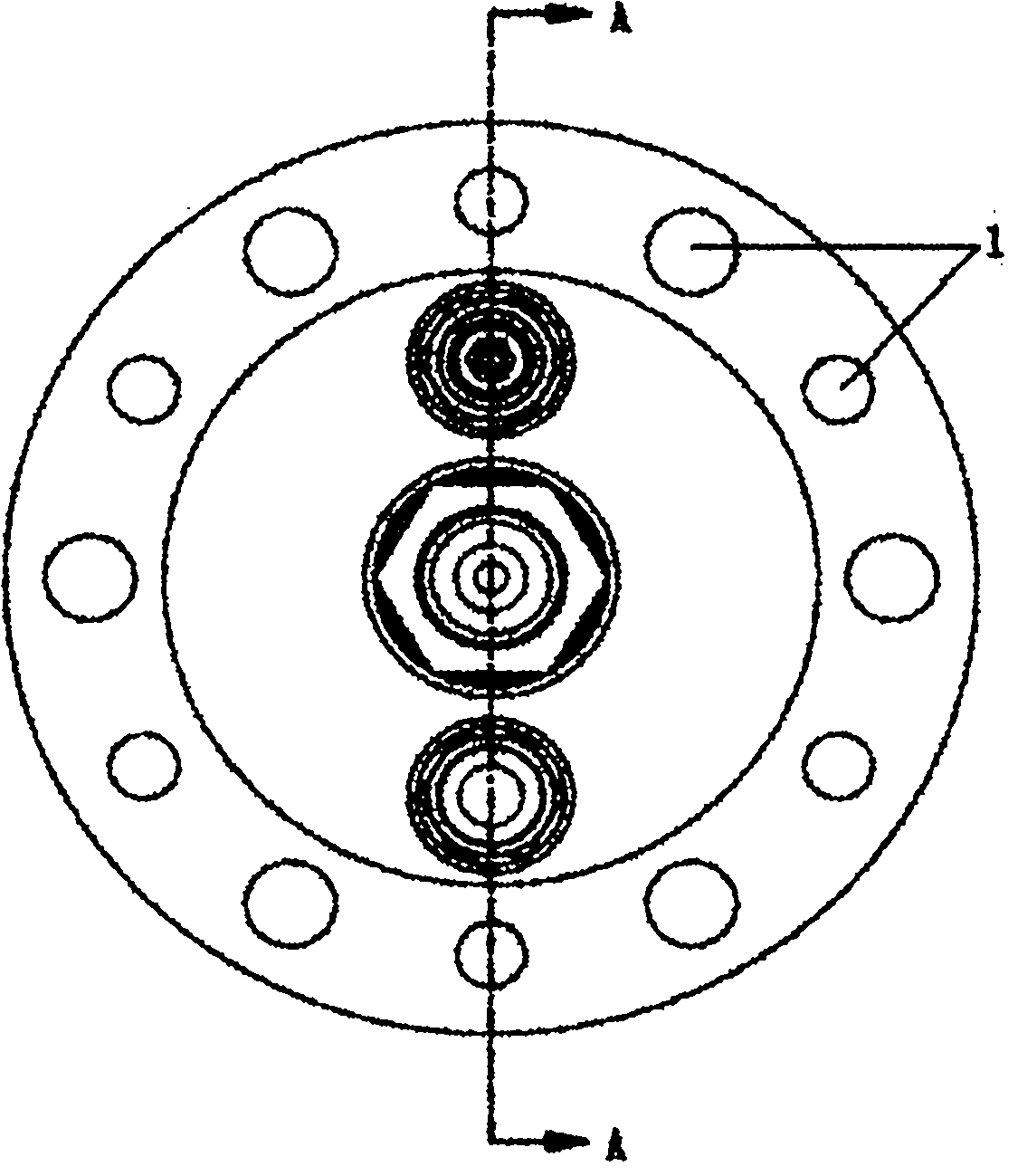

Copper/aluminum ultrasonic liquid-phase diffusion brazing process and brazing device

InactiveCN102513635ASimple structureIngenious designMetal working apparatusSoldering auxillary devicesMolten stateMetallurgy

The invention discloses a copper / aluminum ultrasonic liquid-phase diffusion brazing process and a brazing device. The brazing process adopts the technical scheme that the copper / aluminum ultrasonic liquid-phase diffusion brazing process adopts Sn-9Zn eutectic alloy brazing filler metal, and does not adopt brazing flux; the brazing temperature is low; and the requirements on the surface and the structure of a copper / aluminum brazing connector are not high. The brazing process has the beneficial effects that the brazing process is accomplished in brazing filler metal at a molten state, and the problem of heat preservation of the brazing filler metal during the brazing is eliminated; the controllability of brazing technological parameters is high, the operation process is simple, and the efficiency is high; the copper / aluminum connector adopting the brazing process is smooth, and the performances of the copper / aluminum connector are remarkably improved; and the anti-corrosion capability and both the high and low temperature impact resistance of the copper / aluminum brazing connector meet the requirements of national relevant standards.

Owner:SHANDONG JIANZHU UNIV

Low-Ag Cu-based medium-temperature solder

InactiveCN106514041AReduce dosageImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaRare-earth elementCopper

The invention provides low-Ag Cu-based medium-temperature solder. The solder is prepared from raw materials in percentage by weight as follows: 1.2%-2.0% of Ag, 6.5%-7.2% of P, 1%-3% of Ni, 1.5%-4% of Sn, 1.4%-3.6% of NaF, 0.5%-2.4% of mixed rare-earth elements and the balance of Cu; mixed rare-earth comprises components in percentage by weight as follows: 30%-40% of Nd, 20%-30% of Pr and 30%-40% of La. According to the solder, the Ag content is low, the melting temperature of the solder is relatively low, the wettability and the corrosion resistance are good, the surface of a soldered joint is bright and clean, the mechanical strength is high, and the soldering process performance is excellent.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Low-temperature brazing method for ceramics

The invention discloses a low-temperature brazing method for ceramics. The method includes the steps that a to-be-welded surface of ceramic parent metal is plated with an active metal coating; the active metal coating is modified with ultrasonic waves; ultrasonic-assisted brazing is conducted. Particularly, the to-be-welded surface of ceramic parent metal is plated with one active metal coating through a coating technology; then the ceramic parent metal with the active metal coating is soaked in melt Sn, by means of a phonochemistry effect formed by the ultrasonic waves in the melt Sn medium, the bonding performance between the active metal coating and a ceramic matrix is improved, and a layer of Sn metal is attached to the surface of the active metal coating; low-melting-point brazing filler metal combined with the ultrasonic-assisted brazing technology is used for brazing the ceramic matrix coated with the Sn metal surface layer and the active metal middle layer at low temperature, and therefore low-temperature and high-strength connection of the ceramic material is achieved.

Owner:WUHAN UNIV OF TECH

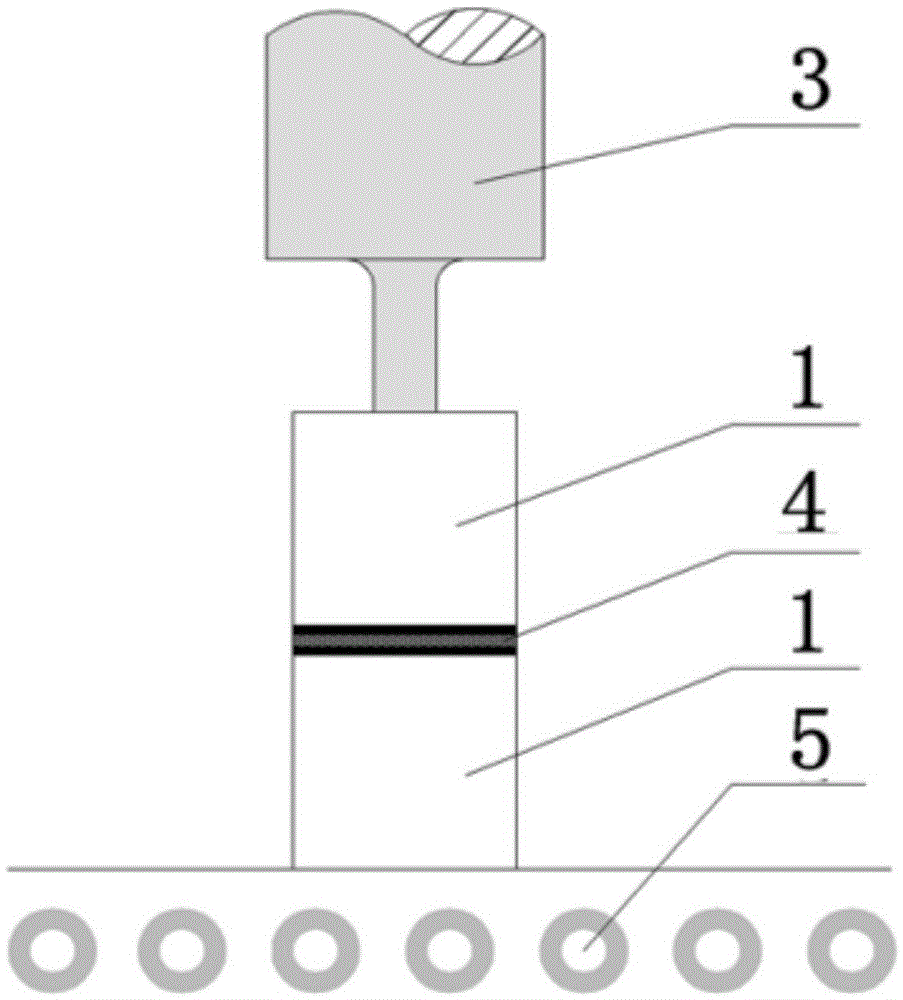

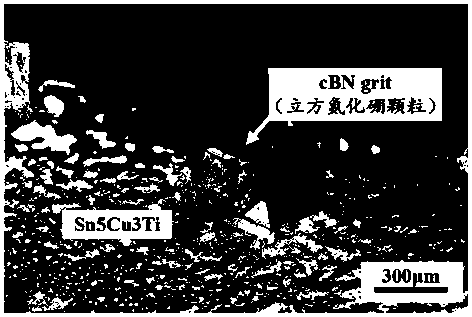

Method for brazing CBN (Cubic Boron Nitride) abrasive particles at low temperature

ActiveCN108655524ASufficient binding strengthReduce residual stressWelding/cutting media/materialsSoldering mediaMetallic materialsBoron nitride

The invention discloses a method for brazing CBN (Cubic Boron Nitride) abrasive particles at a low temperature and belongs to the technical field of superhard abrasive material tool manufacture. The method comprises the following steps: adopting acetone to clean CBN abrasive particles ultrasonically and drying the CBN abrasive particles, sequentially paving and spraying Sn-Cu-Ti alloy powder and CBN abrasive particles on a polished tool substrate; placing the tool substrate in a quartz tube and vacuumizing; then, moving the tool substrate to a heating furnace and heating the tool substrate for5-60 minutes at 350-700 DEG C; and finally, cooling the tool substrate to the room temperature under the vacuumizing state. The method has the following technological advantages: on the premise thatbrazing filler metal and the CBN abrasive particles are ensured to generate chemical bonding and the abrasive particles have sufficient bonding strength, the brazing temperature is greatly reduced toreduce loss of the metal material performance, size and shape of the tool substrate and the residual thermal stress at the bonding interface of the CBN abrasive particles and brazing filler metal is reduced.

Owner:HUAQIAO UNIVERSITY

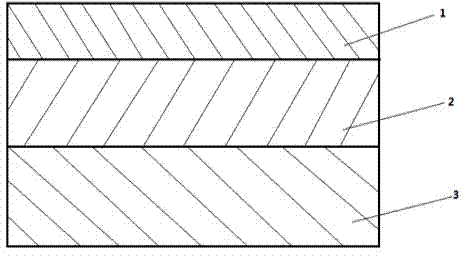

Heat dissipation material for air cooling tubes and preparation method thereof

InactiveCN104745898AReduce brazing temperatureSave energyMetal rolling arrangementsSolderingAir cooling

The invention discloses a heat dissipation material for air cooling tubes, which comprises a substrate, a heat conduction layer and a soldering layer which are sequentially arranged from bottom to top. The soldering layer can greatly lower the soldering temperature of the material during soldering, saves the energy and enhances the economic benefit.

Owner:NANTONG HENGXIU ALUMINUM HEAT TRANSFER MATERIAL

Al-base amorphous/nanocrystalline composite solder and preparing method thereof

ActiveCN104889610AImprove wettabilityIncreased diffusion rateWelding/cutting media/materialsSoldering mediaAluminum matrix compositesSoldering

The invention relates to Al-base amorphous / nanocrystalline composite solder and a preparing method thereof and solves the problems that the existing foiled solder is difficult to wet and high in melting point and the powdered solder is difficult to clamp and poor in uniformity. Atomic percent of Al, Cu and Ti in the al-base amorphous / nanocrystalline composite solder are (70-77):20:(3-10). The preparing method includes: smelting alloy, and performing rapid solidification by means of a single-roller method to obtain foil strips 0.08mm to 0.15mm in thickness. The al-base amorphous / nanocrystalline composite solder is mainly applied to soldering of aluminum alloys and Al-based composites.

Owner:HENAN POLYTECHNIC UNIV +1

Al-Si-Cu-Ni series brazing filler metal for connecting Cu/Al connector and preparation method of Al-Si-Cu-Ni series brazing filler metal

ActiveCN112975203ALow melting pointReduce brittlenessWelding/cutting media/materialsSoldering mediaFiller metalPlastic property

The invention discloses Al-Si-Cu-Ni series brazing filler metal for connecting a Cu / Al connector and a preparation method of the Al-Si-Cu-Ni series brazing filler metal. The Al-Si-Cu-Ni series brazing filler metal for connecting the Cu / Al connector comprises, by weight, 8-12% of silicon, 2-10% of copper, 1-4% of nickel, 0-0.3% of erbium, 0-0.3% of zirconium and the balance aluminum. The preparation method comprises the steps of raw material selection, alloy smelting, stirring and ingot casting. The brazing filler metal provided by the method is good in plasticity and has relatively appropriate brazing temperature, and an obtained copper-aluminum brazed connector is high in strength and good in corrosion resistance; and the brazing temperature of the brazing filler metal is low and is generally about 590 DEG C, the brittleness of the connector is small, the strength is higher, the highest shear strength of the brazing filler metal can reach 98.12 MPa and is greatly higher than that of traditional brazing filler metal, and the novel copper-aluminum connector brazing filler metal with excellent performance is suitable for application and popularization.

Owner:ZHEJIANG UNIV OF TECH

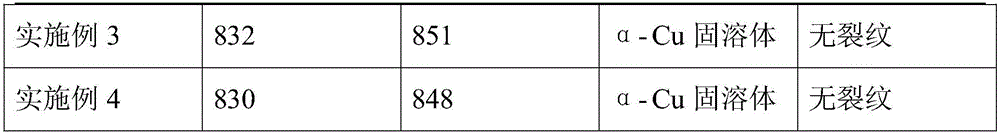

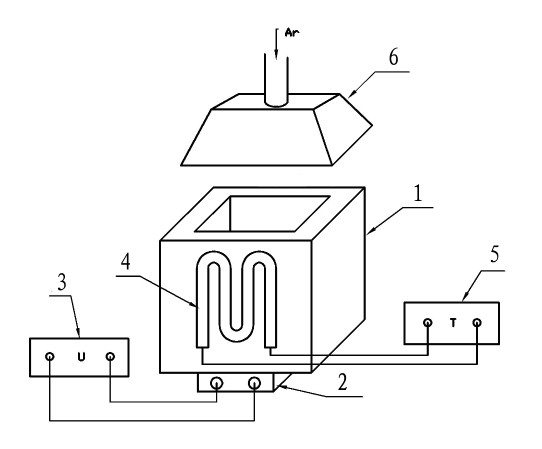

Copper alloy contact reaction brazing method and used active connecting agent

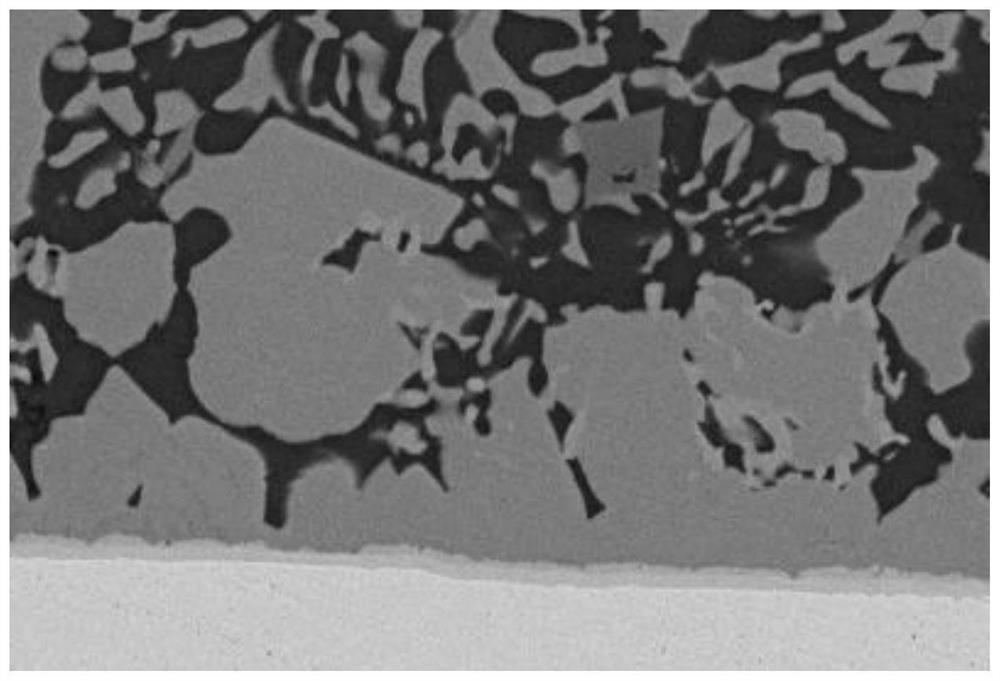

InactiveCN106270869AHigh densityLow soldering temperatureWelding/cutting media/materialsWelding/soldering/cutting articlesBoronVacuum chamber

The invention relates to a copper alloy contact reaction brazing method and a used active connecting agent. The active connecting agent comprises the following components in percentage by weight: 78-85 percent of red phosphorus powder, 5-12 percent of boron powder and 10 percent of a bonding agent. The copper alloy contact reaction brazing method comprises the following steps: (1) coating the joint surface of copper blocks to be welded with the active connecting agent; (2) combining the copper blocks to form a butt brazing joint, fixing and compressing on a welding fixture and putting into a vacuum chamber of a hot isothermal furnace; (3) applying the welding pressure of 0.085-0.02 MPa and pumping to a certain vacuum degree; (4) introducing high-purity argon gas with the purity of 99.999 percent, performing heating and heat preservation on a workpiece when the pressure intensity in the furnace is not lower than 4,357 KPa and completing brazing. As the active connecting agent provided by the invention is utilized for copper alloy contact reaction brazing, the copper alloy in-situ synthesis brazing joint is realized, and a solder flux is not required; the brazing temperature is low, so that the influence on base materials is less; the compactness of the brazing joint is high, and the shearing strength of the brazing joint achieves is 80 percent or above of the strength of the copper alloy base materials.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

American window solder and seamless welding method using same

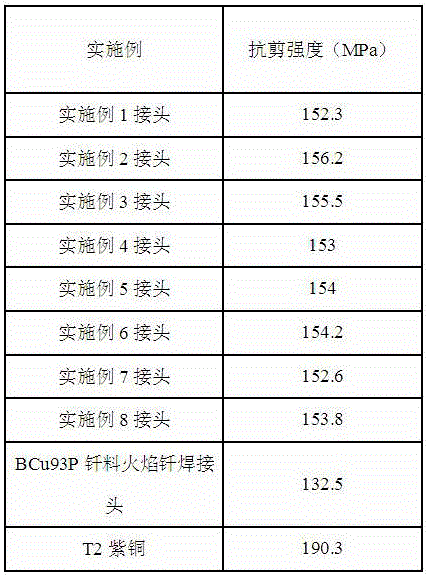

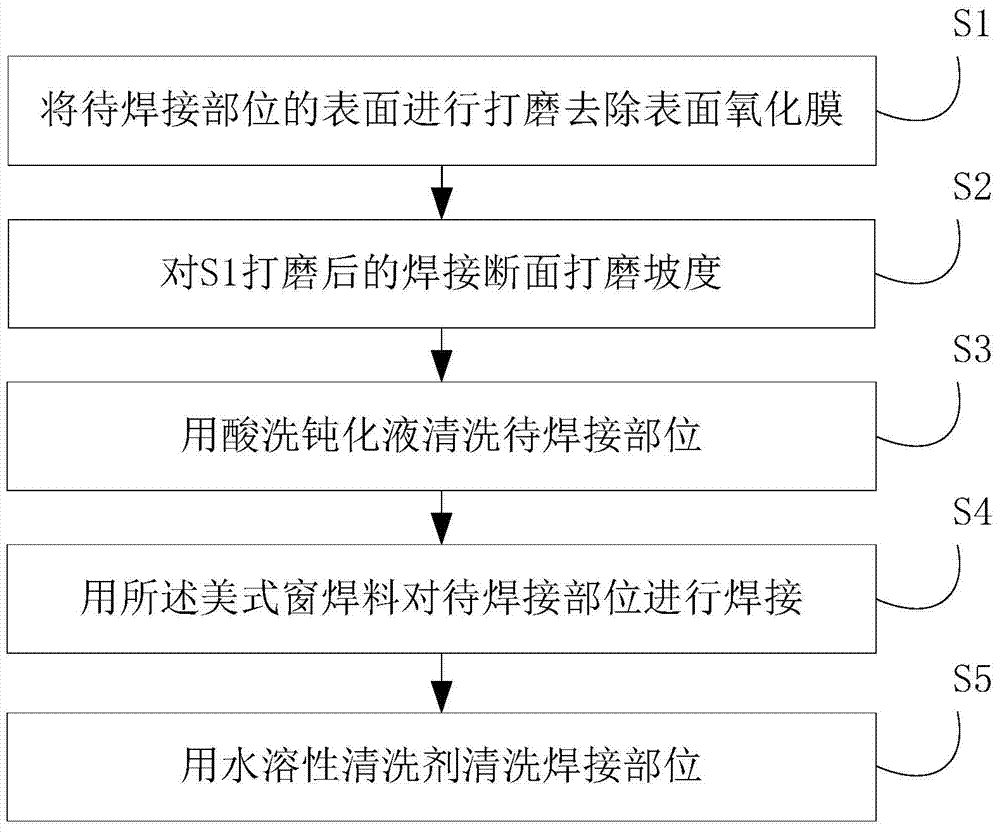

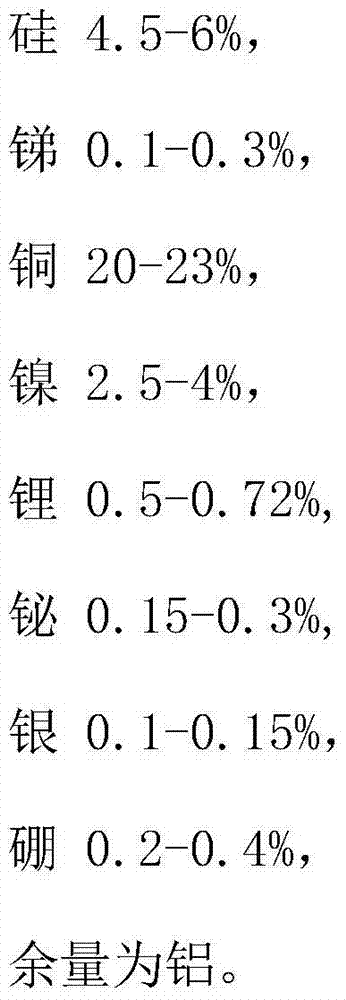

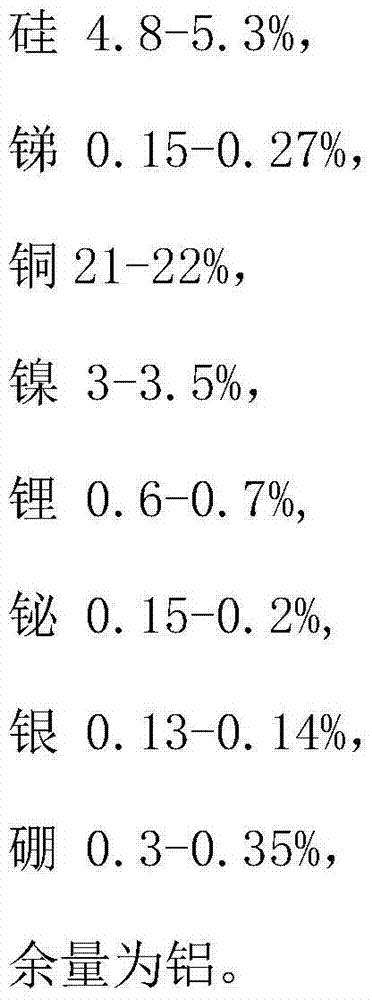

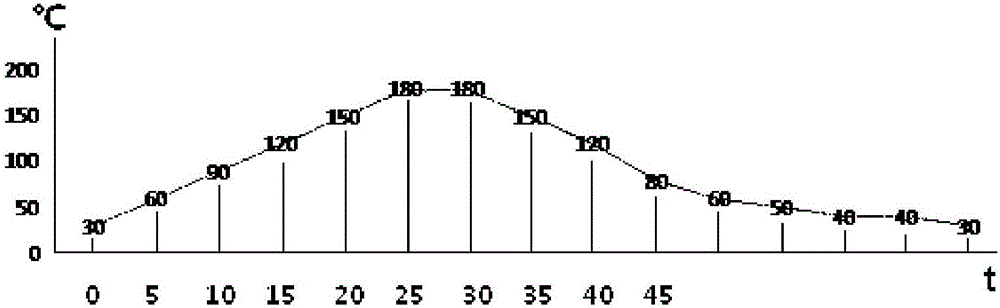

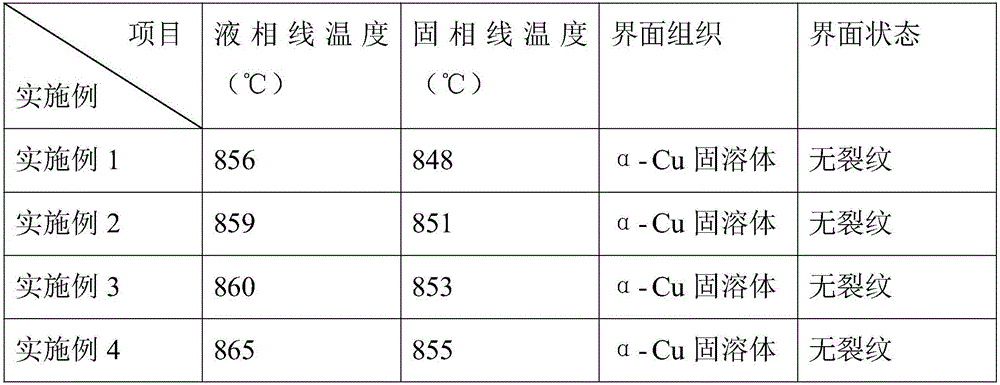

InactiveCN103921011AImprove impact resistanceImprove heat cycle resistanceWelding/cutting media/materialsSoldering mediaMechanical propertyAntimony

The invention discloses American window solder. The American window solder is made with, by weight, 4.5-6% of silicon, 0.1-0.3% of antimony, 20-23% of copper, 2.5-4% of nickel, 0.5-0.72% of lithium, 0.15-0.3% of bismuth, 0.1-0.15% of silver, 0.2-0.4% of boron, and the balance of aluminum. The invention further discloses a seamless welding method using the American window solder. The seamless welding method includes: polishing the surface of a part to be welded so as to remove a surface oxide film; polishing the polished weld break to obtain a slope; cleaning the part to be welded, with pickling passivating solution; welding the part to be welded, with the American window solder; cleaning the welded part with water-soluble cleaner. The American window solder is low in soldering temperature, good in heat resisting cycling performance, good in wear resistance and corrosion resistance and excellent in mechanical properties.

Owner:ANHUI WEISIJIA ENERGY SAVING WINDOWS & DOORS

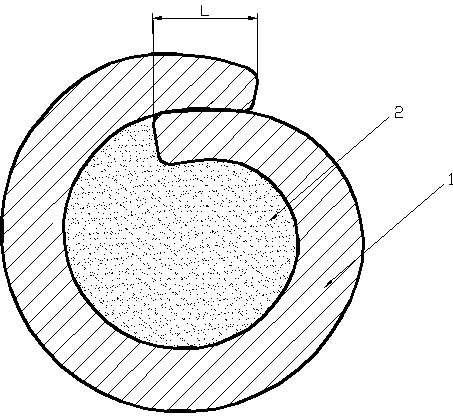

Copper pipe socket brazed connection construction method

ActiveCN103600147AReduce brazing temperatureSmall mechanical propertiesSoldering apparatusMetal working apparatusFuel gasWelding torch

The invention discloses a copper pipe socket brazed connection construction method. The copper pipe socket brazed connection construction method comprises the following steps of a, preweld cleaning and detecting; b, installing a socket socket-and-spigot joint and confirming a welding torch, a welding nozzle and the fuel gas; c, adjusting flames and preheating; d, welding; e, processing after welding. According to the copper pipe socket brazed connection construction method, the copper pipe socket brazing is particularly improved, constructors can operate according to the technical scheme, and requirement for constructor technology is not too high.

Owner:CHONGQING NO 3 CONSTR +1

Brazing material and preparing method thereof

InactiveCN105880872AAchieve connectionLow melting pointWelding/cutting media/materialsWelding/soldering/cutting articlesMetallic aluminumComposite ceramic

A brazing material comprises 80-90 parts by weight of metallic alloy powder and 10-20 parts by weight of a soldering paste, wherein the metallic alloy powder comprises the following materials: 1-20 parts by weight of Bi, 0.1-1 part by weight of Ag and 79-99 parts by weight of Sn; and the soldering paste consists of one or a plurality of rosin and a derivative thereof, tetraethoxysilane, a surfactant, an antioxidant and an inorganic filler. The brazing material can connect materials, such as metallic aluminum alloy composites, composite ceramic and glass, is lower in melting point as a lead-free brazing material in comparison with the existing brazing material, lowers brazing temperature, and at the same time, solves the technical problem that the class of materials are difficult to connect due to respective stable chemical properties.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

Method for making induction brazing monolayer diamond grinding wheel

The invention provides a method for making an induction brazing monolayer diamond grinding wheel. The method includes the following steps that carbon steel or spring steel and the like is selected asa grinding wheel matrix material, a grinding wheel matrix is made, after melting, Cu powder, Mn powder, Ni powder, Cr powder and C powder are sprayed to prepare pre-alloyed powder, namely brazing filler metal, after alloying, the brazing filler metal is uniform i component, then powdered brazing filler metal and grinding materials are prepared, the brazing filler metal is heated through inductionbrazing, and then the induction brazing monolayer diamond grinding wheel can be made. After welding, a thin layer of carbide can be formed on the surfaces of diamond abrasive particles, and chemical metallurgical bonding between diamond and a steel matrix is achieved. The method is used for making the grinding wheel, and the method has the advantages that the thermal damage of the diamond abrasiveparticles is small and the brazing effect is good.

Owner:泰兴市中博钻石科技股份有限公司

Alloy for braze welding of high-intensity graphite and titanium alloy and preparation method thereof

InactiveCN103173654AImprovement ingredientsIncrease temperatureWelding/cutting media/materialsSoldering mediaChemical reactionHigh intensity

The invention discloses an alloy for braze welding of high-intensity graphite and titanium alloy and a preparation method thereof. The alloy comprises the following elements in percentage by weight: 50%-65% of Ti, 30%-45% of Cu and 5%-10% of Si. The preparation method of the alloy comprises the following steps of: preparing materials according to the following elements in percentage by weight: 50%-65% of Ti, 30%-45% of Cu and 5%-10% of Si; performing vacuum electric arc smelting at a vacuum degree of 5*10<-3>-8*10<-3> Pa and at an electric arc current of 1100-1300 A; and electromagnetically stirring for 1-3 minutes, and then cooling. According to the invention, the alloy components are optimized, various chemical reaction products with good mechanical properties at high temperature are formed on the reaction interface, the braze welding temperature is effectively reduced, and the application temperature of a welded joint is increased.

Owner:CENT SOUTH UNIV

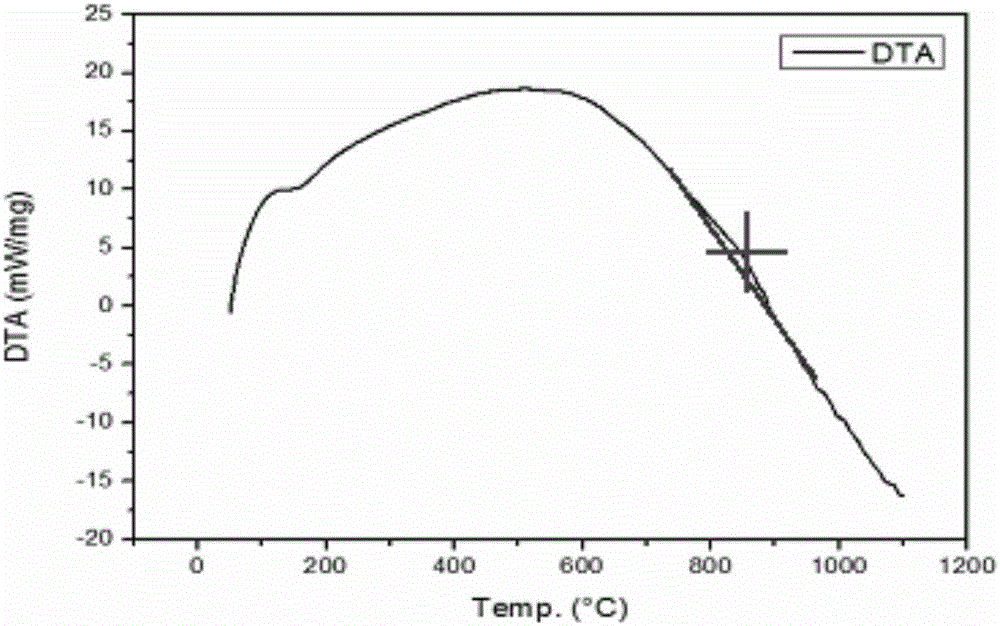

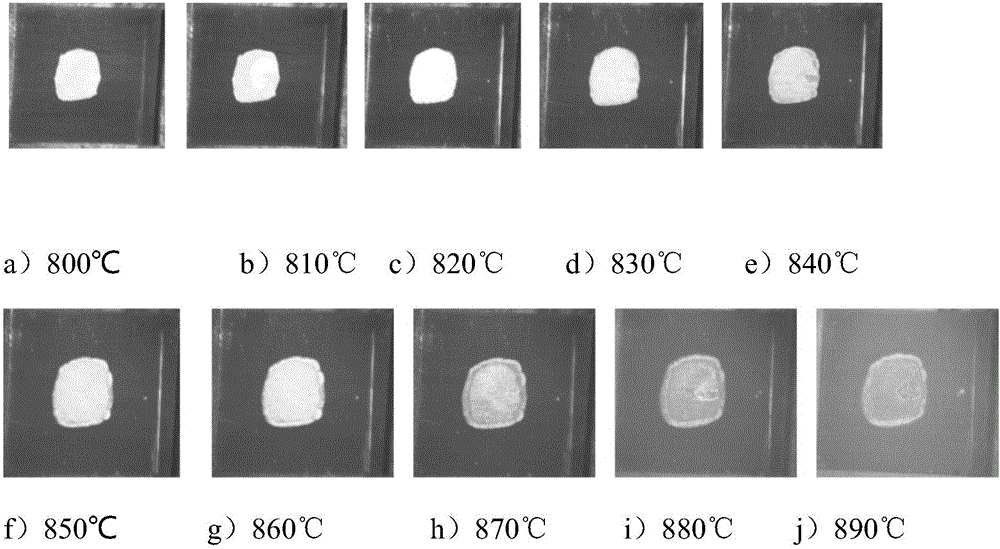

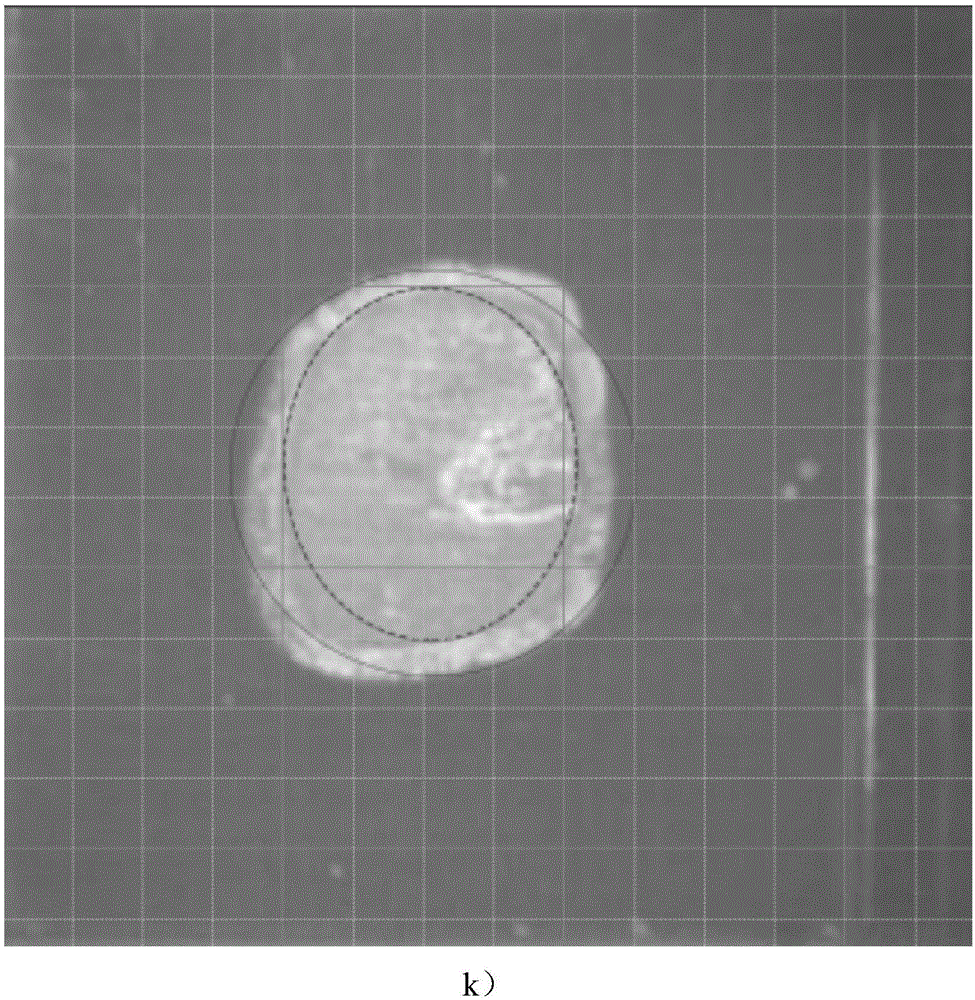

Aluminum powder-containing flux-cored silver brazing filler metal for brazing hard alloy and preparation method

ActiveCN112621014ARestore blockHigh affinityWelding/cutting media/materialsSoldering mediaBorideAluminium powder

The invention discloses aluminum powder-containing flux-cored silver brazing filler metal for brazing a hard alloy. The aluminum powder-containing flux-cored silver brazing filler metal comprises a brazing flux core, and a silver-containing metal layer wrapping the brazing flux core; the brazing flux core contains aluminum powder, and the particle size of the aluminum powder ranges from 200 nm to 500 nm; and preferably, the brazing flux core comprises, by mass, 0.5%-4.3% of aluminum powder, 13.0%-36.0% of fluoride, 15.0%-26.0% of boride, and 44.7%-60.5% of fluoroborate salt. The invention further discloses a preparation method for the aluminum powder-containing flux-cored silver brazing filler metal. The aluminum powder in the flux core instantly releases heat to promote brazing when the aluminum powder and metal oxide are subjected to an aluminothermic reaction in the brazing process, and the aluminum powder generates dispersed-phase aluminum oxide, so that the hardness and abrasion resistance of brazing seams are effectively enhanced.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

Yellow brass brazing filler metal alloy

InactiveCN106624443ALow melting pointLow costWelding/cutting media/materialsSoldering mediaAlloyTitanium

The invention provides a yellow brass brazing filler metal alloy. The alloy is prepared from, by weight, 50-55% of copper, 0.2-0.4% of tin, 2-5% of bismuth, 0.1-1% of titanium and 0.02-0.06% of germanium, and the balance being zinc. The yellow brass brazing filler metal alloy does not contain silver and cadmium, but is capable of lowering the melting point of traditional yellow brass brazing filler metal, and has the advantages of high reactivity and low cost.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Low-temperature brazing method of graphite-copper composite structural commutator

InactiveCN104701708ASolving Difficult-to-Solder ProblemsImprove composite effectSoldered/welded connectionsCommutators manufactureAxial pressureGraphite

The invention discloses a low-temperature brazing method of a graphite-copper composite structural commutator. The method is characterized by comprising the steps of preparing SnCr metal powder containing an active element Cr by the ball grinding method; coating the prepared SnCr metal powder on the surface of a graphite disc; heating to reach 700 to 1000 DEG C under a vacuum or inert gas protection condition to obtain a metalizing layer being 50 to 200 microns in thickness on the surface of the graphite disc; assembling the metalizing graphite disc and a copper inverting blade; applying 0.5 to 2MPa axial pressure; heating to be 200 to 500 DEG C. According to the method, the brazing temperature is reduced by pre-metalizing, so that the connection strength between the graphite and the copper inverting blade can be improved; the method has the advantages of being simple in process, convenient to carry out, high in graphite-copper combining effect, and long in service life of the prepared inverter.

Owner:HARBIN INST OF TECH AT WEIHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com