Brazed superhard abrasive tool and preparation method thereof

A superabrasive and brazing technology, which is applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of poor spreading performance on the surface of the substrate, insufficient abrasive holding force, and easy agglomeration, so as to improve the wetting and spreading performance , reduce heat damage, reduce the effect of brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

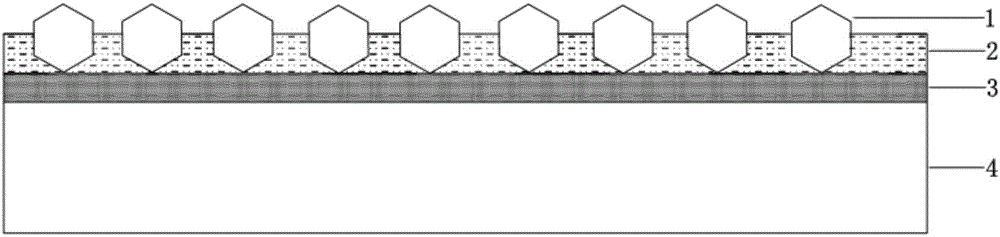

[0033] Present embodiment brazing superabrasive tool, as figure 1 As shown, it includes a 65Mn steel keyhole saw blade substrate 4, a NiCr15 alloy nickel-based brazing filler metal layer 3 arranged on the substrate, a CuSn15Ti10 copper-based brazing filler metal layer 2 arranged on the surface of the nickel-based brazing filler metal layer, and a copper-based brazing filler metal layer embedded in a copper-based brazing filler metal layer. Diamond particles in the solder layer 1.

[0034] The preparation method of the brazing superabrasive tool of the present embodiment comprises the following steps:

[0035] (1) Take a 65Mn steel keyhole saw blade substrate with a size of 100mm×1.2mm×16mm and put it into 5% alcohol for ultrasonic cleaning for 2 minutes to remove oil stains and impurities on the surface of the substrate, and dry it for later use;

[0036] (2) Measure a 10mm wide ring-shaped working layer on the substrate, evenly coat a layer of stickers with a thickness of ab...

Embodiment 2

[0039] The brazing superabrasive material tool of this embodiment comprises No. 50 steel flat grinding disc base body, is arranged on the NiCr14B3Si5 alloy nickel-based solder layer of base body, is arranged on the CuSn15Ti10 copper-based solder layer on the surface of nickel-based solder layer, and embedding Cubic boron nitride in a copper-based solder layer.

[0040] The preparation method of the brazing superabrasive tool of the present embodiment comprises the following steps:

[0041] (1) Take the No. 50 steel flat grinding disc substrate whose size is 100mm×1.5mm×16mm and carry out sandblasting treatment (the sand is white corundum with a particle size of 60 mesh), and remove impurities such as rust spots on the surface of the substrate;

[0042] (2) Evenly coat a layer of 0.5mm thick self-adhesive on the working layer area of the substrate, arrange a layer of 200-mesh NiCr14B3Si5 alloy solder on the surface of the self-adhesive, put it into a vacuum brazing furnace, a...

Embodiment 3

[0045] The brazing superabrasive material tool of present embodiment comprises 75Cr steel keyhole saw blade base body, is arranged on the NiCr15 alloy nickel base solder layer on the base body, is arranged on the CuSn15Ti10 copper base solder layer on the nickel base solder layer surface, and embedded Diamond in a layer of copper-based solder.

[0046] The preparation method of the brazing superabrasive tool of the present embodiment comprises the following steps:

[0047] (1) Take a 75Cr steel keyhole saw blade substrate with a size of 100mm×1.2mm×16mm and put it into 15% alcohol for ultrasonic cleaning for 3 minutes to remove oil stains and impurities on the surface of the substrate, and dry it for later use;

[0048] (2) Take a 10mm wide ring-shaped working layer on the substrate, evenly coat a layer of stickers with a thickness of about 1mm and 200 mesh NiCr15 alloy solder on the working layer area, put it into a vacuum brazing furnace, and under vacuum conditions, Raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com