Magnesium alloy middle temperature brazing material

A magnesium alloy and brazing material technology, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of poor joint performance, poor surface spreadability, and high cost of brazing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The main chemical composition and mass percentage of the solder are: 2.5% Al, 52.0% Zn, and the balance Mg. The solder alloy is smelted by the flux protection method, poured into ingots, and then the solder is divided into strips and blocks by mechanical division. Before brazing, the magnesium alloy workpiece is cleaned with sandpaper and acetone to remove surface dirt and oxide film. The brazing material is placed at the joint, and flux is sprinkled on it. The joint is fixed by a clamp and then brazed in an argon protection device. During the brazing process, the argon gas flow rate is 10L / min, the heating rate is 2.5°C / s, the brazing temperature is 380°C, and the heat preservation time is 30s. After brazing, the appearance of the joint is well formed, and the mechanical test is carried out on it. The shear strength and tensile strength of the joint are shown in Table 1.

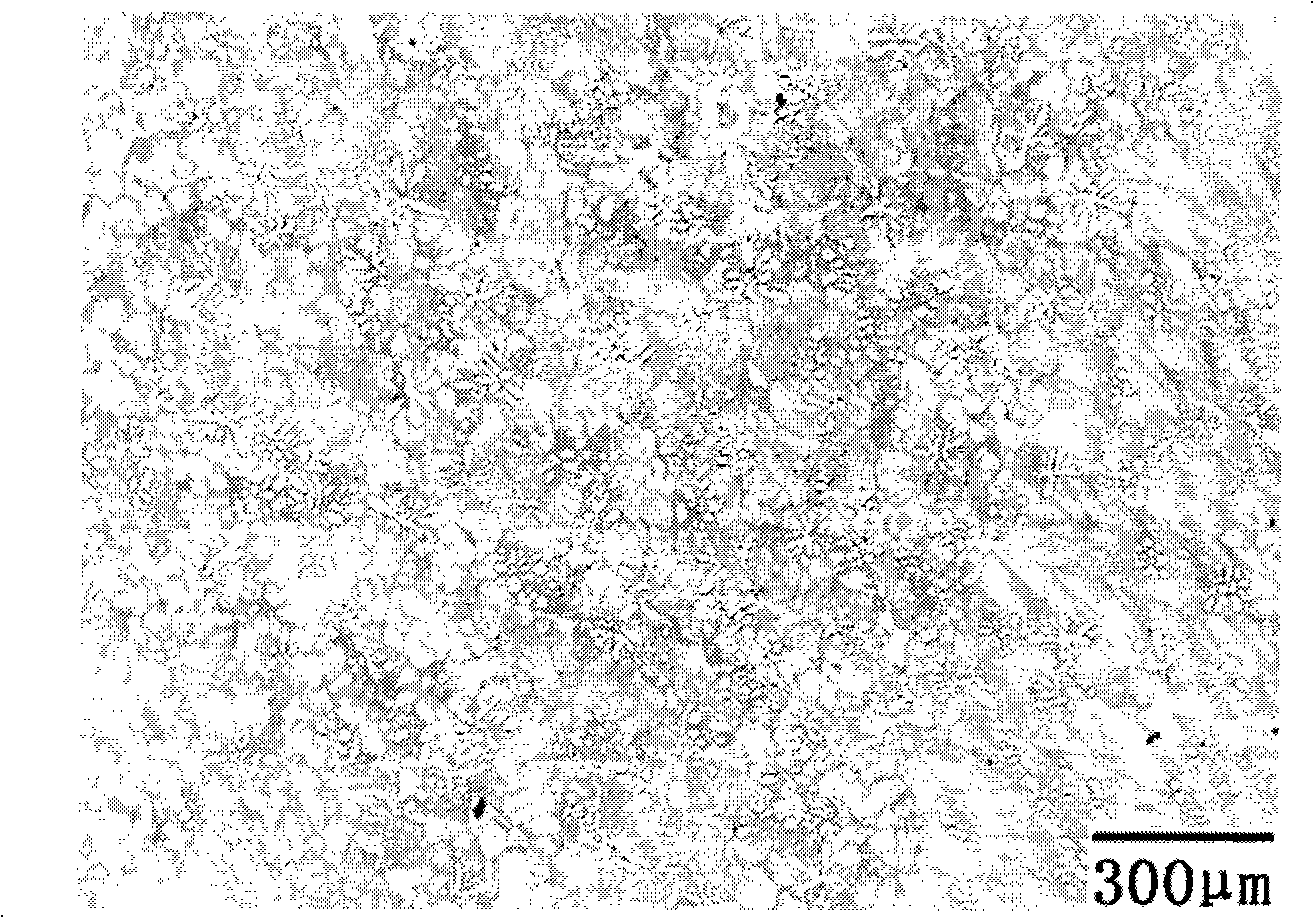

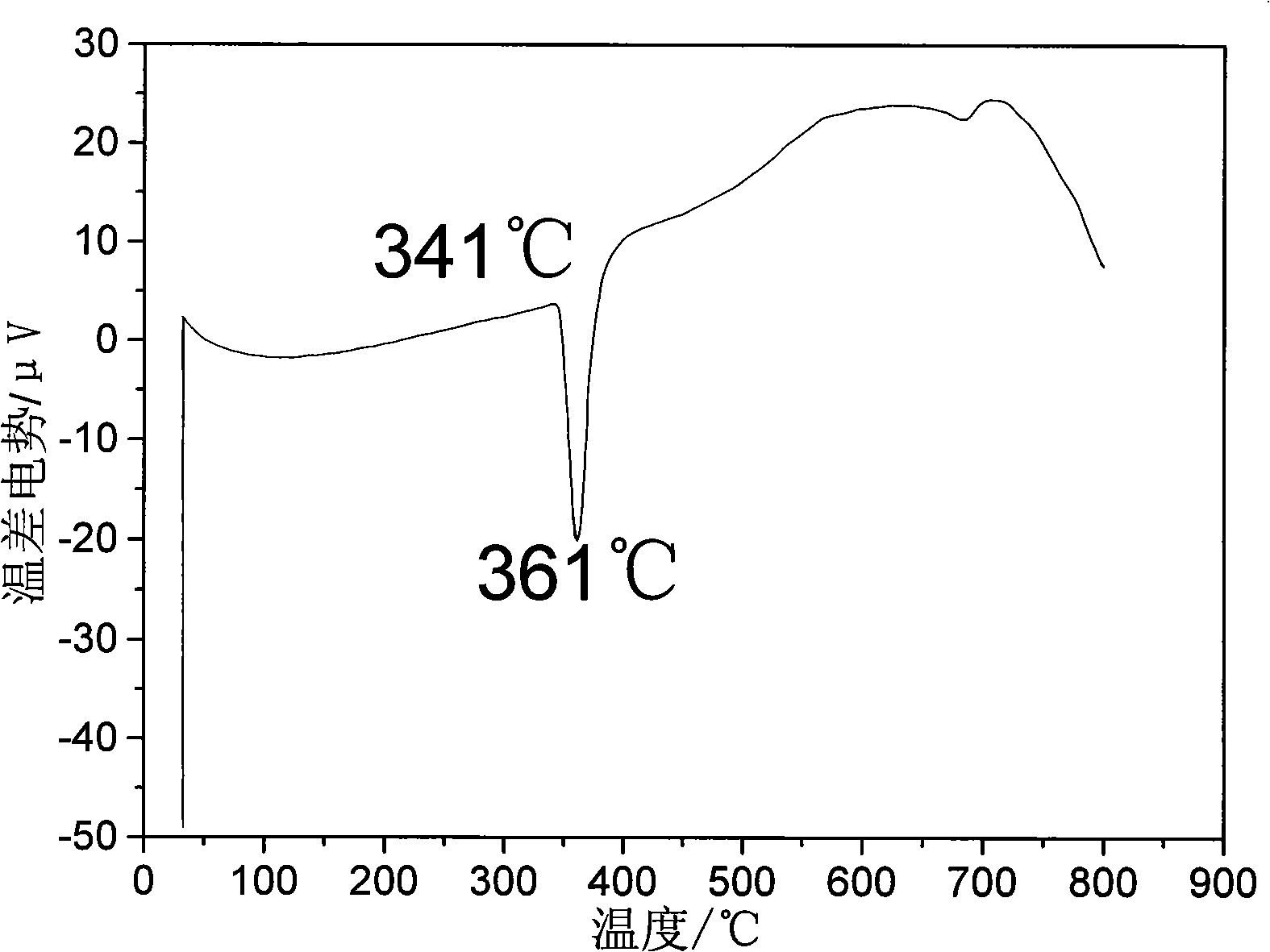

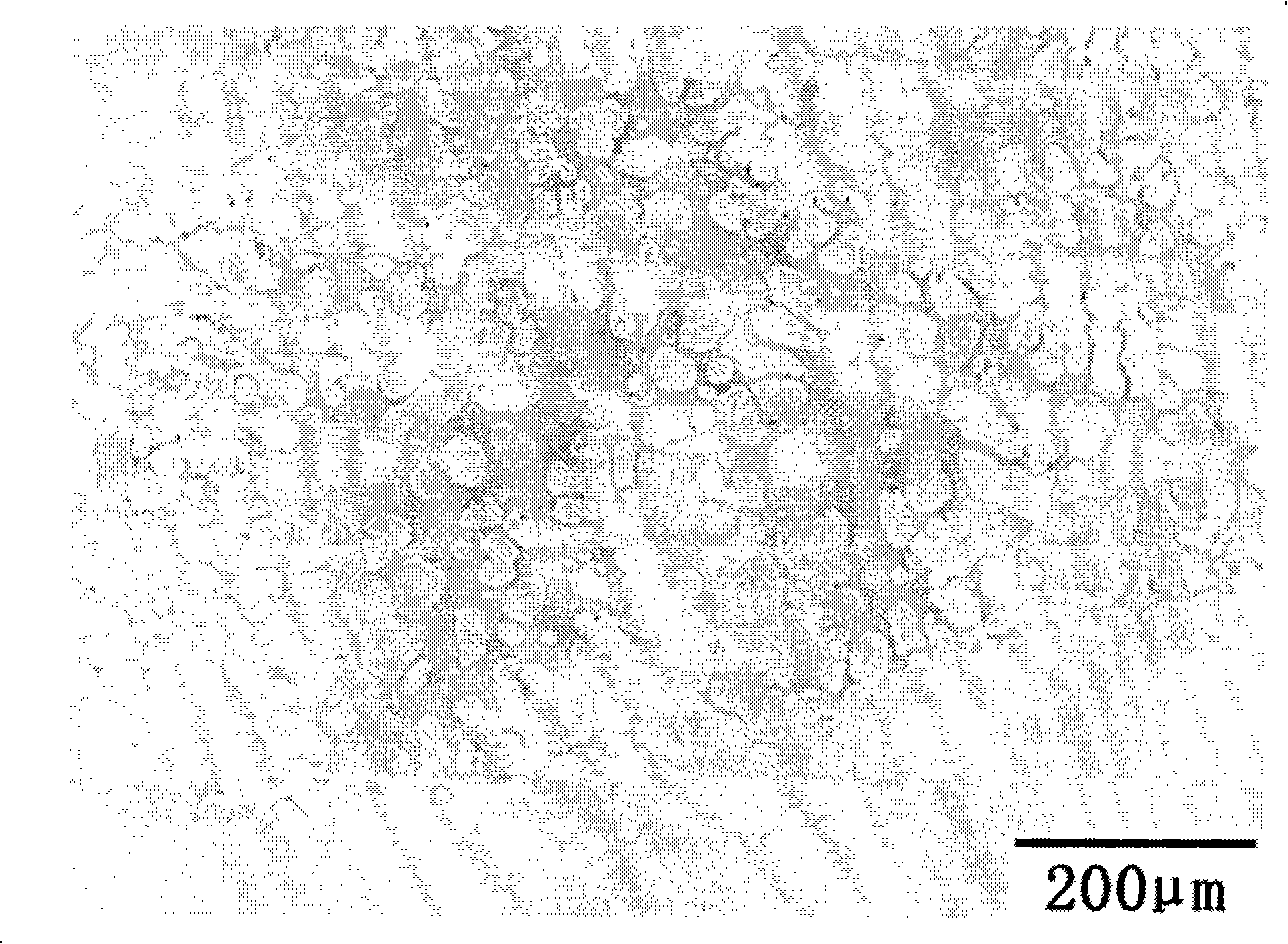

[0027] figure 1 It is the microstructure diagram of the alloy. It can be seen from the figure t...

Embodiment 2

[0032] The main chemical composition and mass percentage of the solder are: 1.0% Al, 48.0% Zn, and the balance Mg. The solder alloy is smelted by the flux protection method, poured into ingots, and then the solder is divided into strips and blocks by mechanical division. Before brazing, the magnesium alloy workpiece is cleaned with sandpaper and acetone to remove surface dirt and oxide film. The brazing material is placed at the joint, and flux is sprinkled on it. The joint is fixed by a clamp and then brazed in an argon protection device. The brazing temperature is 390° C., and other brazing process parameters are the same as in Example 1. After brazing, the appearance of the joint is well formed, and the mechanical test is carried out on it. The shear strength and tensile strength of the joint are shown in Table 1.

Embodiment 3

[0034] The main chemical composition and mass percentage of the solder are: 2.0% Al, 47.0% Zn, and the balance Mg. The solder alloy is smelted by the flux protection method, poured into ingots, and then the solder is divided into strips and blocks by mechanical division. Before brazing, the magnesium alloy workpiece is cleaned with sandpaper and acetone to remove surface dirt and oxide film. The brazing material is placed at the joint, and flux is sprinkled on it. The joint is fixed by a clamp and then brazed in an argon protection device. The brazing temperature is 400° C., and other brazing process parameters are the same as in Example 1. After brazing, the appearance of the joint is well formed, and the mechanical test is carried out on it. The shear strength and tensile strength of the joint are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com