Yellow brass brazing filler metal alloy

A brass brazing filler metal and alloy technology, applied in metal processing equipment, welding/cutting media/materials, welding media, etc., can solve the problems of copper annealing, strength index reduction, excessive grain growth, etc., to reduce costs, Low cost, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

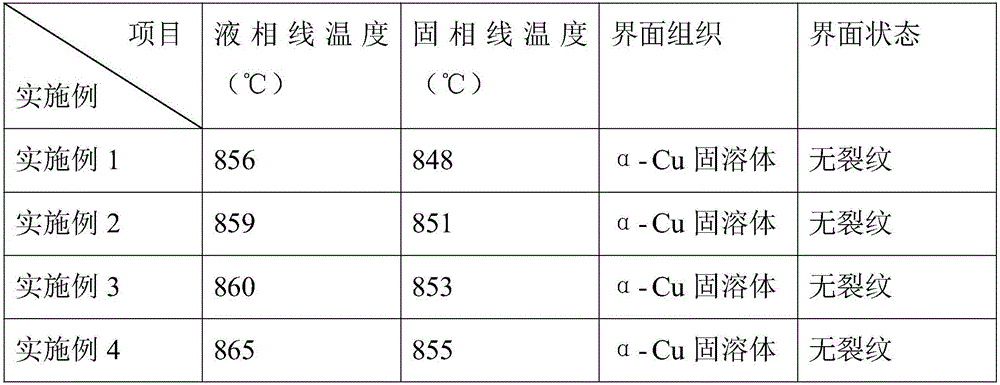

Examples

Embodiment 1

[0025] A brass solder alloy, calculated by weight percentage, is made of the following raw materials:

[0026] Copper 53%, tin 0.3%, bismuth 3%, titanium 0.5%, germanium 0.05%, and the balance is zinc.

[0027] Preparation:

[0028] 1) Prepare a total of 5000 grams of each material according to the above formula;

[0029] 2) Put Cu into an induction furnace and heat it to above 1100°C and melt it;

[0030] 3) Add Zn and stir fully, while rapidly reducing the temperature of the molten metal to 920°C;

[0031] 4) After the molten metal is uniform, add Bi and stir thoroughly;

[0032] 5) Add Sn, Ti and Ge and stir evenly, then cast;

[0033] 6) The brazing alloy is obtained by extruding and wire drawing according to the conventional brazing filler metal processing method.

Embodiment 2

[0035] A brass solder alloy, calculated by weight percentage, is made of the following raw materials:

[0036] 50% copper, 0.4% tin, 5% bismuth, 1% titanium, 0.06% germanium, and the balance is zinc.

[0037] The preparation method of the brass solder alloy in this embodiment is consistent with the method described in embodiment 1, the only difference is that the weight percentages of the components of the brass solder alloy are weighed according to the proportions in this embodiment.

Embodiment 3

[0039] A brass solder alloy, calculated by weight percentage, is made of the following raw materials:

[0040] Copper 55%, tin 0.2%, bismuth 2%, titanium 0.1%, germanium 0.02%, and the balance is zinc.

[0041] The preparation method of the brass solder alloy in this embodiment is consistent with the method described in embodiment 1, the only difference is that the weight percentages of the components of the brass solder alloy are weighed according to the proportions in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com